Induction heating cooker and cooking table using the same

A technology of induction heating and cooker, which is applied in the direction of induction heating, induction heating control, induction heating device, etc., and can solve the problems of increasing the heat release of the main body of the cooker and high output of the heating part, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

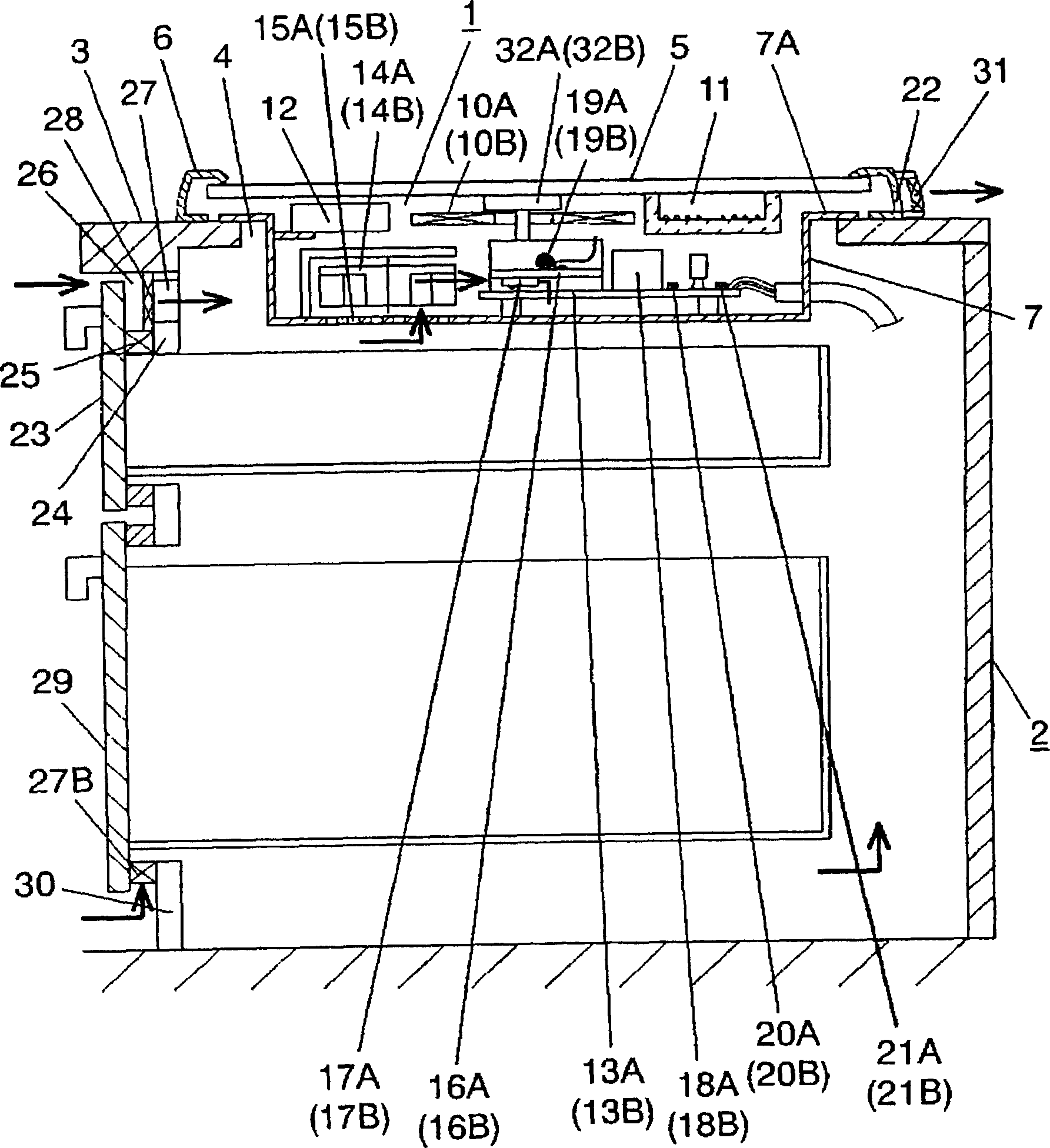

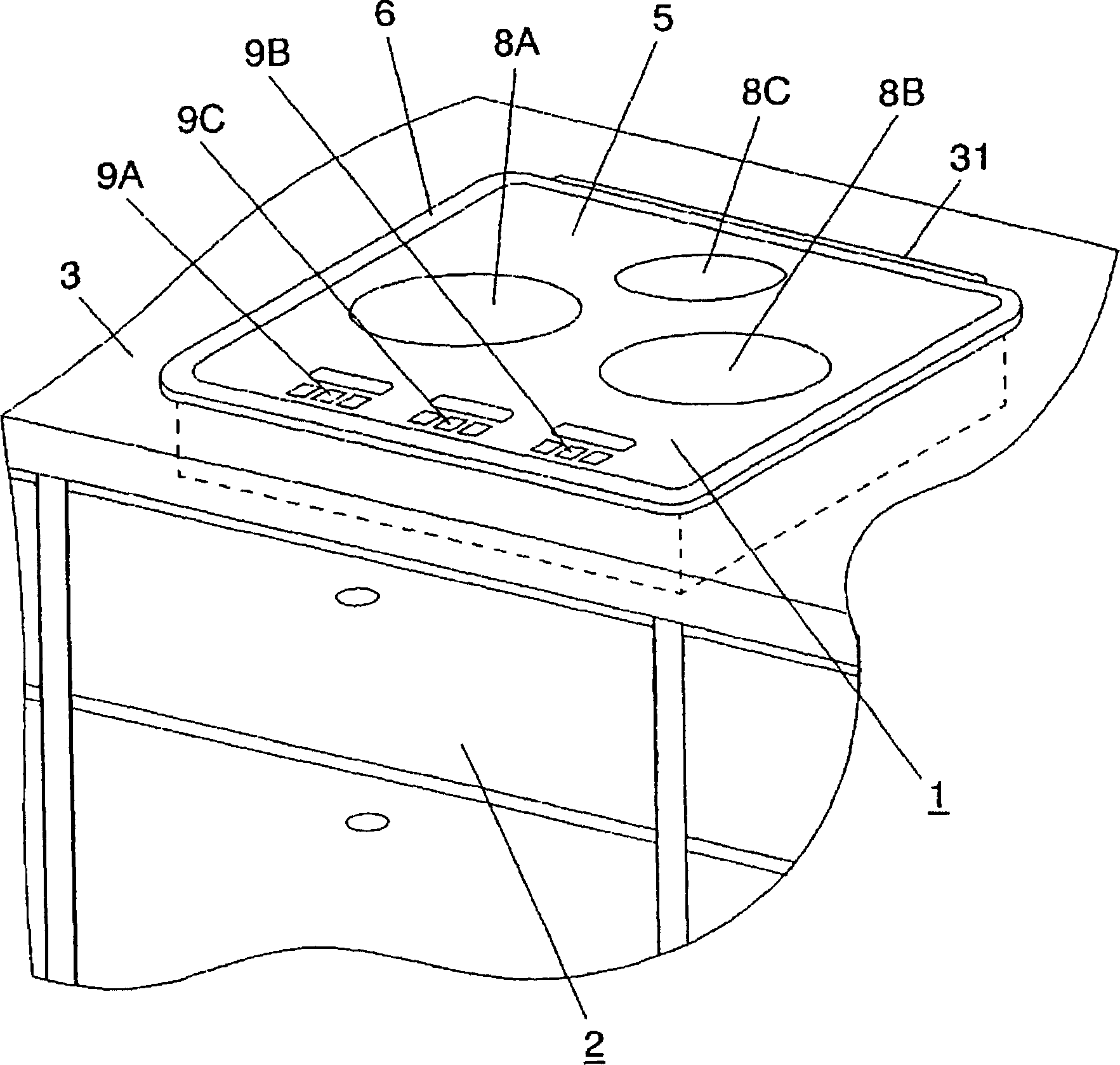

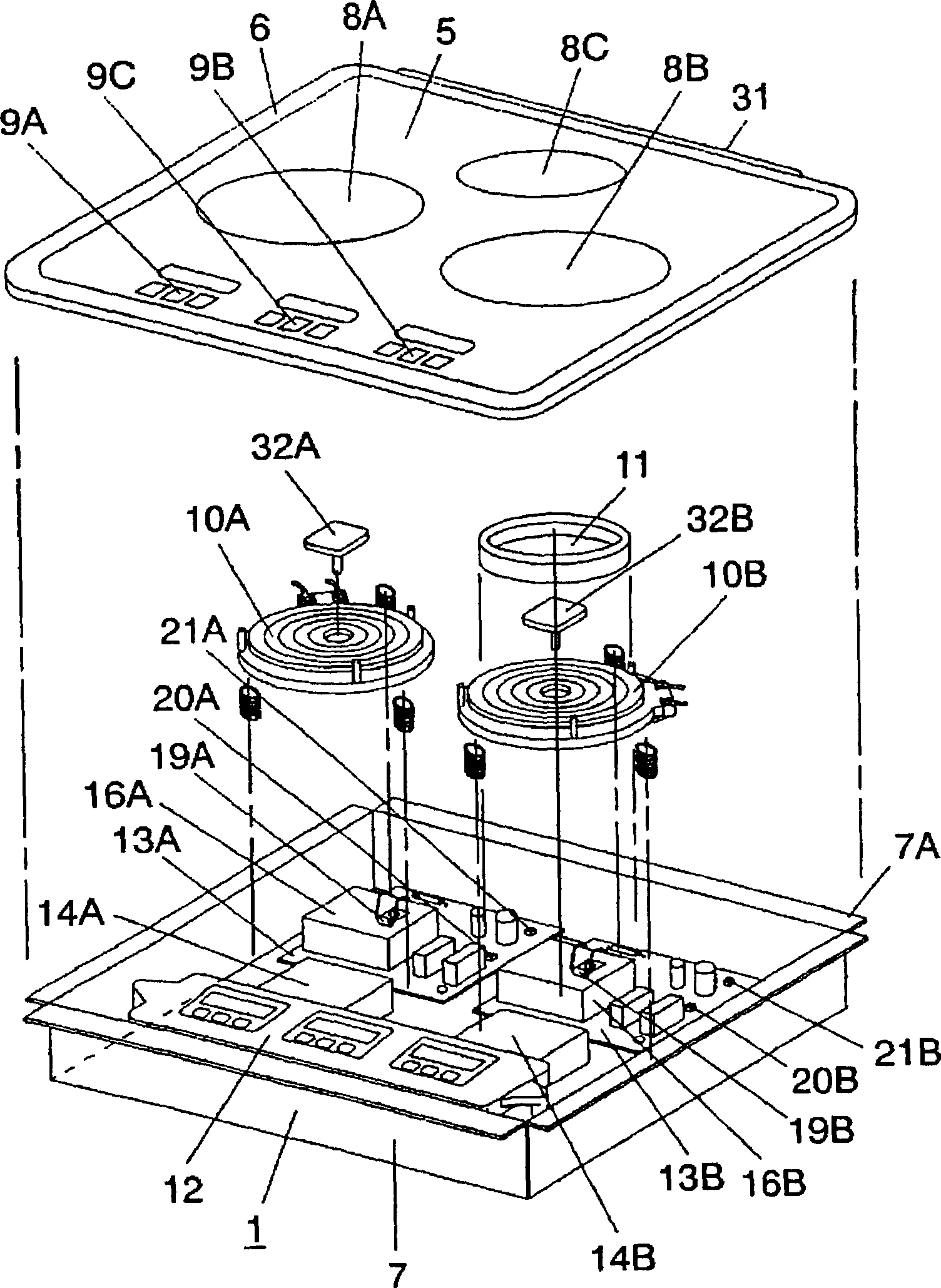

[0013] figure 1 , figure 2 A cross-sectional view and a perspective view of a cooking table including an induction heating cooker according to an embodiment of the present invention are respectively shown, image 3 An exploded perspective view showing the induction heating cooker.

[0014] The cooker 1 is fitted into the opening 4 of the counter top 3 provided on the upper surface of the kitchen cabinet 2 from above, and is installed. The cooker 1 has a top plate 5 and a plate frame (hereinafter referred to as a frame) 6 covering the periphery thereof on the upper surface. The top plate 5 is made of crystallized glass as a raw material. In the cooker 1 , the upper end of the outer profile 7 , which is a portion that enters the opening 4 , is engaged with the table top 3 bent into a flange shape. Top plate 5 , frame 6 , outer contour 7 form the housing of cooker 1 . Heating sections 8A, 8B, and 8C are printed on top plate 5 , and operating sections 9A, 9B, and 9C corresp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com