Method for preparing nanometer indium cadmium sulfide-indium hydroxide composite photocatalyst

A technology of indium cadmium sulfide and indium hydroxide, applied in the direction of physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of low equilibrium conversion rate, low catalyst loading rate, and narrow semiconductor light absorption wavelength range etc. to achieve the effect of simple operation, high photocatalytic activity and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

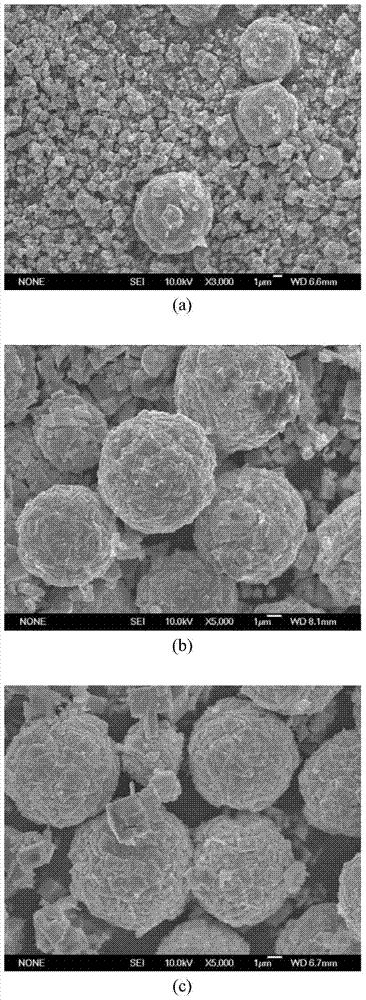

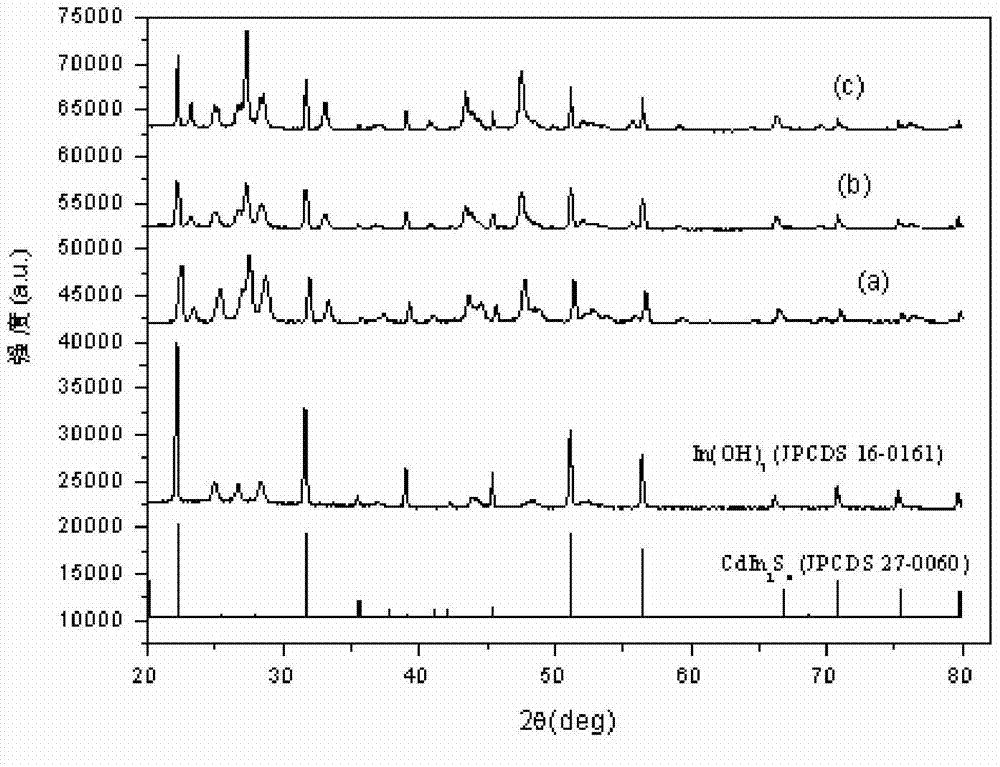

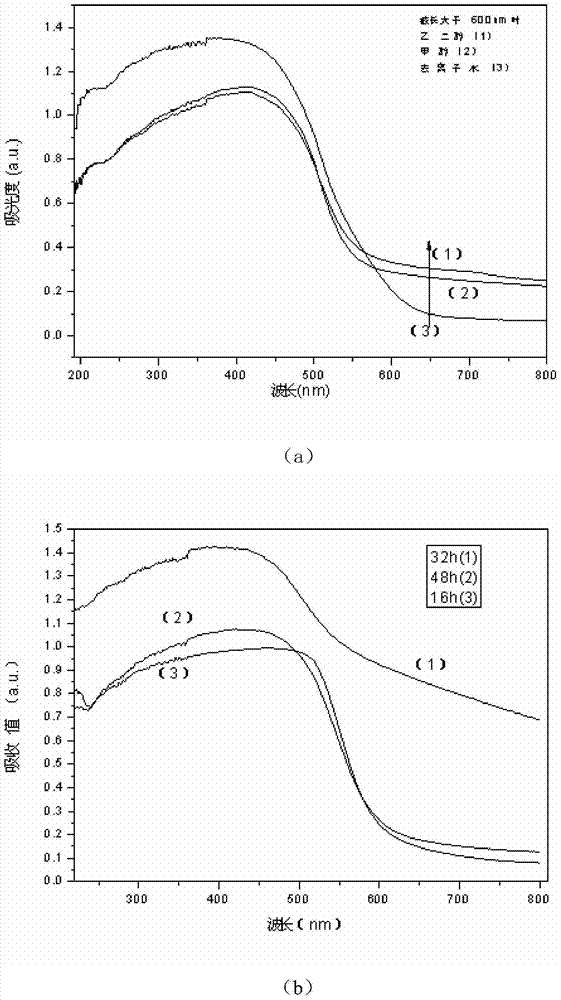

[0025] A method for preparing a nano-indium cadmium sulfide-indium hydroxide composite photocatalyst, which is prepared by a hydrothermal method, and the steps are as follows:

[0026] 1) Add 0.35g of indium chloride, 0.14g of cadmium chloride and 0.35g of thiourea into 55mL of deionized water and stir vigorously for 15 minutes to obtain a mixed solution;

[0027] 2) Move the above mixed solution into a hydrothermal kettle, then place the hydrothermal kettle in an oven for constant temperature crystallization at 140°C, and the time for constant temperature crystallization is 16h, 32h, and 48h;

[0028] 3) Take out the hydrothermal kettle after the constant temperature reaction is over, and discard the supernatant after cooling to room temperature;

[0029] 4) Collect the precipitate in the kettle, and wash it with absolute ethanol and deionized water for 3 times to remove the impurities in the precipitate;

[0030] 5) Dry the washed precipitate at a constant temperature of 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com