Nb-doped nano indium tin oxide powder and method for preparing high density sputtering coating target thereof

A technology of oxide powder and sputtering coating, which is applied in the field of powder metallurgy and ceramics, can solve the problems of poor performance of ITO film, and achieve the effect of low cost, uniform composition and improved conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

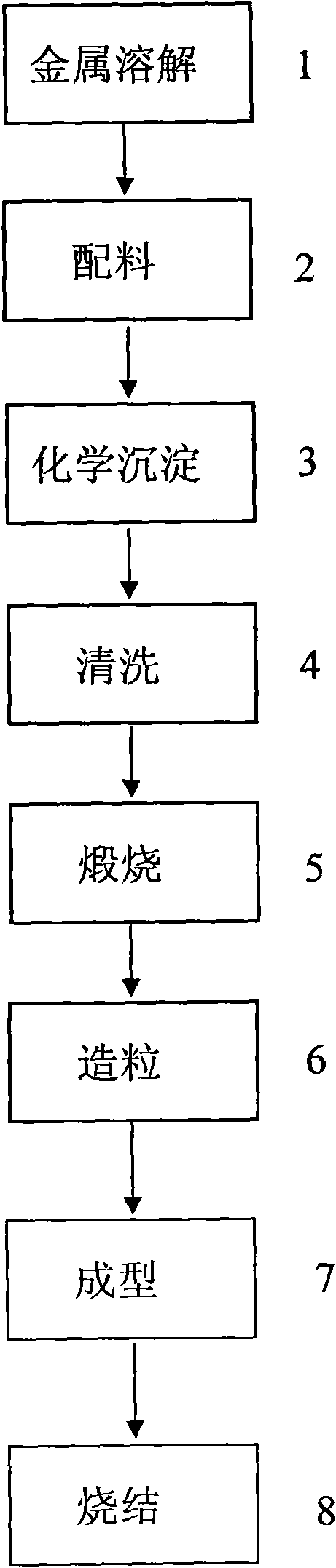

[0052] The invention discloses a method for preparing niobium-doped nano-indium tin oxide powder and its high-density sputtering coating target, comprising the following steps:

[0053] Step 1: First, dissolve the high-purity niobium raw material into a transparent solution of niobium hydrofluoric acid niobium nitrate with a mixed solution of hydrofluoric acid and nitric acid; Aqua regia dissolves high-purity tin raw material into tin chloride transparent solution.

[0054] Step 2: Divide the above transparent solutions into respective containers according to the ratio of In:Sn:Nb=100:8.6:0.3.

[0055] Step 3: The above three kinds of transparent solutions are mixed in a 5000mL three-necked beaker according to the mass ratio of niobium, tin and indium in the ratio of In:Sn:Nb=100:8.6:0.3 by homogeneous co-precipitation method, and the order of mixing is as follows: : first indium nitrate salt solution is mixed with urea and deionized water, and the mass ratio of the three is ...

Embodiment 2

[0062] The invention discloses a method for preparing niobium-doped nano-indium tin oxide powder and its high-density sputtering coating target, comprising the following steps:

[0063] Step 1: First, dissolve the high-purity niobium raw material into a transparent solution of niobium nitrate hydrofluoric acid with a mixed solution of hydrofluoric acid and nitric acid; Dissolve high-purity tin raw materials into tin chloride transparent solution.

[0064] Step 2: Divide the above transparent solutions into respective containers according to the ratio of In:Sn:Nb=100:9.6:0.5.

[0065] Step 3: The above three kinds of transparent solutions are mixed in a 5000mL three-necked beaker according to the mass ratio of niobium, tin and indium in the ratio of In:Sn:Nb=100:9.6:0.5 by homogeneous co-precipitation method, and the order of mixing is as follows: : first indium nitrate salt solution is mixed with urea and deionized water, and the mass ratio of the three is In:(NH 2 ) 2 CO:H...

Embodiment 3

[0072] The invention discloses a method for preparing niobium-doped nano-indium tin oxide powder and its high-density sputtering coating target, comprising the following steps:

[0073] Step 1: First, dissolve the high-purity niobium raw material into a transparent solution of niobium hydrofluoric acid niobium nitrate with a mixed solution of hydrofluoric acid and nitric acid; Aqua regia dissolves high-purity tin raw material into tin chloride transparent solution.

[0074] Step 2: Divide the above transparent solutions into respective containers according to the ratio of In:Sn:Nb=100:10.6:0.7.

[0075] Step 3: The above three transparent solutions are mixed in a 5000mL three-necked beaker according to the mass ratio of niobium, tin and indium in the ratio of In:Sn:Nb=100:10.6:0.7 by homogeneous co-precipitation method, and the order of mixing is as follows: : first indium nitrate salt solution is mixed with urea and deionized water, and the mass ratio of the three is In:(NH ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com