Method for production of metal hydroxide and method for production of ITO sputtering target

A hydroxide and manufacturing method technology, applied in sputtering coating, metal material coating process, vacuum evaporation coating, etc., can solve the problem of damage to mass production, unstable pH value and temperature of electrolyte, and inability to reduce manufacturing costs And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

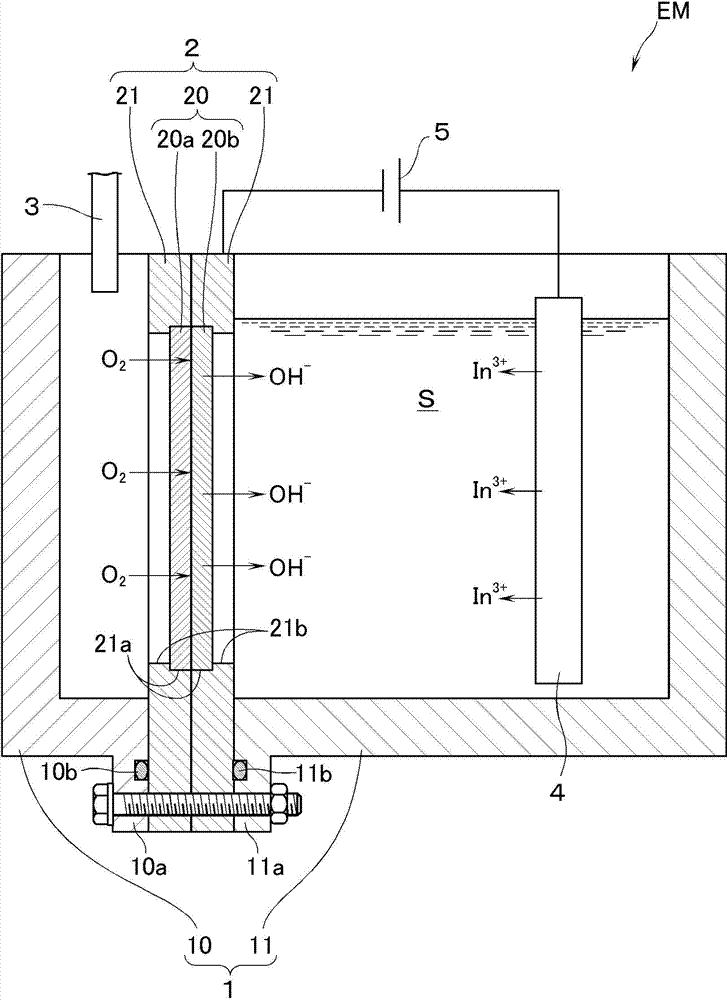

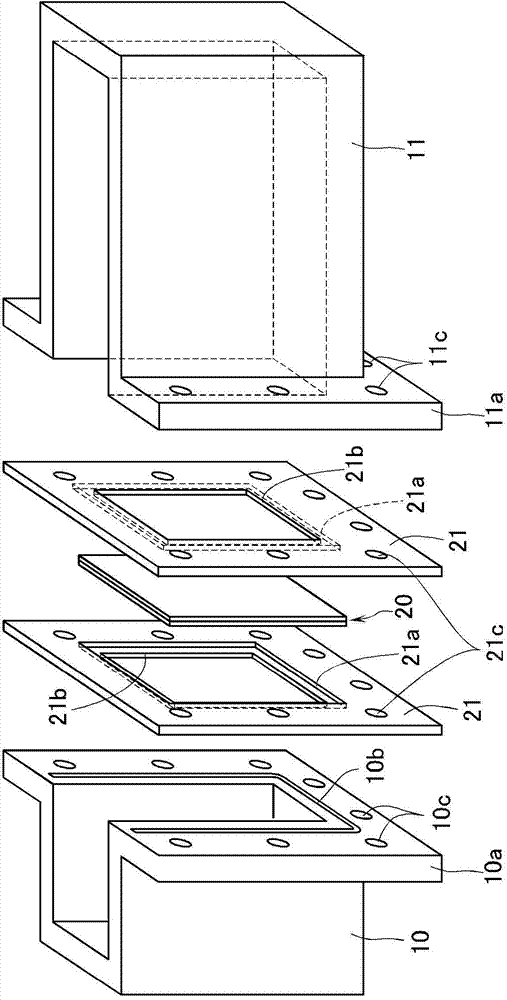

[0022] refer to figure 1 , EM is an electrolysis device used in this embodiment, and the electrolysis device EM includes an electrolytic cell 1 . The electrolytic tank 1 is composed of an air tank 10 and a settling tank 11 . The air tank 10 and the settling tank 11 are opened on the top surface and one side surface, and flange portions 10a, 11a are formed around the one side surface. Packages 10b, 11b are fitted in grooves formed in the flange portions 10a, 11a, and the electrolyte solution can be sealed between them and a holding plate 21 described later.

[0023] A cathode 2 is arranged in the electrolytic cell 1 , and the electrolytic cell 1 is partitioned by the cathode 2 . The cathode 2 is composed of a gas diffusion electrode 20 and two holding plates 21 made of titanium sandwiching the gas diffusion electrode 20 . The holding plate 21 functions to efficiently conduct electricity to the gas diffusion electrode 20 . The gas diffusion electrode 20 is formed by laminati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com