High-performance desulfurization and denitrification activated carbon and preparation method thereof

A desulfurization and denitrification, activated carbon technology, applied in the direction of separation methods, chemical instruments and methods, program control, etc., can solve the problems of poor treatment effect of desulfurization and denitrification activated carbon, polluting the environment, cumbersome preparation methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

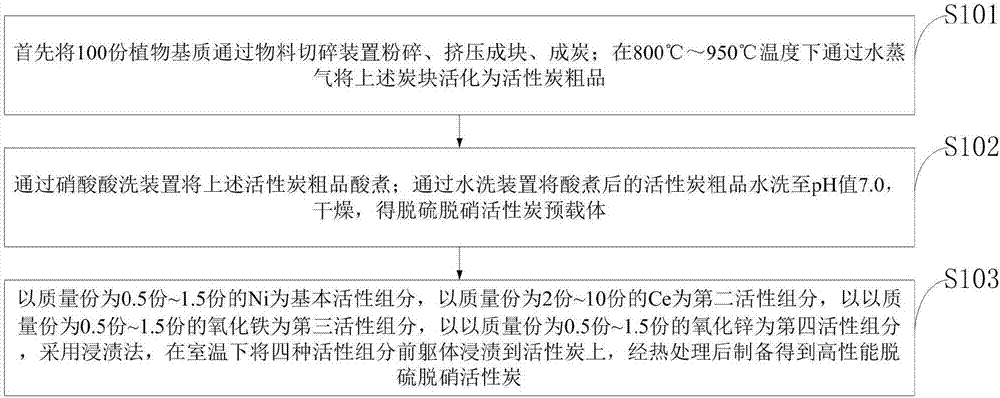

[0067] Such as figure 1 As shown, the preparation method of the high-performance desulfurization and denitrification activated carbon provided by the embodiment of the present invention comprises the following steps:

[0068] S101: First, crush 100 parts of the plant matrix through a material chopping device, extrude into blocks, and form charcoal; activate the above-mentioned charcoal blocks into crude activated carbon by steam at a temperature of 800° C. to 950° C.;

[0069] S102: Pickling the above-mentioned crude activated carbon with a nitric acid pickling device; washing the crude activated carbon after pickling with a water washing device to a pH value of 7.0, and drying to obtain a desulfurization and denitrification activated carbon pre-carrier;

[0070] S103: 0.5-1.5 parts by mass of Ni as the basic active component, 2-10 parts by mass of Ce as the second active component, and 0.5-1.5 parts by mass of iron oxide It is the third active component, with zinc oxide of 0...

Embodiment 1

[0118] The preparation method of the high-performance desulfurization and denitrification activated carbon provided by the embodiment of the present invention comprises the following steps:

[0119] First, 100 parts of plant substrates are pulverized by a material chopping device, extruded into blocks, and formed into charcoal; the above-mentioned carbon blocks are activated by water vapor at a temperature of 800 ° C into crude activated carbon;

[0120] The above crude activated carbon is acid-boiled by a nitric acid pickling device; the acid-boiled crude activated carbon is washed to a pH value of 7.0 by a water washing device, and dried to obtain a desulfurization and denitrification activated carbon pre-carrier;

[0121] 0.5 parts by mass of Ni is the basic active component, 2 parts by mass of Ce is the second active component, 0.5 parts by mass of iron oxide is the third active component, and Zinc oxide with a mass part of 0.5 parts is the fourth active component. The pre...

Embodiment 2

[0123] The preparation method of the high-performance desulfurization and denitrification activated carbon provided by the embodiment of the present invention comprises the following steps:

[0124] First, 100 parts of plant substrates are crushed by a material chopping device, extruded into blocks, and formed into charcoal; at a temperature of 950 ° C, the above-mentioned carbon blocks are activated by water vapor into crude activated carbon;

[0125] The above crude activated carbon is acid-boiled by a nitric acid pickling device; the acid-boiled crude activated carbon is washed to a pH value of 7.0 by a water washing device, and dried to obtain a desulfurization and denitrification activated carbon pre-carrier;

[0126]1.5 parts by mass of Ni is the basic active component, 10 parts by mass of Ce is the second active component, 1.5 parts by mass of iron oxide is the third active component, and 1.5 parts by mass of Ni is the third active component. 1.5 parts of zinc oxide is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com