Method for simply regulating ferroferric oxide nanoparticle morphology

A technology of ferric tetroxide and nanoparticles, which is applied in the directions of iron oxide/ferric hydroxide, nanotechnology, nanotechnology, etc., can solve the problems of never seen ferric tetroxide nanocubes and nanorods, expensive raw materials, and preparation technology. Complexity and other problems, to achieve the effect of low production cost, simple preparation method and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

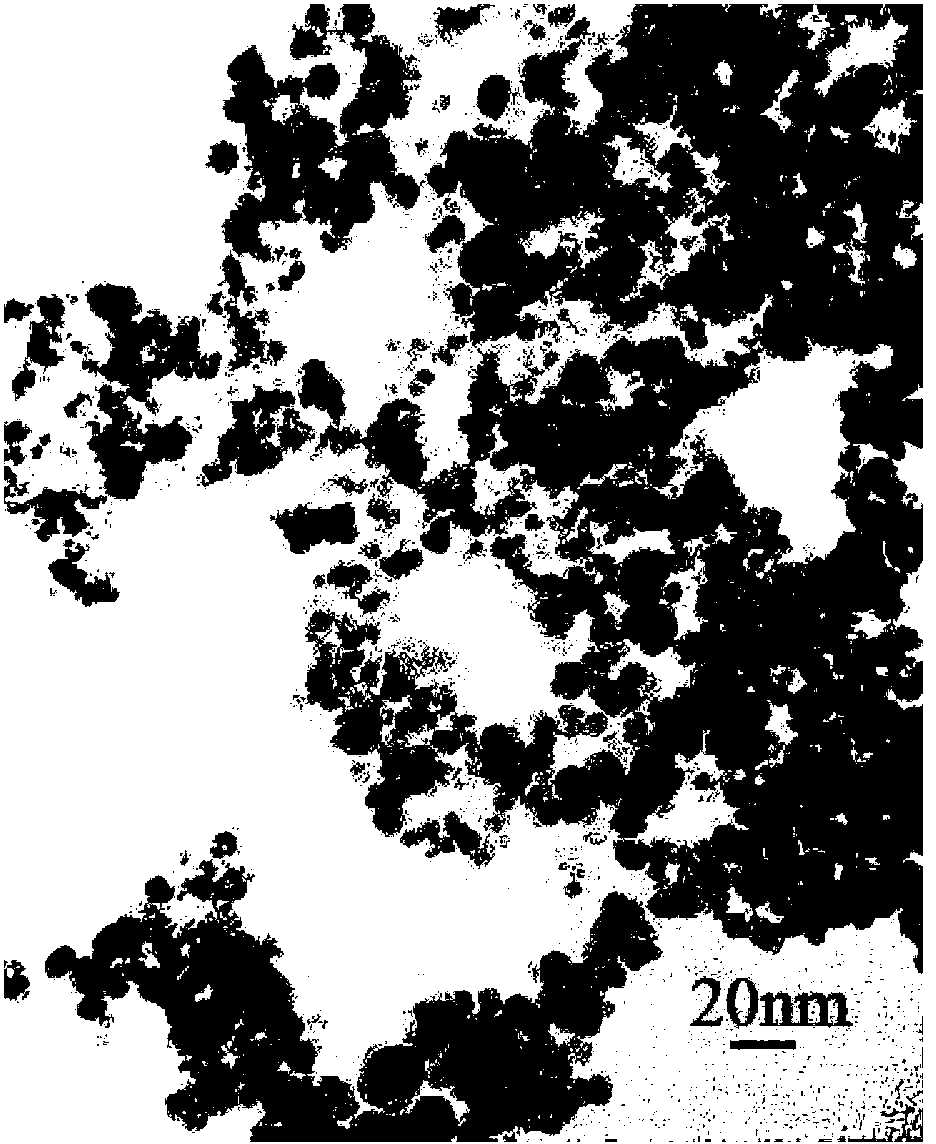

[0028] Weigh 1.4g FeSO 4 ·7H 2 O and 2.0 g Fe 2 (SO 4 ) 3 Dissolve in 100mL deionized water, stir fully to completely dissolve ferric sulfate and ferrous sulfate to obtain a solution with a concentration of 0.15mol / L, add solid NaOH to the solution, and adjust the pH value to 10 after fully dissolving. Stir for 30 minutes to obtain a black precipitate of iron ferric oxide. After filtration, the precipitate is washed three times with deionized water and absolute ethanol, and dried at room temperature for 24 hours to obtain nanoparticles of iron ferric oxide. The results of transmission electron microscopy observations are as follows: figure 1 As shown, it can be seen that the iron ferric oxide nanoparticles are spherical, the particle size distribution is between 5-20nm, the particle size is uniform, and there is no agglomeration phenomenon.

Embodiment 2

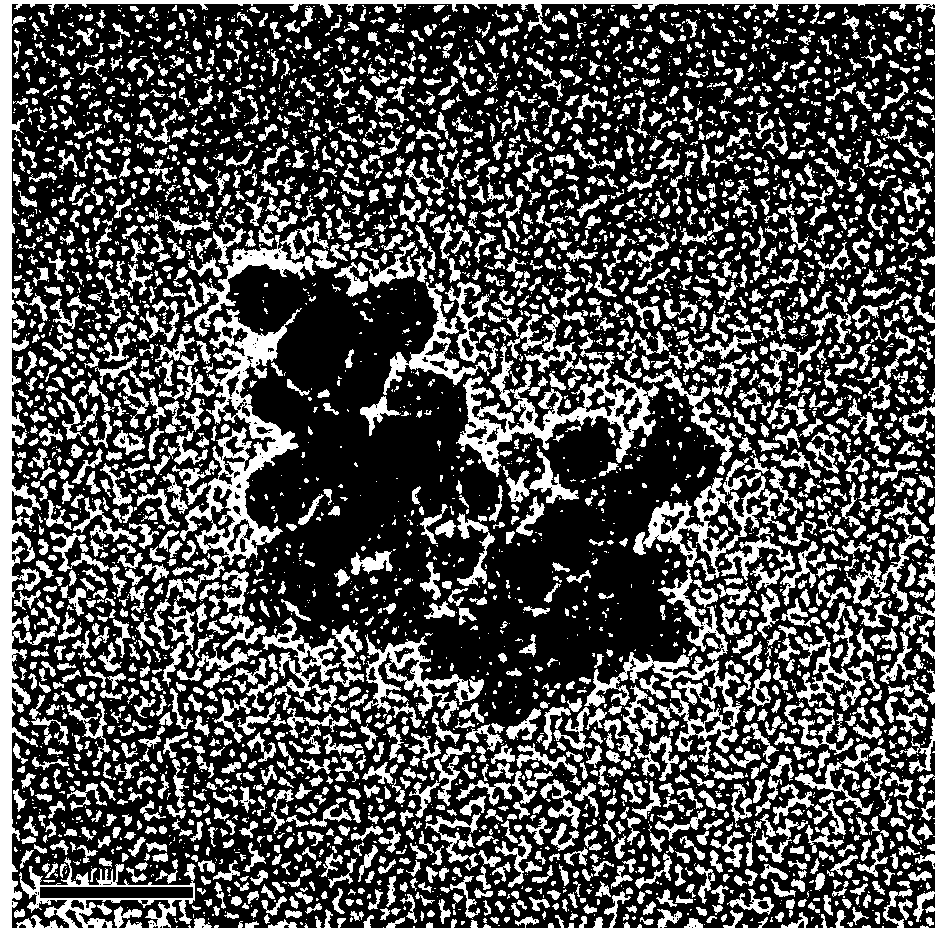

[0030] Weigh 7.36g FeCl 2 4H 2 O and 17.0 g FeCl 3 ·6H 2 Dissolve O in 100mL deionized water, stir fully to dissolve the iron salt completely, and obtain a solution with a concentration of 1.0mol / L, add solid NaOH to the solution, adjust the pH value to 12 after fully dissolving, and stir at room temperature for 60 minutes , to obtain a black precipitate of ferric oxide, which was filtered and washed five times with deionized water and absolute ethanol respectively, and dried at room temperature for 24 hours to obtain ferric oxide nanoparticles. The results of transmission electron microscopy observations are as follows: figure 2 As shown, it can be seen that the iron ferric oxide nanoparticles are spherical, the particle size distribution is between 10-15nm, the particle size is uniform, and there is no agglomeration phenomenon.

Embodiment 3

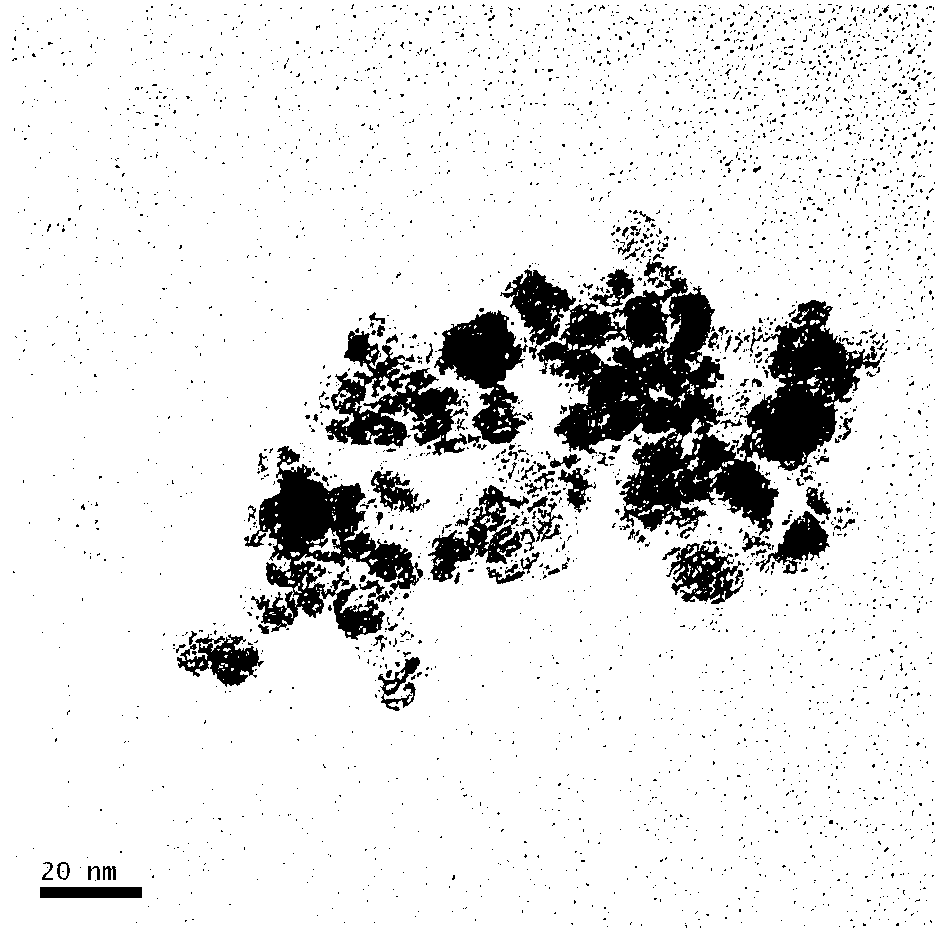

[0032] Weigh 4.3g Fe(NO 3 ) 2 ·6H 2 O and 12.1g Fe(NO 3 ) 3 9H 2 Dissolve O in 100mL deionized water, stir fully to dissolve the iron salt completely, and obtain a solution with a concentration of 0.45mol / L, add solid NaOH to the solution, adjust the pH value to 11 after fully dissolving, and stir at room temperature for 10 minutes , to obtain a black precipitate of ferric oxide, which was filtered and washed with deionized water and absolute ethanol for 4 times, and dried at room temperature for 24 hours to obtain ferric oxide nanoparticles. The results of transmission electron microscopy observations are as follows: image 3 As shown, it can be seen that the iron ferric oxide nanoparticles are spherical, the particle size distribution is between 5-15nm, the particle size is uniform, and there is no agglomeration phenomenon.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com