Method for preparing calcium sulfate whiskers from bone gelatin wastewater

A technology of calcium sulfate whisker and bone gelatin is applied in the field of three-waste treatment of bone gelatin production workshop, which can solve the problems of products staying in the experimental verification stage, unable to realize industrial production, polluting the surrounding environment, etc., and achieves simple and controllable growth process conditions, The effect of improving the treatment level and reducing the discharge of three wastes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

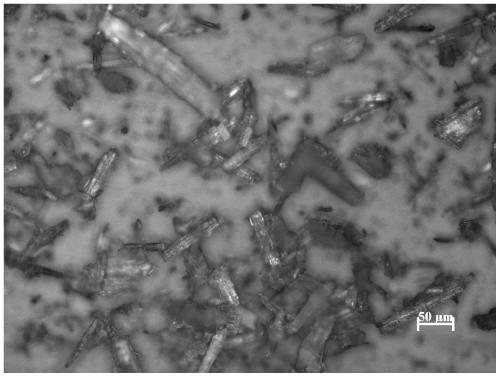

Image

Examples

Embodiment 1

[0040] A kind of method utilizing bone gelatin waste water to prepare calcium sulfate whisker, comprises the following steps:

[0041] 1) Take the wastewater from the bone gelatin pickling workshop, filter it with a 200-mesh PE filter cloth, and dilute the filtrate with water until the molar concentration of calcium ions is 0.25mol / L;

[0042] 2) Place the diluted filtrate on a magnetic heating furnace and heat it to 40° C. and keep it warm, and add ammonium chloride to the above filtrate while stirring until the concentration of ammonium chloride is 13%;

[0043] 3) Slowly add 40wt% sulfuric acid so that the molar ratio of calcium ions to sulfate ions is 1:2, heat to 95°C and keep warm for 18min;

[0044] 4) After cooling down to 80°C, heat-preserve and age for 2.5 hours, pour off the supernatant, separate out the solid matter, wash the solid matter with tap water for 2-3 times, and collect the washing liquid;

[0045] 5) The solid matter was centrifuged in a bag type centri...

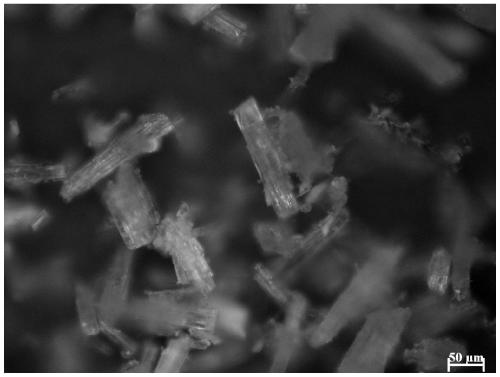

Embodiment 2

[0049] A kind of method utilizing bone gelatin waste water to prepare calcium sulfate whisker, comprises the following steps:

[0050] 1) Take the wastewater from the bone gelatin pickling workshop, filter it with a 200-mesh PPS filter cloth, and dilute the filtrate with water until the molar concentration of calcium ions is 0.2mol / L;

[0051] 2) Place the diluted filtrate on a magnetic heating furnace and heat it to 35° C. and keep it warm, and add ammonium chloride to the above filtrate while stirring until the concentration of ammonium chloride is 10%;

[0052] 3) Slowly add 40wt% sulfuric acid so that the molar ratio of calcium ions to sulfate ions is 2:5, heat to 90°C and keep warm for 15min;

[0053] 4) After cooling down to 75°C, heat preservation and aging for 2 hours, pour off the supernatant, separate the solid matter, wash the solid matter with tap water 2-3 times, and collect the washing liquid;

[0054] 5) The solid matter was centrifuged in a bag type centrifuge...

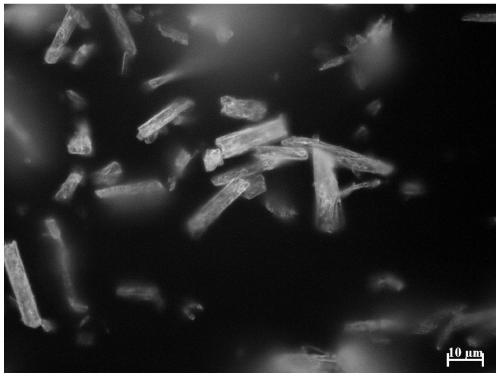

Embodiment 3

[0058] A kind of method utilizing bone gelatin waste water to prepare calcium sulfate whisker, comprises the following steps:

[0059] 1) Take the wastewater from the bone gelatin pickling workshop, filter it with a 200-mesh PPS filter cloth, and dilute the filtrate with water until the molar concentration of calcium ions is 0.3mol / L;

[0060] 2) Place the diluted filtrate on a magnetic heating furnace and heat it to 55°C and keep it warm, and add ammonium chloride to the above filtrate while stirring until the concentration of ammonium chloride is 15%;

[0061] 3) Slowly add 40wt% sulfuric acid so that the molar ratio of calcium ions to sulfate ions is 3:5, heat to 90°C and keep warm for 20min;

[0062] 4) After cooling down to 75°C, heat preservation and aging for 2 hours, pour off the supernatant, separate the solid matter, wash the solid matter with tap water 2-3 times, and collect the washing liquid;

[0063] 5) The solid matter is centrifuged in a bag type centrifuge, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| aspect ratio | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com