Preparation method of cobalt manganese spinel microspheres

A technology of cobalt-manganese spinel and spinel, which is applied in chemical instruments and methods, cobalt compounds, and hydrocarbon production from carbon oxides, etc., can solve problems such as affecting catalytic efficiency, limiting contact area, and high conversion reaction, and achieve environmental protection Friendly, lower reaction temperature, high selectivity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] (1) Measure 2.63g of manganese chloride and 0.35g of cobalt chloride and dissolve them in deionized water, measure 3.5g of ammonium bicarbonate as a pH adjuster, mix and stir the two for 10 minutes, and carry out water at 120°C. Heat pretreatment. After the reaction product is naturally cooled, it is centrifugally filtered, and the obtained precipitate is washed with deionized water and ethanol in turn, and then dried to obtain cobalt carbonate and manganese carbonate precursors;

[0025] (2) Calcining the precursor in a muffle furnace for 5 hours at a temperature of 500°C to obtain cobalt manganate spinel microspheres;

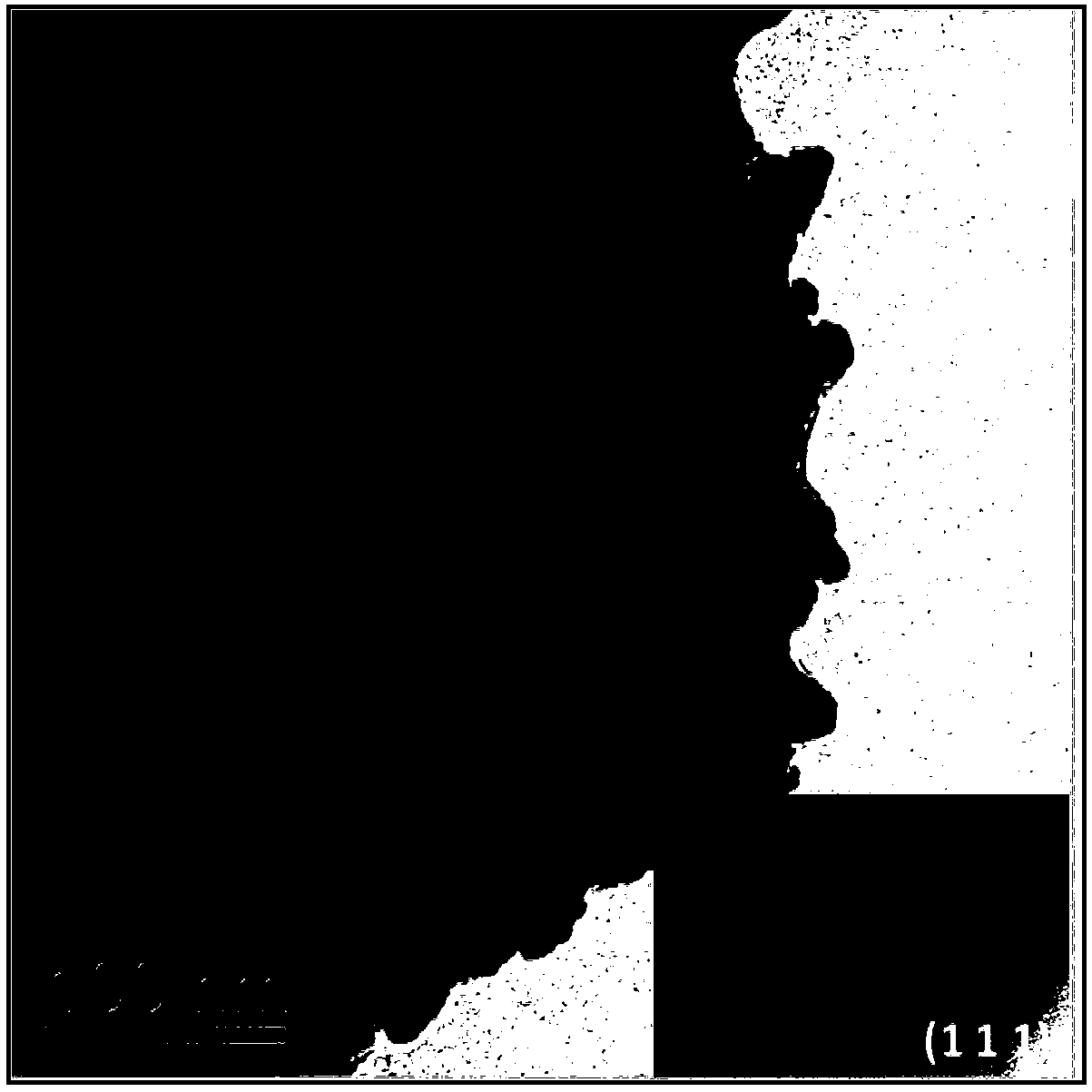

[0026] figure 1 It is the scanning electron microscope spectrum of the cobalt-manganese spinel microsphere synthesized in embodiment 1. The shape is spherical, figure 2 It is a TEM image. By calculating the d value of about 0.45nm, the crystal phase index represented by this particle corresponds to the XRD pattern, and the crystal plane is (1 11). ...

Embodiment 2

[0028] (1) Measure 1.75g of manganese chloride and 1.4g of cobalt chloride and dissolve them in deionized water, measure 3.5g of ammonium bicarbonate as a pH regulator, mix and stir the two for 20 minutes, and carry out water at 100°C. Heat pretreatment. After the reaction product is naturally cooled, it is centrifugally filtered, and the resulting precipitate is washed with deionized water and ethanol successively, and then dried to obtain cobalt carbonate and manganese carbonate precursors;

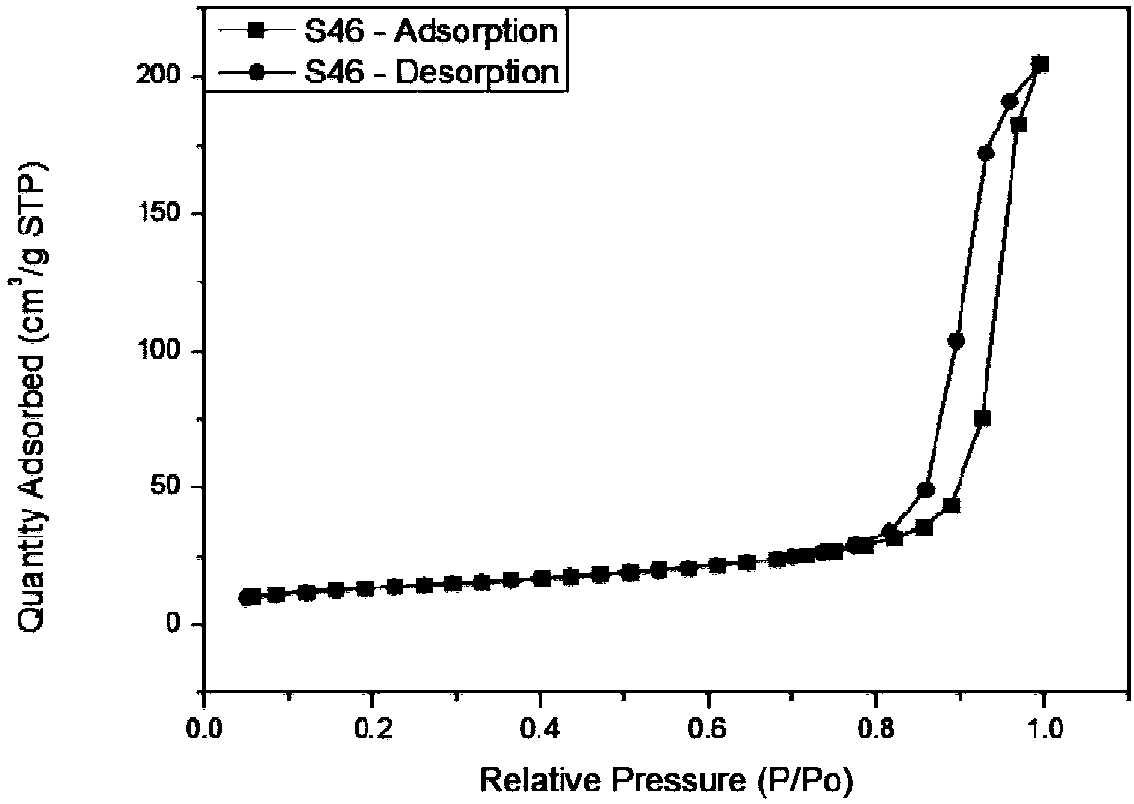

[0029] (2) Calcining the precursor in a muffle furnace for 3 hours at a temperature of 600°C to obtain cobalt manganate spinel microspheres; image 3 It is the nitrogen adsorption-desorption curve of the cobalt-manganese spinel microsphere synthesized in embodiment 2, and the specific surface area of sample S46 (m (cobalt): m (manganese)=4:6) is 48.17m 2 / g.

Embodiment 3

[0031] (1) Measure 0.29g of manganese chloride and 3.16g of cobalt chloride and dissolve them in deionized water, measure 3.5g of ammonium bicarbonate as a pH adjuster, mix and stir the two for 30 minutes, and carry out water at 150°C. Heat pretreatment. After the reaction product is naturally cooled, it is centrifugally filtered, and the obtained precipitate is washed with deionized water and ethanol in turn, and then dried to obtain cobalt carbonate and manganese carbonate precursors;

[0032] (2) Calcining the precursor in a muffle furnace for 0.5h at a temperature of 700°C to obtain cobalt manganate spinel microspheres; Figure 4 XRD pattern of the prepared manganese-cobalt spinel microspheres. Obvious diffraction peaks appeared at 18.20°, 29.35°, 31.25°, 36.36°, 38.87°, 44.78°, 59.01°, 60.67° and 65.18°, and the largest diffraction peak appeared at 36.36°. It can be attributed to the tetragonal crystal structure of Co3O4 (JCPDS file no.180408T), corresponding to (111), ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com