Waterproof starch film taking biodegradable polyurethane as coating and preparation method of waterproof starch film

A polyurethane coating and biodegradable technology, applied in polyurea/polyurethane coatings, coatings, bio-packaging, etc., can solve problems such as poor interface compatibility and poor water resistance of starch films, and achieve good mechanical properties and low production costs. Effects from a wide range of sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

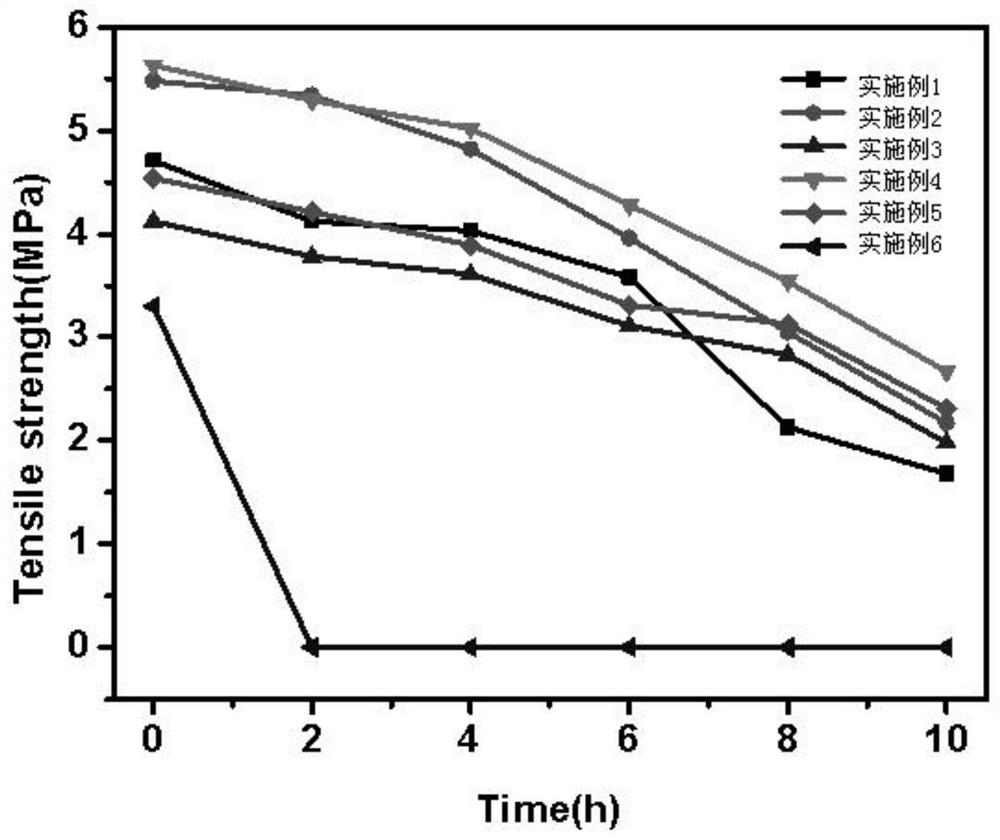

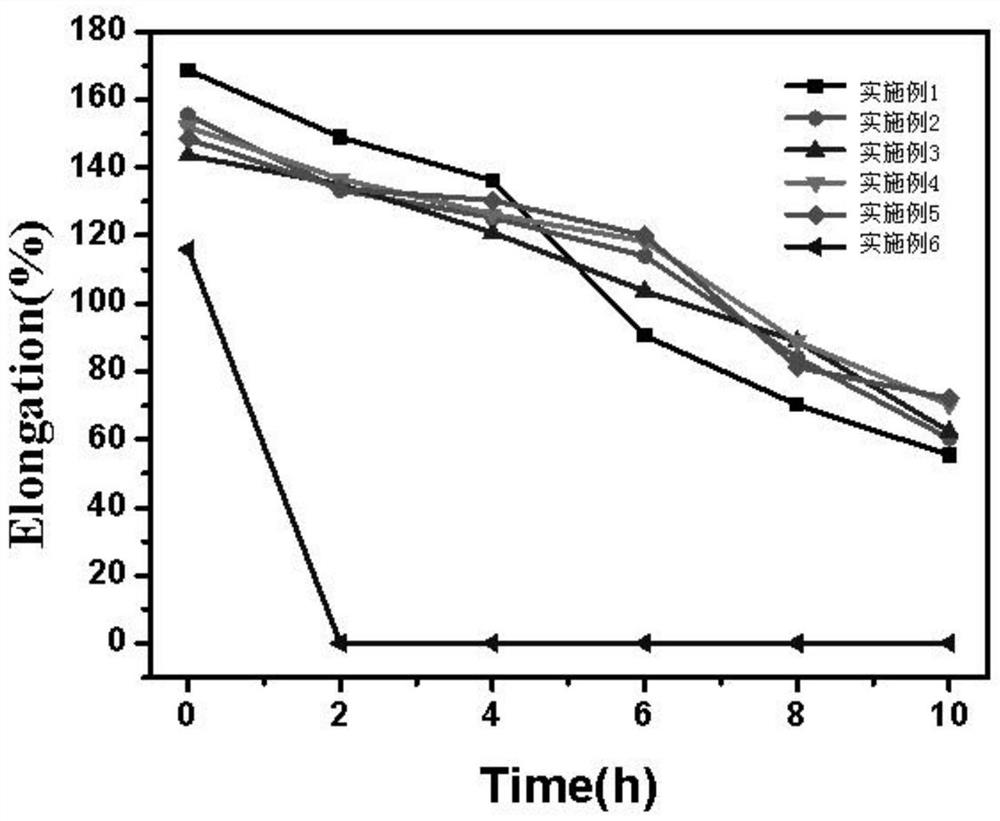

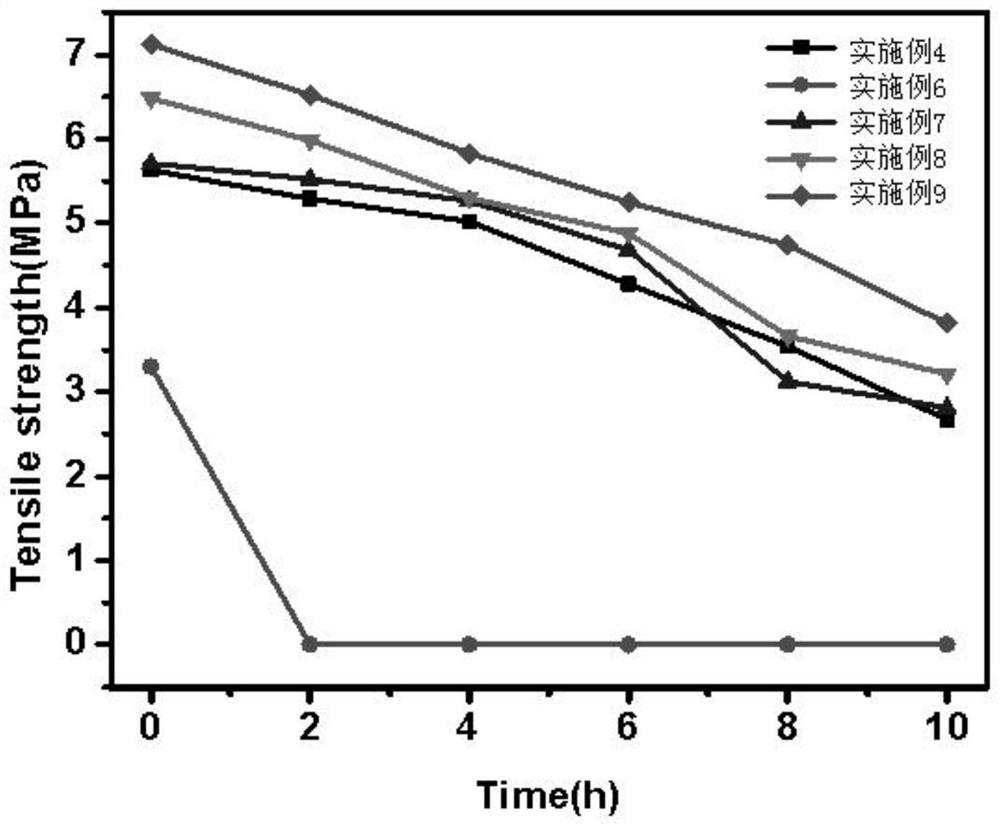

Examples

Embodiment 1

[0043] A kind of waterproof starch film that is coated with biodegradable polyurethane water emulsion is prepared by the following steps:

[0044] (1) Preparation and pretreatment of whole starch film materials: 100 parts of acetylated starch is used as raw material, 30 parts of glycerin is added as a plasticizer, and co-rotating parallel twin-screw extruder (model is LTE20-40) is used to extrude The machine has eight temperature control zones, each temperature is (feed port) 90°C, 125°C, 125°C, 125°C, 130°C, 130°C, 130°C, 120°C (head), and the speed is 60rpm. Pellet to obtain thermoplastic starch. Extrusion casting mechanism is used for full starch film, and the barrel of the casting machine has eight temperature control zones, each temperature is (feed port) 40°C, 60°C, 90°C, 120°C, 120°C, 120°C, 100°C ℃, 95℃ (machine head). The extruded film is collected by a traction device, and the thickness of the extruded film is about 0.30 mm. The obtained starch film material was p...

Embodiment 2

[0048] The difference between this embodiment and embodiment 1 is: 0.1 mol polycaprolactone diol, 0.3 mol toluene diisocyanate (TDI-100). Other steps and parameters are the same as in Example 1. Samples were prepared according to the GB / T 1040.3-2006 test standard, and the tensile strength and elongation at break of the film were tested. Samples were prepared according to the GB / T 30693-2014 test standard, and the contact angle between the film and water was tested. The results are shown in Table 1.

Embodiment 3

[0050] The difference between this embodiment and embodiment 1 is: 0.1 mol polycaprolactone diol, 0.4 mol toluene diisocyanate (TDI-100). Other steps and parameters are the same as in Example 1. Samples were prepared according to the GB / T 1040.3-2006 test standard, and the tensile strength and elongation at break of the film were tested. Samples were prepared according to the GB / T 30693-2014 test standard, and the contact angle between the film and water was tested. The results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com