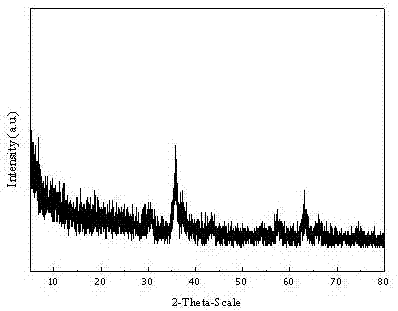

Composite ferroferric oxide and manganese dioxide Fenton catalyst and preparation method thereof

A technology of ferric tetroxide and manganese dioxide, applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problem of easy formation of soft agglomerates and even hard agglomerates It can solve the problems of bulk, difficult dispersion, poor dispersibility, etc., to achieve excellent recycling performance, enhance dispersion performance, and inhibit agglomeration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

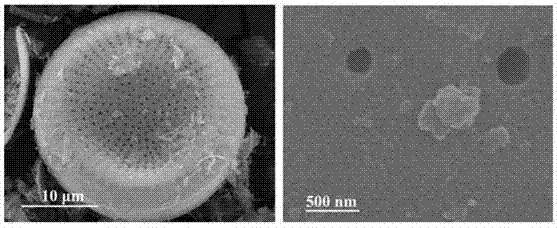

Embodiment 1

[0033] Weigh 10 g of natural diatomaceous earth and completely disperse it in 0.60 L of triethylene glycol under vigorous stirring to form a uniform suspension. Weighing 20.00 g of iron acetylacetonate was added to the above suspension, and kept stirring until it was completely dissolved to obtain a primary suspension. The above-mentioned primary suspension was heated to 250° C. at a heating rate of 3° C. / min under the protection of nitrogen, and kept for 30 minutes. After the reaction was over, it was naturally cooled to room temperature. The reacted suspension was separated from solid to liquid, and the obtained solid product was washed with water for 3 times. Add the washed solid product and 18.2 g of potassium permanganate into 0.50 L of water under stirring, and keep stirring for 10 min to obtain a secondary suspension. The secondary suspension was transferred into an autoclave, and the temperature was raised to 150° C. for 6 hours. After the reaction is finished, cool...

Embodiment 2

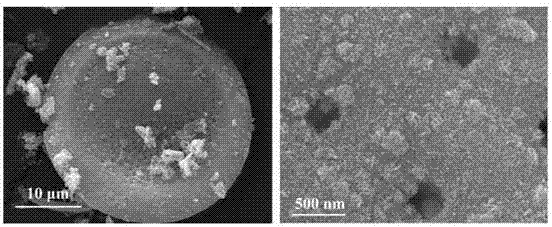

[0035] Weigh 10 g of natural diatomaceous earth, and completely disperse it in 0.80 L of octadecene under vigorous stirring to form a uniform suspension. 14.00 g of iron acetylacetonate was weighed and added to the above suspension, and stirred continuously until it was completely dissolved to obtain a primary suspension. The primary suspension was heated to 270° C. at a heating rate of 4° C. / min under the protection of argon, and kept for 40 minutes. After the reaction was over, it was naturally cooled to room temperature. The reacted suspension was separated from solid to liquid, and the obtained solid product was washed with water for 3 times. Add the washed solid product and 22 g of potassium permanganate into 0.60 L of water under stirring, and keep stirring for 10 min to obtain a secondary suspension. The secondary suspension was transferred into an autoclave, and the temperature was raised to 120° C. for 8 hours. After the reaction is finished, cool naturally to room...

Embodiment 3

[0037] Weigh 10 g of natural diatomaceous earth and completely disperse it in 1 L of glycerin under vigorous stirring to form a uniform suspension. Weighing 21.00 g of iron acetylacetonate was added to the above suspension, and kept stirring until it was completely dissolved to obtain a primary suspension. The primary suspension was heated to 265° C. at a heating rate of 5° C. / min under the protection of argon, and kept for 35 minutes. After the reaction was over, it was naturally cooled to room temperature. The reacted suspension was separated from solid to liquid, and the obtained solid product was washed with water for 3 times. Add the washed solid product and 28 g of potassium permanganate into 0.5 L of water under stirring, and keep stirring for 10 min to obtain a secondary suspension. The secondary suspension was transferred into an autoclave, and the temperature was raised to 160° C. for 6 hours. After the reaction is finished, cool naturally to room temperature, sep...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com