Method for preparing high-entropy alloy/diamond composite film or coating by fixed-point energy input and rapid cooling

A composite material film and high-entropy alloy technology, which is applied in the field of preparation of special composite materials, can solve the problems of diamond, high-entropy alloy carcass and substrate can not be effectively combined, binder powder melting is insufficient, energy density is not suitable, etc. , achieve the effect of shortening the contact time, controllable alloy composition and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

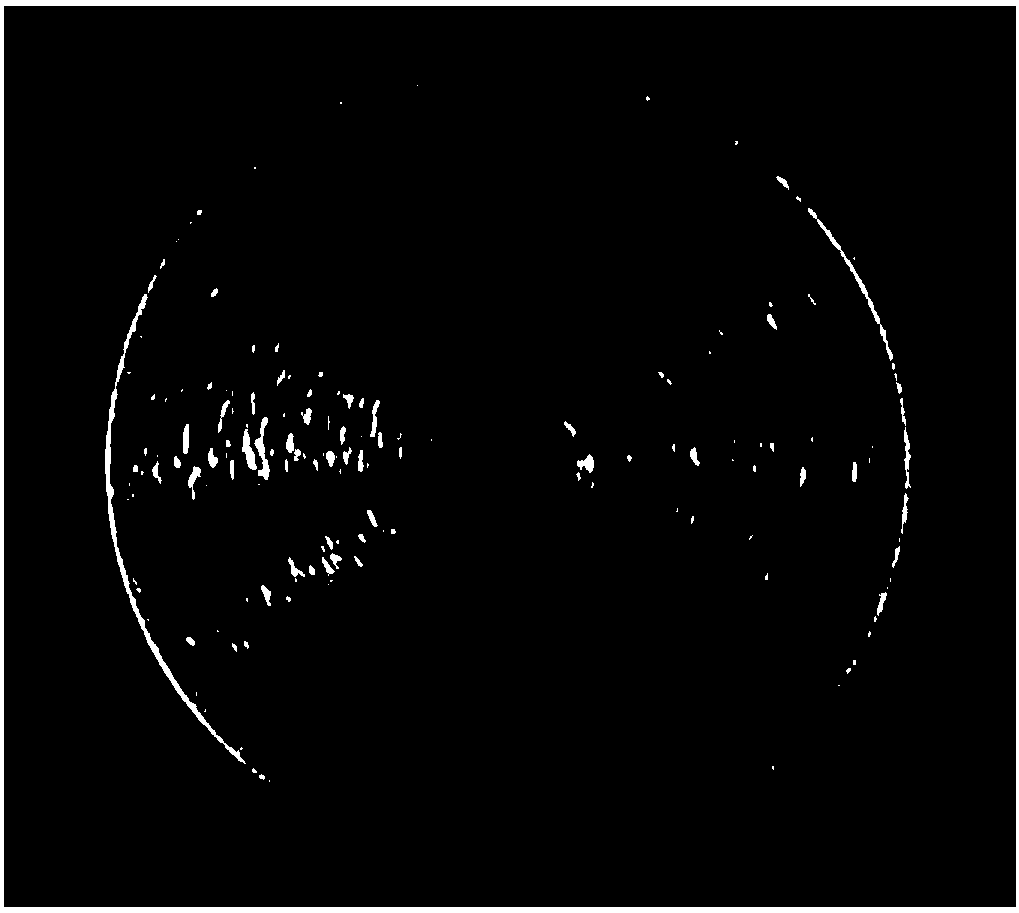

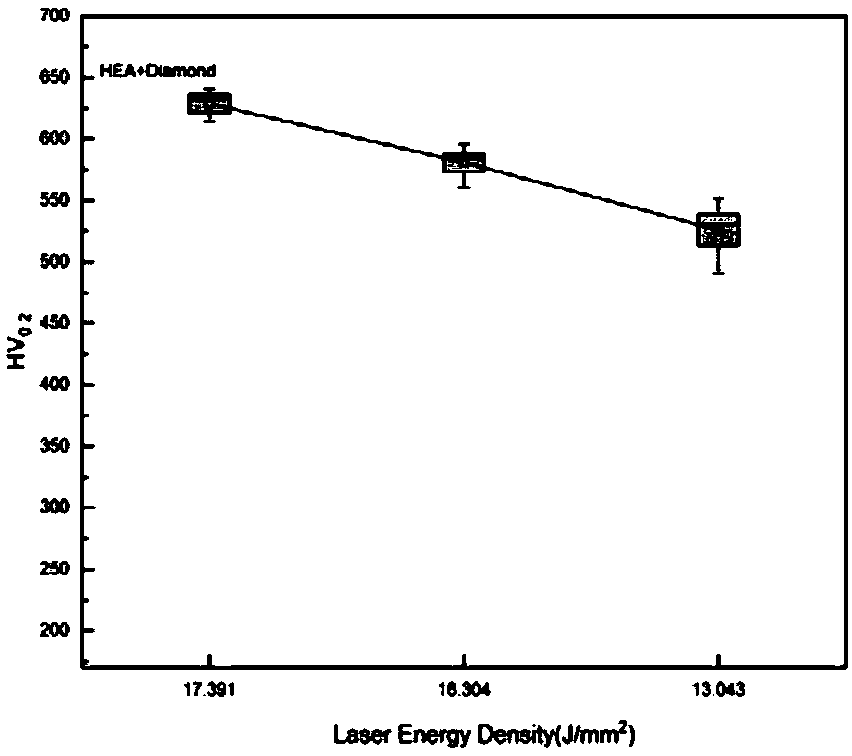

[0051] A method for rapidly preparing high-entropy alloy / diamond circular saw blades by high-speed laser cladding, using FeCoCrNiMo alloy as the matrix material to prepare high-entropy alloy / diamond composite saw blades by high-speed laser cladding, and the diamond particles The mass ratio fraction is 5%.

[0052] The method for rapidly preparing a high-entropy alloy / diamond circular saw blade by high-speed laser cladding in this embodiment includes the following steps:

[0053] (1) Select atomized FeCoCrNiMo high-entropy alloy powder with a particle size of 45-90 μm and an oxygen content of 215ppm, select 140 / 170 mesh broken diamond particles for mixing, and the mass percentage of diamond particles is 5%;

[0054] (2) Preheat the high-entropy alloy powder / diamond mixture below 70°C for 30 minutes, put it into the silo, and adopt a high-speed laser cladding process (placed vertically, the laser spot with a diameter of 4.5mm, 40mm / s cladding rate, 2000w laser power, 1L / min pr...

Embodiment 2

[0058] A method for rapidly preparing high-entropy alloy / diamond circular saw blades by high-speed laser cladding, using FeCoCrNiMo alloy as the matrix material to prepare high-entropy alloy / diamond composite saw blades by high-speed laser cladding, and the diamond particles The mass ratio fraction is 2%.

[0059] The method for rapidly preparing a high-entropy alloy / diamond circular saw blade by high-speed laser cladding in this embodiment includes the following steps:

[0060] (1) Select atomized FeCoCrNiMo high-entropy alloy powder with a particle size of 45-90 μm and an oxygen content of 375 ppm, and select B-grade diamond particles of 140 / 170 mesh for uniform mixing;

[0061] (2) Preheat the high-entropy alloy powder / diamond mixture below 70°C for 60 minutes, put it into the silo, and adopt a high-speed laser cladding process (placed vertically, the laser spot with a diameter of 6.3mm, 50mm / s cladding rate, 5500w laser power, 15L / min shielding gas flow) cladding on both...

Embodiment 3

[0065] A method for rapidly preparing high-entropy alloy / diamond circular saw blades by high-speed laser cladding, using FeCoCrNiMo alloy as the matrix material to prepare high-entropy alloy / diamond composite saw blades by high-speed laser cladding, and the diamond particles The mass ratio fraction is 20%.

[0066] The method for rapidly preparing a high-entropy alloy / diamond circular saw blade by high-speed laser cladding in this embodiment includes the following steps:

[0067] (1) Select atomized FeCoCrNiMo high-entropy alloy powder with a particle size of 45-90 μm and an oxygen content of 315 ppm, and select C-grade diamond particles of 50 / 60 mesh for uniform mixing;

[0068] (2) Preheat the high-entropy alloy powder / diamond mixture below 70°C for 60 minutes, put it into the silo, and adopt the high-speed laser cladding process (placed horizontally, the laser spot with a diameter of 4.5mm, 100mm / s The cladding rate, 5500w laser power, 30L / min protective gas flow rate, liq...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| fluidity | aaaaa | aaaaa |

| oxygen content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com