Preparation method for indium oxide nanometer material

A technology of nanometer material and indium oxide, which is applied in the field of preparation of inorganic materials, can solve the problems of being unsuitable for large-scale production, high requirement of experimental conditions, high cost, etc., and achieves easy industrialized large-scale production, simple production process and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

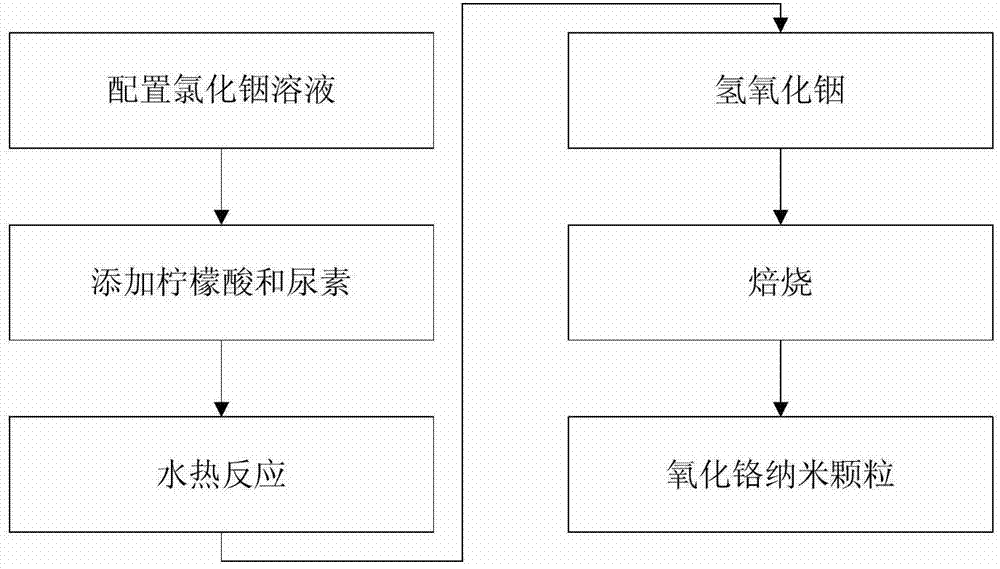

Method used

Image

Examples

Embodiment 1

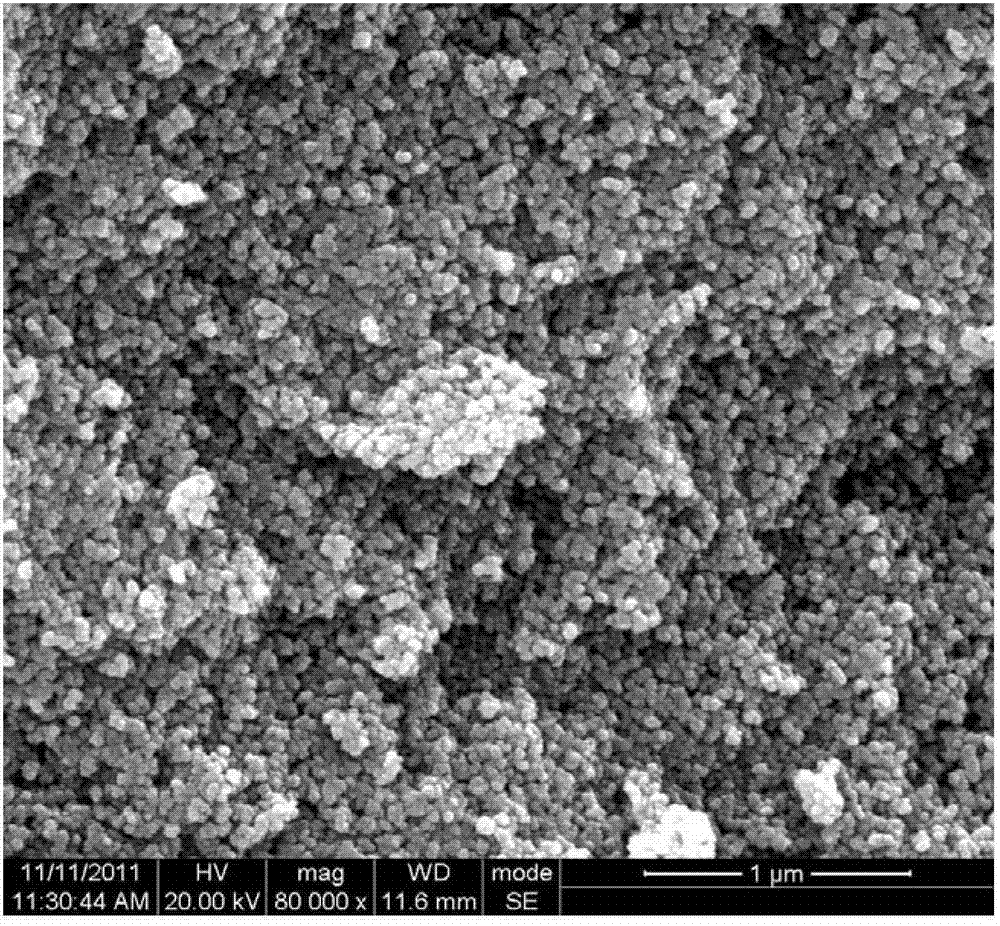

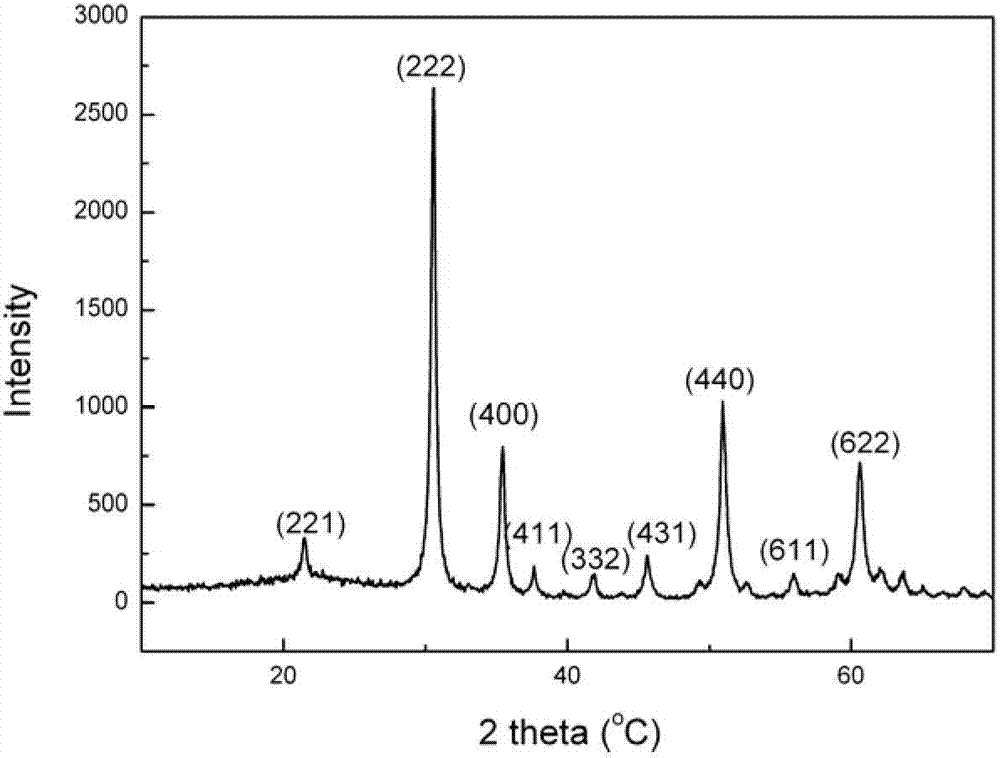

[0020] Add 120ml of deionized water, then add 0.58g InCl 3 4H 2 O, stirred until completely dissolved to obtain a clear indium chloride solution. Then add 0.768g citric acid and 0.24g urea, stir to dissolve. The above solution was transferred to a polytetrafluoroethylene-lined hydrothermal kettle, sealed, and hydrothermally reacted at 150°C for 24 hours. The product after the hydrothermal reaction was filtered, washed with deionized water, and dried at 110° C. to obtain indium hydroxide nanoparticles. Indium hydroxide nanoparticles were calcined at 600°C for 1 hour to obtain indium oxide spherical nanoparticles. Observed under the electron microscope, the average diameter of this nanocomposite particle is 30nm, the particle is spherical, the particle size is uniform, and it has good dispersion. The specific surface area is 48.2m 2 / g. XRD measurement results show that chromium oxide has a better cubic crystal form.

Embodiment 2

[0022] Add 2000ml of deionized water, then add 10g InCl 3 4H 2 O, stirred until completely dissolved to obtain a clear indium chloride solution. Then add 15g citric acid and 5g urea, stir to dissolve. The above solution was transferred to a polytetrafluoroethylene-lined hydrothermal kettle, sealed, and hydrothermally reacted at 140°C for 20 hours. The product after the hydrothermal reaction was filtered, washed with deionized water, and dried at 110° C. to obtain indium hydroxide nanoparticles. Indium hydroxide nanoparticles were calcined at 550°C for 1 hour to obtain indium oxide spherical nanoparticles. Observed under the electron microscope, the average diameter of this kind of nanocomposite particles is 35nm, the particles are spherical, the particle size is uniform, and it has good dispersion. The specific surface area is 45.6m 2 / g. XRD measurement results show that chromium oxide has a better cubic crystal form.

Embodiment 3

[0024] After adding 500ml of deionized water, then add 5.8g of InCl 3 4H 2 O, stirred until completely dissolved to obtain a clear indium chloride solution. Then add 7.7g citric acid and 2.4g urea, stir to dissolve. The above solution was transferred to a polytetrafluoroethylene-lined hydrothermal kettle, sealed, and hydrothermally reacted at 160°C for 24 hours. The product after the hydrothermal reaction was filtered, washed with deionized water, and dried at 110° C. to obtain indium hydroxide nanoparticles. Indium hydroxide nanoparticles were calcined at 600°C for 1 hour to obtain indium oxide spherical nanoparticles. Observed under an electron microscope, the average diameter of this nanocomposite particle is 40nm, the particle is spherical, the particle size is uniform, and it has good dispersion. The specific surface area is 34.2m 2 / g. XRD measurement results show that chromium oxide has a better cubic crystal form.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com