Collophanite direct-reverse flotation collecting agent and preparation method and application thereof

A technology of positive and negative flotation and collophosite, which is applied in flotation, solid separation, etc., can solve the problems of increased production cost of phosphate concentrate and complex soil-embedded relationship, etc., and achieves high comprehensive efficiency of ore dressing, simple preparation process, and easy The effect of the operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

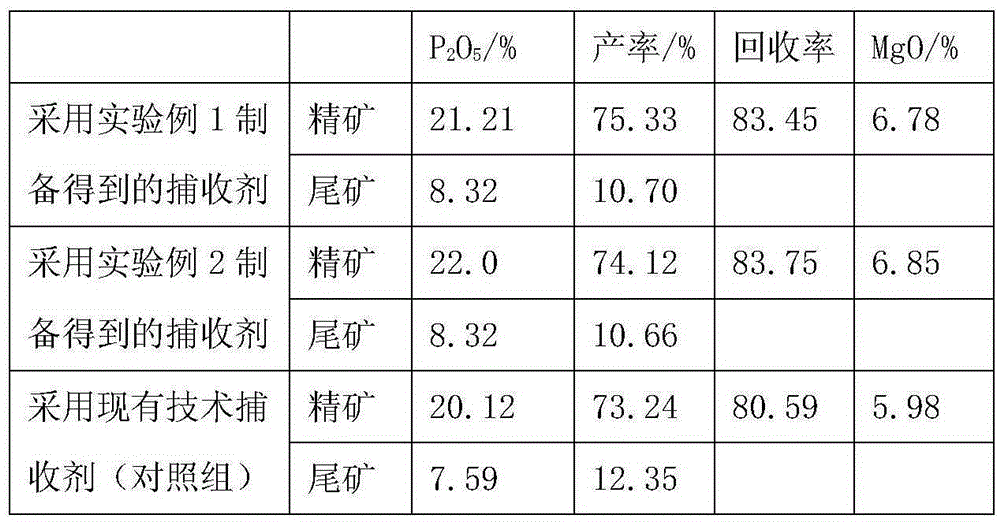

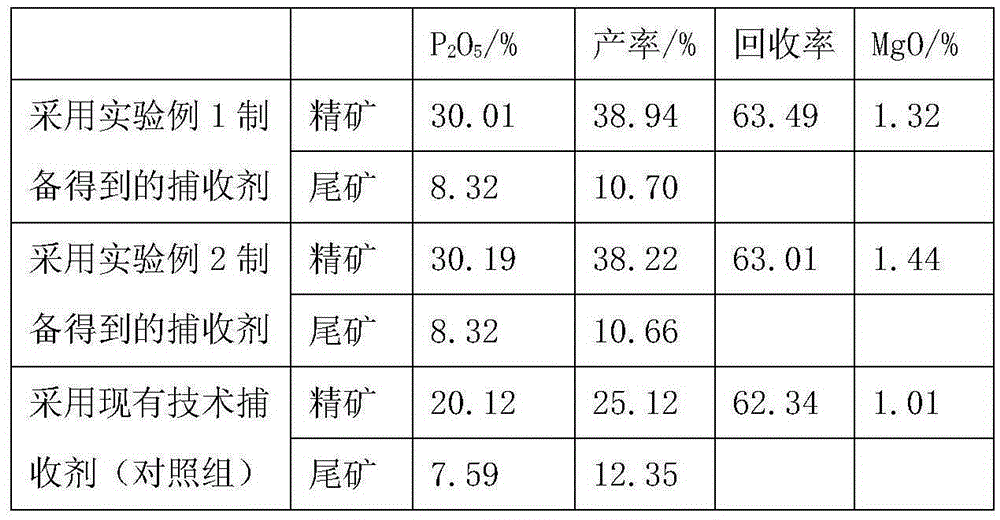

Examples

Embodiment 1

[0023] A collophanite forward and reverse flotation collector is prepared by the following method:

[0024] (1) Preparation of adsorbent: Weigh 500g of collephosite tailings in a 2L beaker, add excess dilute hydrochloric acid (the concentration of dilute hydrochloric acid is 17% to 19%) to react for 25 minutes, filter, wash the solid with water three times, and dry Standby; take 60g of the dried solid and put it in a mortar, add 30g of aluminum hydroxide and grind it evenly, transfer it to a crucible and calcine at 800°C for 3 hours to cool, and grind to obtain an adsorbent for use;

[0025] (2) Take 80g of vegetable oil residue in a 1L beaker, add 4g of hydrogen peroxide, stir and heat up at 80°C for 50 minutes, then add 8g of the adsorbent obtained in step (1), add 300ml of distilled water after continuing to stir for 30 minutes, stand still and cool to take the upper milk The turbid liquid was placed in a beaker; then the temperature was raised to 90°C, 32g of stearic acid ...

Embodiment 2

[0027] A collophanite forward and reverse flotation collector is prepared by the following method:

[0028] (1) Preparation of adsorbent: Weigh 500g of collephosite tailings in a 2L beaker, add excess dilute hydrochloric acid (the concentration of dilute hydrochloric acid is 17% to 19%) to react for 30 minutes, filter, wash the solid with water three times, and dry Standby; take 70g of the dried solid and put it in a mortar, add 30g of aluminum hydroxide and grind it evenly, transfer it to a crucible and calcine at 850°C for 4 hours to cool, and grind to obtain an adsorbent for use;

[0029] (2) Take 100g of vegetable oil residue in a 1L beaker, add 8g of hydrogen peroxide, stir and heat up at 90°C for 40 minutes, then add 10g of the adsorbent obtained in step (1), continue stirring for 40 minutes, then add 400ml of distilled water, cool still and take the upper milk Put the turbid liquid in a beaker, heat up to 100°C, add 40g of stearic acid, stir for 3 hours, and put the bla...

Embodiment 3

[0031] A collophanite forward and reverse flotation collector is prepared by the following method:

[0032] (1) Preparation of adsorbent: Weigh 500g of collophosite tailings in a 2L beaker, add excess dilute hydrochloric acid (the concentration of dilute hydrochloric acid is 17% to 19%) to react for 40 minutes, filter, wash the solid with water three times, and dry Standby; take 80g of the dried solid and put it in a mortar, add 40g of aluminum hydroxide and grind it evenly, transfer it to a crucible and calcine at 900°C for 5 hours to cool, and grind it to obtain an adsorbent for use;

[0033] (2) Take 150g of vegetable oil residue in a 1L beaker, add 16g of hydrogen peroxide, stir and heat up at 100°C for 50 minutes, then add 15g of the adsorbent obtained in step (1), add 500ml of distilled water after continuing to stir for 50 minutes, stand still and cool to take the upper milk Put the turbid liquid in a beaker, raise the temperature to 110°C, add 48g of stearic acid, stir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com