Method for electrochemically extracting uranium from seawater by using oxygen vacancy-containing metal oxide

An oxide and oxygen vacancy technology, applied in chemical instruments and methods, uranium oxide/hydroxide, uranium dioxide, etc., can solve the problems of difficult recycling, poor selectivity, and high production costs, and achieve a simple extraction method. easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

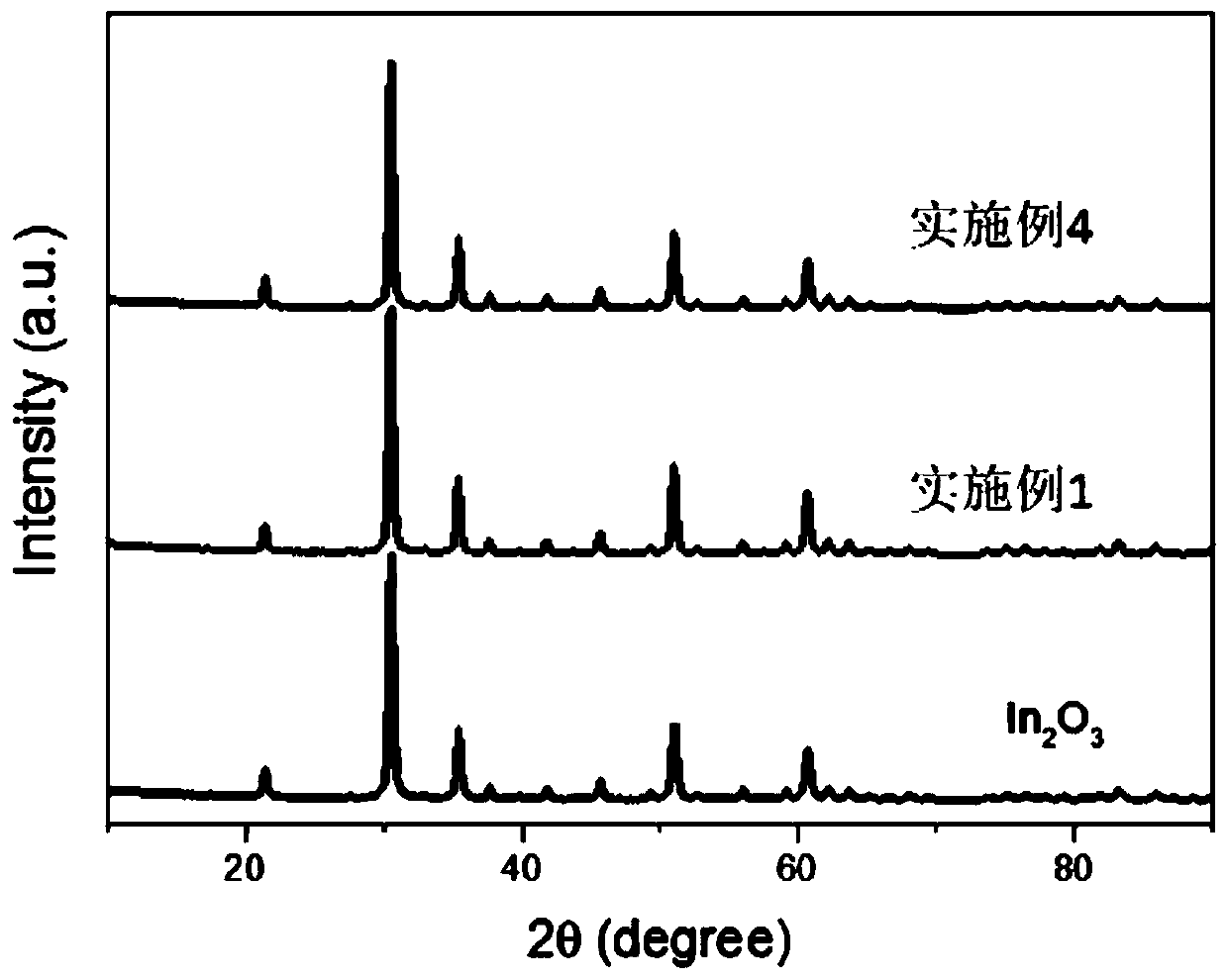

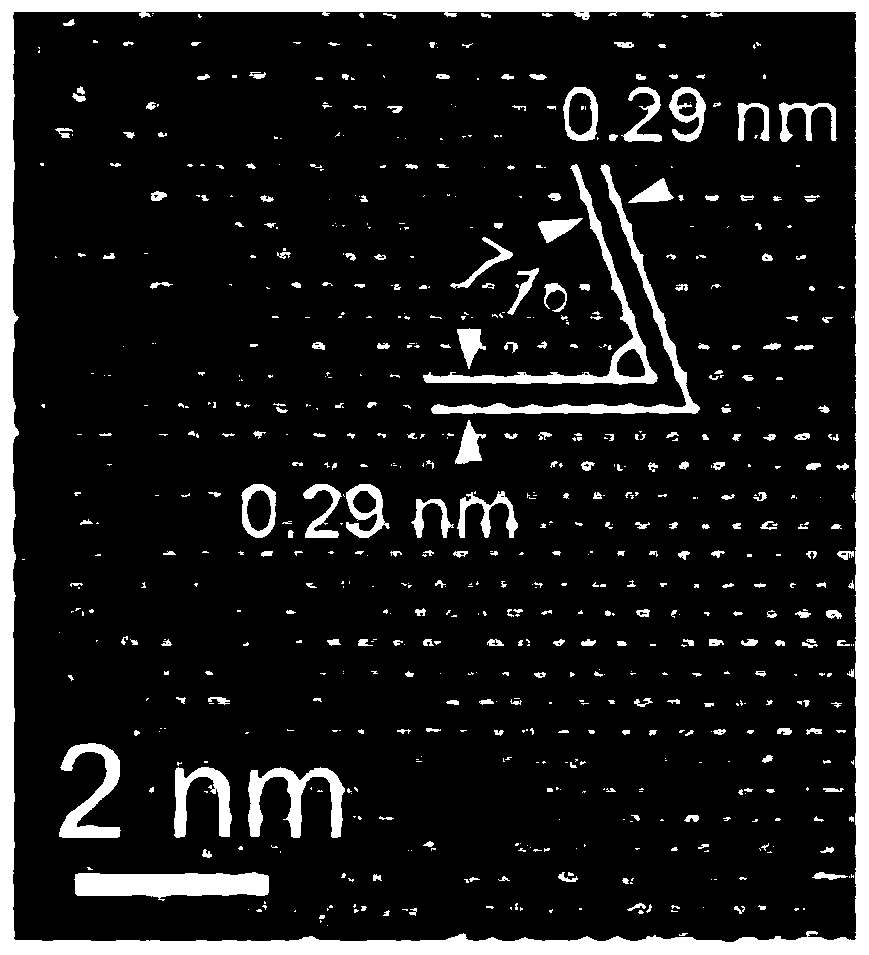

Embodiment 1

[0034] A method for electrochemically extracting uranium from seawater using metal oxides containing oxygen vacancies, comprising the following steps:

[0035] Step 1, add 3g In(NO 3 ) 3 4.5H 2 O was dissolved in 300mL of isopropanol, stirred for 0.5 hours, and ultrasonicated for 1 hour to obtain an indium nitrate isopropanol solution; 100 g of glycerol was added to the indium nitrate in isopropanol solution, stirred for 0.5 hours, and ultrasonicated for 0.5 hours to obtain a mixed solution ; The power of the ultrasound is 800W, and the frequency is 35KHz;

[0036] Step 2. Transfer the mixed solution to a polytetrafluoroethylene high-temperature and high-pressure reactor, raise the temperature to 180°C at a rate of 5°C / min, keep it warm for 1 hour, and cool to room temperature naturally, then separate the solid from the liquid, and use deionized water to separate the solids. Wash with ethanol, then dry in a vacuum oven at 60°C for 12 hours to obtain a spherical indium hydro...

Embodiment 2

[0043] A method for electrochemically extracting uranium from seawater using metal oxides containing oxygen vacancies, comprising the following steps:

[0044] Step 1, add 3g In(NO 3 ) 3 4.5H 2 O was dissolved in 300mL isopropanol, stirred for 1 hour, and ultrasonicated for 0.5 hours to obtain an indium nitrate isopropanol solution; 100 g of glycerol was added to the indium nitrate isopropanol solution, stirred for 1 hour, and ultrasonically used for 0.5 hours to obtain a mixed solution ; The power of the ultrasound is 800W, and the frequency is 40KHz;

[0045] Step 2. Transfer the mixed solution to a polytetrafluoroethylene high-temperature and high-pressure reactor, raise the temperature to 185°C at a rate of 5°C / min, keep it warm for 2 hours, and cool it to room temperature naturally, then separate the solid from the liquid, and use deionized water to separate the solids. Wash with ethanol, then dry in a vacuum oven at 60°C for 12 hours to obtain a spherical indium hydro...

Embodiment 3

[0052] A method for electrochemically extracting uranium from seawater using metal oxides containing oxygen vacancies, comprising the following steps:

[0053] Step 1, add 3g In(NO 3 ) 3 4.5H 2 O was dissolved in 300mL of isopropanol, stirred for 1 hour, and ultrasonicated for 1 hour to obtain an indium nitrate isopropanol solution; 100 g of glycerol was added to the indium nitrate in isopropanol solution, stirred for 1 hour, and ultrasonicated for 1 hour to obtain a mixed solution ; The power of the ultrasound is 800W, and the frequency is 40KHz;

[0054] Step 2. Transfer the mixed solution to a polytetrafluoroethylene high-temperature and high-pressure reactor, raise the temperature to 200°C at a rate of 5°C / min, and keep it warm for 1 hour. After cooling to room temperature naturally, separate the solid and liquid, and use deionized water to separate the solids. Wash with ethanol, then dry in a vacuum oven at 60°C for 12 hours to obtain a spherical indium hydroxide solid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com