Indium oxide nanosphere and preparation method thereof

A technology of nanospheres and indium oxide, which is applied to the field of indium oxide nanospheres and their preparation, can solve the problems of long reaction time, high synthesis temperature, complicated preparation process and the like, and achieve the effects of less harsh reaction conditions, low cost and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

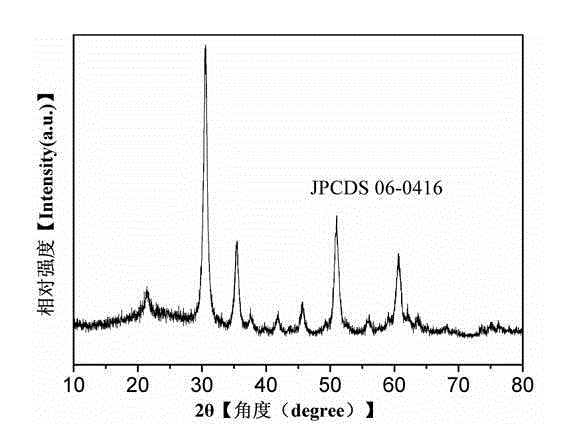

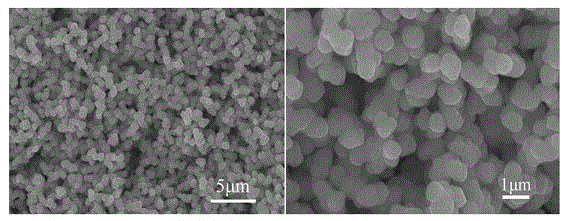

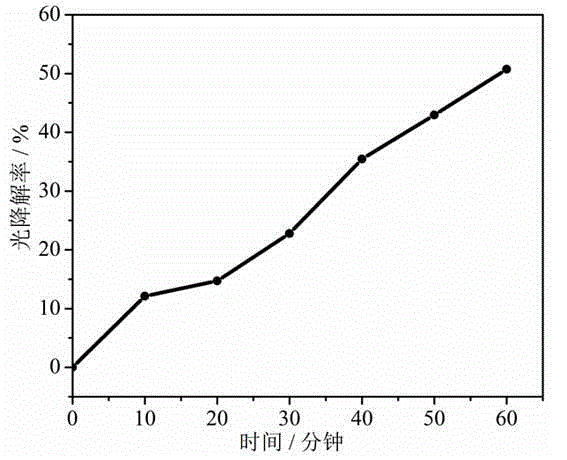

[0025] An indium oxide (In 2 o 3 ) The preparation method of nanospheres is carried out according to the following steps:

[0026] Step one: take by weighing 1 mmol of indium nitrate (In(NO 3 ) 3 4.5 H 2 (2) and 1 mmol of urea, prepare indium nitrate and urea mixed solution, be dissolved in 35mL ethanol, be configured into a uniform colorless transparent solution after magnetic stirring;

[0027] Step 2: Transfer the mixed system obtained in Step 1 to a polytetrafluoroethylene-lined reactor, raise the temperature to 120°C for 1 hour, and cool naturally to obtain a solvothermal product;

[0028] Step 3: Centrifuge the solvothermal product obtained in Step 2, wash it three times with deionized water and absolute ethanol; dry the centrifuged product in air at 60°C for 6 h to obtain the precursor indium hydroxide (In(OH ) 3 );

[0029] Step 4: the indium hydroxide (In(OH)) obtained in step 3 3 ) precursors were calcined in a muffle furnace at 300 °C in an air atmosphere fo...

Embodiment 2

[0037] An indium oxide (In 2 o 3 ) The preparation method of nanospheres is carried out according to the following steps:

[0038] Step one: take by weighing 1 mmol of indium nitrate (In(NO 3 ) 3 4.5 H 2 O) with 5 millimoles of urea, be dissolved in 35mL ethylene glycol, be configured into a uniform colorless transparent solution after magnetic stirring;

[0039] Step 2: Transfer the mixed system obtained in Step 1 to a polytetrafluoroethylene-lined reactor, raise the temperature to 180 °C for 12 h, and cool naturally to obtain a solvothermal product;

[0040] Step 3: Centrifuge the solvothermal product obtained in Step 2, wash it three times with deionized water and absolute ethanol; dry the centrifuged product in air at 80°C for 12 h to obtain the precursor indium hydroxide (In(OH ) 3 );

[0041] Step 4: the indium hydroxide (In(OH)) obtained in step 3 3 ) precursors were calcined in a muffle furnace at 600 °C in an air atmosphere for 240 min to obtain indium oxide (In...

Embodiment 3

[0043] An indium oxide (In 2 o 3 ) The preparation method of nanospheres is carried out according to the following steps:

[0044] Step 1: take by weighing 1 mmol of indium nitrate (In(NO 3 ) 3 4.5 H 2 O) with 1 mmol of urea, dissolved in 20 mL of ethanol and 15 mL of ethylene glycol, configured into a uniform colorless and transparent solution after magnetic stirring;

[0045] Step 2: Transfer the mixed system obtained in Step 1 to a polytetrafluoroethylene-lined reactor, raise the temperature to 120 °C for 1 h, and cool naturally to obtain a solvothermal product;

[0046] Step 3: centrifuge the solvothermal product obtained in step B, wash with deionized water and absolute ethanol three times respectively; dry the centrifuged product in air at 80°C for 12 h to obtain the precursor indium hydroxide (In(OH ) 3 );

[0047] Step 4: the indium hydroxide (In(OH)) obtained in step 3 3 ) precursors were calcined in a muffle furnace at 600 °C in an air atmosphere for 240 min ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com