Coating type ammonia sensor nano film and method for preparing same

An ammonia gas sensor and nano-film technology, which is applied to the film coated on the sensor, the preparation of the above-mentioned nano-film, and the coating-type ammonia sensor nano-film field can solve the problem that the sensitive film is unstable, the ammonia gas selectivity is poor, Affecting gas sensing performance and other issues, achieving the effects of good responsiveness, low cost, and low operating temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The steps of the manufacturing process of the thin film of coating type ammonia sensor provided by the invention are:

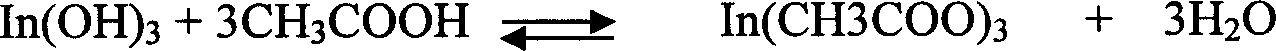

[0032] (1) The analytically pure crystalline InCl 3 4H 2 O is prepared into a solution with a concentration of 0.25 mol / L, slowly dripping ammonia water with a concentration of 1 mol / L under the condition of controlling the speed of 400 (rev / min), when PH=8, stop adding ammonia water, and continue to stir for three Hours make the indium hydroxide coagulate evenly.

[0033] (2) at a centrifugal speed of 10,000 rpm, filter, and wash with deionized water, so that the chloride ion in the solution is less than 10 -5 mol / L.

[0034] (3) Put the repeatedly cleaned indium hydroxide in a vacuum oven at 120° C. for 10 hours to vacuum dry.

[0035] (4) Fully dissolve indium hydroxide with 1g / mL glacial acetic acid, add 1% (ratio of substance amount) butyl titanate dropwise, then add a small amount of water to hydrolyze it, and then make glacial acetic acid at...

Embodiment 2

[0039] The steps of the manufacturing process of the thin film of coating type ammonia sensor provided by the invention are:

[0040] (1) The analytically pure crystalline InCl 3 4H 2 O is prepared into a solution with a concentration of 0.2 mol / L, and slowly drips ammonia water with a concentration of 0.9 mol / L under the condition of controlling the speed of 450 (rev / min). When PH=8, stop adding ammonia water and continue stirring 2.8 hours to uniformly coagulate the indium hydroxide.

[0041] (2) At a centrifugal speed of 9500 rpm, filter, and wash with deionized water, so that the chloride ion in the solution is less than 10 -5 mol / L.

[0042] (3) Put the repeatedly washed indium hydroxide in a vacuum oven at 110° C. for 5 hours to vacuum dry.

[0043] (4) Fully dissolve indium hydroxide with 1g / mL glacial acetic acid, add 1% (ratio of substance amount) butyl titanate dropwise, then add a small amount of water to hydrolyze it, and then make glacial acetic acid at room t...

Embodiment 3

[0047] The steps of the manufacturing process of the thin film of coating type ammonia sensor provided by the invention are:

[0048] (1) The analytically pure crystalline InCl 3 4H 2 O is prepared into a solution with a concentration of 0.3 mol / L, and slowly drips the ammonia water with a concentration of 1.1 mol / L under the condition of controlling the speed of 500 (rev / min). When the pH=8, stop adding the ammonia water and continue to stir 3.1 hours to make the indium hydroxide coagulate evenly.

[0049] (2) at a centrifugal speed of 10500 rpm, filter, and clean with deionized water, so that the chloride ion in the solution is less than 10 -5 mol / L.

[0050] (3) Put the repeatedly cleaned indium hydroxide in a vacuum oven at 115° C. for 8 hours to vacuum dry.

[0051] (4) Fully dissolve indium hydroxide with 1g / mL glacial acetic acid, add 1% (ratio of substance amount) butyl titanate dropwise, then add a small amount of water to hydrolyze it, and then make glacial aceti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com