Oil sludge resource utilization system and technology

A technology for resource utilization and sludge, applied in the petroleum industry, chemical instruments and methods, water/sludge/sewage treatment, etc., can solve the problems of large equipment investment, secondary pollution, complex system, etc., and achieve complete extraction and avoid burning. , The effect of uniform and rapid heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

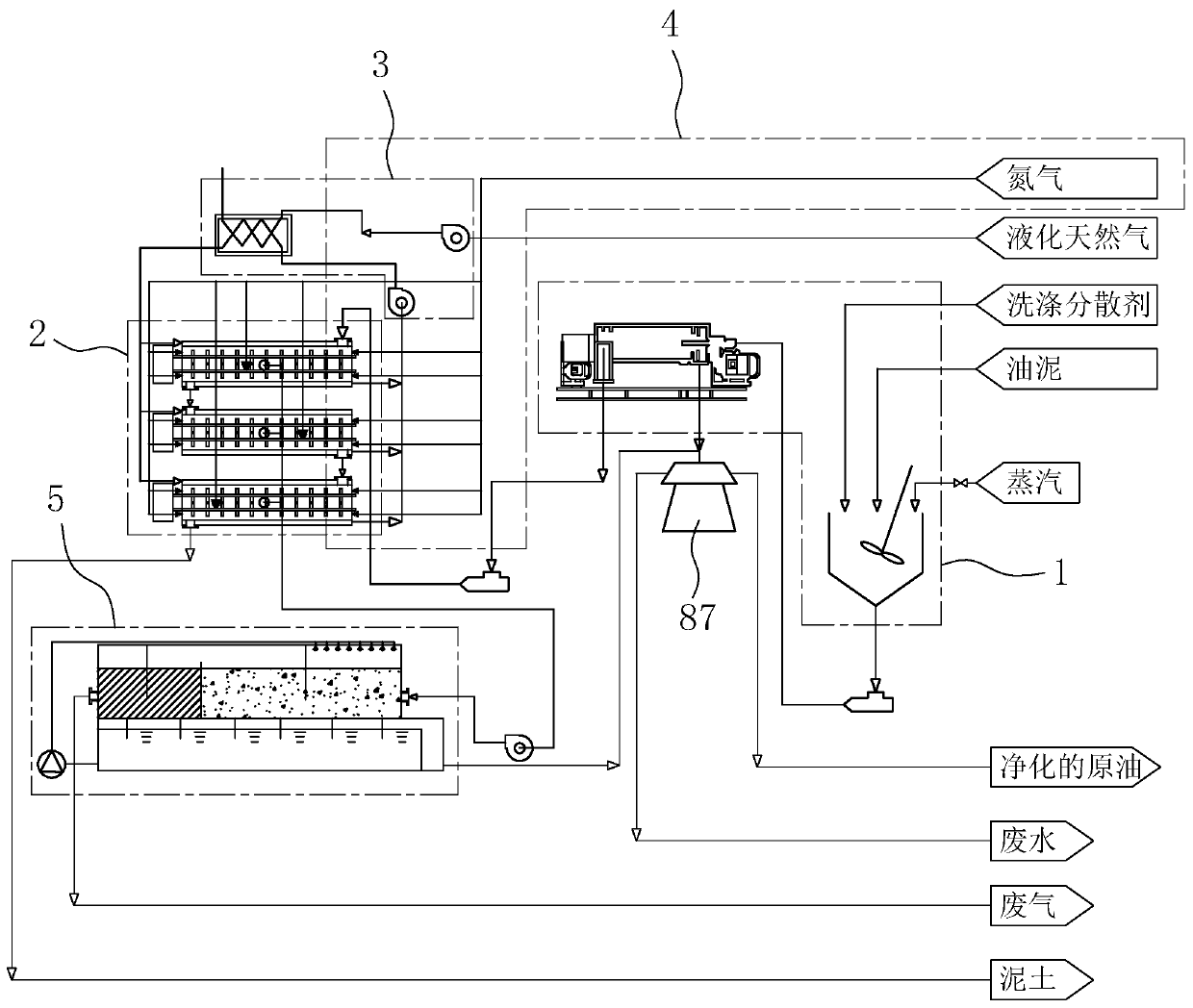

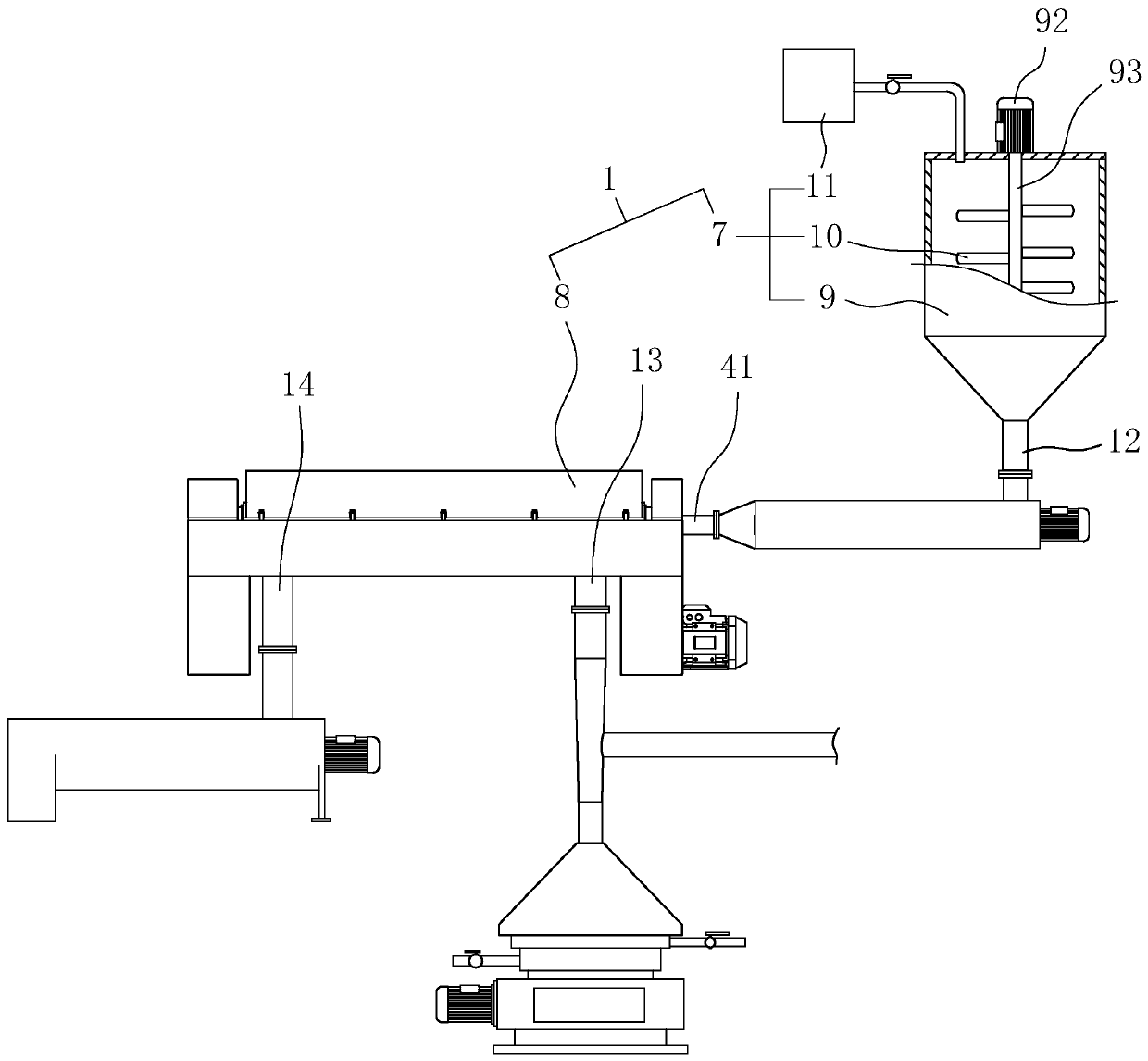

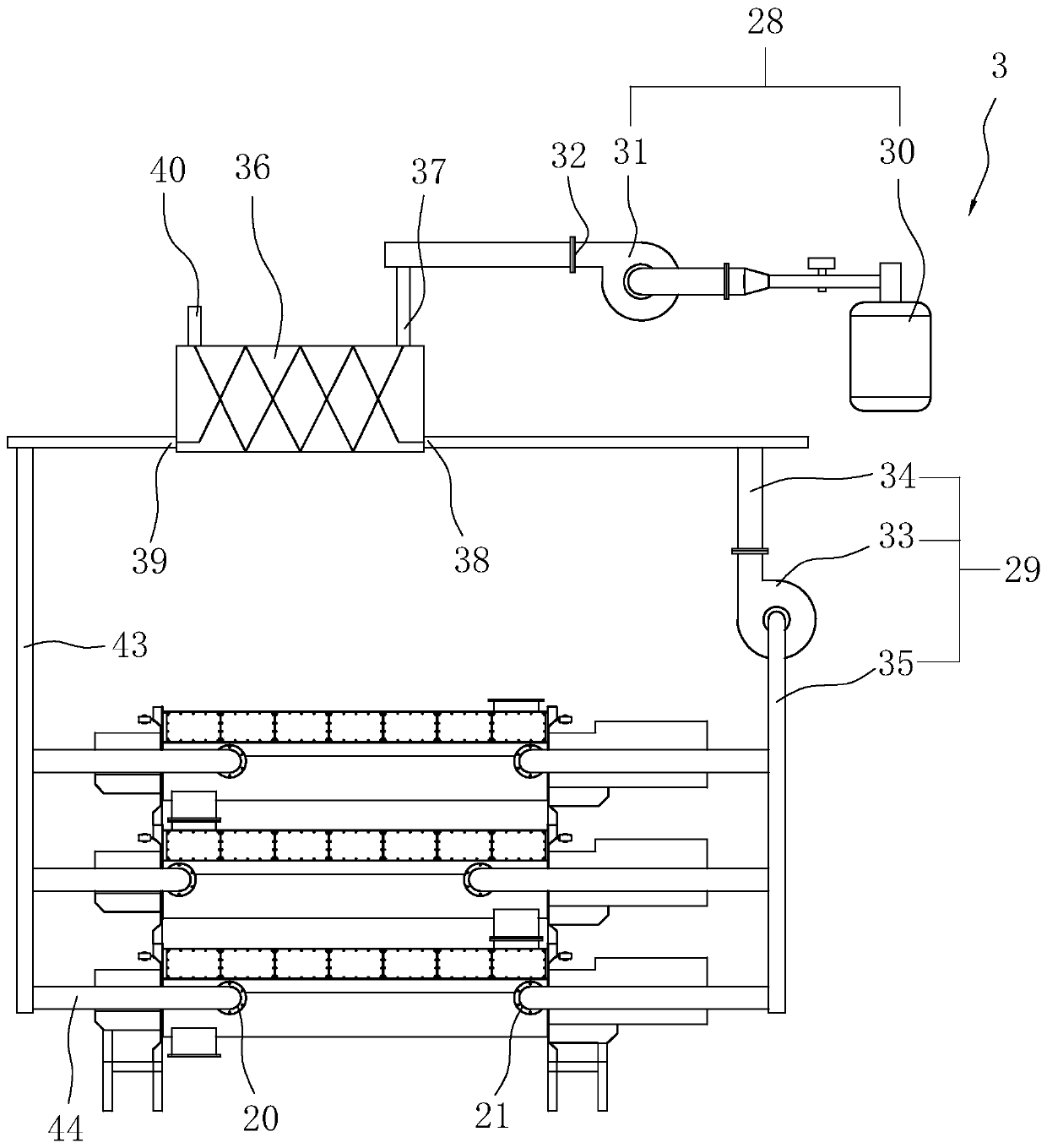

[0056] refer to figure 1 , an oil sludge resource utilization system, comprising an oil sludge preliminary separation system 1, a pyrolysis system 2, a heating system 3, an explosion-proof system 4, a condensation system 5, and an oil-water separation device 87; the oil sludge initial separation system 1 is used for the liquid-containing phase Preliminary treatment of more oil sludge to separate the liquid phase that is relatively easy to separate in the oil sludge; pyrolysis system 2 is used to fully pyrolyze the oil sludge, so as to separate the water, oil and solid phase in the oil sludge to achieve the purpose of fully pyrolyzing the oil sludge; the heat supply system 3 is used to supply heat to the pyrolysis system 2, so that the oil sludge in the pyrolysis system 2 can be kept at a temperature of about 500 ° C, so that the crude oil and water in the oil sludge It is decomposed in the form of gas phase; the explosion-proof system 4 is used to fill the pyrolysis system 2 w...

Embodiment 2

[0076] refer to Figure 12 , an oil sludge resource utilization process, comprising the following steps:

[0077] Step 1, pretreatment of oil sludge, first put the oil sludge into the oil sludge washing tank 9 in Example 1, and add washing and dispersing agent to the oil sludge, and pass high-temperature steam into the oil sludge, while using the oil sludge in Example 1 The stirring blade 10 stirs the sludge;

[0078] Step 2: Preliminary solid-liquid separation, adding the oil sludge obtained in step 1 to the decanter centrifuge 8 for solid-liquid separation to obtain solid phase oil sludge and liquid phase oil-water mixture; the decanter centrifuge 8 is preferably Shanghai Ruiwei The sludge wastewater treatment centrifuge produced by Electromechanical Equipment Co., Ltd. is LW420X1800Y. The decanter centrifuge 8 is provided with a first liquid phase outlet 13 and a first solid phase outlet 14, and the solid phase sludge is discharged from the first solid phase outlet 14. , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com