Gasification process for producing synthesis gas from garbage and biomass raw materials

A technology for synthesis gas and biomass, which is applied to the gasification of biomass and the field of garbage, can solve the problems that the heat energy recovery device cannot be installed in a strong radiation area, easily pollute the land and groundwater, and the impact of heat energy recovery, etc., and achieve environmental protection and ecological effects. The effect of highlighting, alleviating energy shortage and eliminating pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

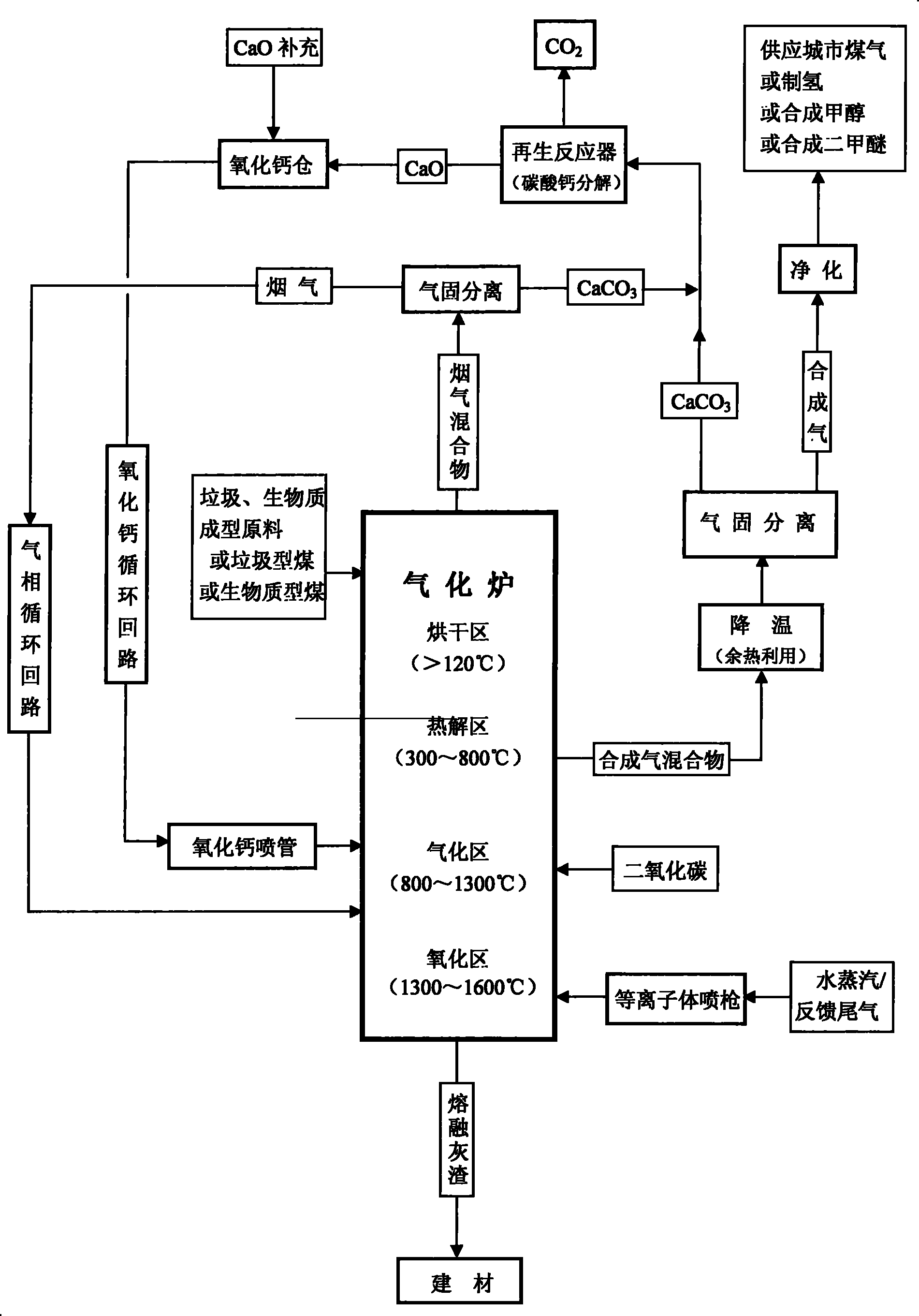

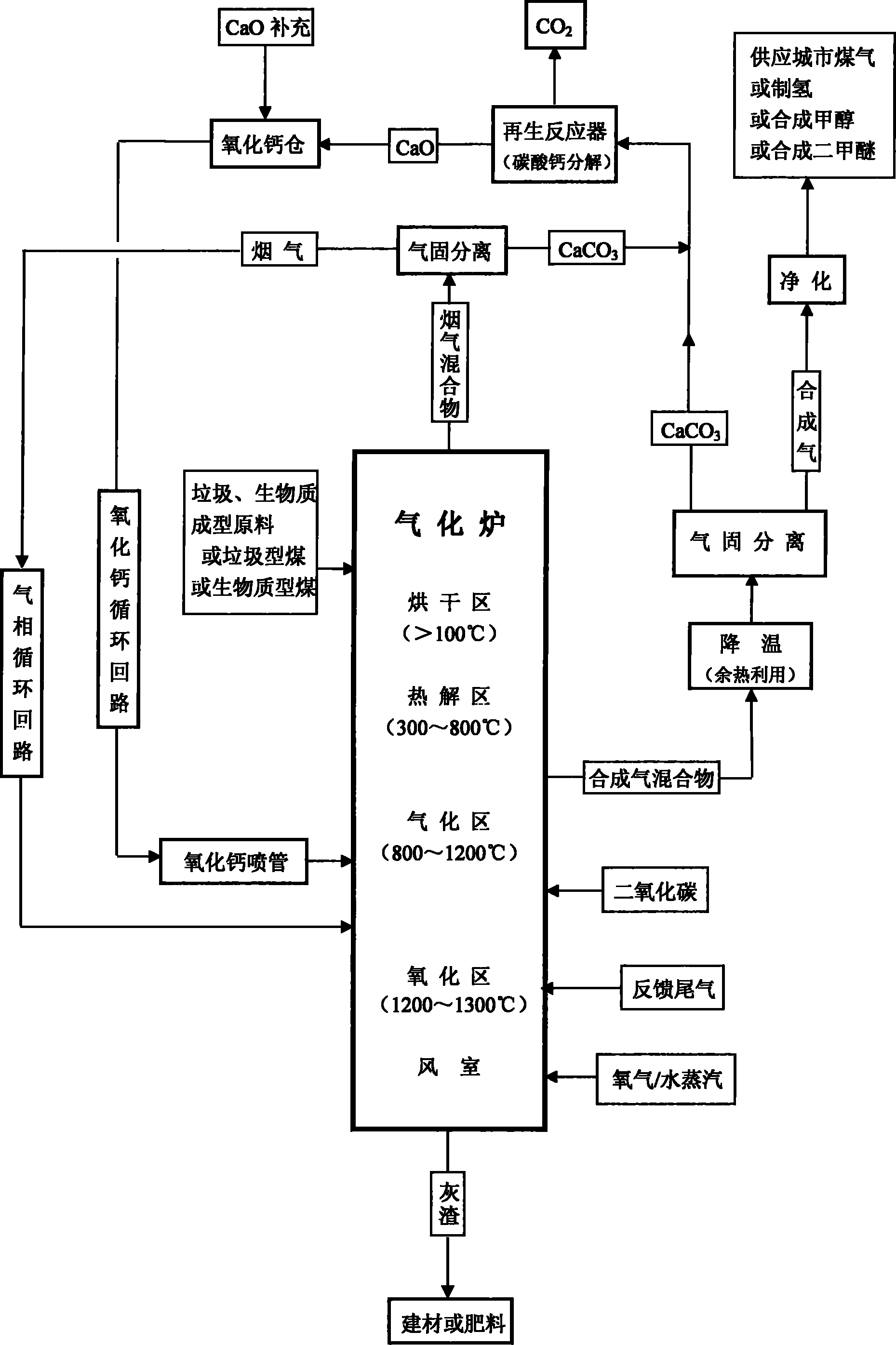

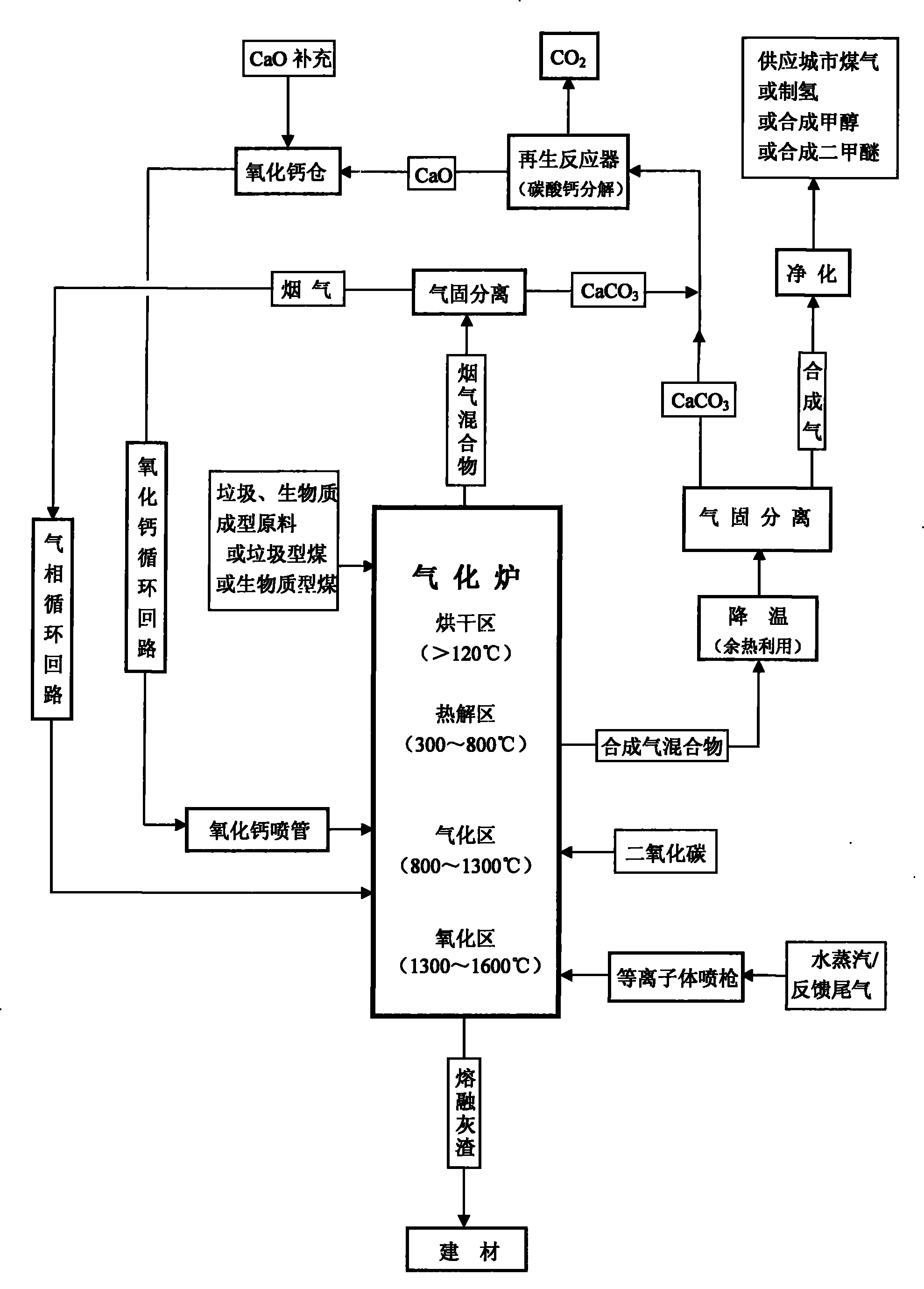

[0035] attached figure 1 In the shown scheme for producing synthesis gas from waste biomass raw materials, the process flow is mainly composed of raw material solid matter flow, gas phase circulation loop, calcium oxide circulation loop and synthesis gas extraction process, wherein the raw material solid matter flow is: the raw material is composed of The entrance enters the drying area, and then passes through the pyrolysis area, gasification area, and oxidation area in sequence, and the ash after oxidation and combustion is discharged out of the furnace through the water-sealed outlet;

[0036] The gas phase circulation loop is as follows: the gaseous matter goes from the oxidation zone to the gasification zone in the furnace, and then passes through the pyrolysis zone, the drying zone, the flue gas circulation outlet, the gas-solid separation device, and the gas phase circulation loop outside the furnace, and then enters the furnace through the gas phase circulation. The fu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com