Alcohol-based high-temperature gasification fire control furnace

A high-temperature, alcohol-based technology, applied in household stoves/stoves, combustion methods, heating fuels, etc., can solve problems such as carbon deposits, carbon blockages, and inability to enter large hotels, and achieve the effect of reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

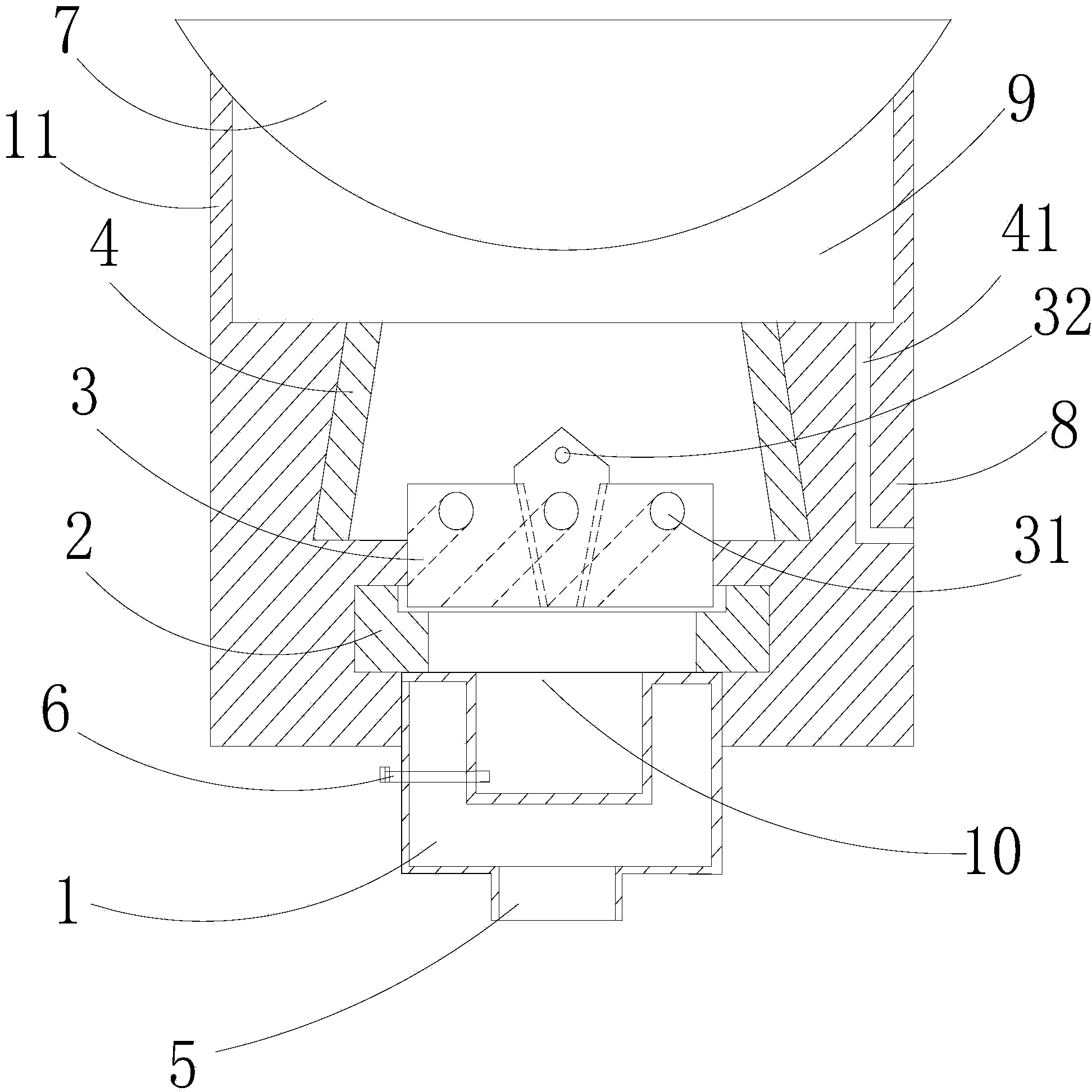

[0028] see Figure 1-5 As shown, it is a kind of alcohol-based high-temperature gasification fire control furnace according to the present invention, including a furnace core 1, a refractory ring 2, a fire control cover 3 and a fire control ring 4, and the refractory ring 2 is arranged above the furnace core 1, and the control The fire cover 3 is arranged above the refractory ring 2, a high-temperature gasification combustion chamber 10 is formed between the furnace core 1, the refractory ring 2 and the fire control cover 3, and the lower part of the fire control ring 4 is placed on the upper periphery of the fire control cover 3, A plurality of fire outlet channels 31 are arranged on the fire control cover 3 , the inlets of the fire outlet channels 31 communicate with the high-temperature gasification combustion chamber 10 , and the fire outlet direction of the outlet of the fire outlet channels 31 faces the inner wall of the fire control ring 4 . The alcohol-based high-tempe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com