Preparation method for high-conductivity liquid crystal light-adjusting film

A liquid crystal dimming film, high conductivity technology, applied in optics, nonlinear optics, instruments, etc., can solve the problems of poor conductivity of liquid crystal dimming film, high driving voltage of dimming film, poor light transmission performance, etc. The visible light transmittance is increased, the grain boundary scattering is reduced, and the application prospect is broad.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

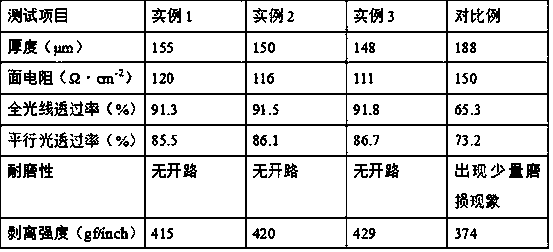

Examples

example 1

[0027]Dissolve 10g of zinc acetate dihydrate in a beaker containing 180mL of isopropanol, place the beaker in a water bath, heat up to 70°C, add 30mL of diethanolamine to the beaker, and use a magnetic stirrer at a speed of 300r / min Heat and stir for 30 minutes, continue to add 15g of aluminum nitrate nonahydrate to the beaker, heat and stir until the solid is completely dissolved, and obtain a transparent homogeneous sol; take 100mL of DMF and add it to the beaker, move the beaker into a water bath with a magnetic stirrer, and control the temperature of the water bath to 35°C, start the magnetic stirrer, stir at a speed of 500r / min, add 5g of 4,4'-diaminodiphenyl ether into the beaker, stir for 10min, then add 6g of pyromellitic anhydride, stir for 3h to obtain poly Amic acid sol; in parts by weight, 10 parts of stannous sulfate, 20 parts of ethylenediaminetetraacetic acid and 6 parts of potassium hydroxide are added in a beaker with 80 parts of deionized water, and stirred fo...

example 2

[0029] Dissolve 11g of zinc acetate dihydrate in a beaker containing 190mL of isopropanol, place the beaker in a water bath, heat up to 75°C, add 35mL of diethanolamine to the beaker, and use a magnetic stirrer at a speed of 325r / min Heat and stir for 33 minutes, continue to add 16g of aluminum nitrate nonahydrate to the beaker, heat and stir until the solid is completely dissolved, and obtain a transparent homogeneous sol; take 110mL of DMF and add it to the beaker, move the beaker into a water bath with a magnetic stirrer, and control the temperature of the water bath At 36°C, start the magnetic stirrer, stir at a speed of 525r / min, add 6g of 4,4'-diaminodiphenyl ether into the beaker, stir for 13min, then add 7g of pyromellitic anhydride, stir for 3.5h, and get Polyamic acid sol; in parts by weight, 11 parts of stannous sulfate, 23 parts of ethylenediaminetetraacetic acid and 8 parts of potassium hydroxide are added in a beaker with 85 parts of deionized water, and stirred f...

example 3

[0031] Dissolve 12g of zinc acetate dihydrate in a beaker containing 200mL of isopropanol, place the beaker in a water bath, heat up to 80°C, add 40mL of diethanolamine to the beaker, and use a magnetic stirrer at a speed of 350r / min Heat and stir for 35 minutes, continue to add 18g of aluminum nitrate nonahydrate to the beaker, heat and stir until the solid is completely dissolved, and obtain a transparent homogeneous sol; take 120mL of DMF and add it to the beaker, move the beaker into a water bath with a magnetic stirrer, and control the temperature of the water bath At 40°C, start the magnetic stirrer, stir at a speed of 550r / min, add 7g of 4,4'-diaminodiphenyl ether into the beaker, stir for 15min, then add 8g of pyromellitic anhydride, stir for 4h to obtain poly Amic acid sol; In parts by weight, 12 parts of stannous sulfate, 25 parts of ethylenediaminetetraacetic acid and 10 parts of potassium hydroxide are added in the beaker that 90 parts of deionized water are housed,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com