Efficient recycling method of crude zinc oxide raw material

A technology for secondary zinc oxide and resource utilization is applied in the field of efficient resource utilization of secondary zinc oxide raw materials, which can solve the problems of low recovery rate of zinc metal, unprofitable extraction of indium, low added value of products, etc., and achieves significant economic benefits, Good production environment, convenient low-cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

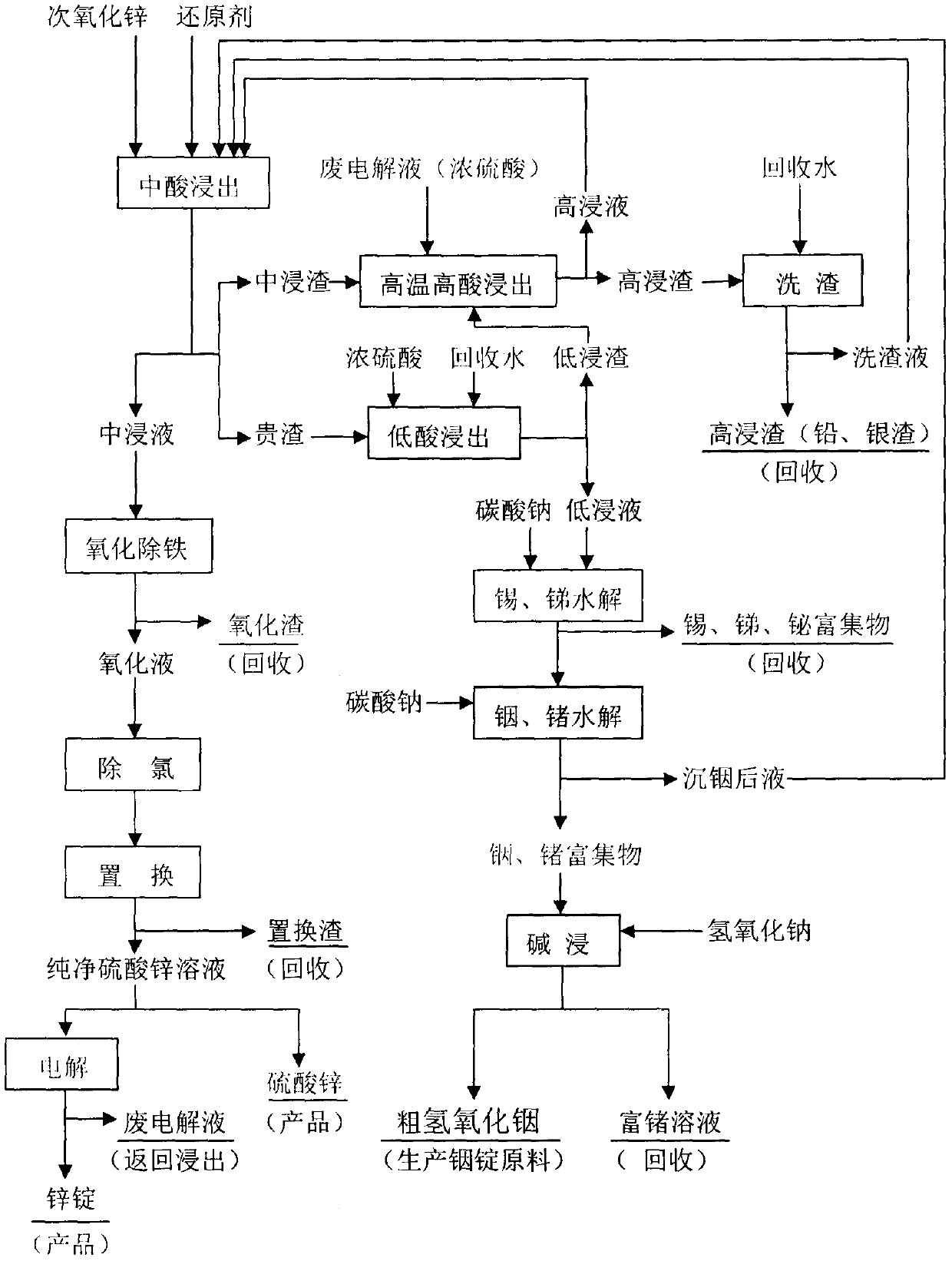

[0032] Such as figure 1 As shown, an efficient resource utilization method of zinc suboxide raw material of the present invention includes the following steps:

[0033] 1. Add 65L of high leaching solution, slag washing solution and post-indium immersion solution to a 200L medium acid leaching reaction tank, a total of 35L, sampling and testing: the mixed solution contains 112.5g / L sulfuric acid, and the raw material of zinc hypoxide is a factory smoked The quality of the furnace product is as follows: Zn51.2%, Pb6.03%, Sb4.25%, Sn0.36%, Bi0.07%, In0.09%. Add 17 kg of zinc hypoxide raw material and react with sulfuric acid in the mixed solution under normal pressure. The reaction temperature is 30-80° C., the reaction time is 1.5 h, and the final solution pH is 5.4. The solid-liquid separation obtains intermediate leaching liquid and intermediate leaching residue. The leaching solution is used as the raw material for the production of electrolytic zinc ingots or zinc sulfate pr...

Embodiment 2

[0041] 1. Add 65L of high leaching solution, slag washing solution and post-indium immersion solution to a 200L medium acid leaching reaction tank, a total of 35L, sampling and testing: the mixed solution contains 110.3g / L sulfuric acid, and the raw material for zinc hypoxide is a rotary kiln of a factory The quality of the product is as follows: Zn 53.5%, Pb 10.6%, Sh 0.05%, Sn 0.76%, Bi 0.87%, In 0.031%. Put 16.5 kg of zinc hypoxide raw material and react with sulfuric acid in the mixed solution under normal pressure, the reaction temperature is 30-80°C, the reaction time is 1.5h, and the end solution pH=5.4. The solid-liquid separation obtains intermediate leaching liquid and intermediate leaching residue. The leaching solution is used as the raw material for the production of electrolytic zinc ingots or zinc sulfate products.

[0042] 2. Add waste electrolyte to the high acid leaching reaction tank or use concentrated sulfuric acid to recycle waste water to obtain 65L of a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com