Preparation method of nano indium oxide

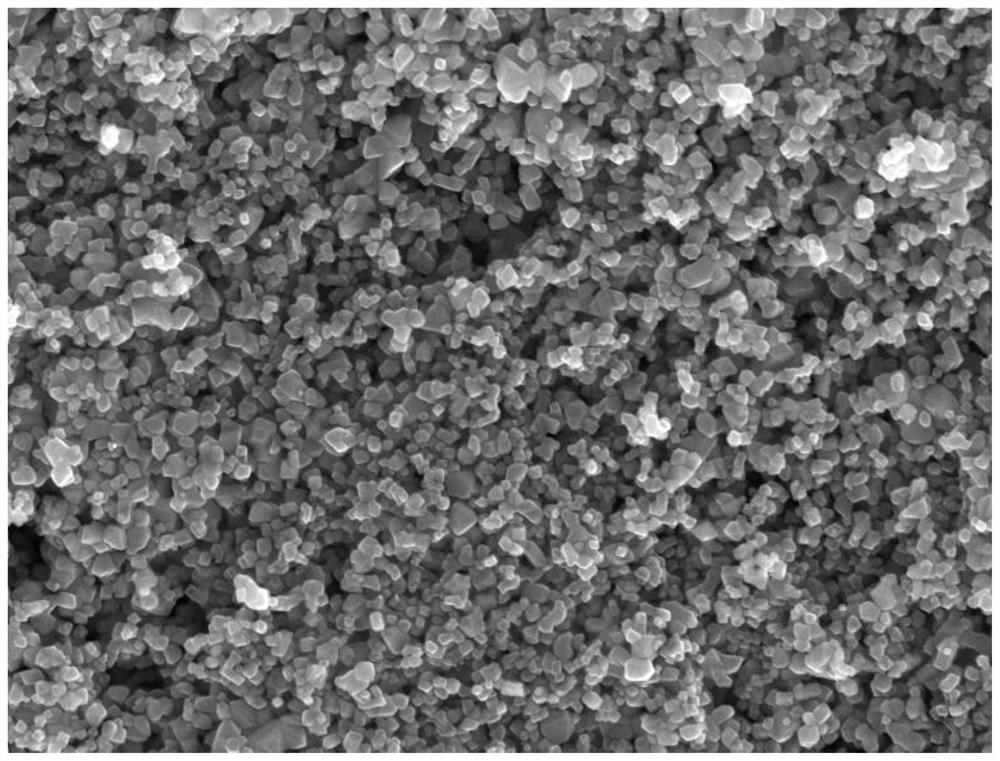

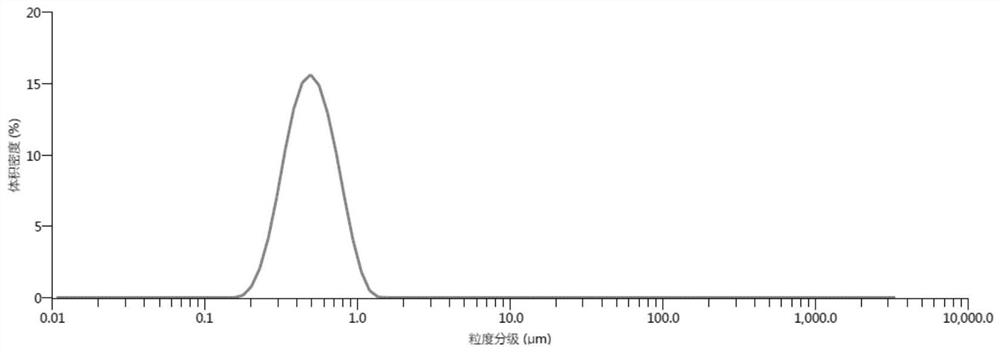

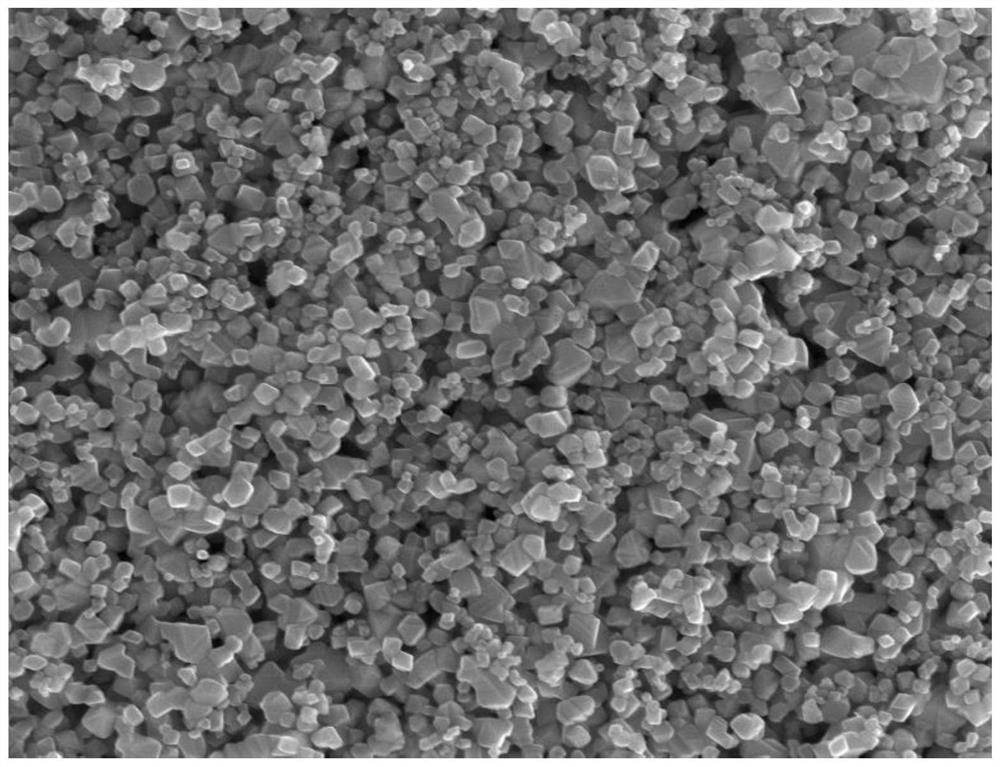

A nanometer indium oxide, metal indium technology, applied in chemical instruments and methods, nanotechnology, nanotechnology and other directions, can solve the problems of high equipment requirements, long production cycle, many synthesis process steps, etc., and achieve uniform particle distribution and stability. Good, uniform particle size results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] The present invention provides a kind of preparation method of nano indium oxide, and this preparation method comprises the following steps:

[0027] The electrolysis is carried out with metal indium as anode, inert electrode as cathode and ammonium salt aqueous solution as electrolyte. Among them, the electrode spacing between the anode and the cathode is 30-200mm. When the electrode spacing is greater than 200mm, the resistance between the cathode and the anode increases, and the power consumption increases; when the electrode spacing is less than 30mm, it is easy to produce contact or short circuit between electrodes.

[0028] The inert electrode is one of a titanium plate, a graphite plate, a platinum plate, and a gold-plated plate. As a further preferred embodiment of the method for preparing nano-indium oxide in the present invention, the inert electrode is preferably a graphite plate or a titanium plate.

[0029] The ammonium salt in the ammonium salt aqueous sol...

Embodiment 1

[0049] An embodiment of the preparation method of nano-indium oxide of the present invention. The electrolysis device used in the preparation method is an electrolysis chamber with a size of 1000*500*150mm and a capacity of 7.5L. The anode and cathode are installed in the same electrolysis chamber at the same time, and the anode and cathode are connected by contact with the electrolyte in the electrolysis chamber. Generally, the electrode spacing between the anode and the cathode is 30mm, and the preparation method of the present embodiment is as follows:

[0050] (1) Add ammonium nitrate aqueous solution to the electrolysis chamber, control the pH to 3 during the electrolysis process, then heat the electrolysis chamber to 50°C, turn on the power, and set the current density to 500A / m 2 ;

[0051] (2) After continuous electrolysis for 18 hours, heat the electrolyzed solution to 60°C, continuously add ammonia solution with a solute mass fraction of 35% to the electrolyzed solu...

Embodiment 2

[0054] An embodiment of the preparation method of nano-indium oxide of the present invention. The electrolysis device used in the preparation method is an electrolysis chamber with a size of 1000*500*150mm and a capacity of 7.5L. The anode and cathode are installed in the same electrolysis chamber at the same time, and the anode and cathode are connected by contact with the electrolyte in the electrolysis chamber. Generally, the electrode spacing between the anode and the cathode is 30mm, and the preparation method of the present embodiment is as follows:

[0055] (1) Add ammonium nitrate aqueous solution into the electrolysis chamber, control the pH during the electrolysis process to keep it at 3.5, then heat the electrolysis chamber to 35°C, turn on the power, and set the current density to 1300A / m 2 ;

[0056] (2) After continuous electrolysis for 24 hours, heat the electrolyzed solution to 80°C, continuously add ammonia solution with a solute mass fraction of 20% to the e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com