Method for producing indium hydroxide or compound containing indium hydroxide

An indium hydroxide and compound technology, which is applied in the field of manufacturing indium hydroxide or indium hydroxide-containing compounds, can solve the problems of poor current efficiency, poor sintering characteristics, and inability to improve density, and achieves efficient production and improved sinterability. , the effect of improving productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0114] Hydroxide was precipitated by electrolysis using an indium plate as an anode, a stainless steel plate as a cathode, and an ammonium nitrate aqueous solution as an electrolytic solution. When the conductivity of the electrolytic solution at this time was set to 10 mS / cm and electrolysis was performed, the current efficiency was 95%.

[0115] This hydroxide was further filtered and washed with pure water until the electric conductivity of the washing liquid was 0.1 mS / cm. It is then dried to form indium oxide, and then sintered at 1500°C to obtain an indium sintered body with a relative density of 98%.

[0116] It should be noted that, although an example of using indium as an anode to precipitate indium hydroxide by electrolysis is given at this time, when an indium alloy such as an indium tin alloy is used, a compound containing indium hydroxide (for example, indium hydroxide and hydroxide The same result can also be obtained when the mixture of tin) is precipitated. ...

Embodiment 2

[0119] Electrolysis was performed by changing the conductivity of the electrolytic solution in Example 1 to 100 mS / cm. The current efficiency at this time was 99%. Then, repulping washing was performed with pure water until the electrical conductivity of the washing liquid was 0.01 mS / cm. Sintering was performed under the same conditions as in Example 1, and as a result, a high-density sintered body having a relative density of 99.5% was obtained.

[0120] It should be noted that, although an example of using indium as an anode to precipitate indium hydroxide by electrolysis is given at this time, when an indium alloy such as an indium tin alloy is used, a compound containing indium hydroxide (for example, indium hydroxide and hydroxide The same result can also be obtained when the mixture of tin) is precipitated.

[0121] As in Example 1, it was confirmed that the relative density was increased by washing indium hydroxide or an indium hydroxide-containing compound, and as a...

Embodiment 3

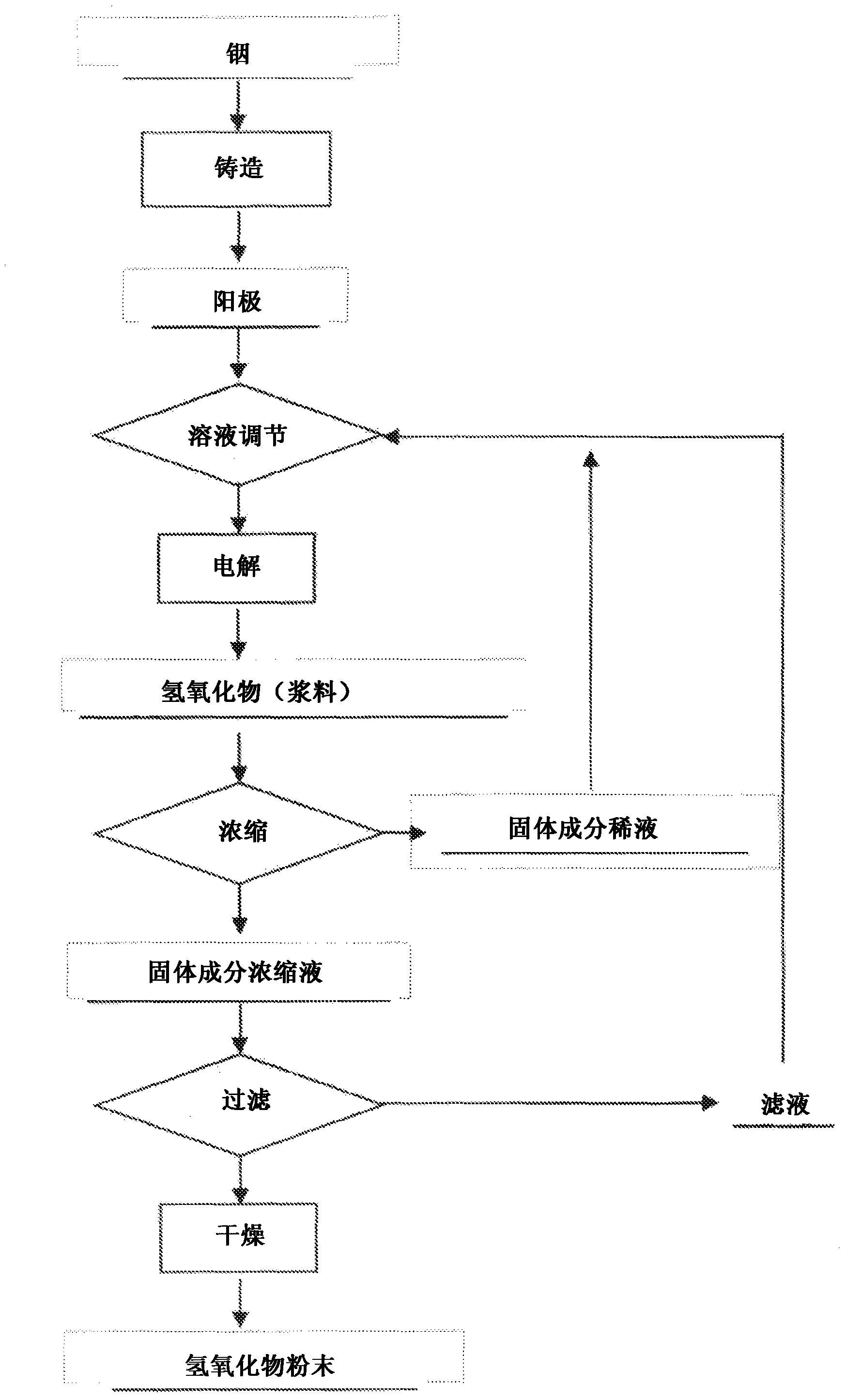

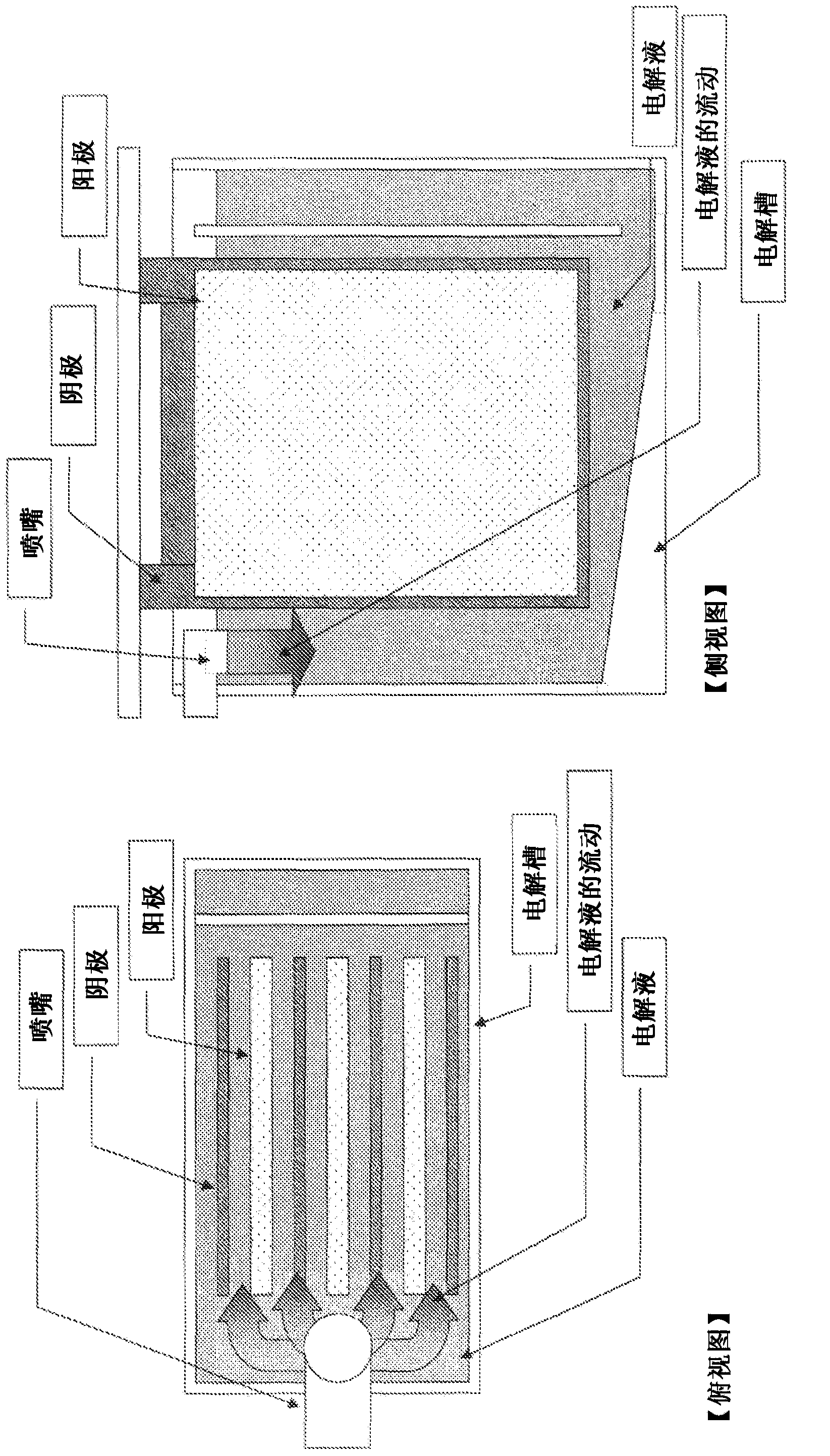

[0132] In the manufacture of indium hydroxide (In(OH)) from metal indium (In) 3 ) in the electrolysis process, metal indium as a raw material is cast, and an anode plate made of metal indium is manufactured and placed in an electrolytic tank. Cathode plates made of stainless steel plates or titanium plates are alternately arranged in the electrolytic cell. A plurality of these anode plates and cathode plates are arranged in parallel. An electrolytic solution is supplied to the electrolytic cell. Ammonium nitrate solution (NH 4 NO 3 ) as the electrolyte to start electrolysis.

[0133] Next, indium hydroxide particles were precipitated in the electrolytic solution, and the electrolysis was terminated when it reached 80% of the initial weight of the anode plate. The used anode plate is then removed and melted down. During melting, new indium metal is added and cast to remake the anode plate.

[0134] Using the newly produced indium metal anode plate, electrolysis can be st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com