A method and device for steam recovery

A technology of steam and superheated steam, which is applied in the direction of pump devices, lighting and heating equipment, liquid variable capacity machinery, etc., can solve the problems of incomplete gasification of spray liquid, etc., to improve the use value, complete spray liquid gasification, spray The effect of the appropriate amount of liquid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

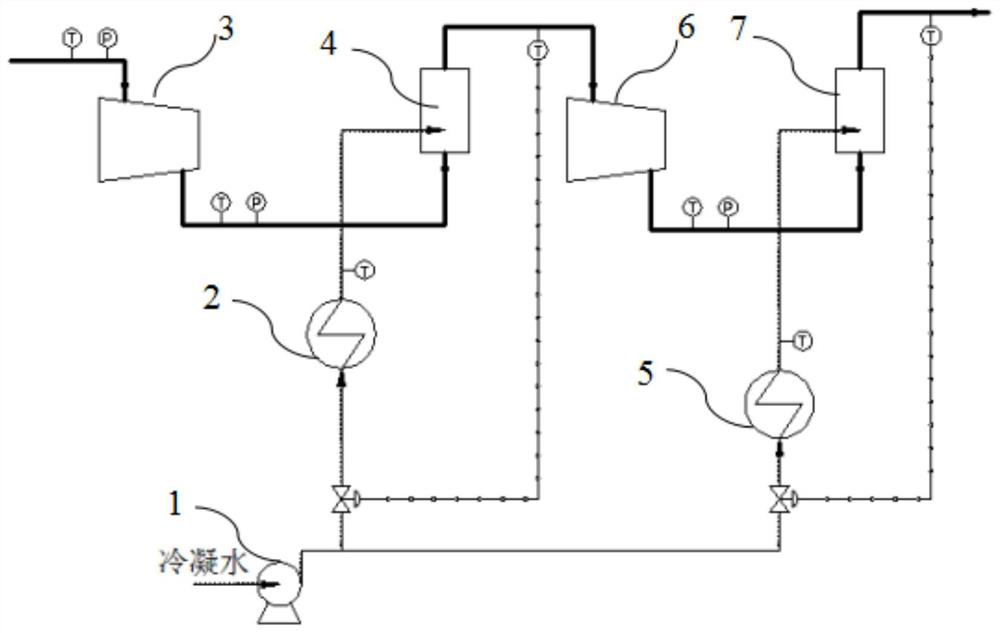

[0074] Such as figure 1 As shown, 10000kg / h, 0.15MPa(G), 127.5℃ saturated steam passes through the first stage compressor 3 (centrifugal type), consumes 326kw of power, and becomes 0.3MPa(G), 188.4℃ superheated steam. The saturation temperature corresponding to 0.3MPa(G) is 143.7°C, and the degree of superheat of the above-mentioned superheated steam is 44.7°C.

[0075] 1190kg / h, 90°C normal pressure condensed water is pressurized to 0.85MPa(G) by water inlet pump 1, and is divided into two parts with a flow rate of 390kg / h and 800kg / h. The 390kg / h condensed water passes through the first-stage preheater 2, is heated to 143.7°C, and is sprayed into 0.3MPa(G) superheated steam. The gas / liquid two-phase at different temperatures rapidly changes to a gas with a mass flow rate of 10390kg / h, a temperature of 145.4°C, and a superheat of 1.7°C.

[0076] After passing through the second-stage compressor 6 (centrifugal type), the power consumption is 638kw, and it becomes superheated...

Embodiment 2

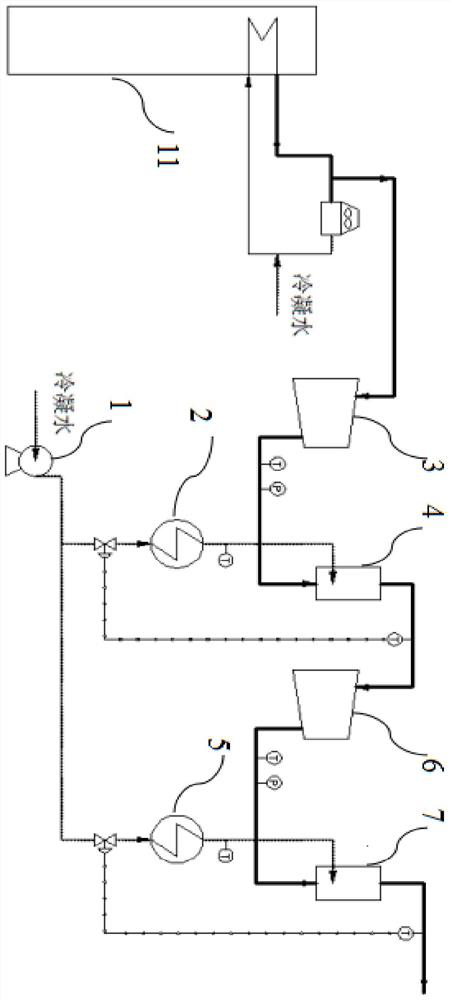

[0079] Such as figure 2 As shown, the by-product of urea scrubber 11 is 8000kg / h, 0.25MPa(G), 138.9℃ saturated steam, after passing through the first-stage compressor 3 (screw type), the power consumption is 488kw, becoming 0.9MPa(G), 289.8 ℃ superheated steam. The saturation temperature corresponding to 0.9MPa(G) is 180°C.

[0080]2150kg / h, condensed water at 95°C normal pressure, pressurized to 4.2MPa(G) with feed water, divided into two parts with a flow rate of 620kg / h and 610kg / h. The condensed water of 620kg / h passes through the first stage preheater 2 and is heated to 184.1°C. This temperature exceeds the saturation temperature of the injected steam, but due to the high pressure of the condensed water, it still maintains a liquid state. The reduced pressure is sprayed into the first-stage mixer 4, and the condensed water becomes a superheated liquid state and partially vaporized. Steam and condensed water rapidly change into 6440kg / h, 182.5°C gas in the first-stage ...

Embodiment 3

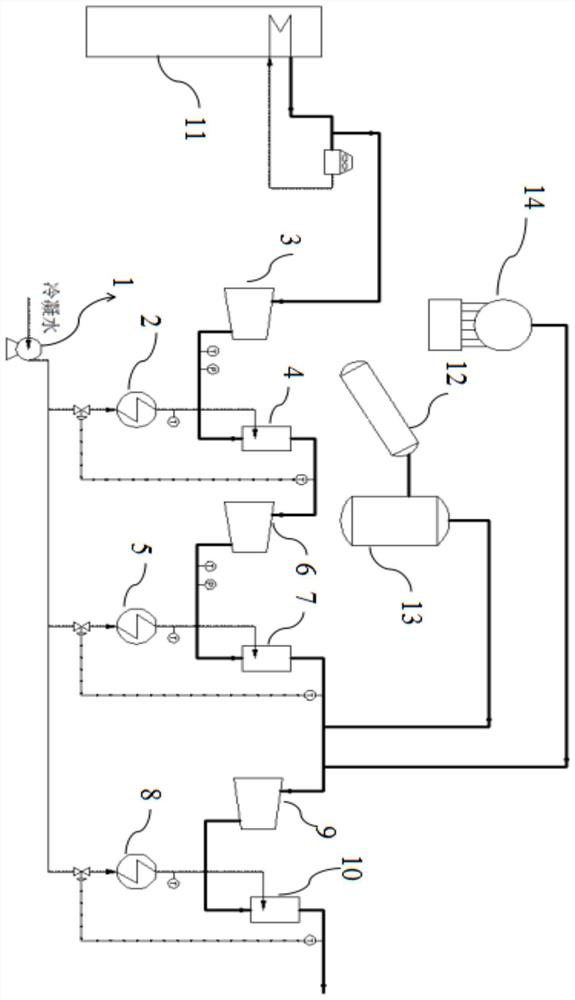

[0083] Such as image 3 As shown, the equipment and material parameters from the urea scrubber 11 to the secondary mixer are the same as in the specific embodiment 2.

[0084] The above-mentioned 7250kg / h, 225.9°C steam, together with the steam (2.3MPa(G), 221.8°C, 2000kg / h) from the steam-water separator 13 attached to the Daosheng condenser 12, and the steam from the waste heat boiler 14M23 (2.4MPa(G ), 224°C, 3500kg / h), and enter the third stage preheater 9 (screw type) together. Power consumption is 599kw, and it becomes superheated steam at 4.0MPa(G) and 361.8°C. 4.0MPa(G) corresponds to a saturation temperature of 251.8°C. Part of the 900kg / h condensed water from the water inlet pump 1 is preheated to 252.8°C through the third-stage preheater 8. Since the condensed water pressure is high at this time, it still maintains a liquid state. The decompression enters the third-stage mixer 10, and is mixed with superheated steam to quickly become steam of 13650kg / h, 4.0MPa(G)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com