Process, system and device for waste biomass multi-production processing

A biomass and polygeneration technology, applied in the catalytic treatment of combustible gas, waste fuel, petroleum industry, etc., can solve the problems of large emissions, low quality of target products, and large land occupation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

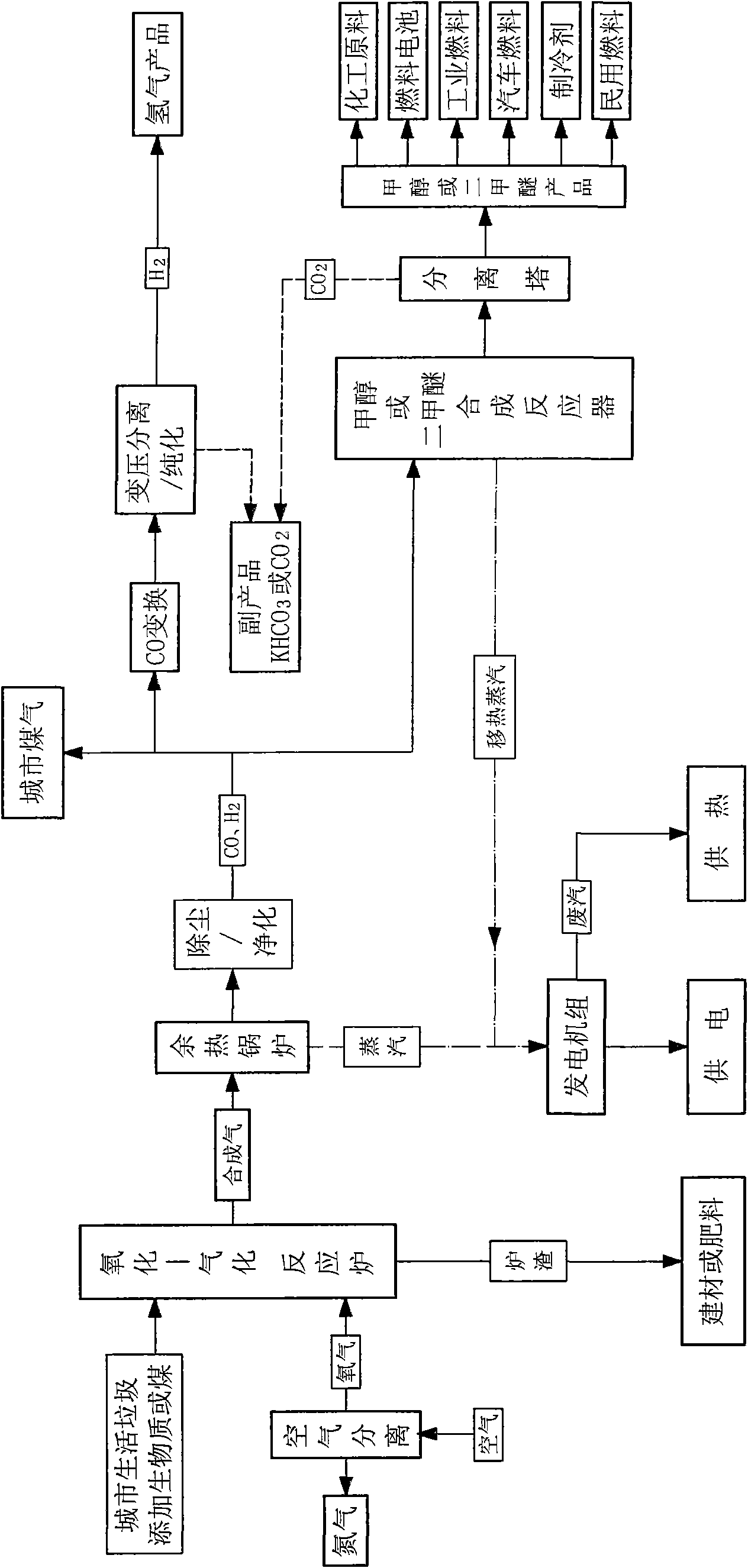

[0103] figure 1 In the scheme of waste biomass polygeneration treatment shown, the municipal solid waste is added with biomass or coal as raw material to be gasified through the oxidation-gasification reactor, and the syngas is used to produce city gas or hydrogen or methanol or carbon dioxide. Methyl ether products, slag are used to produce building materials or fertilizers, waste heat is used for power generation and heat supply, and the separated carbon dioxide is used as chemical raw materials to realize environmental protection and polygeneration treatment of clean energy, building materials, chemical raw materials, power generation and heat supply . In the plan, air separation equipment is used to separate air into oxygen and nitrogen. Oxygen is sent to the oxidation-gasification reactor as an oxidant or gasification agent, and nitrogen is directly evacuated or purified as a product.

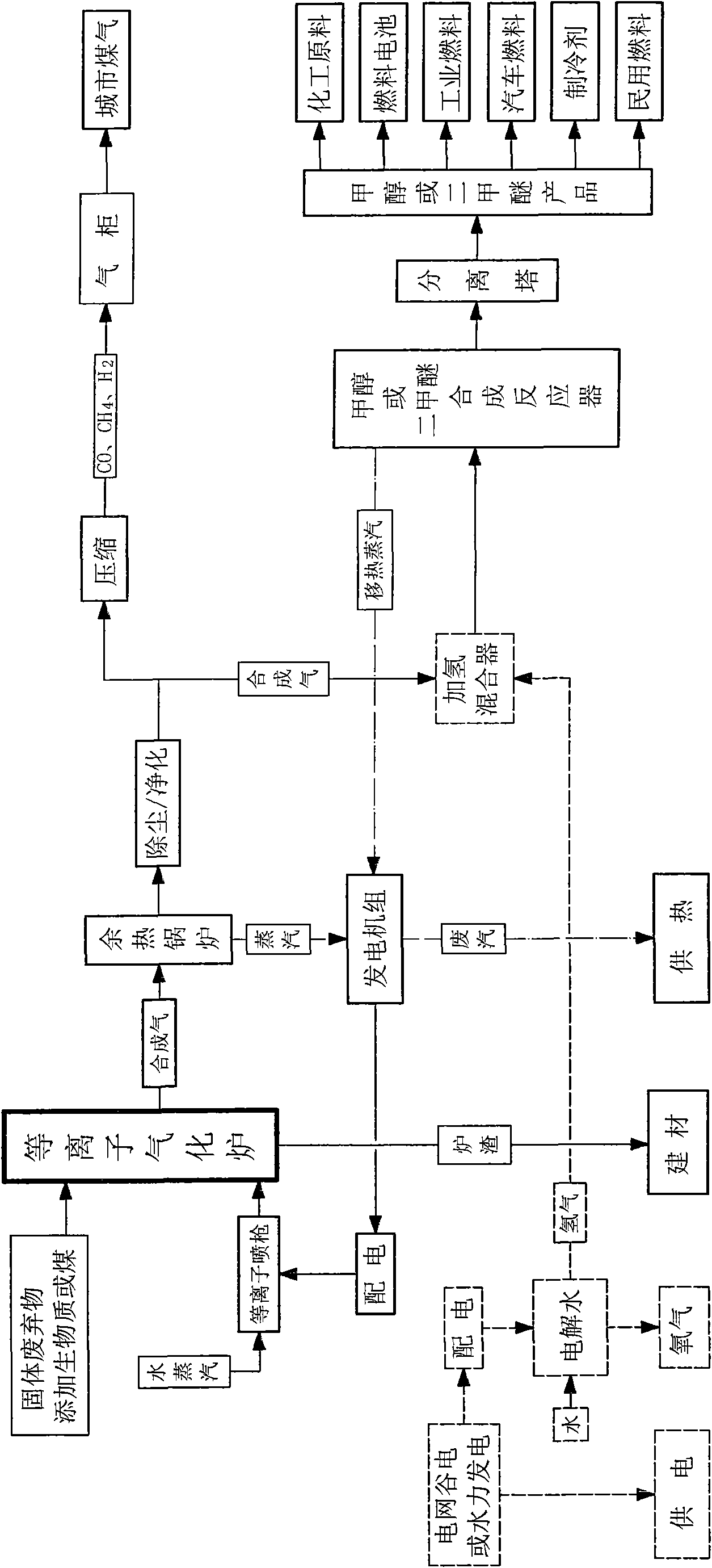

[0104] figure 2 In the scheme of waste biomass polygeneration treatment shown, soli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com