Micro negative pressure black liquor gasifier

A gasification furnace and micro-negative pressure technology, applied in the field of pulp and paper making, can solve the problems of increasing production cost, affecting production efficiency, air leakage and feeding, etc., and achieve the goals of increasing production rate, reducing equipment production cost, and avoiding air leakage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

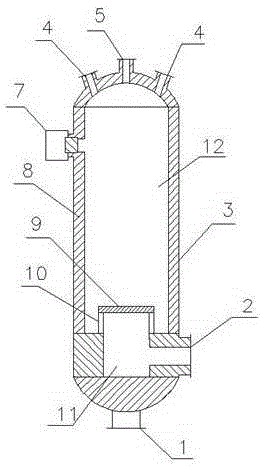

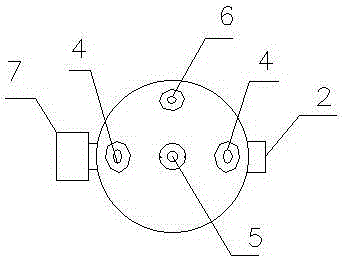

[0022] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0023] 1. Manufacture and installation of micro-negative pressure black liquor gasifier

[0024] 1. Component Manufacturing

[0025] According to the design size, metal components such as the crown, the cylinder, the support tube 1 and the steel shell 3 are manufactured through the processes of cutting, reinforcement and welding. The crown and the cylinder are respectively equipped with an inner lining heat insulation layer 8, and a carbon deposit floor 9 and a carbon deposit floor support 10 are installed in the cylinder, and the entire cylinder inner cavity is divided into a supplementary reaction chamber 11 and a gasification chamber 12. Form complete crown and cylinder assemblies.

[0026] 2. Assembly

[0027] Fix the supporting cylinder 1 on the horizontal base, connect and fix the lower crown above the supporting cylinder 1, then install the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com