Preparation method of composite titanium dioxide

A rutile type titanium dioxide and titanium dioxide technology, applied in chemical instruments and methods, titanium dioxide, titanium oxide/hydroxide, etc., can solve the problem of high production cost of composite titanium dioxide, and achieve sufficient raw material sources, no environmental pollution, The effect of reducing resource consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

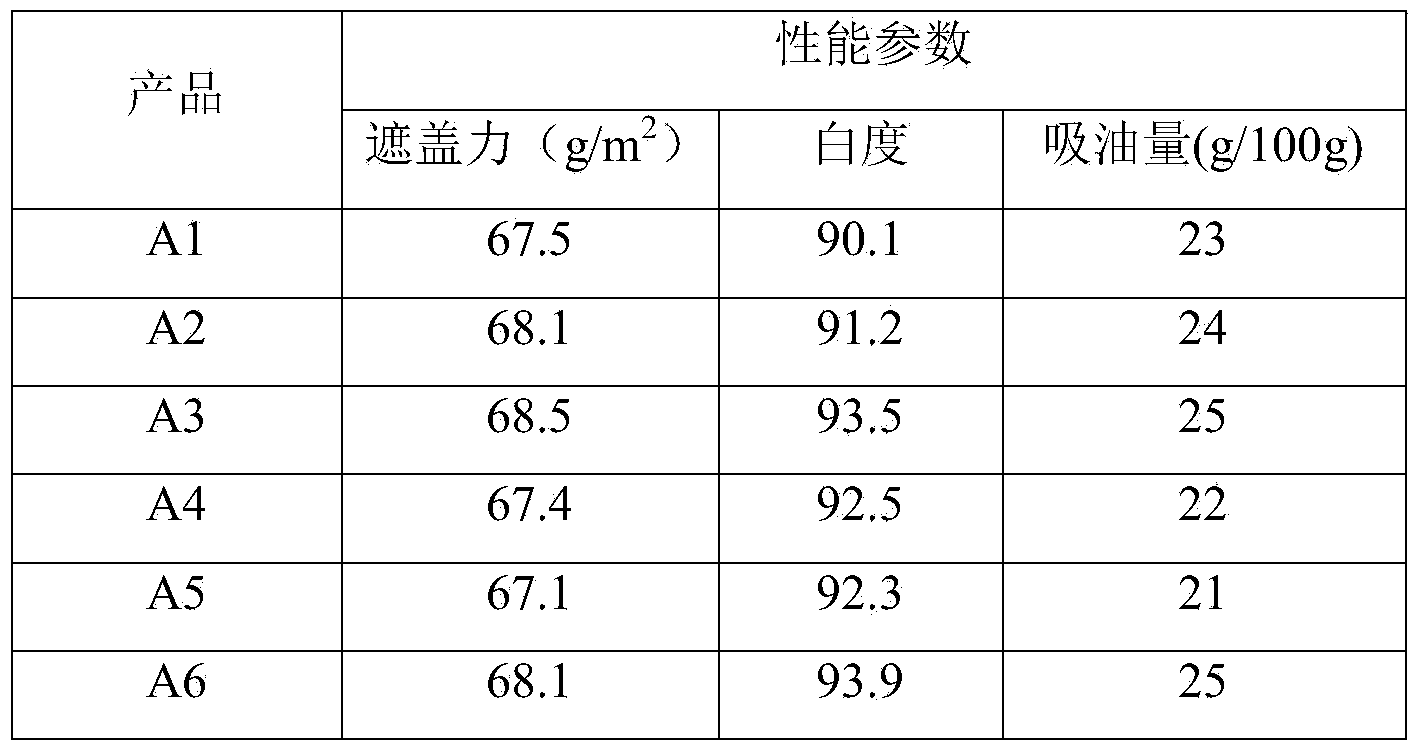

Examples

Embodiment 1

[0020] Embodiment 1: a kind of preparation method of composite titanium dioxide, described method realizes by following scheme:

[0021] (1) Preparation of rutile titanium dioxide

[0022] Weigh 30g solid Ti(NO 3 ) 4 Dissolve in deionized water, prepare a solution with a mass concentration of 15%, and then add it to the three-necked bottle at one time; add 2mol / L ammonia solution dropwise to the three-necked bottle at room temperature, and keep stirring to adjust to an appropriate pH of At 7.5, stop dripping ammonia solution, and generate fresh Ti(OH) 4 White precipitate, after the reaction is complete, the resulting precipitate is centrifuged and washed with water until there is no nitrate ion in the system. Then Ti(OH) 4 The precipitate is dispersed in 0.5mol / HCl solution, in which the HCl and Ti must be ensured 4+ The molar ratio is between 3:1, set the temperature at 55°C, reflux peptization for 25min, the obtained precipitate is centrifuged, washed three times with a...

Embodiment 2

[0025] Embodiment 2: a kind of preparation method of composite titanium dioxide, described method realizes by following scheme:

[0026] (1) Preparation of rutile titanium dioxide

[0027] Weigh 30g solid Ti(NO 3 ) 4Dissolve in deionized water, prepare a solution with a mass concentration of 15%, and then add it to the three-necked bottle at one time; add 2mol / L ammonia solution dropwise to the three-necked bottle at room temperature, and keep stirring to adjust to an appropriate pH of At 8 o'clock, stop adding ammonia solution dropwise, and generate fresh Ti(OH) at this moment 4 White precipitate, after the reaction is complete, the resulting precipitate is centrifuged and washed with water until there is no nitrate ion in the system. Then Ti(OH) 4 The precipitate is dispersed in 0.5mol / HCl solution, in which the HCl and Ti must be ensured 4+ The molar ratio is between 3:1, set the temperature at 60°C, reflux peptization for 20min, the obtained precipitate is centrifuged...

Embodiment 3

[0030] Embodiment 3: a kind of preparation method of composite titanium dioxide, described method realizes by following scheme:

[0031] (1) Preparation of rutile titanium dioxide

[0032] Weigh 30g solid Ti(NO 3 ) 4 Dissolve in deionized water, prepare a solution with a mass concentration of 15%, and then add it to the three-necked bottle at one time; add 2mol / L ammonia solution dropwise to the three-necked bottle at room temperature, and keep stirring to adjust to an appropriate pH of At 8 o'clock, stop adding ammonia solution dropwise, and generate fresh Ti(OH) at this moment 4 White precipitate, after the reaction is complete, the resulting precipitate is centrifuged and washed with water until there is no nitrate ion in the system. Then Ti(OH) 4 The precipitate is dispersed in 0.5mol / HCl solution, in which the HCl and Ti must be ensured 4+ The molar ratio is between 3.5:1, set the temperature at 70°C, reflux and peptize for 10min, the obtained precipitate is centrifu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com