High-dispersion metal-oxide bifunctional catalyst and preparation method and application thereof

A dual-function catalyst, high dispersion technology, applied in metal/metal oxide/metal hydroxide catalysts, carbon compound catalysts, physical/chemical process catalysts, etc., can solve the problem of low catalytic activity of indium oxide, high reaction temperature, low temperature Catalyst stability and other issues, to achieve the effect of simple preparation process, high metal dispersion, and avoiding the formation of green oil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0068] Embodiment 1, preparation carrier In 2 o 3 A

[0069] The carrier In of this embodiment 2 o 3 The preparation of A comprises the steps:

[0070] (a), 5g of indium precursor-indium nitrate hydrate was dissolved in 20mL of absolute ethanol (a purity of 99.8% or more) and 75mL of deionized water, and dissolved evenly to obtain an ethanol aqueous solution of the indium precursor, which was packed in a reactor; 15mL 25wt% ammonia is mixed with 25mL absolute ethanol (more than 99.8% in purity) to obtain an ammonia-ethanol mixture; the reactor is placed in a water bath, and the temperature of the water bath is controlled to be 80°C, and then the ammonia-ethanol mixture is mixed under stirring conditions. Add the indium precursor into the aqueous ethanol solution of the indium precursor at a rate of 4 mL / min by means of a convection pump. After the addition, continue to insulate and stir the reaction for 30 minutes to complete the reaction, and obtain a mixed solution con...

Embodiment 2

[0074] Embodiment 2, preparation carrier In 2 o 3 B

[0075] The carrier In of this embodiment 2 o 3 The preparation steps of B are basically the same as in Example 1, the difference is:

[0076] In step (b), the calcination temperature is 600°C, and the carrier In 2 o 3 b.

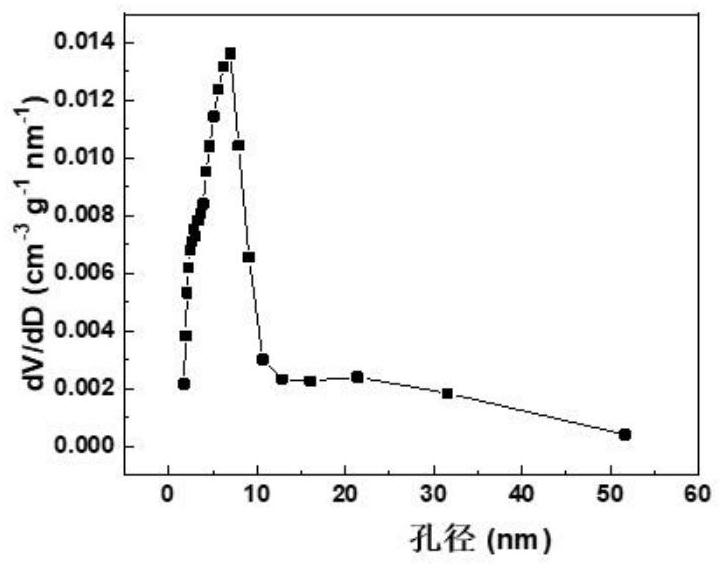

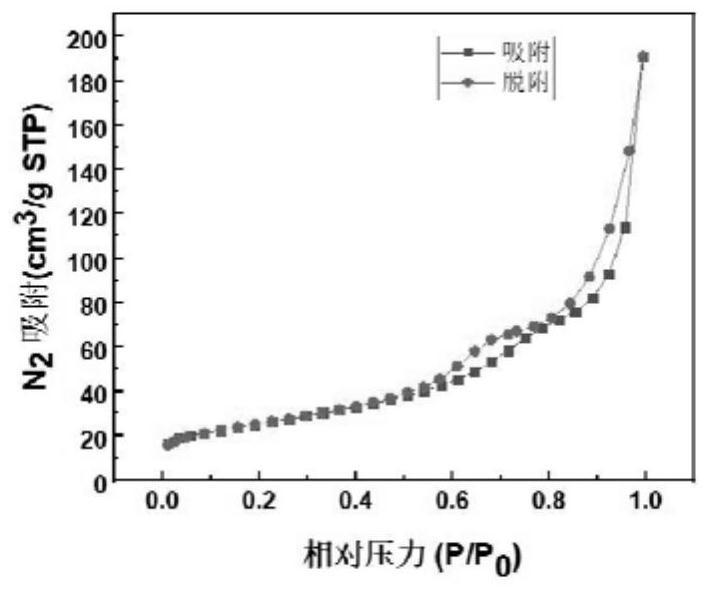

[0077] The carrier In prepared in this example 2 o 3 The adsorption-desorption curve of B and figure 2 similar. CarrierIn 2 o 3 The specific surface area of B is 85.40m 2 / g;

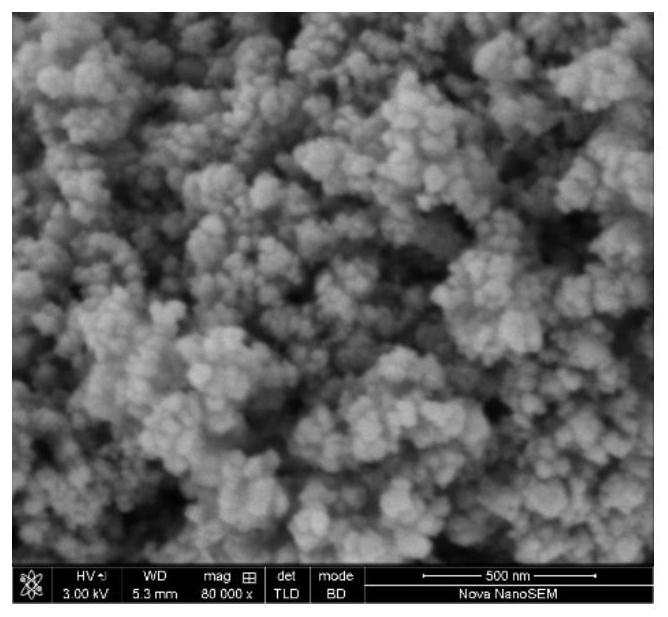

[0078] CarrierIn 2 o 3 The scanning electron microscope of B as Figure 4 shown. Depend on Figure 4 It can be seen that the carrier In 2 o 3 B also has a loose porous structure and a uniform indium oxide surface.

Embodiment 3

[0079] Embodiment 3, preparation carrier In 2 o 3 C

[0080] The preparation steps of this embodiment are basically the same as in Example 1, the difference is:

[0081] In step (b), the calcination temperature is 500°C, and the carrier In 2 o 3 c.

[0082] The carrier In prepared in this example 2 o 3 The adsorption-desorption curve of C and figure 2 similar. CarrierIn 2 o 3 The specific surface area of C is 93.80m 2 / g;

[0083] CarrierIn 2 o 3 SEM of B with Figure 4 Similarly, it can be seen that the carrier In 2 o 3 C also has a loose porous structure and a uniform indium oxide surface.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com