A self-circulating plasma gasifier

A plasma and gasifier technology, which is applied in the gasification process, gasification device electrodes, and the manufacture of combustible gas, etc., can solve the problems of not meeting the application requirements of chemical raw materials, affecting the quality of synthesis gas, and consuming the heat of the gasifier. , to achieve complete gasification, improved efficiency, high decomposition rate and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

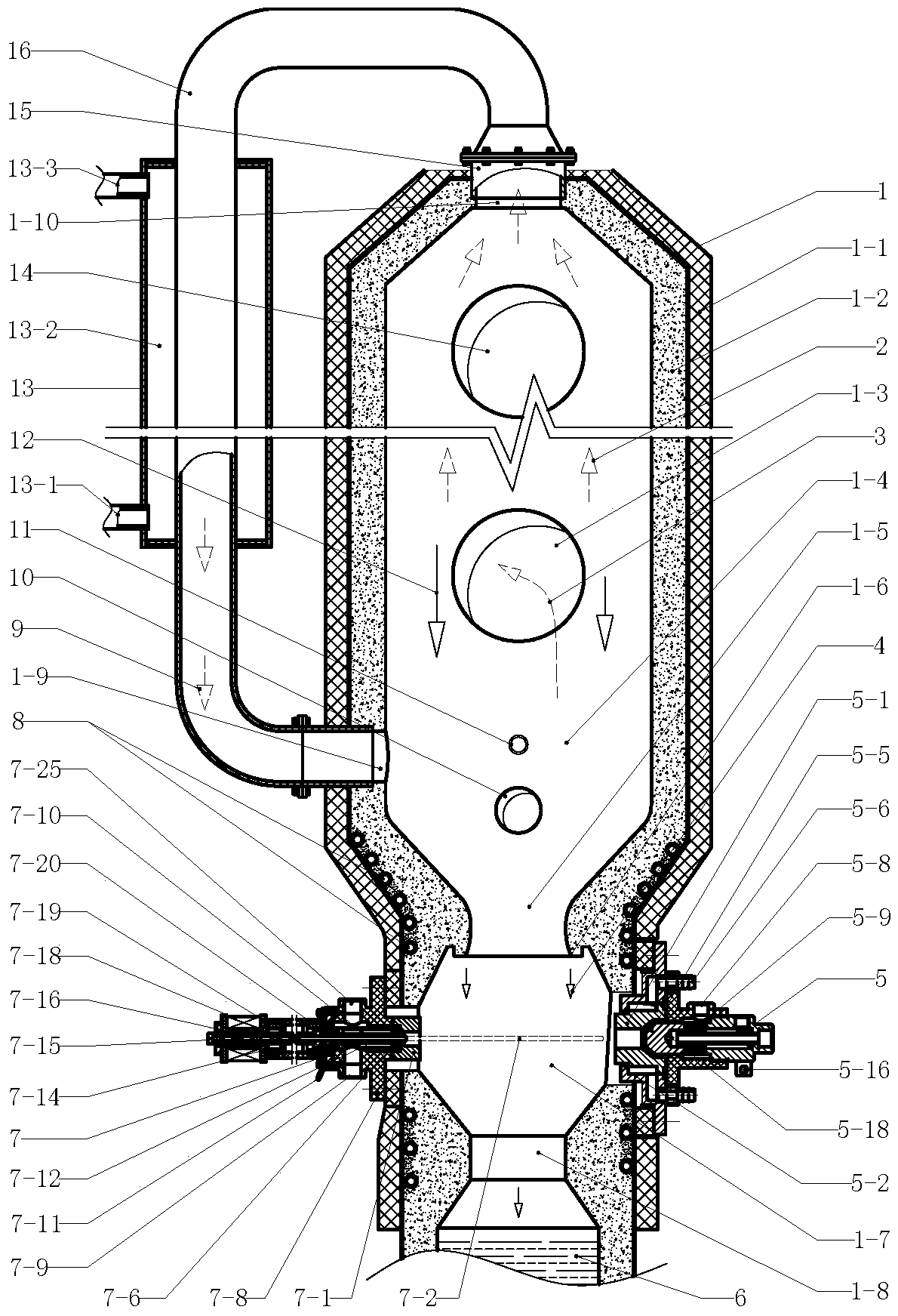

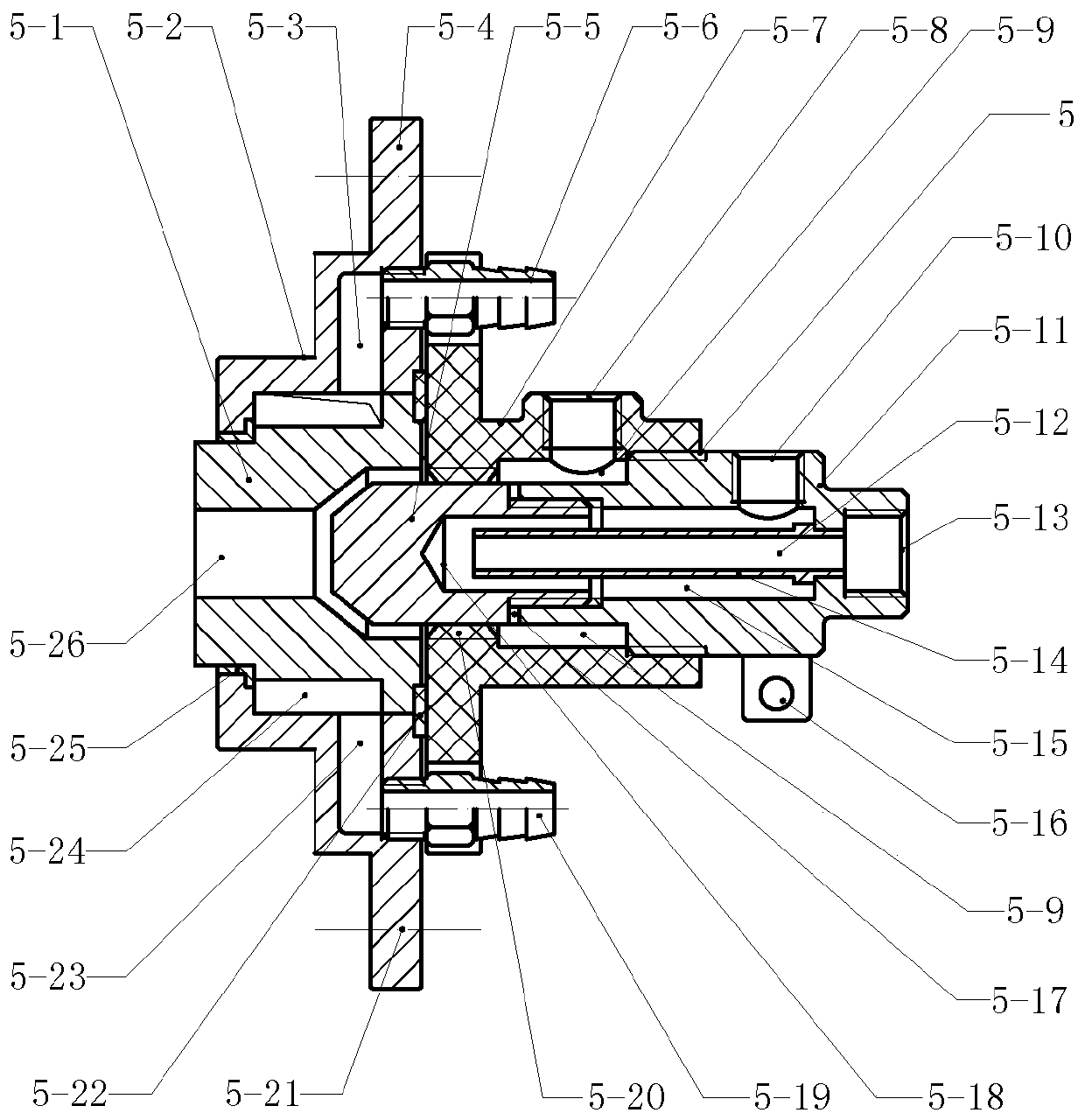

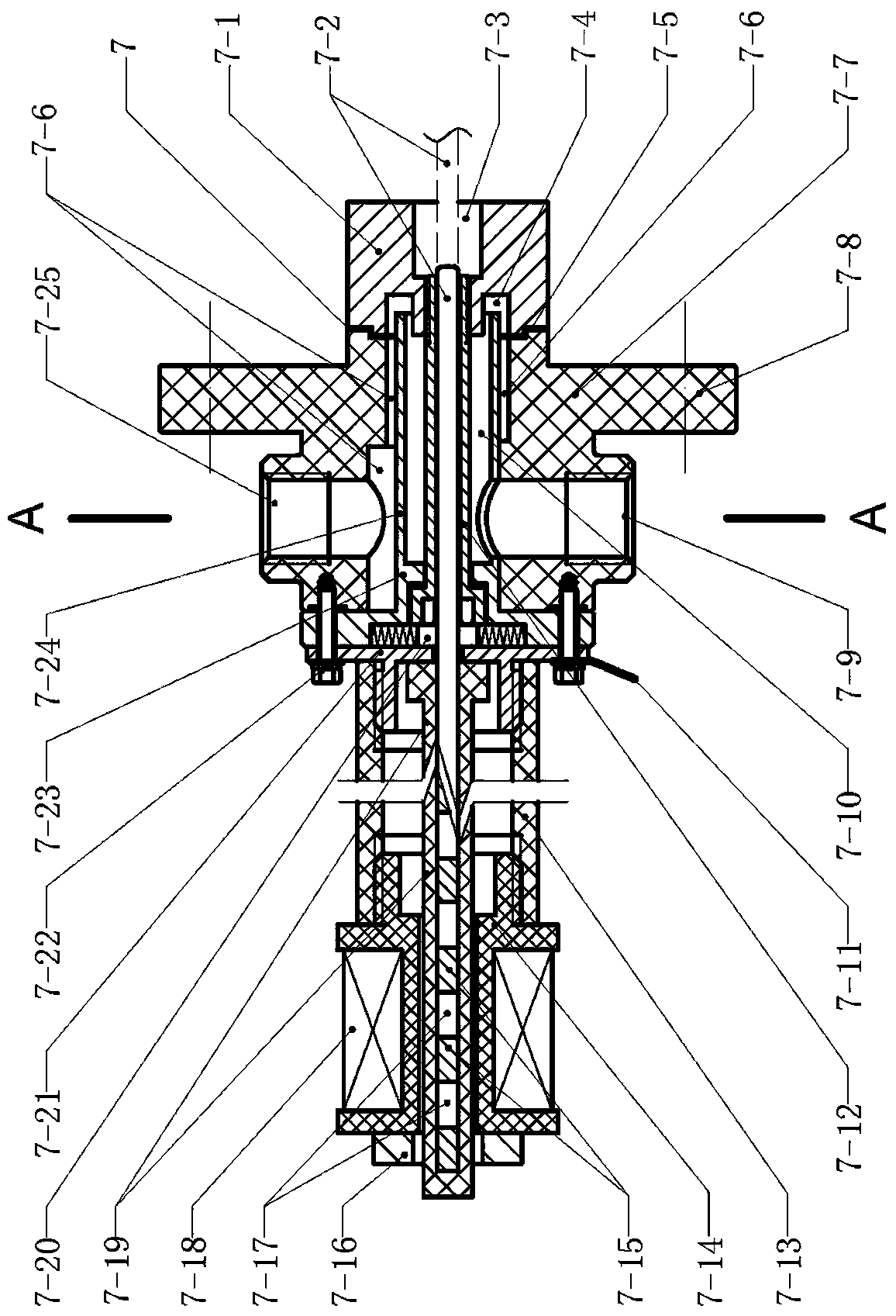

[0021] Example 1 figure 1 In the illustrated embodiment, the self-circulating plasma gasifier includes a plasma device, the gasifier is composed of a refractory furnace wall and an insulating wall, the insulating wall is enclosed on the outer wall of the refractory furnace wall, and the gasifier has a feed inlet The inlet and outlet of syngas are connected, the feed inlet is at the upper part of the gasifier, the outlet of syngas is at the middle of the gasifier, and there is a gasification zone at the lower part of the refractory furnace wall of the gasifier. The top of the furnace 1 is connected to the circulation gas outlet 1-10, and the gasification zone 1-4 at the lower part of the gasification furnace 1 is connected to the circulation gas return port 1-9. 9 is communicated with a circulation return pipe 16, and there is a cooling device 13 on the circulation return pipe 16. The cooling device 13 is a cylindrical structure with both ends closed. The space between the inn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com