VHP sterilization generator

A technology of generator and container, applied in the direction of gasification material, atomization material, disinfection, etc., can solve the problems of uneven hydrogen peroxide particles, incomplete vaporization, and high vaporization temperature, and achieves difficult to condense, complete gasification, and high temperature. The effect of stabilizing the gasification process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

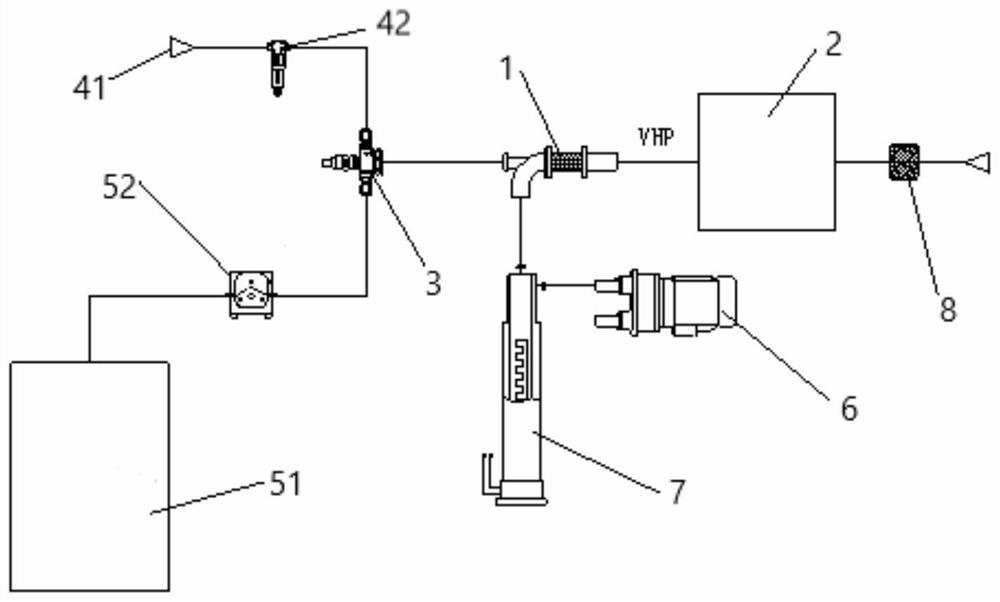

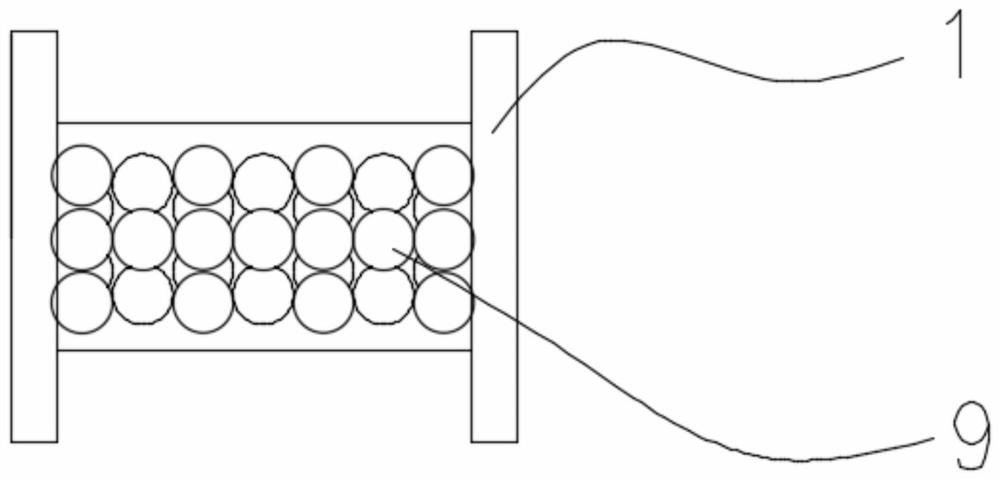

[0033] Such as figure 1 and figure 2 As shown, a VHP sterilization generator disclosed by the present invention includes a flash chamber 1 and a sterilization chamber 2, and the internal channel of the flash chamber 1 is filled with several evenly distributed beads 9, and the beads 9 are made of steel , the pipeline of the flash chamber 1 is connected with the atomizer 3, and one end of the atomizer 3 is connected with the compressed air supply device 41 and the hydrogen peroxide container 51 respectively, and a peristaltic device is arranged between the hydrogen peroxide container 51 and the atomizer 3 A filter device 42 for purification is installed between the pump 52 , the compressed air supply device 41 and the atomizer 3 , and a pressure reducer is installed between the filter device 42 and the compressed air supply device 41 .

[0034] The pipeline of the flash chamber 1 is connected with a heater 7, and the pipeline of the heater 7 is connected with a blower 6 for ex...

Embodiment 2

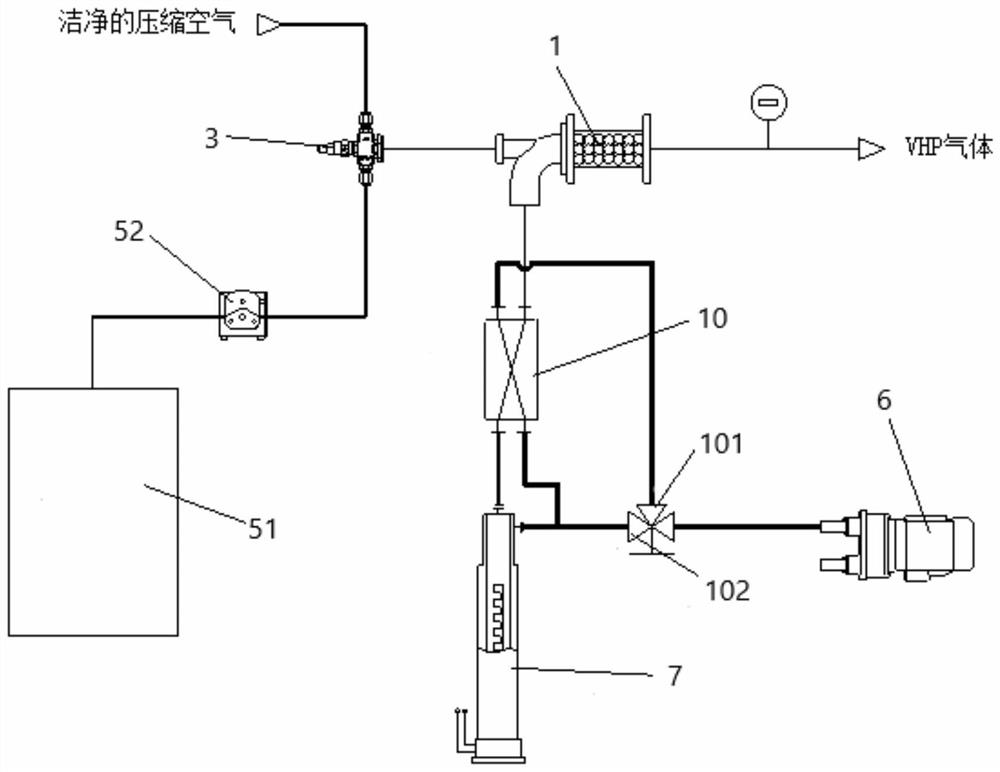

[0039] The difference between this embodiment and Embodiment 1 is that: figure 2 and image 3 As shown, a temperature-adjusting heat exchanger 10 is installed between the heater 7 and the flash chamber 1, and a regulating valve is provided in front of the heat exchanger 10, and the regulating valve is provided with a first valve end 101 and a second valve end 102 respectively. The regulating valve realizes the temperature regulation of the output gas by controlling the flow between the first valve end 101 and the second valve end 102, and the other end of the flash chamber 1 is respectively connected with a temperature sensor, a humidity sensor and a concentration sensor.

[0040] The operating conditions and principles of this embodiment are as follows:

[0041] When sterilization is required, the air blower 6 draws air from the outside and transports it to the heater 7. The heater 7 heats the air to 360°C to form sterile high-temperature air. The sterile high-temperature a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com