Production method for nanometer indium oxide

A nano-indium oxide and production method technology, applied in the field of materials, can solve the problems of unfavorable acquisition of high-density targets, low sintering activity, and wide particle size distribution range of indium oxide powder, achieving narrow particle size distribution range, good dispersion, and The effect of not easy to reunite

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

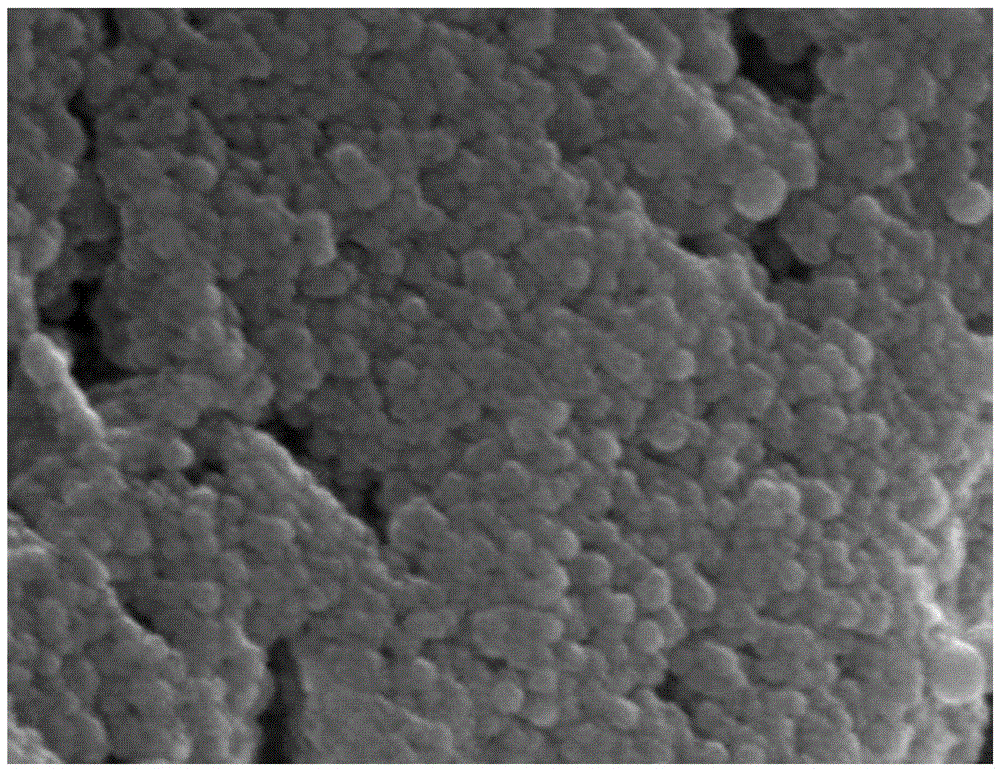

Embodiment 1

[0035] Take 20ml of analytically pure formic acid with a content of 85%, 30ml of distilled water, and 10ml of analytically pure hydrogen peroxide with a content of 30%, and mix them to prepare a 60ml solution; add 20 grams of indium particles with a particle size of not more than 1mm and a purity of 5N to the above solution, and heat to 40 °. After the reaction is completed and cooled, the unreacted indium is taken out to obtain an indium formate solution. Then, add analytically pure ethanol with a content of 95% to the indium formate solution, stir and mix evenly, the solution gradually produces a white precipitate, and after standing for 0.5 hours, filter and separate the precipitate, put it in an oven and dry it at 120 ° for 6 hours, Then put it into an electric furnace and roast at 700° for 2 hours to obtain 10.2 g of indium oxide powder, the particles are spherical and the particle size is 20-50 nanometers.

Embodiment 2

[0037]Take 20ml of analytically pure peracetic acid with a content of 85% and 40ml of distilled water, mix and prepare a 60ml solution; add 20 grams of indium particles with a particle size not greater than 1mm and a purity of 5N to the above solution, and heat to 30°. After the reaction is completed and cooled, the unreacted indium is taken out to obtain an indium acetate solution. Then, add analytically pure ethanol with a content of 95% to the indium acetate solution, stir and mix evenly, the solution gradually produces a white precipitate, and after standing for 0.5 hours, filter and separate the precipitate, put it in an oven and dry it at 120 ° for 6 hours, Then put it into an electric furnace and roast at 700° for 2 hours to obtain 8.6 g of indium oxide powder, the particles are spherical and the particle size is 30-70 nanometers.

[0038] The invention realizes the goals of small and round indium oxide powder particles, uniform particle size, narrow particle size distr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com