Liquid fuel gasification burner

A liquid fuel and burner technology, applied in the direction of burners, combustion methods, combustion types, etc., can solve the problems of alcohol-based mixed fuels and other problems, and achieve the effects of low maintenance rate, saving oil resources, and high flame temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

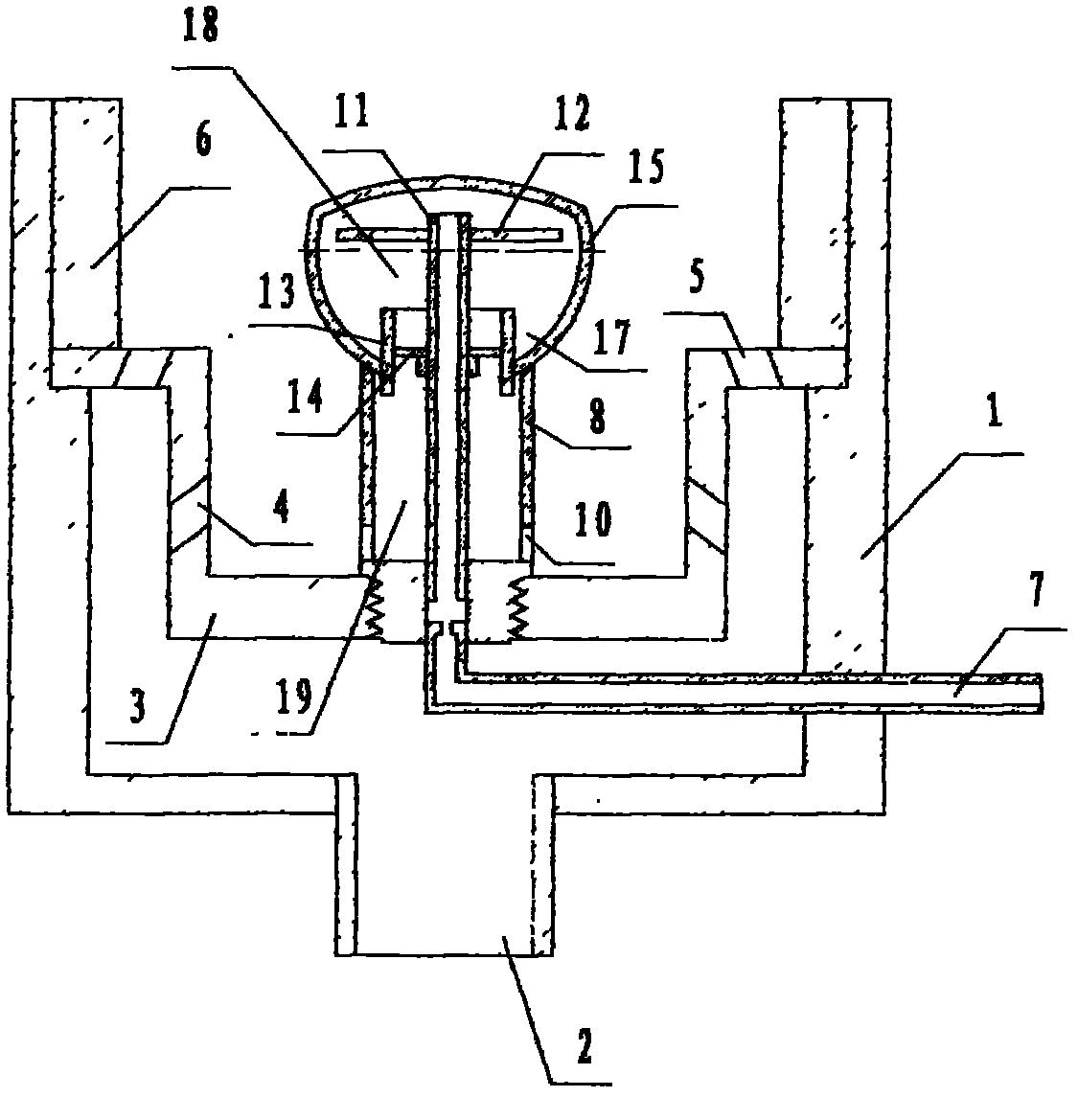

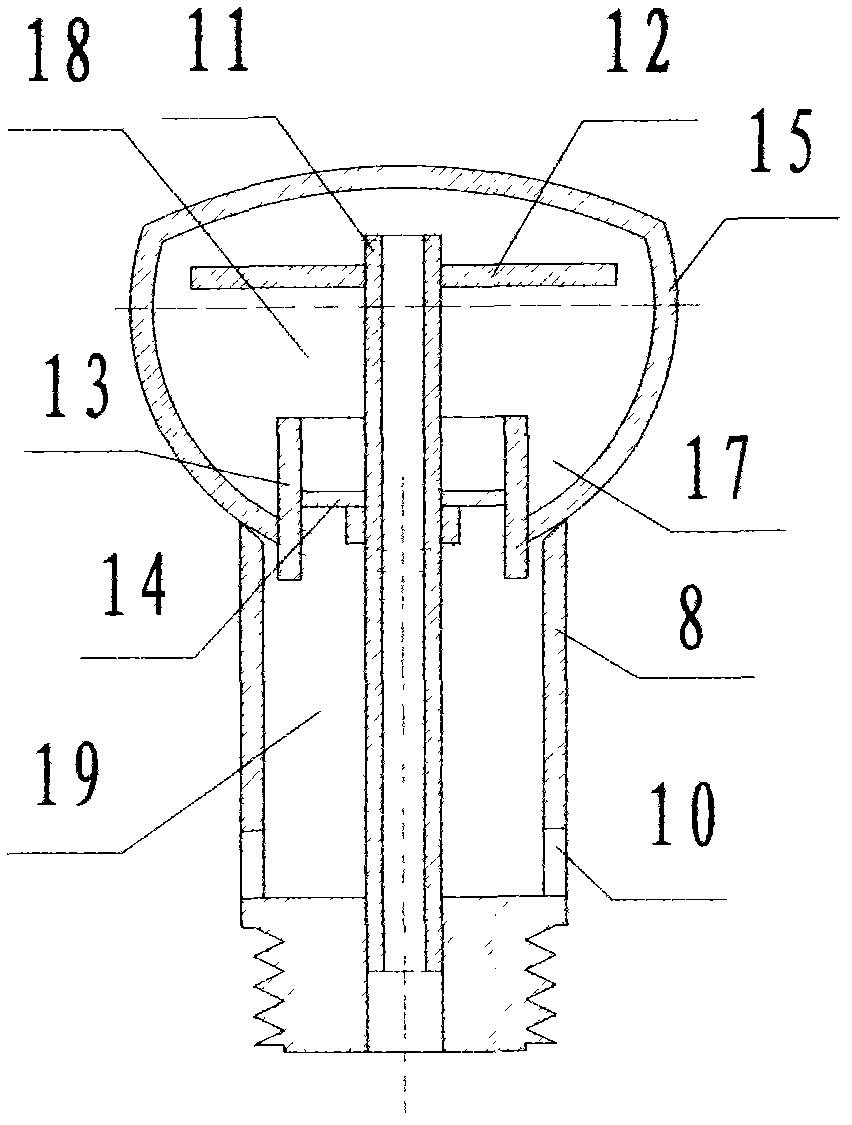

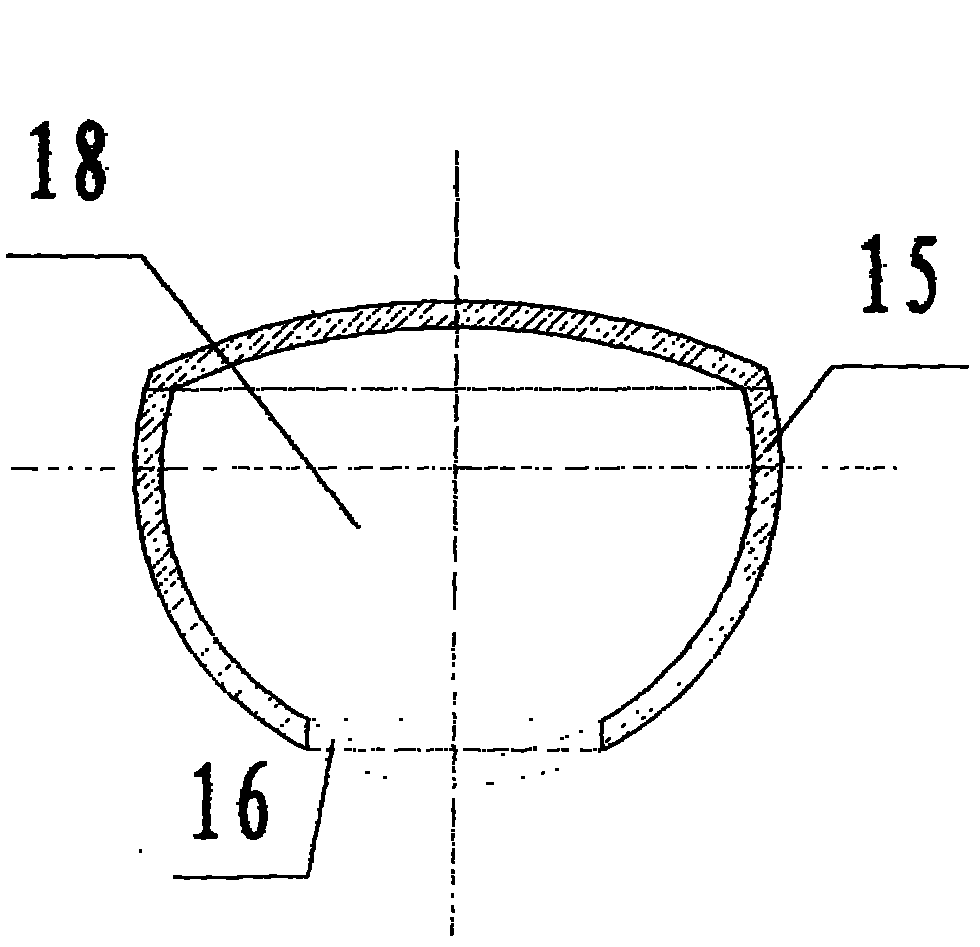

[0031] Before starting a fire, put appropriate liquid fuel from the oil inlet pipe 7 earlier, flow out from the air outlet hole 10 through the oil outlet pipe 11, the oil separator 12, the gasification groove 17, the air guide chamber 19, then close the valve, and ignite the fuel from the fuel tank with an igniter. The liquid fuel flowing out from the air outlet 10 opens the blower, and the wind enters from the air inlet 2, flows out from the side air outlet 4 and the upper air outlet 5, supplies air to the combustion area, and then unscrews the valve to gradually supply fuel. When the temperature of gasification ball 15 rises slowly, part of the liquid fuel that enters oil separator 12 from oil outlet pipe 11 slowly turns into gas, forming a mixed fuel with gas and liquid, and then passes through oil separator 12 and gasification ball The small gap formed between the walls enters the gasification cavity 18 at the bottom of the gasification ball 15, and the liquid fuel that has...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com