Patents

Literature

52results about How to "No effusion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

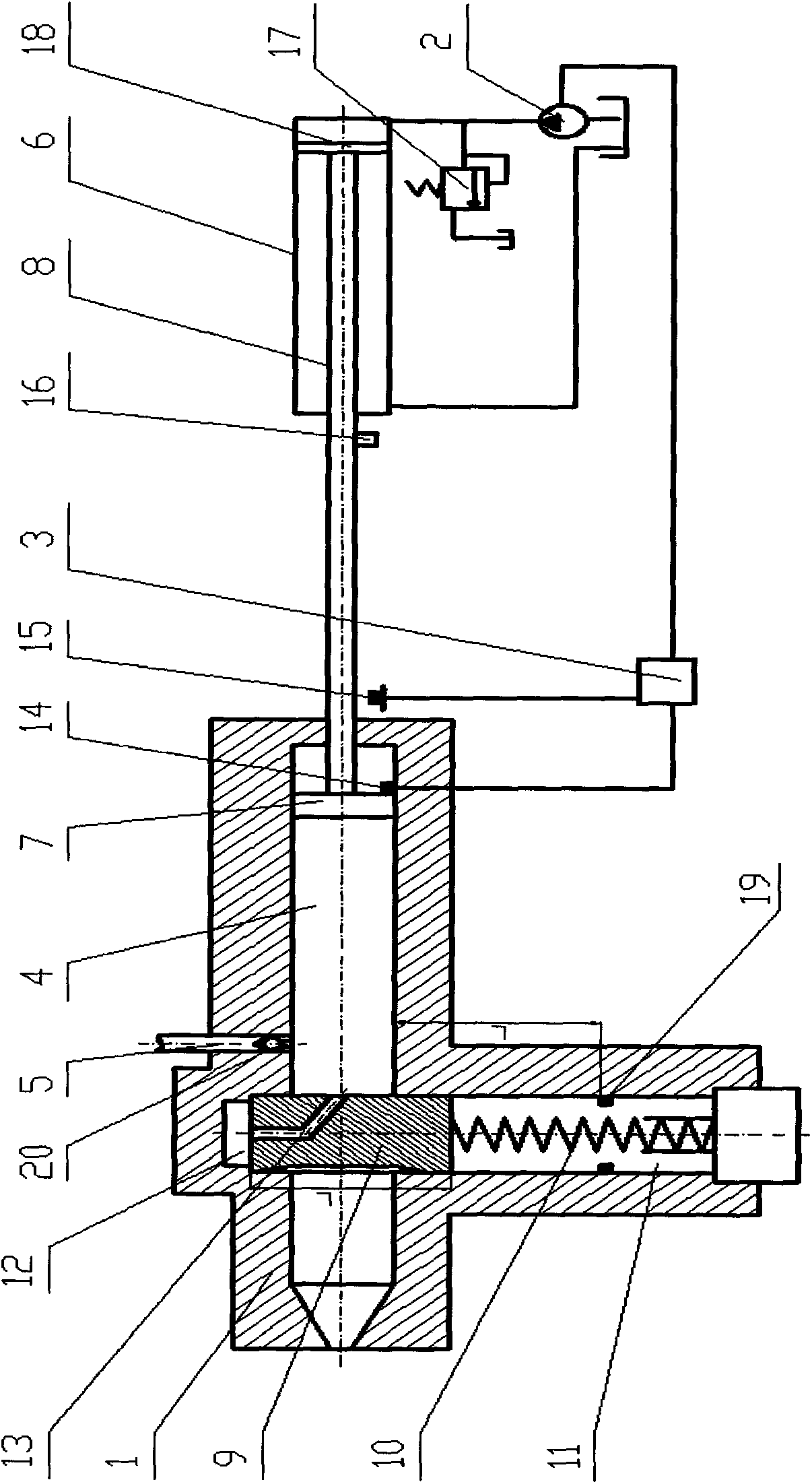

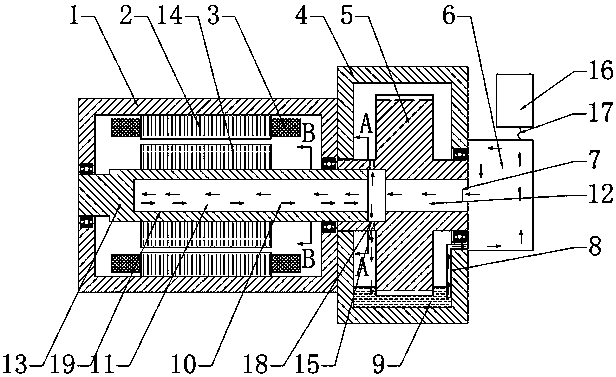

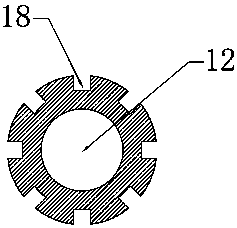

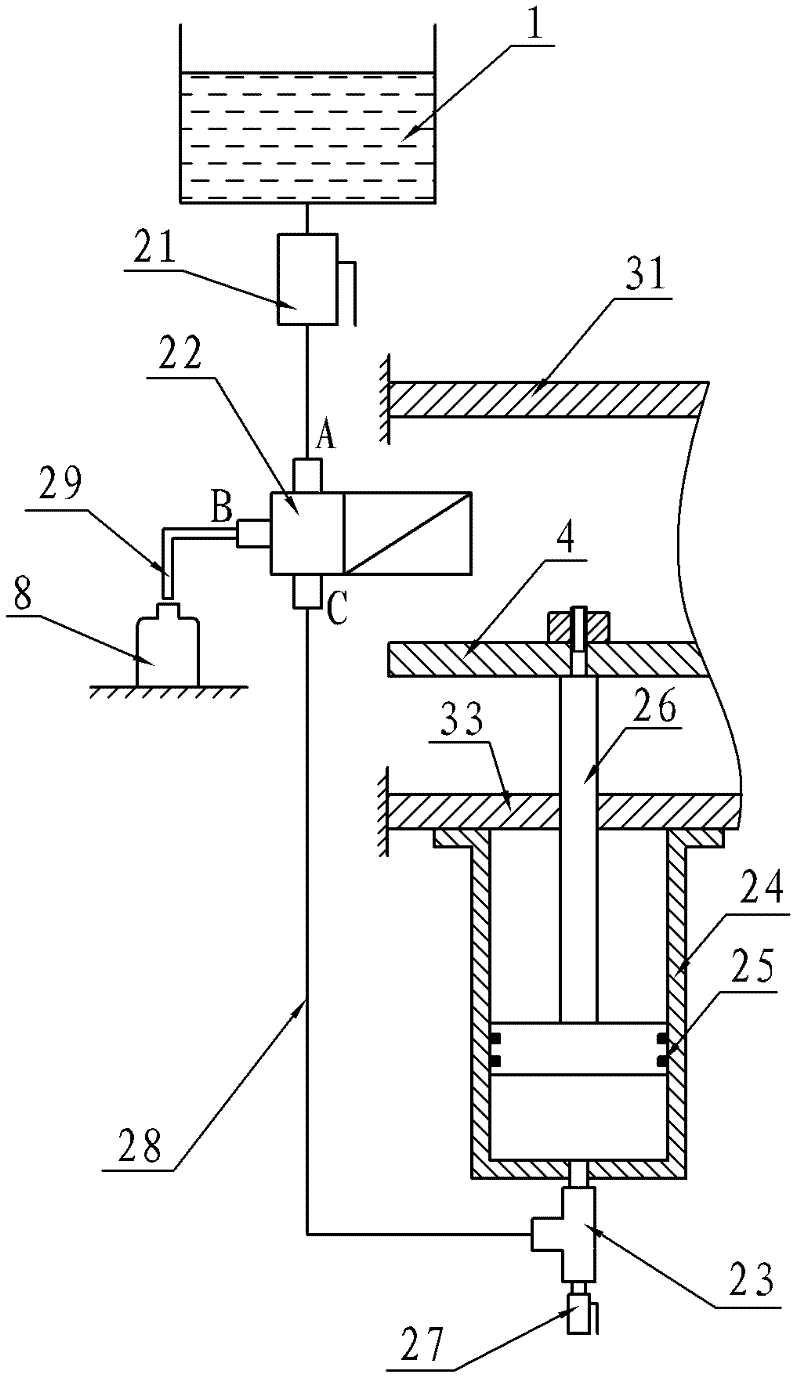

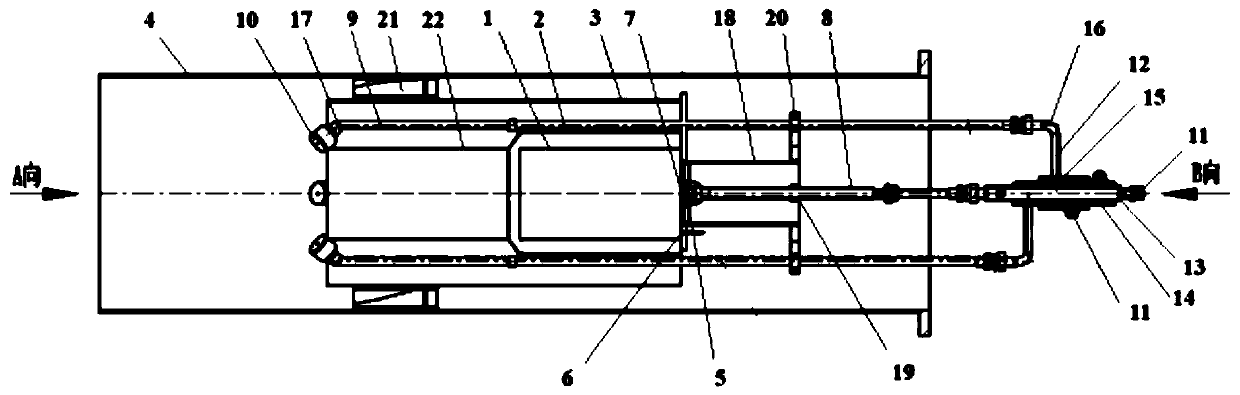

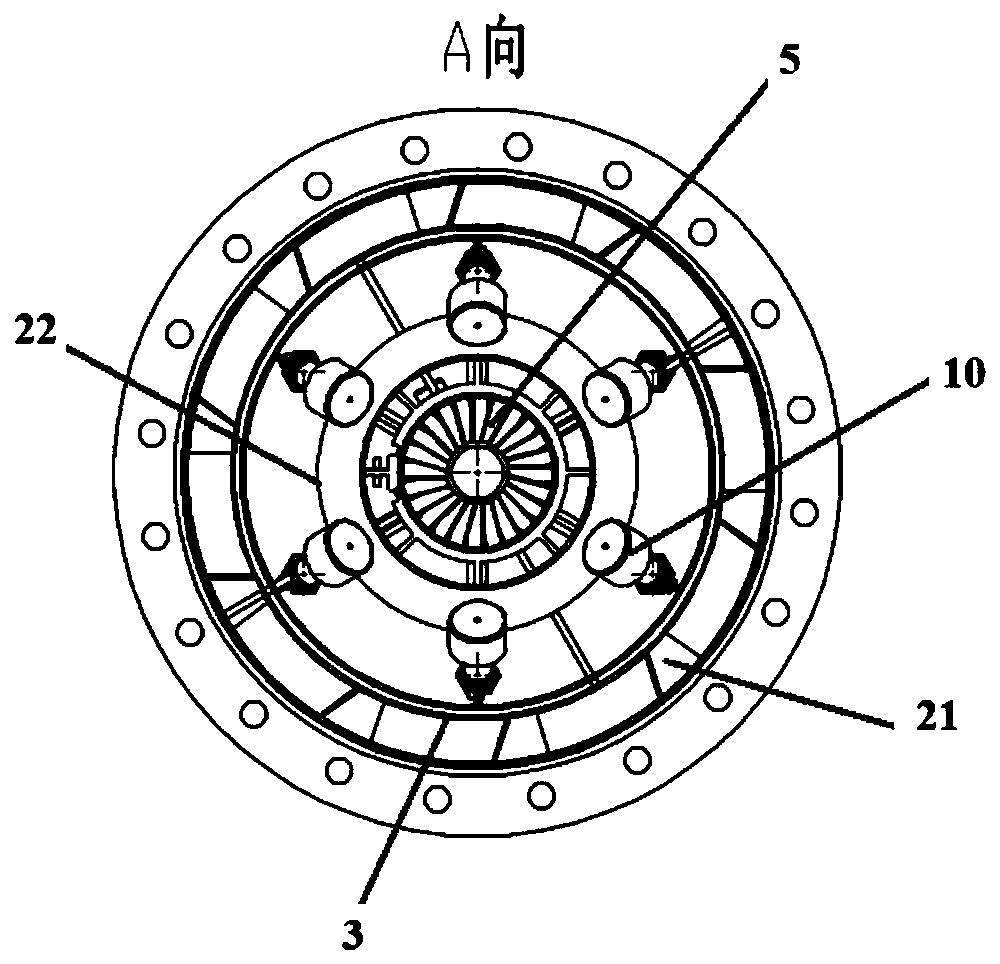

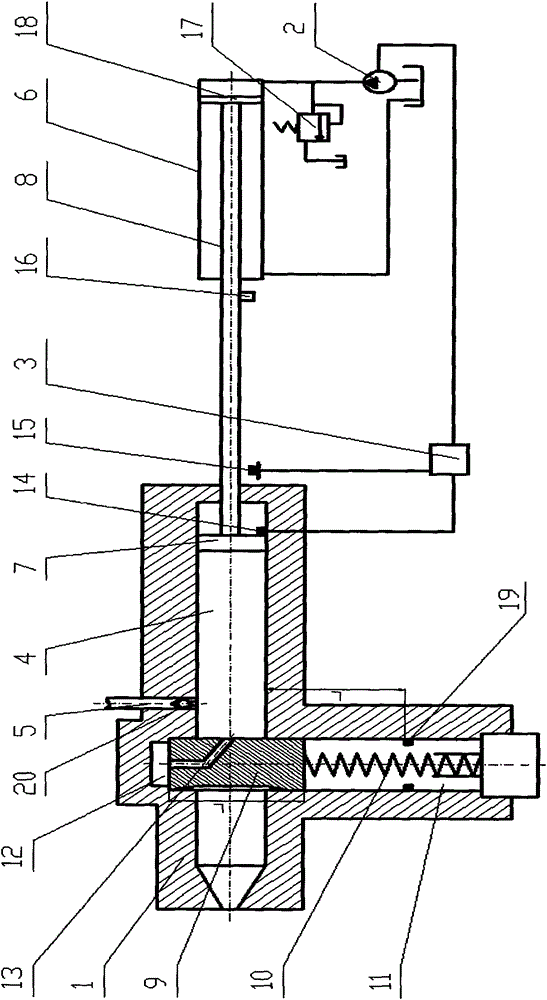

Non-return quantitative constant-pressure injection device

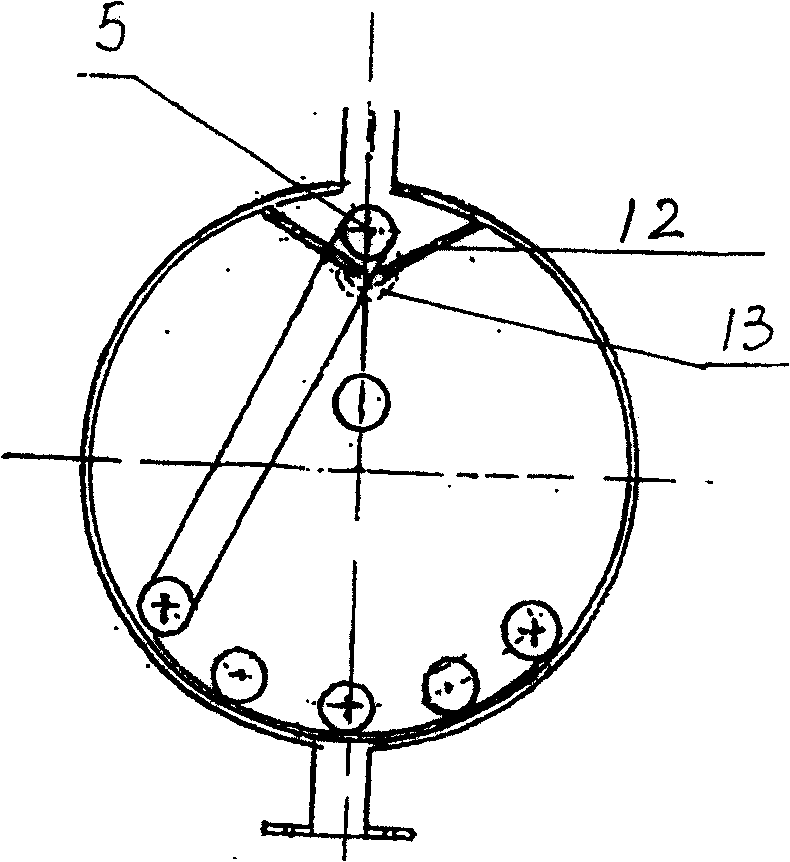

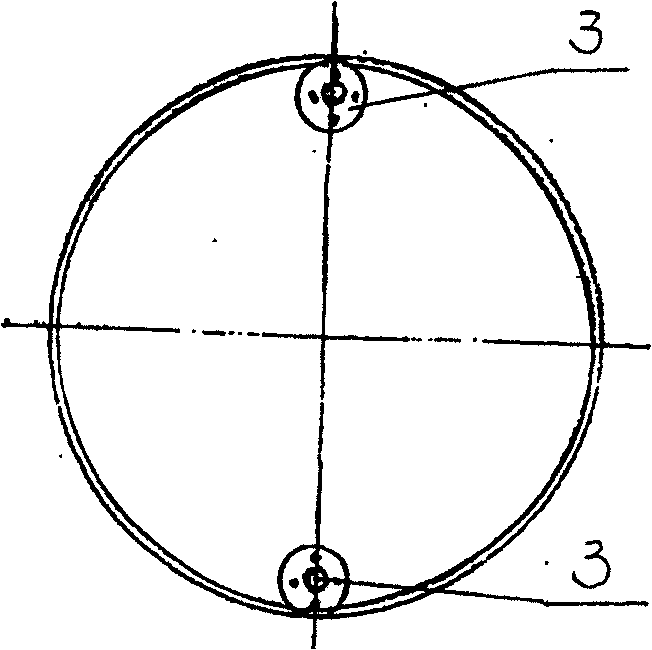

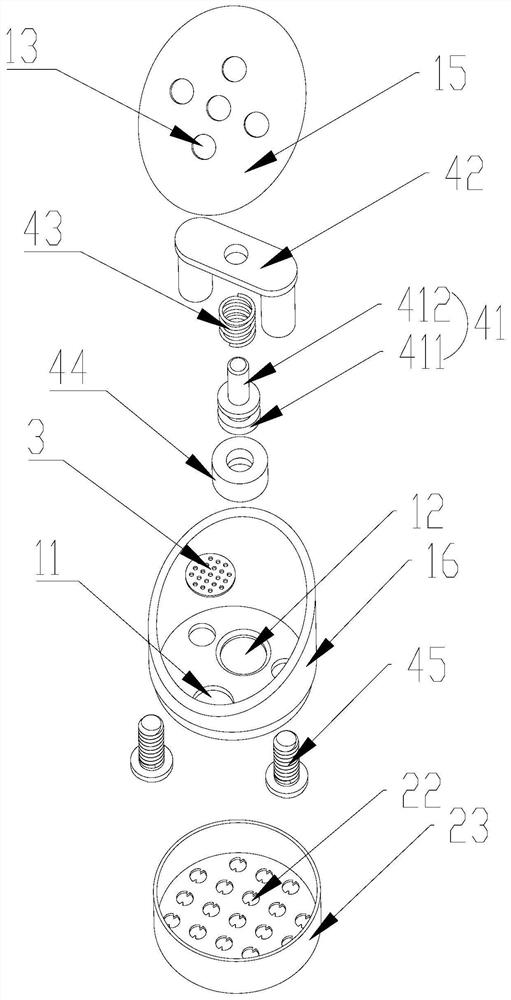

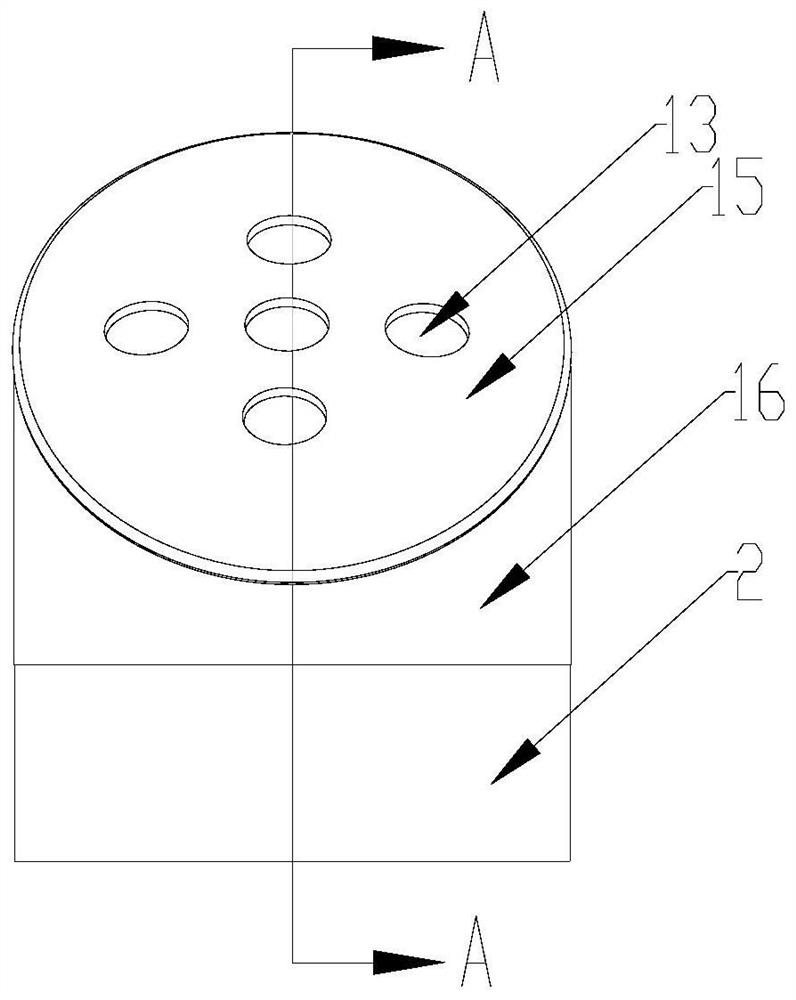

The invention discloses a non-return quantitative constant-pressure injection device which comprises a nozzle body, a valve core mechanism, an injection oil cylinder, a hydraulic system and a controller, wherein a flow channel and a liquid inlet are formed in the nozzle body; the valve core mechanism for opening or closing the nozzle body is mounted in the nozzle body; the injection oil cylinder comprises an oil cylinder body and a hydraulic rod with a first piston at the front end part; the hydraulic rod with the first piston extends into the flow channel of the nozzle body; the hydraulic system is connected with the oil cylinder body and is used for driving the injection oil cylinder. The injection device is characterized by further comprising a hydraulic rod stroke control device; both the hydraulic system and the hydraulic rod stroke control device are electrically connected with the controller. The injection device is simple in structure and high in reliability, and can achieve intermittent, quantitative and constant-pressure injection.

Owner:佛山市韵雄塑料五金制品有限公司

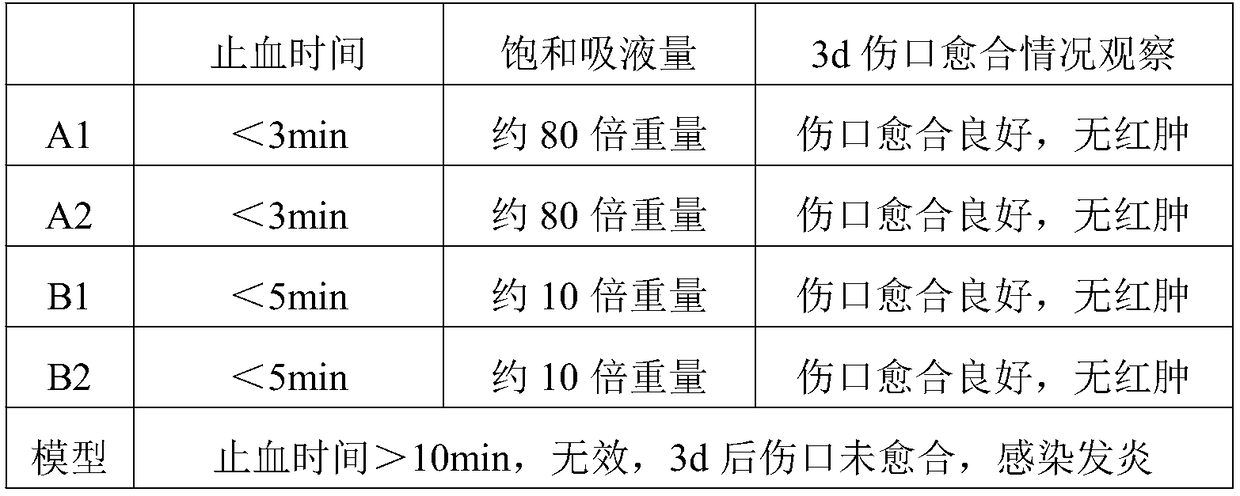

Chitosan biological film-forming glue and preparation method thereof

ActiveCN103550814APromote tissue repair and regenerationPromote applicationAbsorbent padsBandagesAnti bacterialMentha citrata

The invention relates to an external spray type antibacterial liquid dressing, and particularly relates to chitosan biological film-forming glue and a preparation method thereof. The chitosan biological film-forming glue comprises the following raw materials in percentage by weight: 0.5%-6% of modified chitosan, 0.01%-0.15% of mint, 0.01%-0.15% of acidifying agents, 0.2%-0.4% of radix scutellariae, 0.1%-0.3% of phellodendron and the balance of deionized water. The chitosan biological film-forming glue disclosed by the invention is prepared into a solution by adopting the modified chitosan, thereby keeping the self physicochemical characteristics and function roles of the chitosan and achieving good solubility property. The chitosan biological film-forming glue disclosed by the invention has good biocompatibility, multiple unique functions, namely higher solubility, easiness for organism absorption, and the like which do not exist in general chitosan, and well utilizes the biological activity of the chitosan.

Owner:GUANGXI XINYE BIOLOGICAL TECH

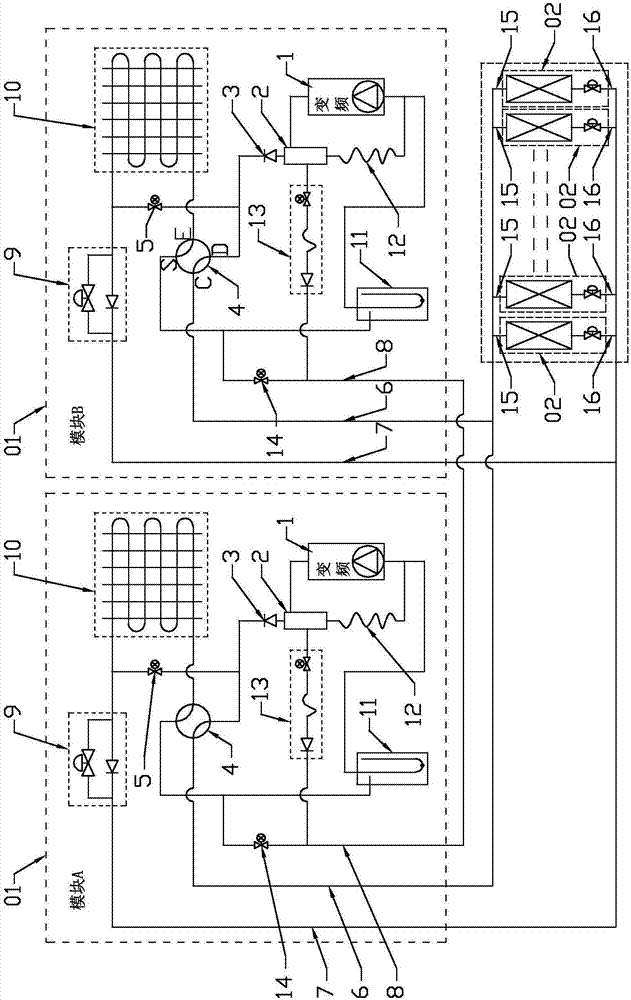

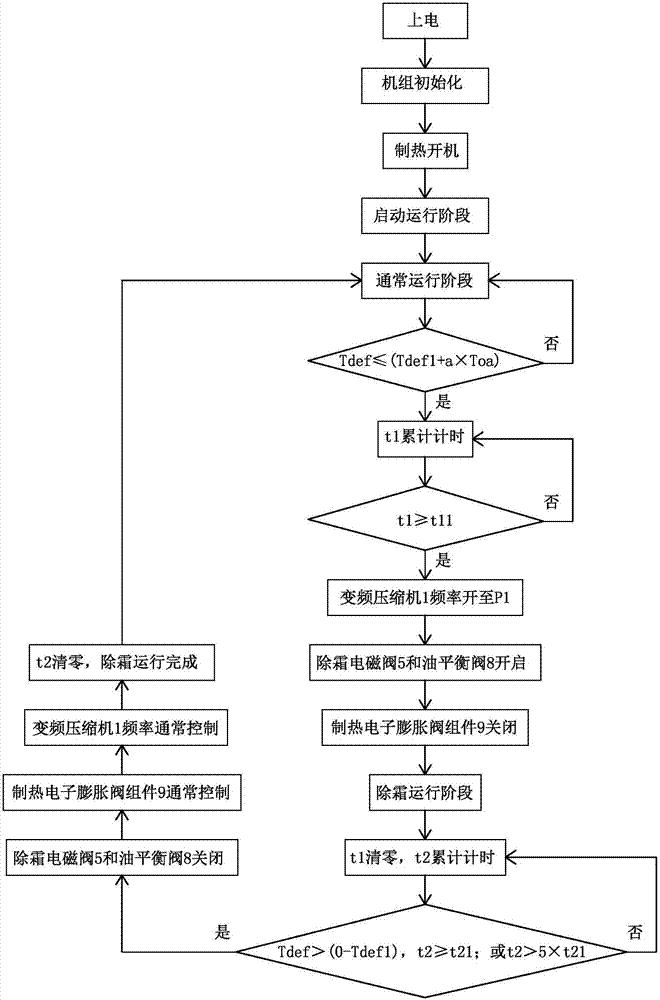

Multi-split system capable of defrosting alternately without stopping as well as defrosting control method

ActiveCN107975990AExtended service lifeSimple actionMechanical apparatusCorrosion preventionHeating effectFour-way valve

The invention discloses a multi-split system capable of defrosting alternately without stopping as well as a defrosting control method, and belongs to the technical field of air conditioning. The combined air-cooling variable-frequency multi-split in the prior art needs to stop a compressor and cooperates with the switching state of a four-way valve to defrost, so that the energy-saving requirement is not met, the service life of the machine unit is influenced and the customer experience is seriously influenced. A hot gas bypass device is arranged between a gas discharge port of the variable-frequency compressor and an outdoor condenser liquid pipe; when any one base module of an outdoor unit meets the defrosting requirement, a defrosting electromagnetic valve and an oil balance valve of the module are controlled to be opened, a heating expanding valve assembly is closed and the variable-frequency compressor is started to reach the defrosting frequency; other base modules of the outdoor unit maintain the heating state and the variable-frequency compressor performs defrosting, compensation and frequency increasing. Alternate defrosting without stopping is realized, the four-way reversing valve does not need to be switched to a refrigeration mode and the service life of parts is high; the heating effect of the outdoor unit is not influenced; and the defrosting action is simple, safety and reliability are achieved, and the defrosting efficiency is high.

Owner:ZHEJIANG KING CO LTD

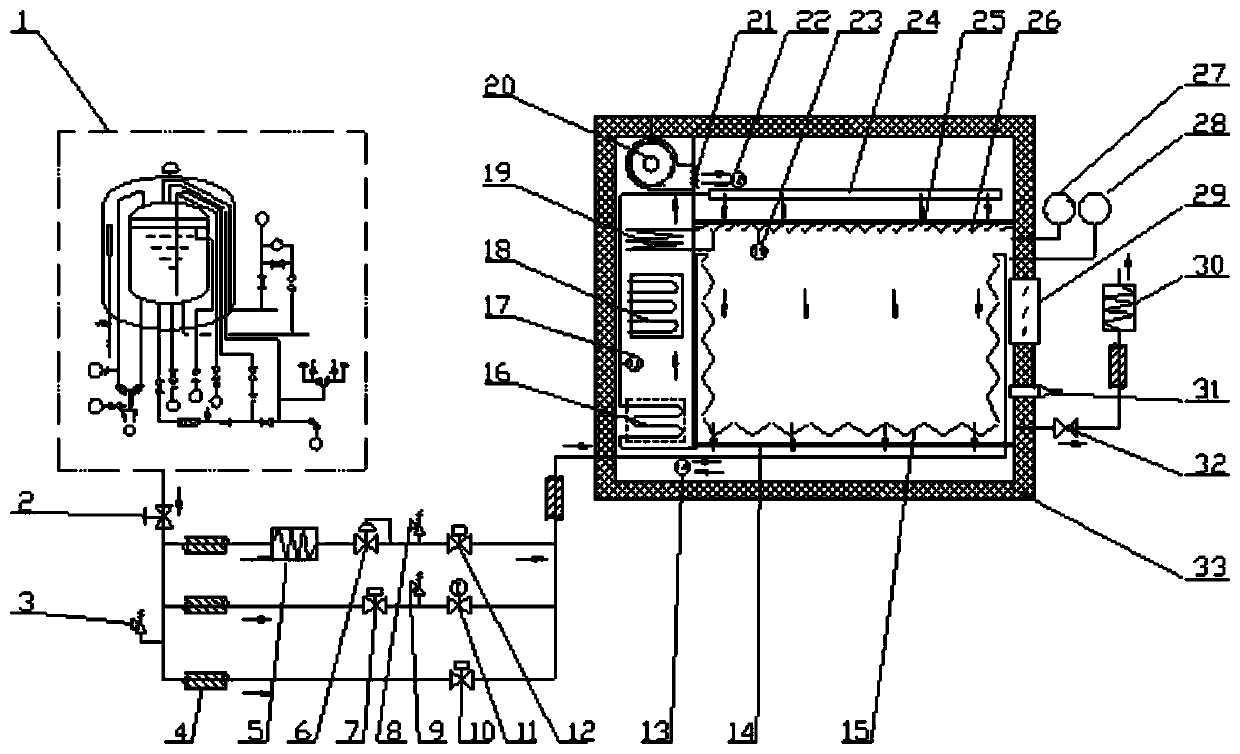

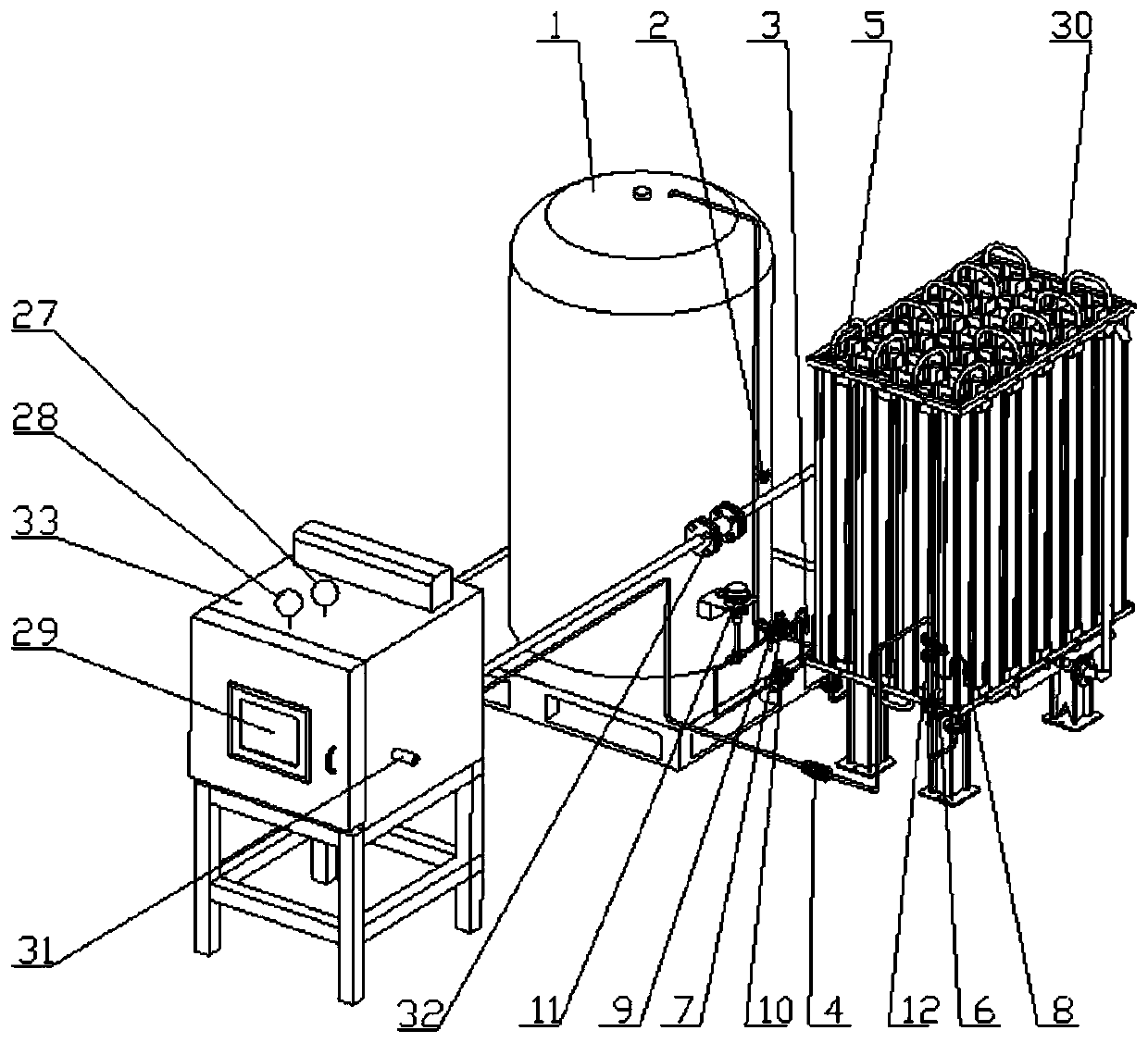

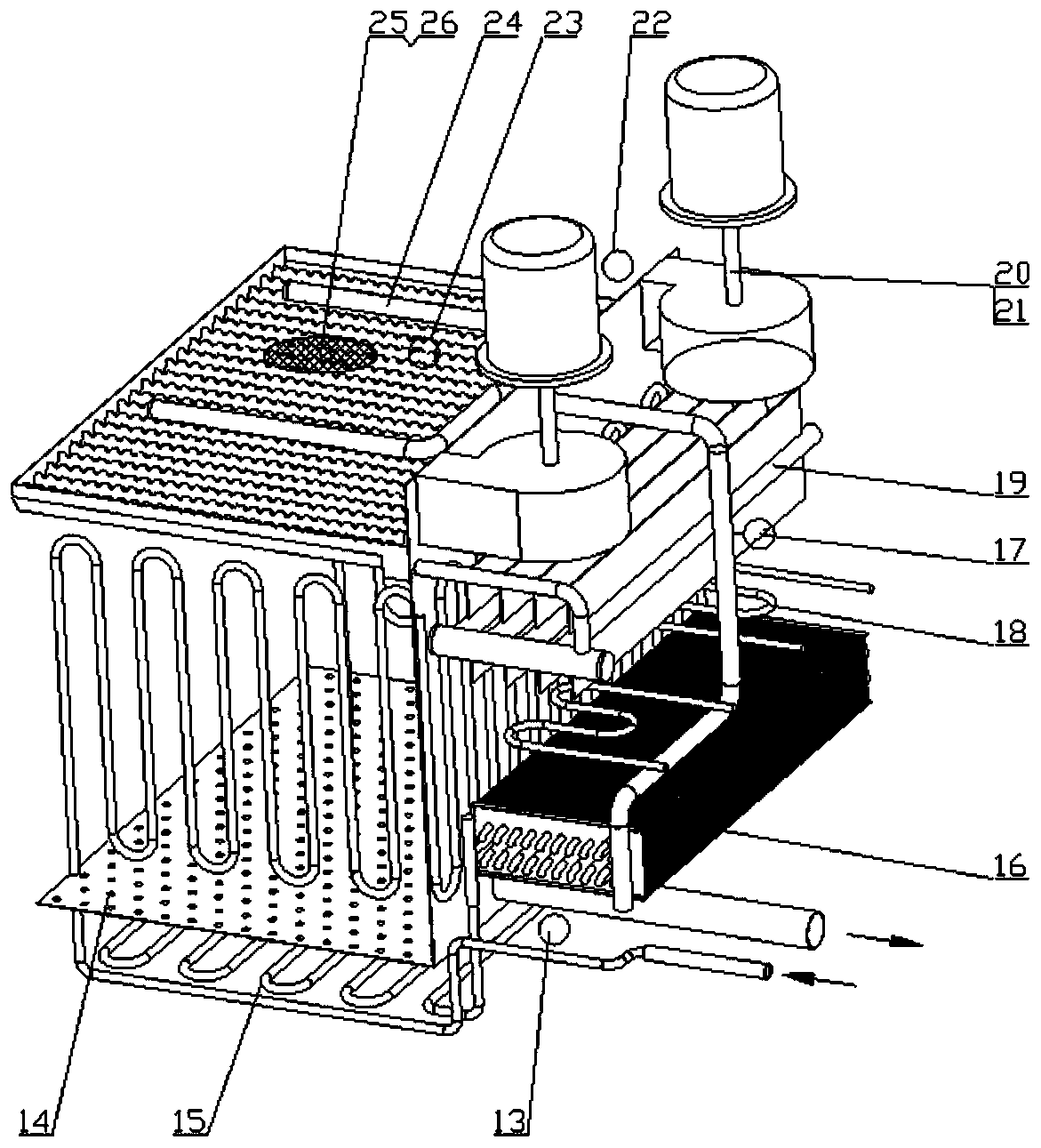

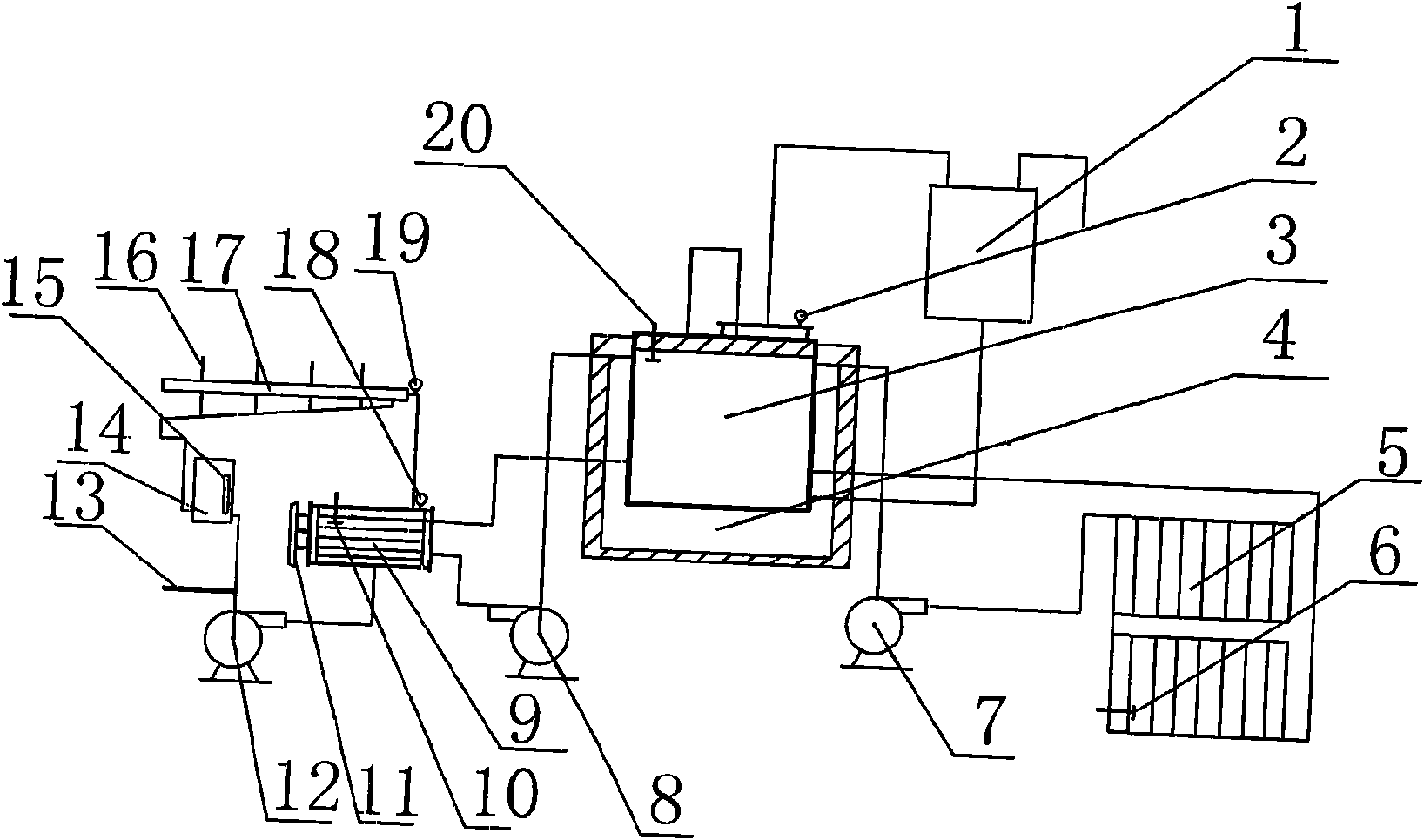

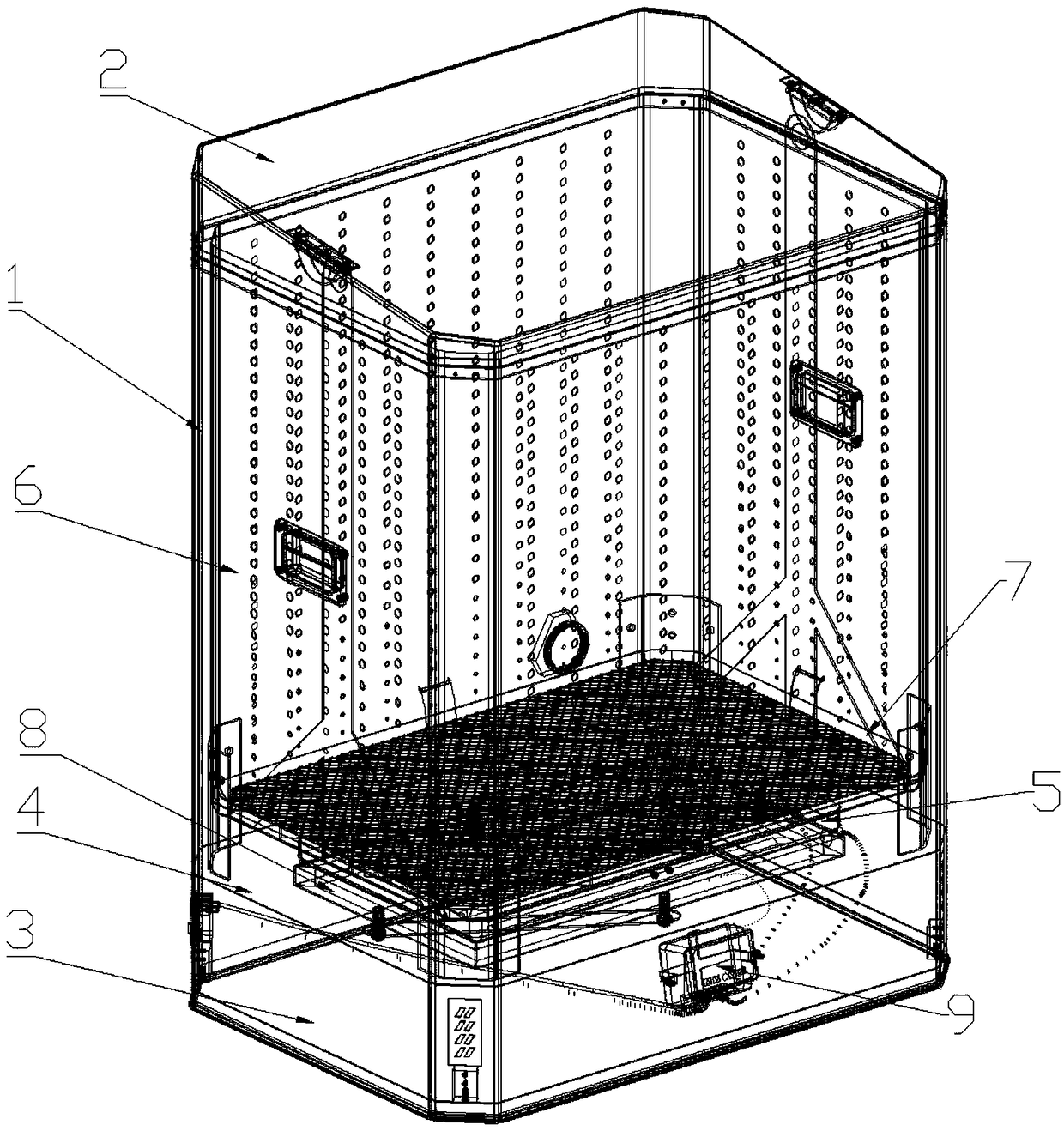

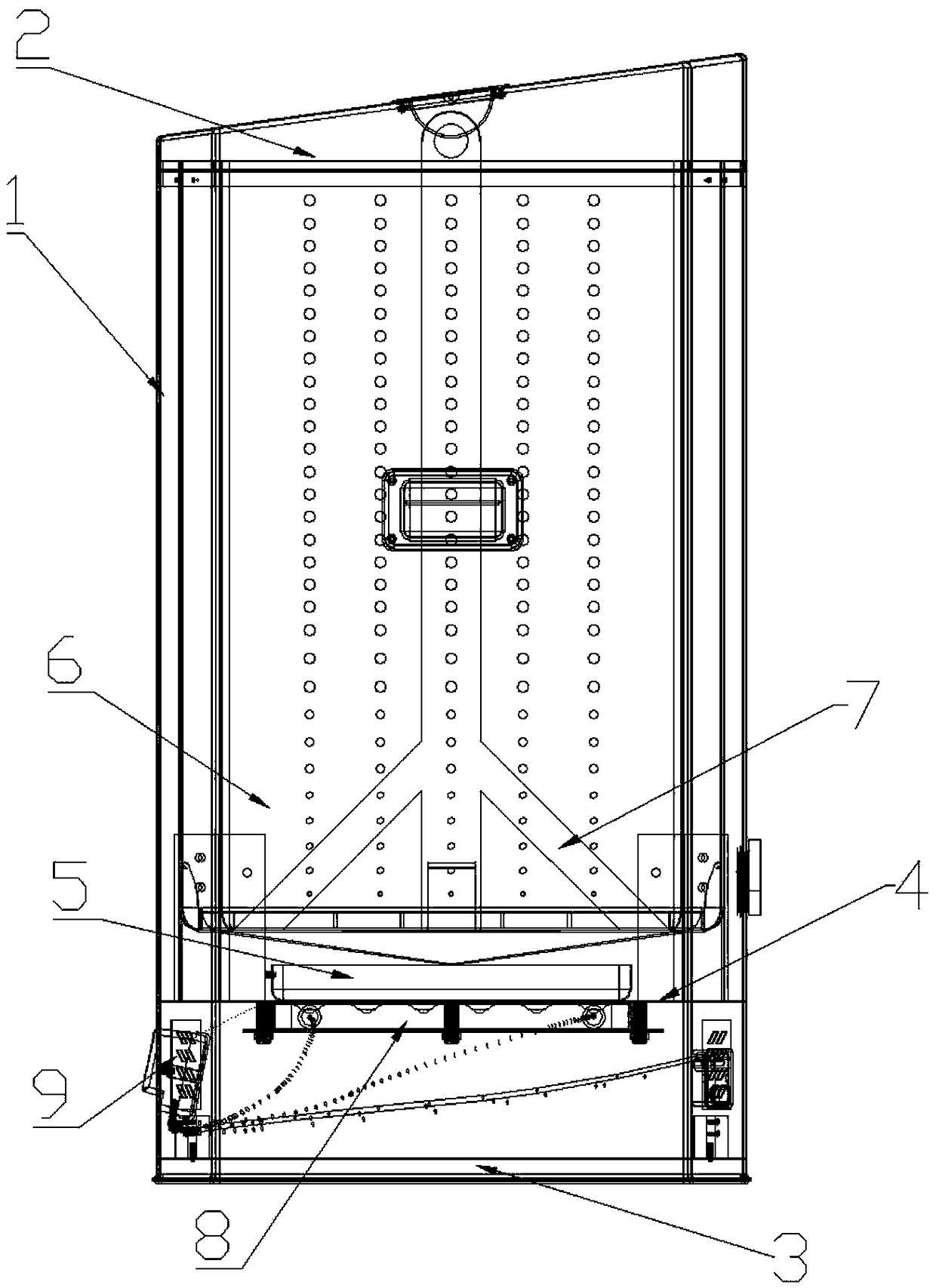

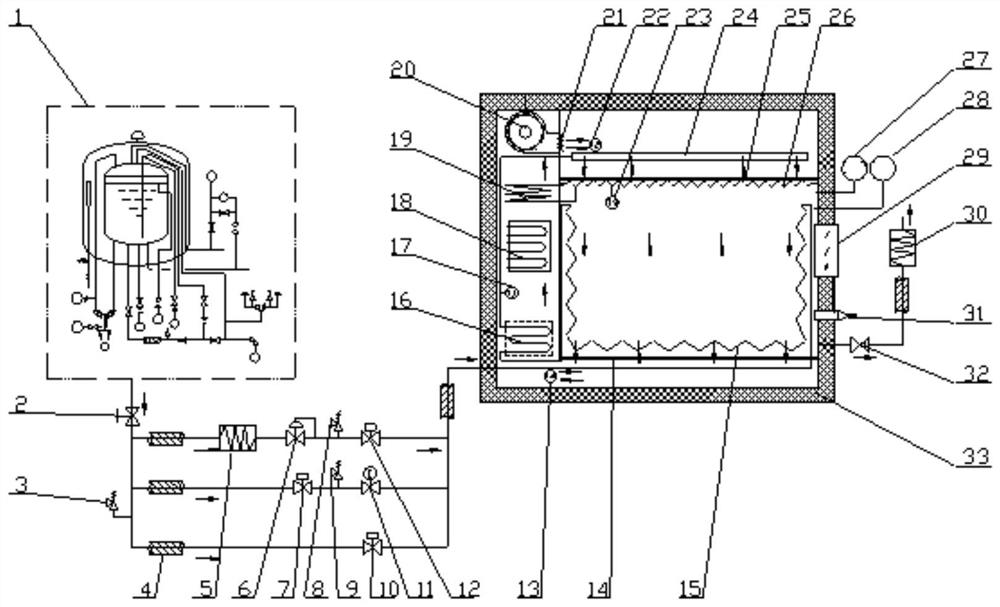

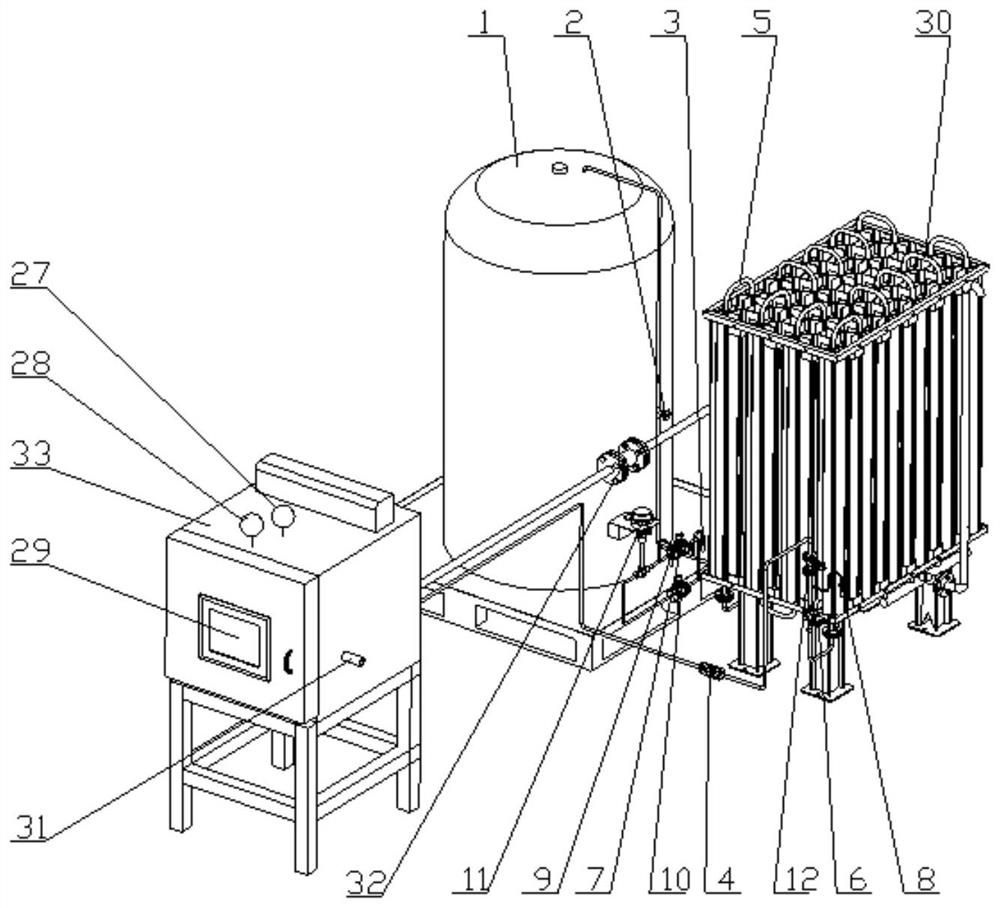

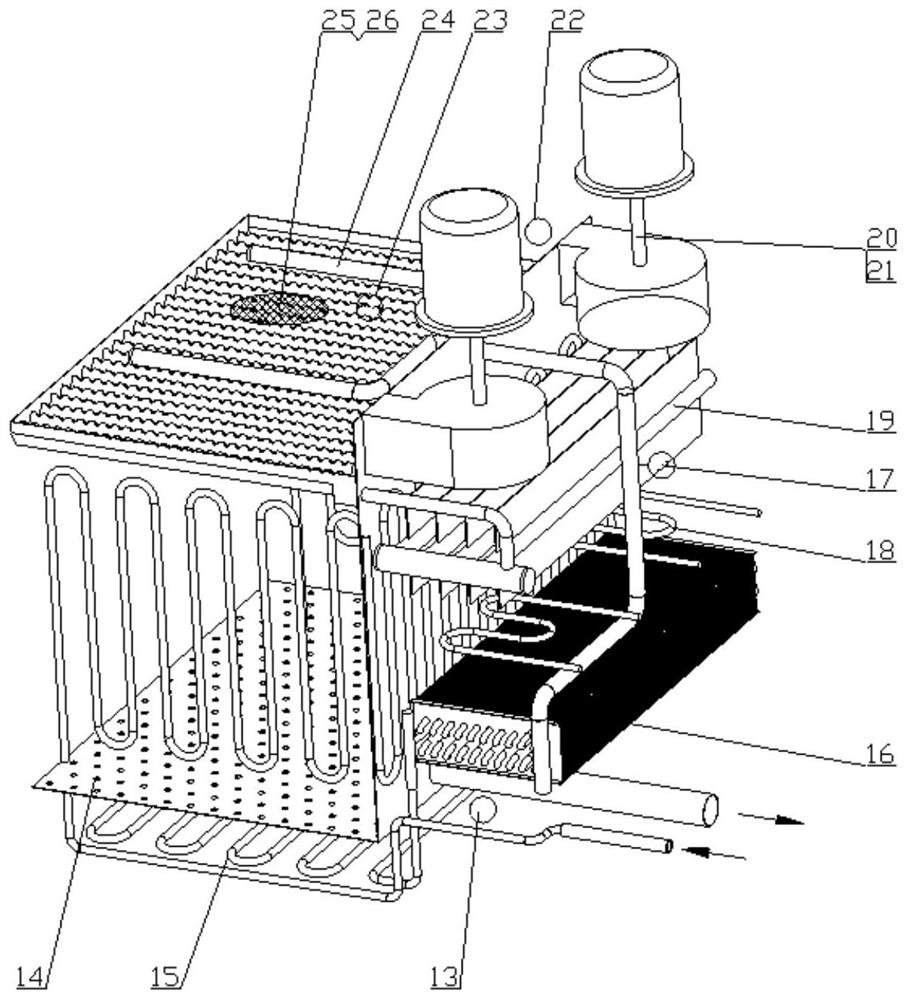

Wide-temperature range low-temperature environment test device

ActiveCN110346665AUniform temperature fieldNo effusionHeating or cooling apparatusTemperature control using electric meansHeating systemEvaporator

The invention discloses a wide-temperature range low-temperature environment test device and relates to the field of low-temperature environment test. The wide-temperature range low-temperature environment test device comprises an insulation cabin body, a liquid nitrogen supply system, a gas nitrogen generating and regulating system, a heating system, a cooling system, a high-low temperature circulation pipeline system, a liquid accumulation preventing device and a measurement control system, wherein the gas nitrogen generating and regulating system comprises a liquid nitrogen vaporizer, a nitrogen pressure reducer, a nitrogen pipeline safety valve and a nitrogen pipeline electromagnetic valve; the insulation cabin body is divided into a static pressure chamber, a work space and a circulation air passage; the heating system comprises an electric heater in the circulation air passage and a solid relay; the cooling system comprises a liquid nitrogen wall evaporator, a secondary liquid nitrogen evaporator and a liquid nitrogen evaporator in the circulation air passage; and the high-low temperature circulation pipeline system connects the insulation cabin body, the liquid nitrogen supply system, the gas nitrogen generating and regulating system, the heating system and the cooling system to form a loop. According to the wide-temperature range low-temperature environment test device,an ultralow-temperature area test temperature environment can be achieved and the wide-temperature range low-temperature environment test device is uniform in temperature field, free of a liquid accumulation phenomenon, safe and reliable.

Owner:SHANGHAI JIAO TONG UNIV

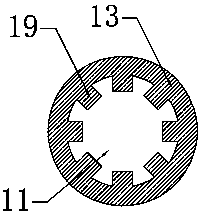

Structure used for motor rotor cooling

PendingCN107659017AReduce the temperatureLow costMagnetic circuit rotating partsCooling/ventillation arrangementElectric machineGear wheel

The invention discloses a structure used for motor rotor cooling. The structure comprises a transmission gear which is fixedly connected with one end of the rotating shaft of a rotor and arranged in atransmission shell. The center of the transmission gear and the rotating shaft is provided with a gear hollow cavity and a shaft hollow cavity which are mutually connected. One end, which is connected with the rotating shaft, of the transmission gear is provided with a back flow hole. The other end of the gear hollow cavity of the transmission gear is connected with an oil pump. The oil pump andthe back flow hole are connected with the liquid oil in the transmission. According to the scheme, the motor rotor is cooled on the basis of minimizing cost increasing; the simple oil cooling system is additionally arranged in the water cooling system for cooling and heat radiation of the rotor especially so that the temperature of the motor rotor can be reduced and the effect of protecting the rotor and magnetic steel can be realized; and the present new energy automobiles use the water cooling system, and a set of simple oil cooling system is additionally arranged so that the cost can be saved, the reliability of the product can be guaranteed and the application prospect is huge.

Owner:HEFEI JUYI POWER SYST CO LTD

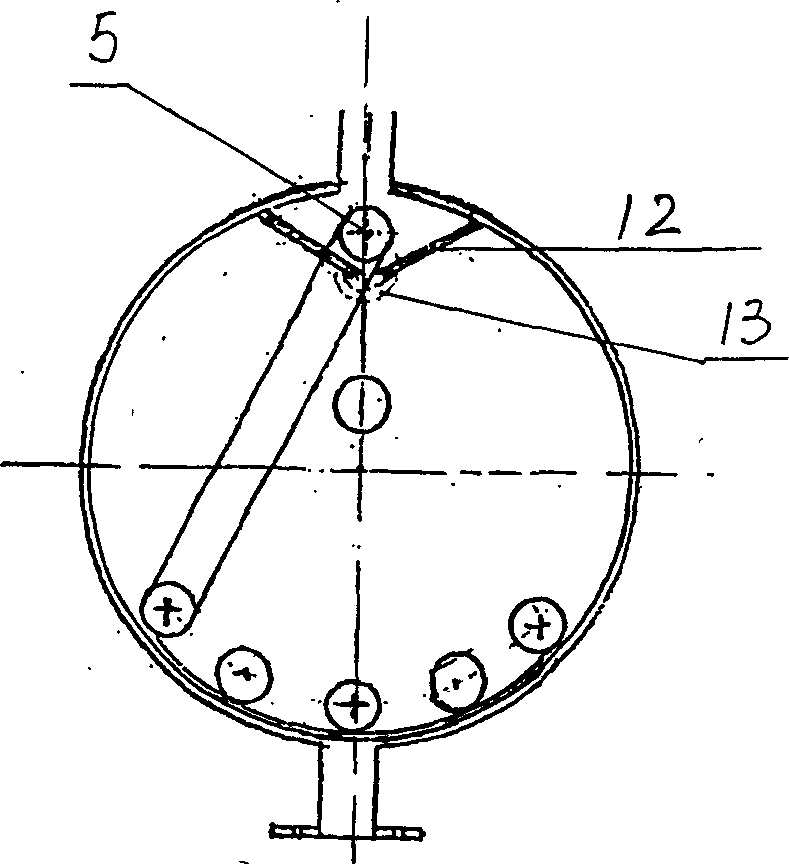

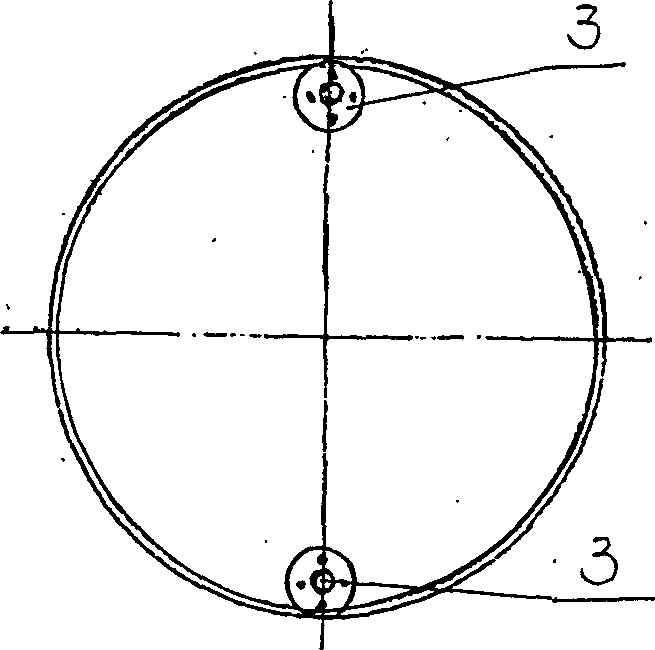

Tube type vaporization device for liquefied gas for industrial use

InactiveCN1789816ABurn fullyContinuous and stable combustionLiquid fuel feeder/distributionCombustion typesCombustorAutomatic control

This invention relates to one industry oiling tube evaporation device, which comprises Evaporation part, heating part, automatic control part, burst part and liquid supply part, wherein, the evaporation tube is one hollow tube with its inside located with heating medium recycling tube; the said evaporation tube two ends are sealed with one end located with liquid level meter connected to the evaporation tube and with the other end located with heating medium entrance, exhaust mouth and gas liquid entrance; the heating medium entrance and exhaust mouth are separately connected to the heating medium recycling tube entrance and exhaust mouth.

Owner:肖杰

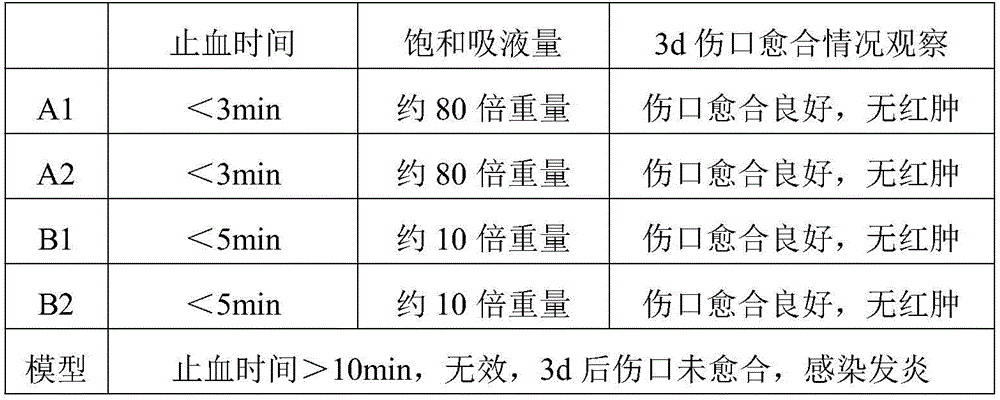

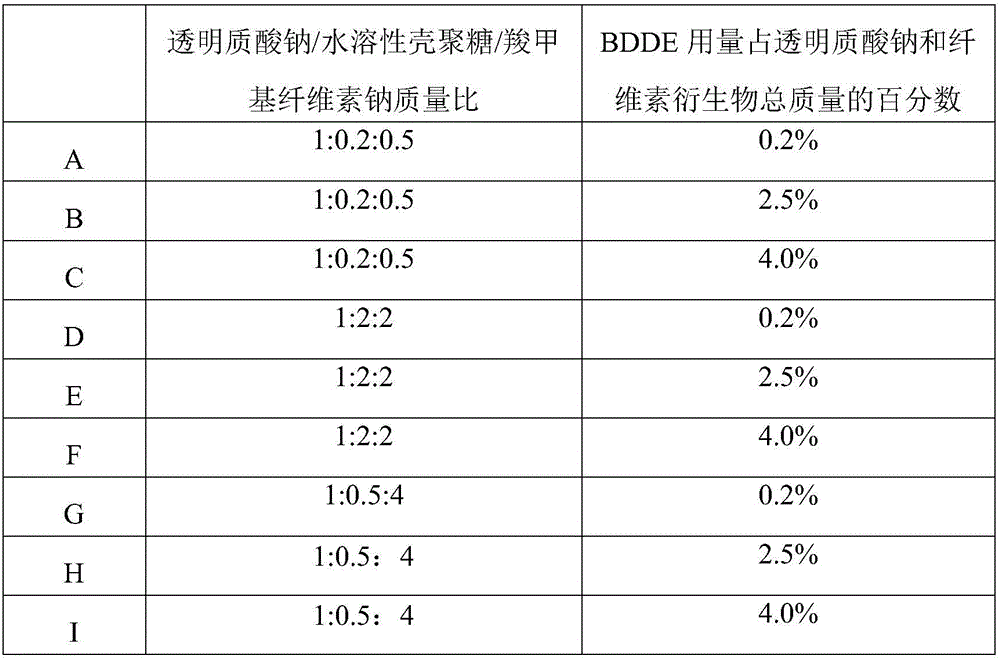

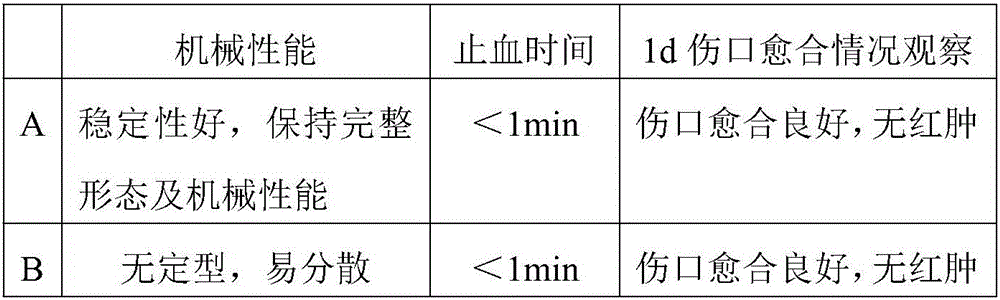

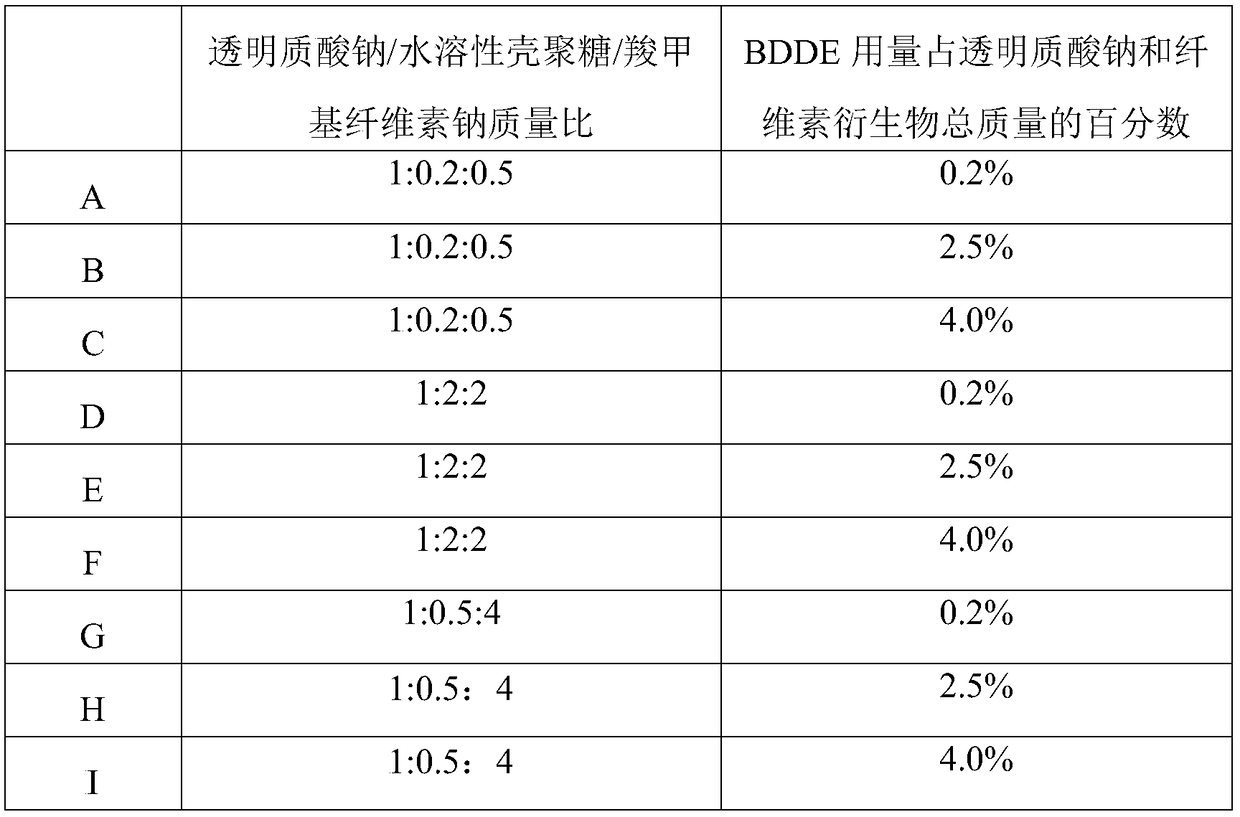

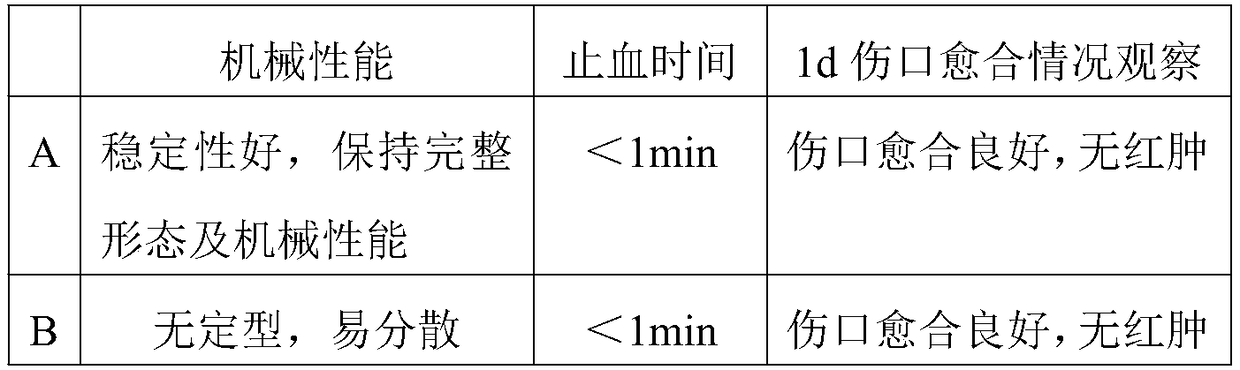

Preparation method for degradable biological wound dressing and obtained product

ActiveCN105833331AUniform textureGood biocompatibilityAbsorbent padsBandagesCross-linkWound dressing

The invention discloses a preparation method for degradable biological wound dressing and an obtained product. The preparation method comprises the following steps: first, cross-linking sodium hyaluronate and a cellulose derivative under an alkaline condition; then, cross-linking the sodium hyaluronate and the cellulose derivative under an acid condition; dialyzing, purifying and granulating the obtained cross-linked gel; uniformly mixing the cross-linked gel and chitosan aqueous solution; removing air bubbles, pouring a mixture into a mould, and drying to obtain the degradable biological wound dressing. The method disclosed by the invention is high in safety and easy and convenient to operate; a cross-linking system is prepared by one step; two-step cross-linking can be completed by only regulating the pH value; the cross-linking time is greatly shortened; industrial production is facilitated. The obtained product is high in biocompatibility and high in safety, and is suitable for liquid suction, wound protection and repair of a mild to severe seepage skin wound; secondary damage is prevented; the degradable biological wound dressing is convenient to replace and convenient to use.

Owner:BLOOMAGE BIOTECHNOLOGY CORP LTD

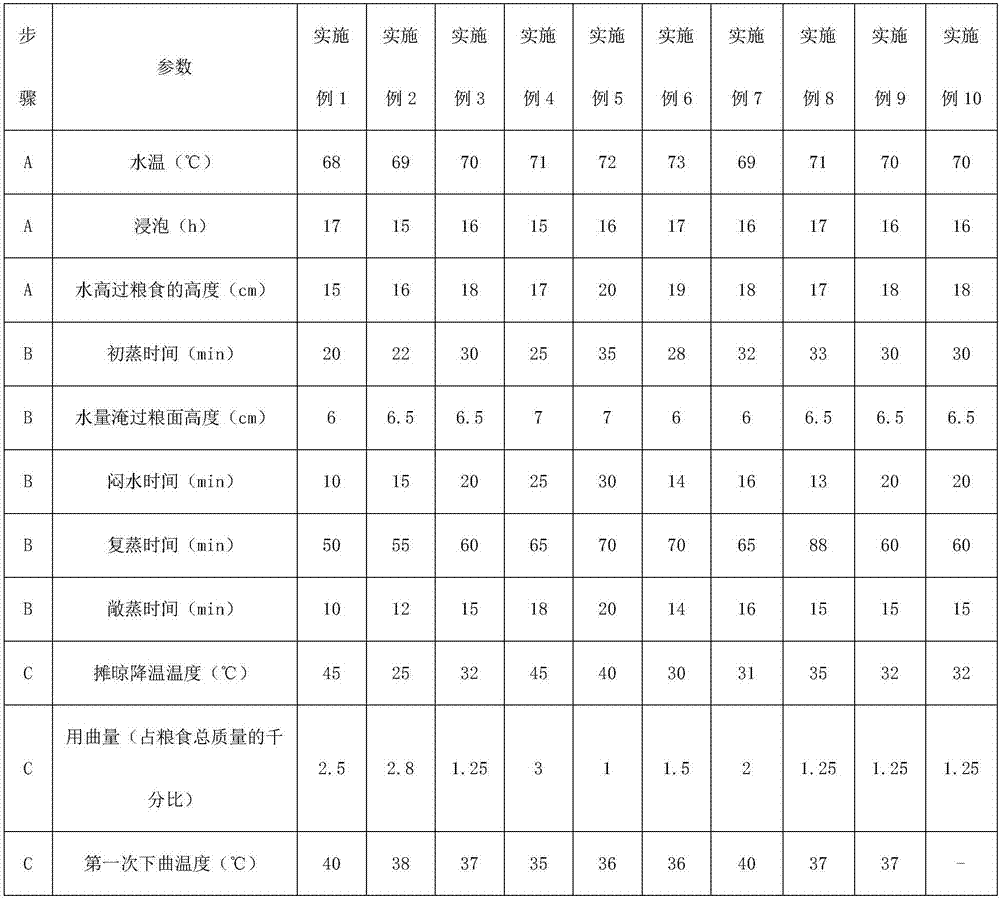

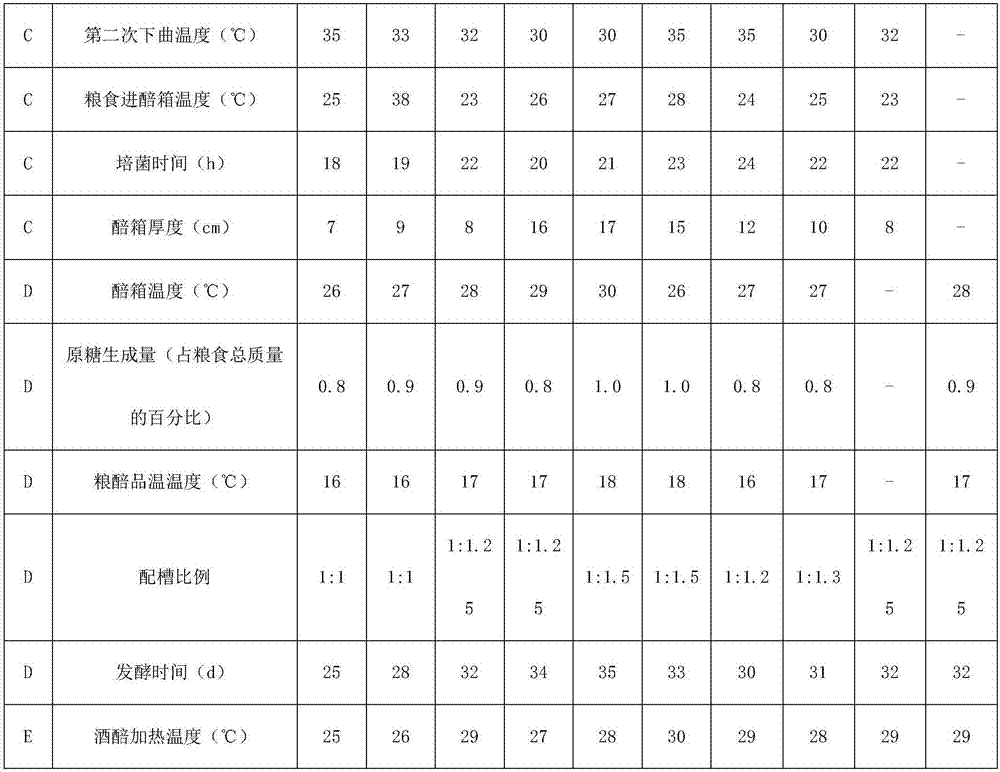

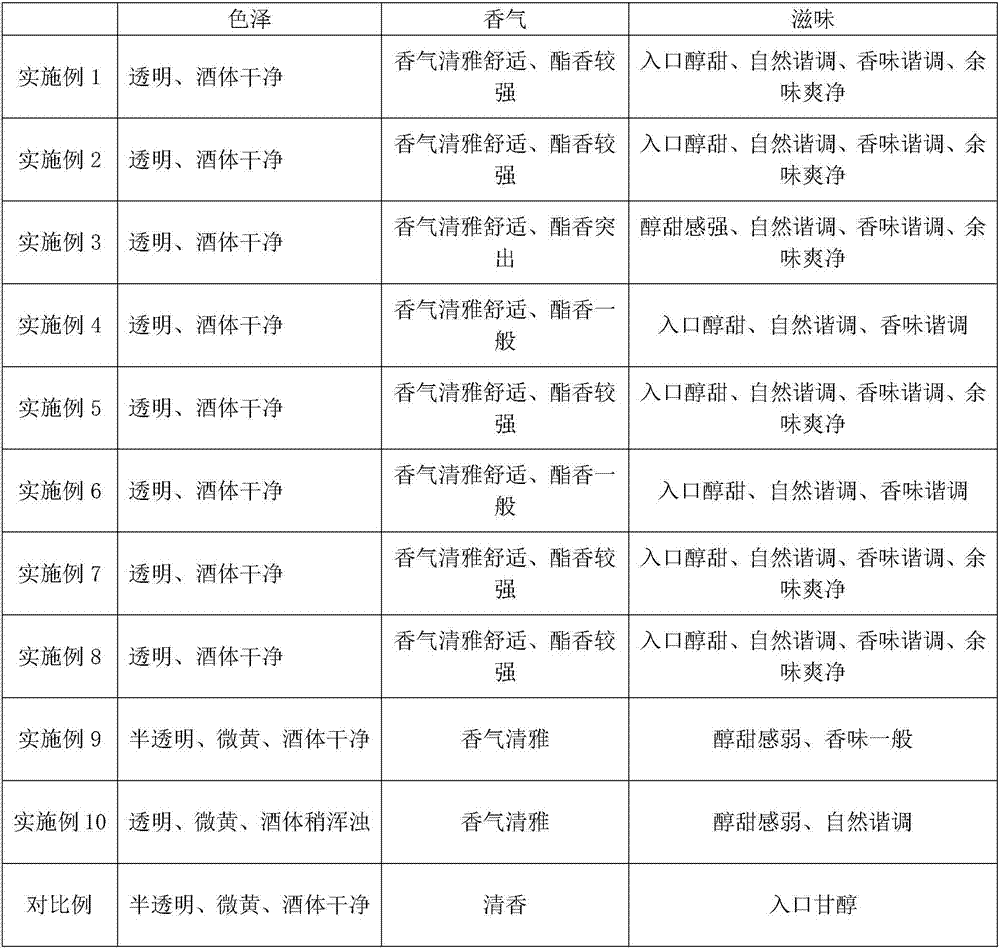

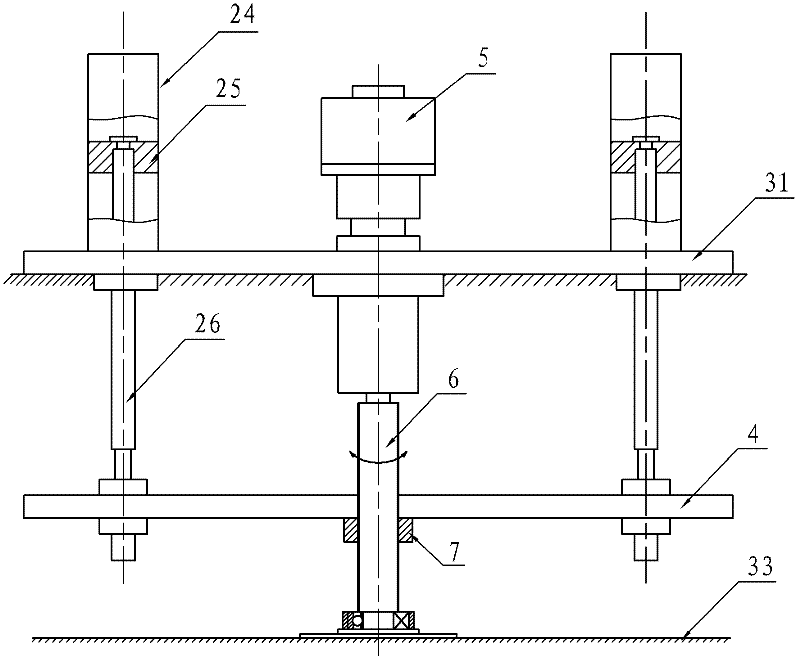

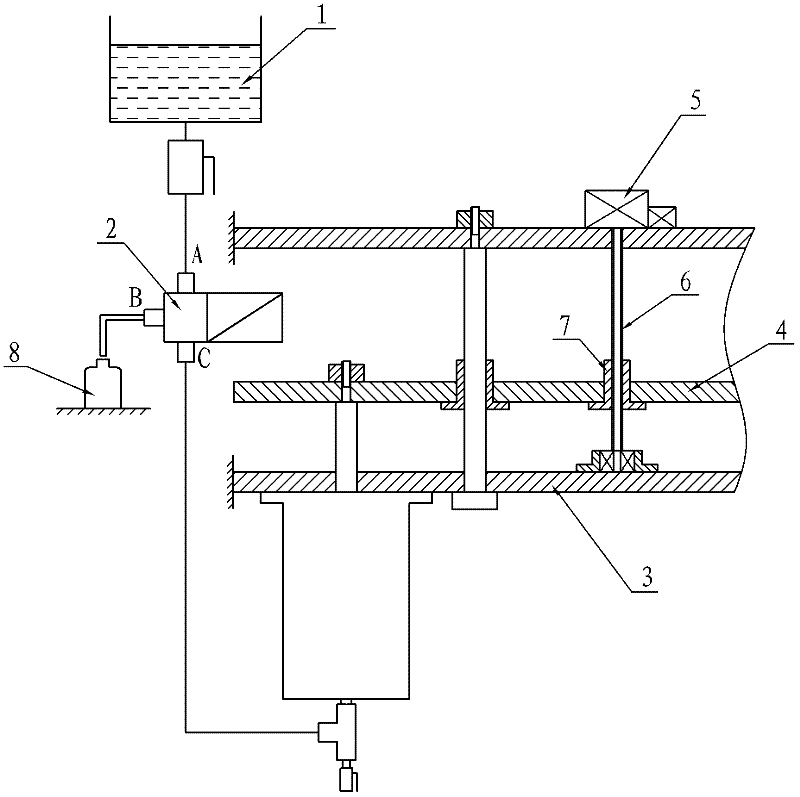

Simple brewing method of baijiu

ActiveCN107227237AIncrease return speedEnhanced transfer processAlcoholic beverage preparationAlcoholDistillation

The invention discloses a simple brewing method of baijiu, which comprises the following steps: A, soaking, B, cooking, C, low-temperature cultivation, D, low-temperature diastatic fermentation and E, distillation. Compared with the prior art, the baijiu produced by the simple brewing method of the baijiu has unique typical style characteristics of faint scent, purity, softness, elegance, comfort, soft, sweet and mellow taste, smoothness, nature, harmony and clear remaining taste; the baijiu with 'faint scent, purity, softness and tastiness' quality is very close to a style of international distilled liquor; however, the baijiu has the characteristics that the baijiu is soft, sweet, clear, pure, and comfortable, people are not drunk after drinking the baijiu, a drunkenness degree is low, and an alcohol effect is dispelled quickly; the baijiu is very popular with massive drinking consumers.

Owner:重庆江记酒庄有限公司

Multichannel synchronous filling device of liquid filling machine

The invention relates to a multichannel synchronous filling device of a liquid filling machine, which comprises a liquid storage bath, a filling unit, a mount, a lifter plate, a servo motor, a ball screw and a screw-nut sleeve. the servo motor is fixed on a fixed plate of the mount, the screw-nut sleeve is fixed on the lifter plate and is in screwed fit with the ball screw; in the filling unit, a filling cylinder is in ceiling mounting, the body of a cylinder sleeve towards downward, a piston rod towards downward, a three-way connection is provided on the lower end face of the filling cylinder, a three-way valve is connected between the liquid storage bath and the three-way connection through a flexible pipe, the discharge hatch of the three-way valve is connected with a filling nozzle. The structure of the invention has no bubbling and draining phenomena, and is capable of saving the filled raw materials, and avoiding accident damage on operators caused by the leakage of the materials, the filling machine can reach maintenance-free requirement. The power consumption for driving lifting is low, so that the energy and the cost can be saved. The product type can be replaced in a convenient and fast mode, so that the user requirement can be satisfied.

Owner:常州市金坛新鑫包装机械有限公司

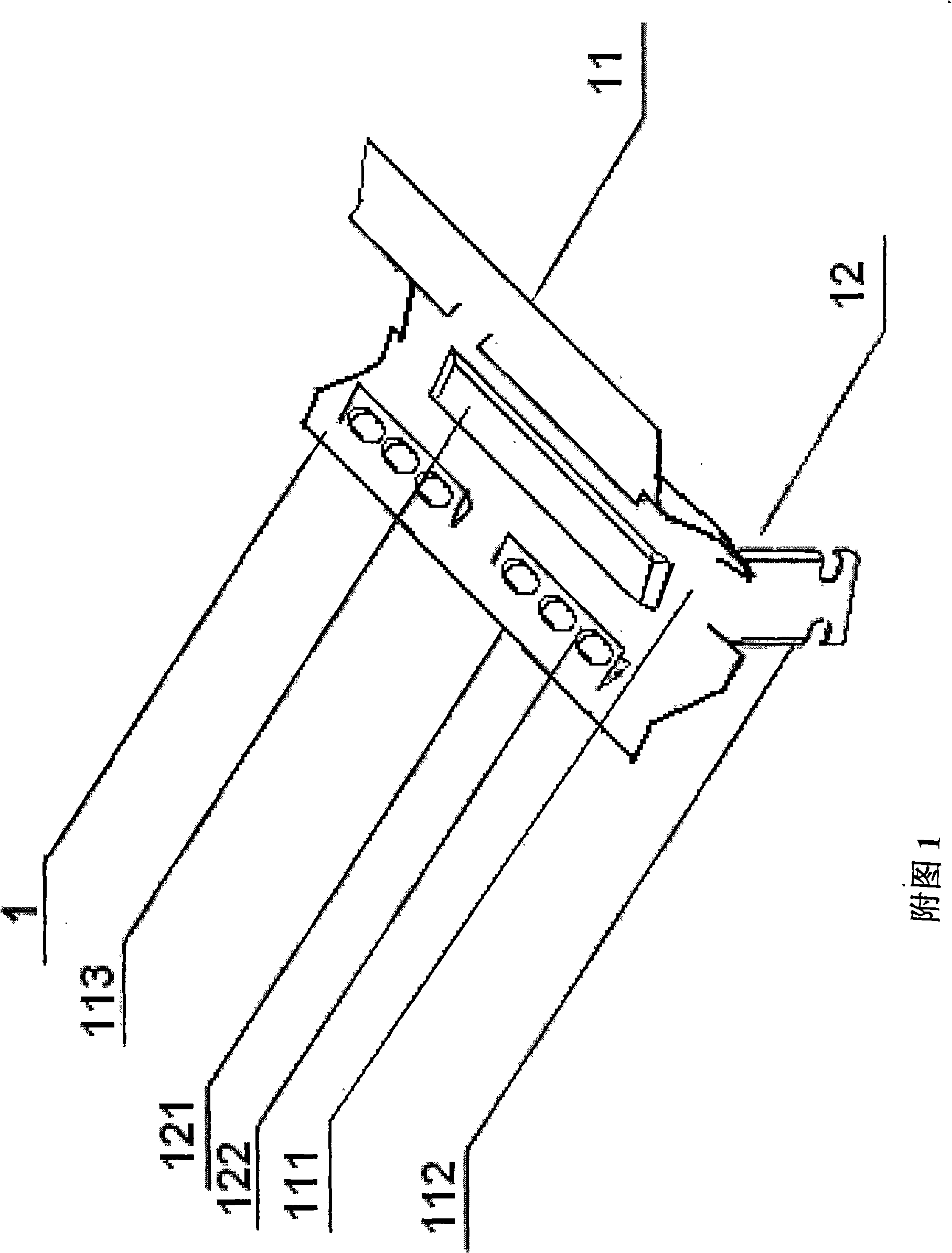

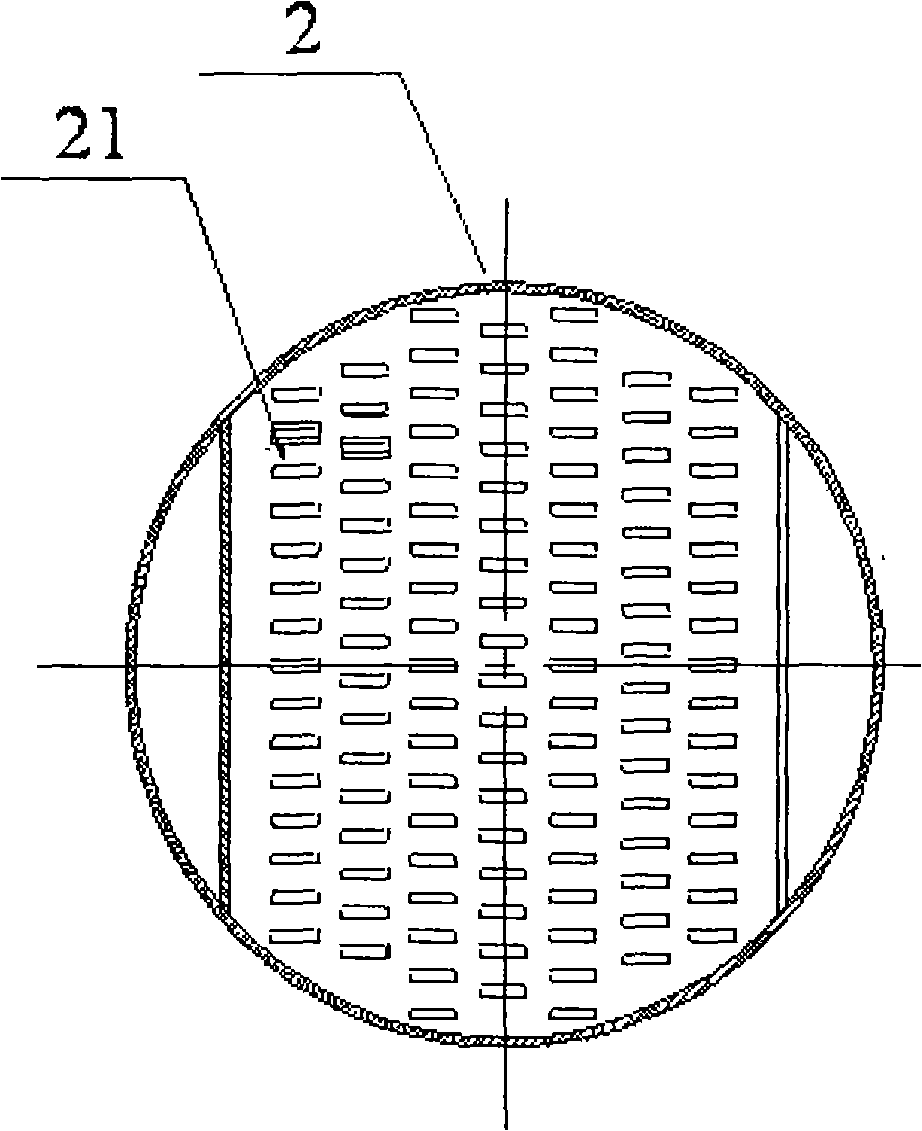

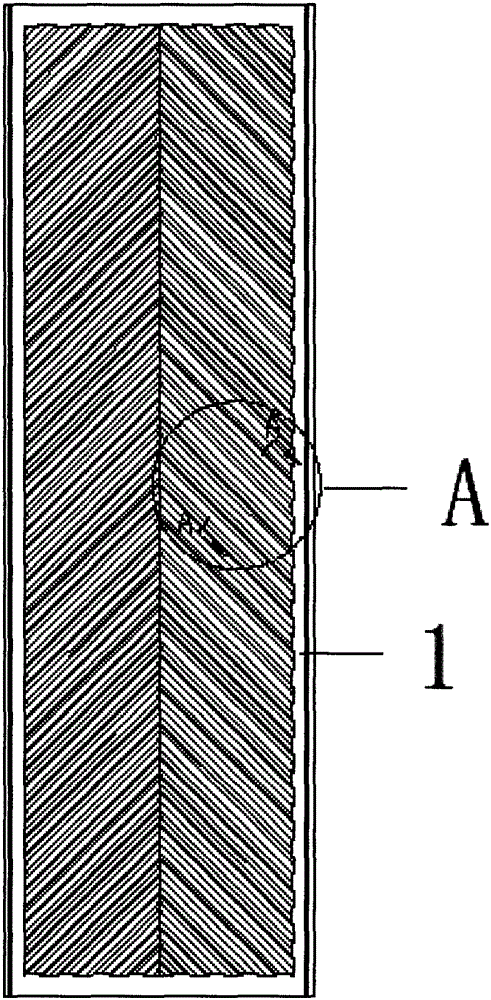

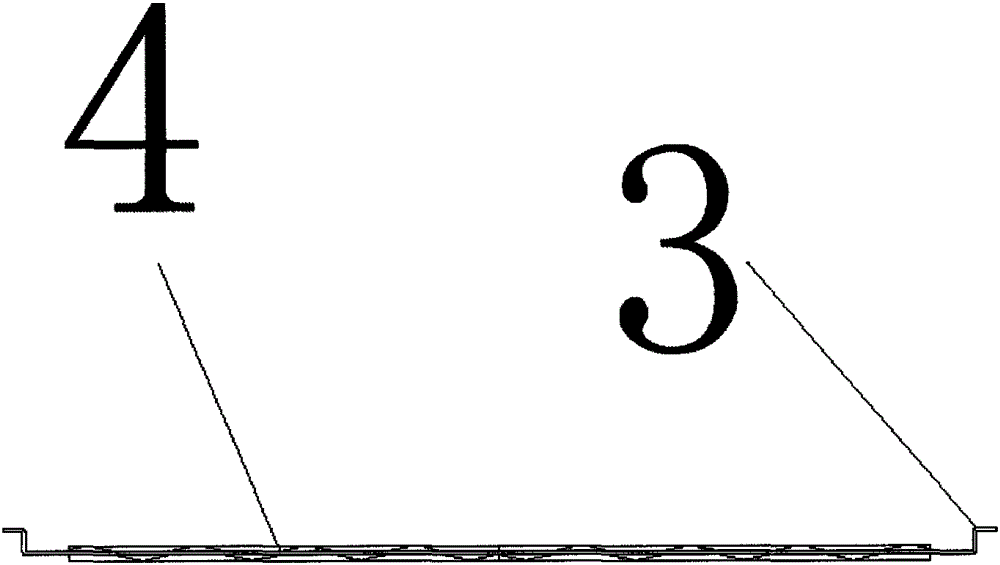

A packing float valve plate

InactiveCN101279143AReduce leak rateIncrease contact areaFractional distillationPressure systemLow voltage

The invention relates to a stuffing floating valve tray which consists of a floating valve (1) and a tray (2). The floating valve (1) is installed in a valve opening (21) and is hung at the tray (2). The stuffing floating valve tray is characterized in that the floating valve (1) has a rectangle structure formed by a valve body (11) and a stuffing part (12); the valve body (11) consists of a valve plate (111) and a valve leg (112); the stuffing part (12) is positioned at the upper part of the valve body (11), and is connected with the valve body (11). Compared with the prior art, the stuffing floating valve tray integrates the characteristics of the floating valve tray and that of the stuffing, thus not only having the advantages of large stuffing interface contact area, comparatively low voltage drop and comparatively high tray efficiency, but also being characterized in that the floating valve tray has large operation flexibility and high processing ability. The stuffing floating tray is applicable to regular type gas-liquid tower devices and ultra-large type gas-liquid tray devices with normal pressure system and pressurized system.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

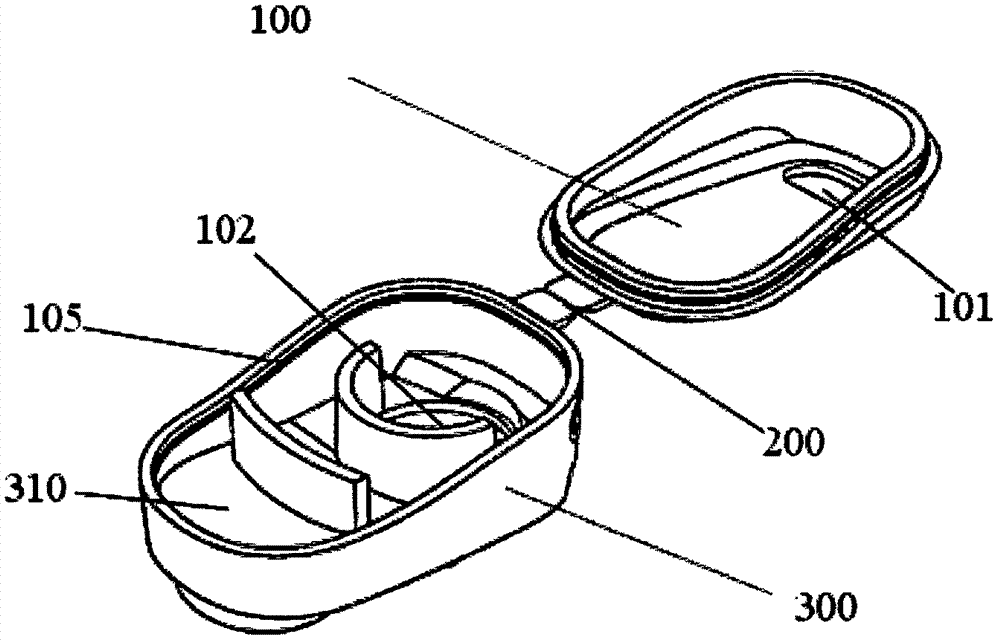

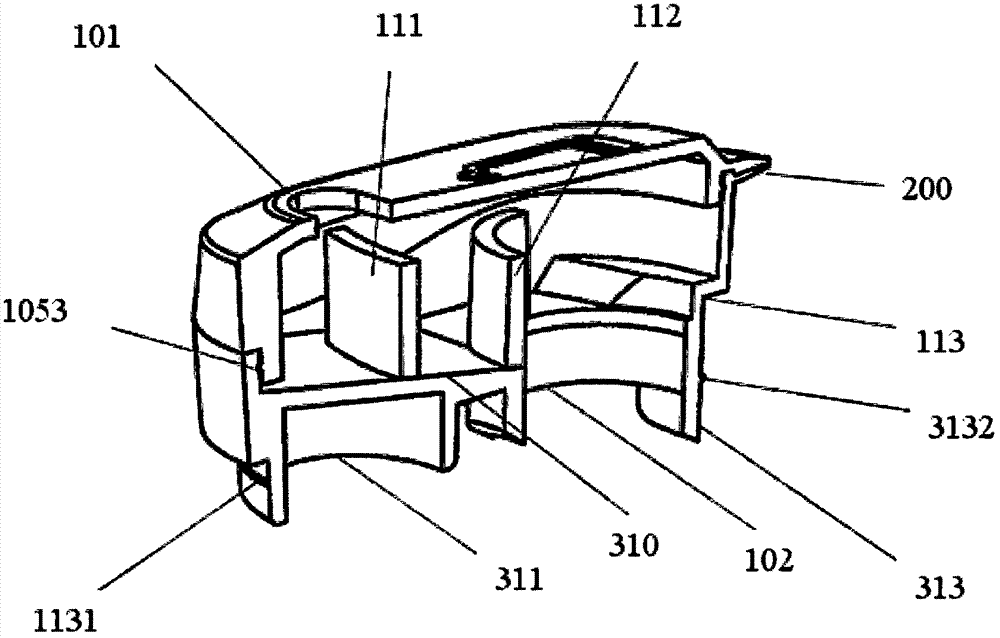

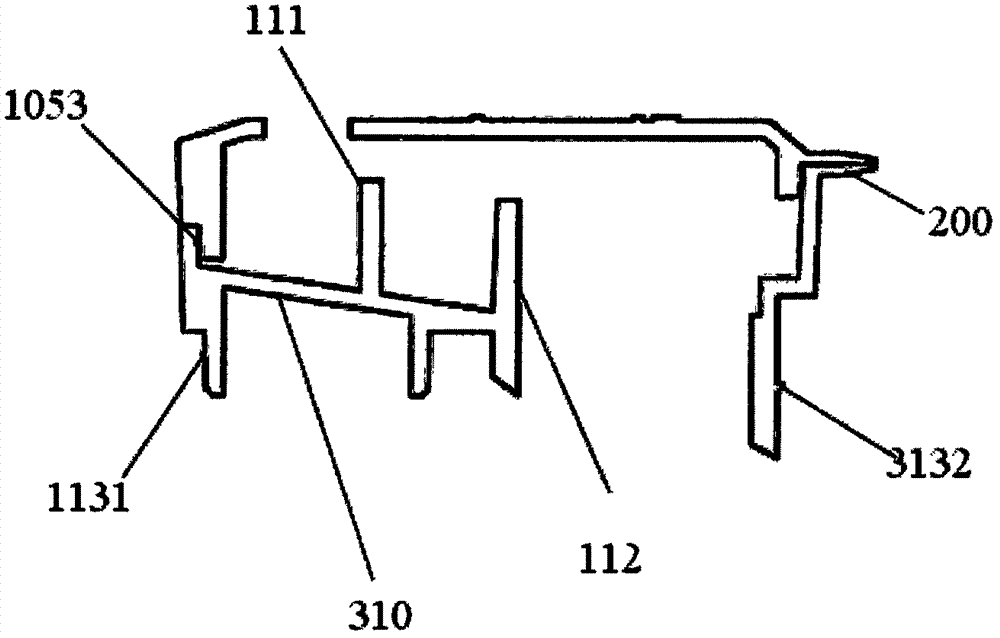

Cup plug, leak-proof assembly, and preparation method

The application of the invention discloses a cup plug and a leak-proof assembly. The cup plug is provided with a cup plug cap and a cup plug body, wherein a guiding flow return device is arranged in the cup plug body; and the cup plug cap is connected with the cup plug body through a tail folding connection part. The cup plug disclosed by the invention has the advantages that the structure is simple; and the guiding flow return device is arranged in the cup plug body, so that during delivery, under the condition that an delivered cup product is placed in a delivery box or a carry-on bag, the phenomenon that beverage spills or leaks due to jolting during delivery or shaking in hands can be avoided. Through the adoption of the cup plug, gas in a cup can be exhausted in time, and besides, when hot drink is loaded in the cup with the cup plug, through the structure of the cup plug, guiding flow return can be effectively performed on the liquid which enters the cup plug during shaking, so that, in operation, the phenomenon that during the delivery of the hot drink, a cup cap is pushed out of the paper cup by heat expansion gas is avoided; and the phenomenon that the liquid is gathered at the mouth of the cup is avoided.

Owner:SHANGHAI LIANJUAN BUSINESS CONSULTING

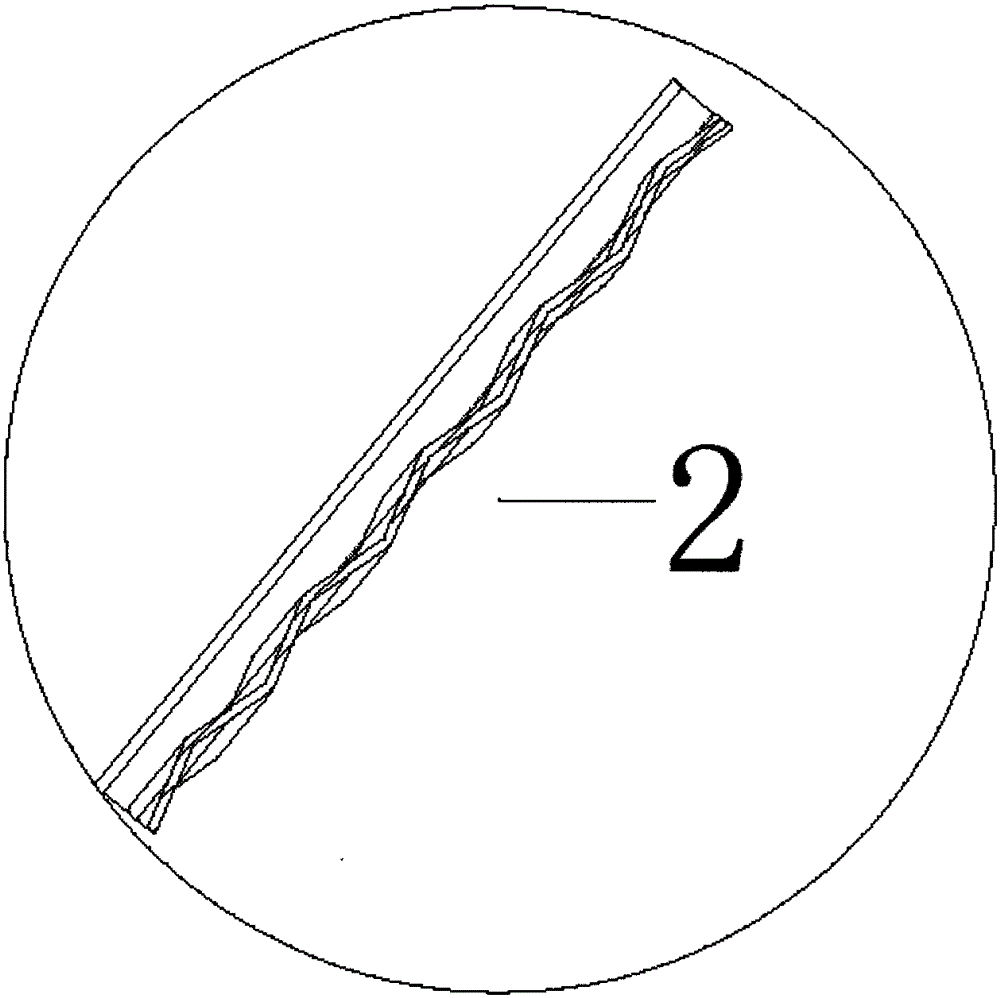

Natural silk sericin-free silk fibroin core and application thereof

InactiveCN102327644AHigh mechanical strengthDoes not cause discomfortSurgeryProsthesisHuman bodySILK SERICIN

The invention discloses novel application of a natural silk sericin-free silk fibroin core to preparation of a medical surgical instrument for human bodies. The natural silk sericin-free silk fibroin core has high mechanical property, high flexibility and an appropriate degradation speed. As proved by an in-vivo experiment on an animal, the natural silk sericin-free silk fibroin core is immune to exclusive reactions and toxic reaction, and is a good material for preparing various in-vivo medical instruments.

Owner:邱轶伟

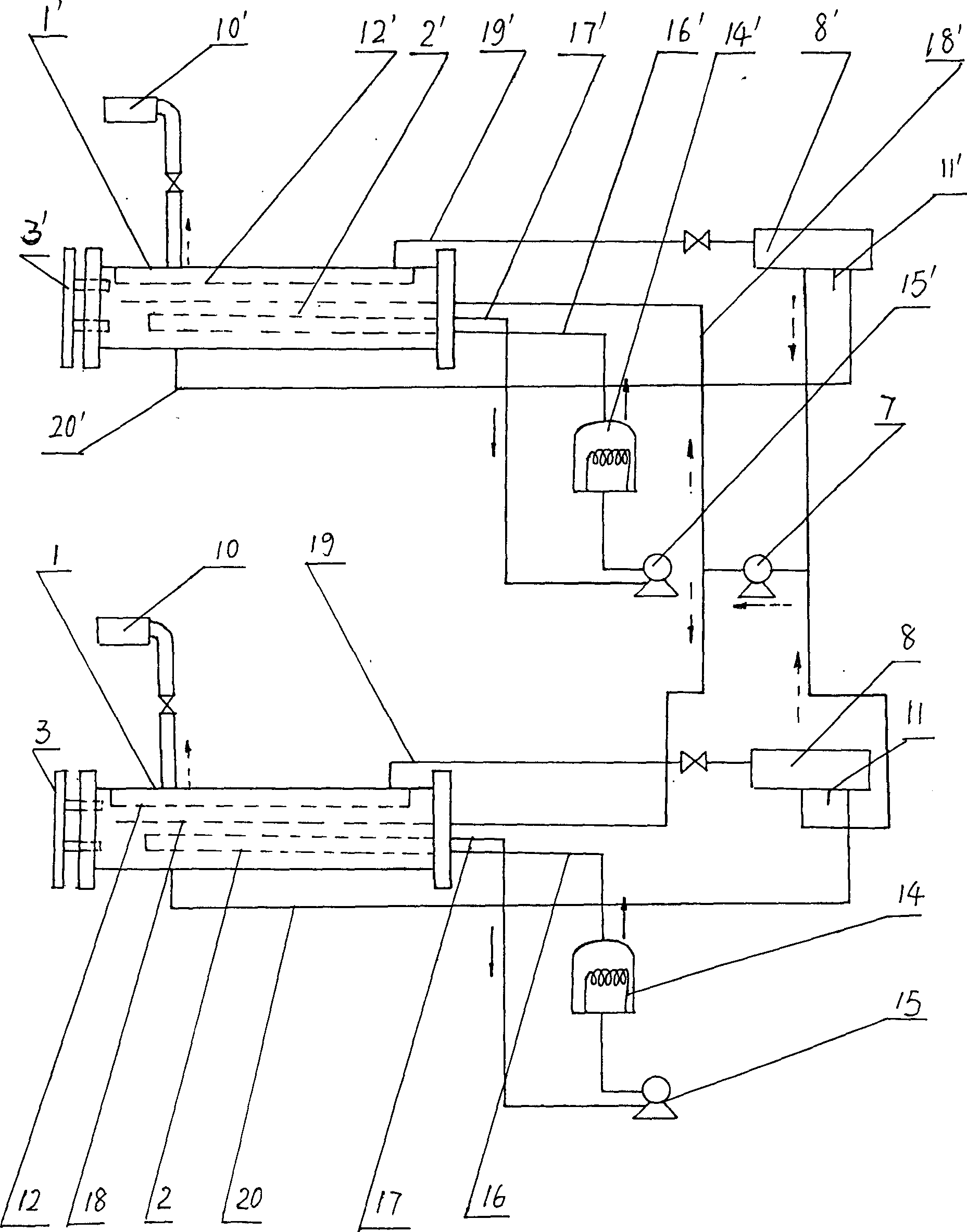

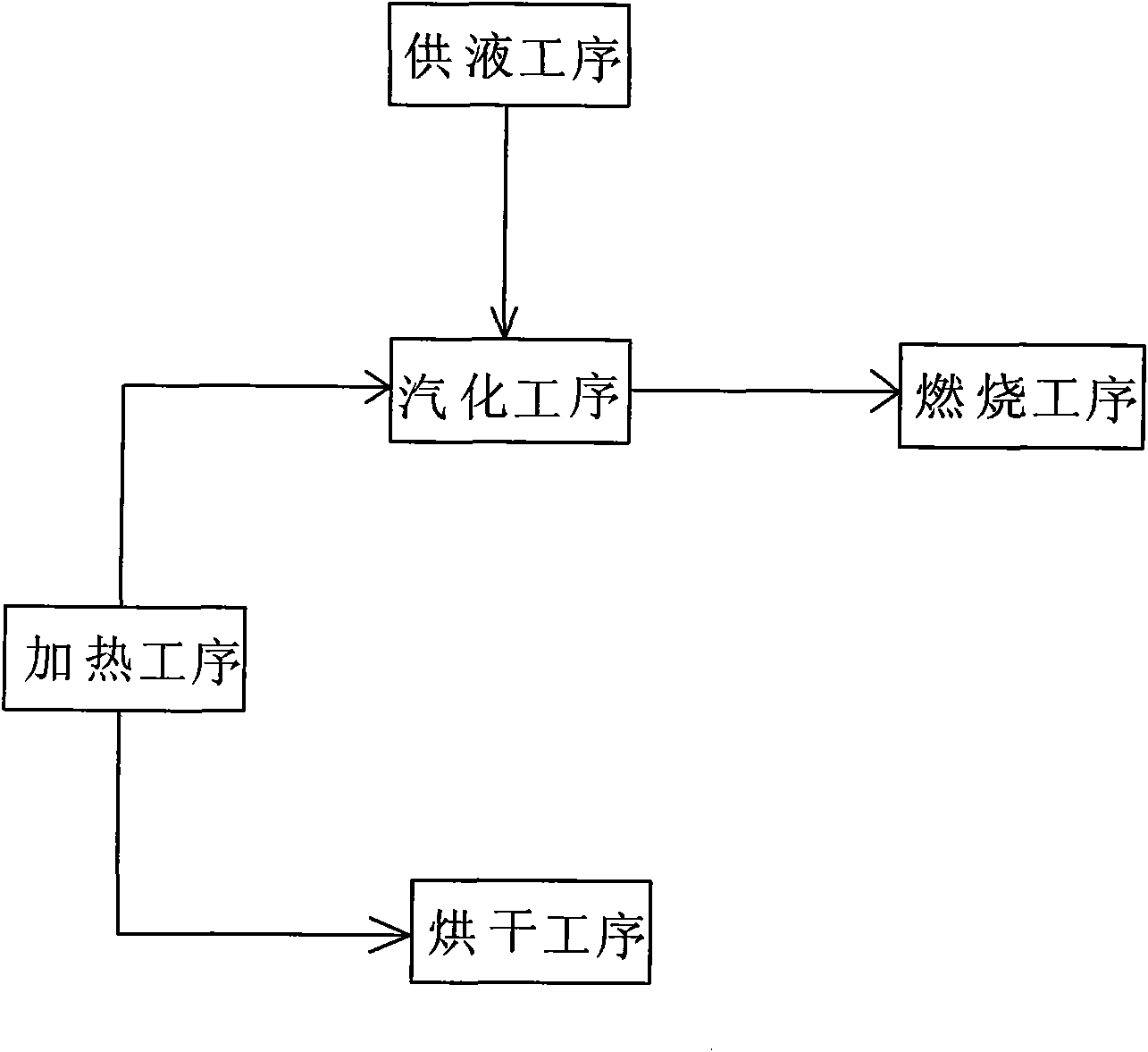

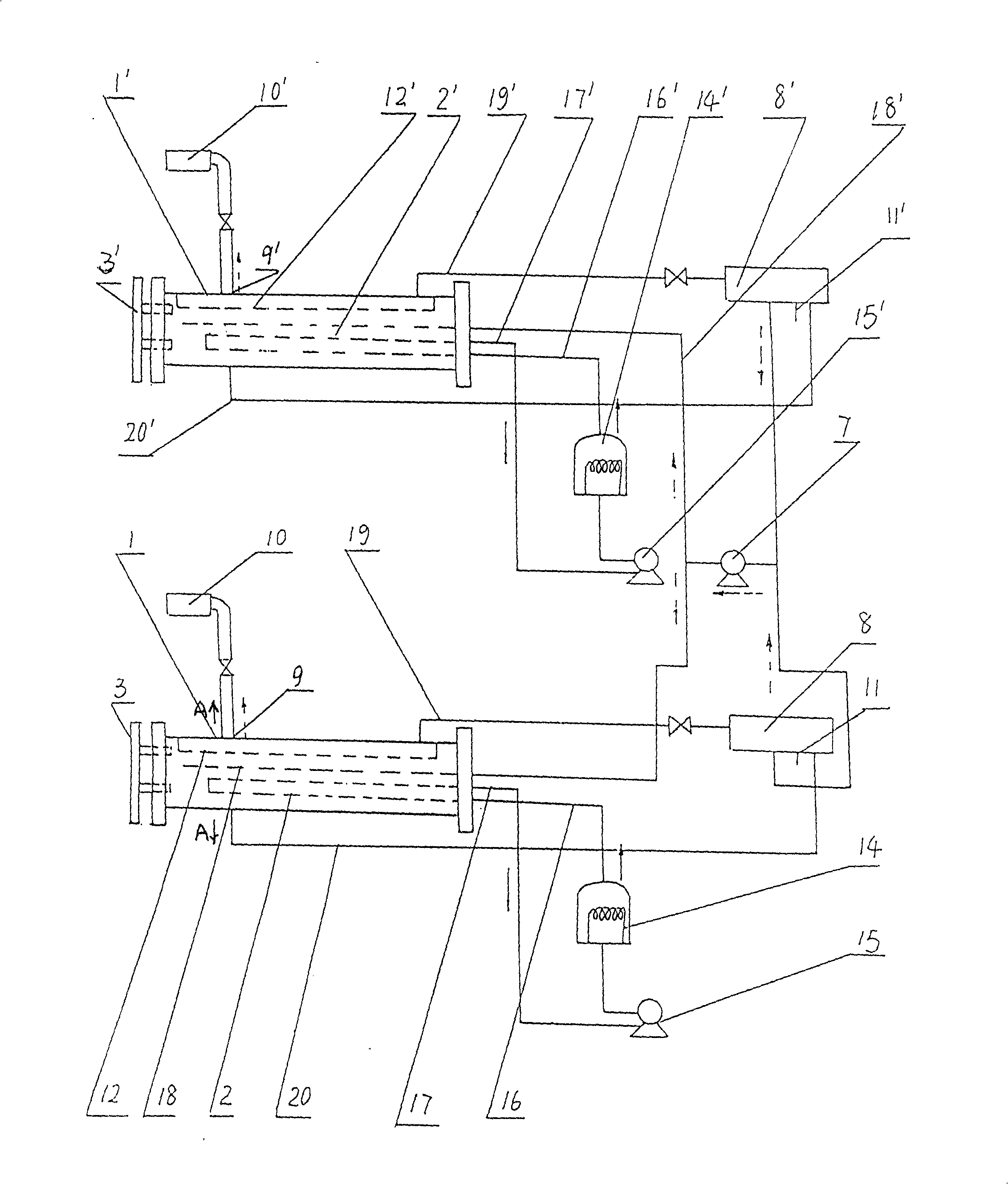

Process and device thereof for vaporizing petroleum gas by heat transfer oil for ceramic industry

InactiveCN101592342AReduce high temperature oxidation rate and gel thickening rateExtended service lifeCombustion using gaseous and pulverulent fuelLiquid fuel feeder/distributionAutomatic controlPetroleum

The invention relates to a process and a device thereof for vaporizing petroleum gas by heat transfer oil for the ceramic industry. The process comprises a liquid supply procedure, a heating procedure, a vaporizing procedure and a burning procedure, and also comprises a drying procedure, wherein in the drying procedure, the drying temperature of a ceramic die is between 65 and 75 DEG C, and the drying temperature of a ceramic blank is between 80 and 90 DEG C. The device comprises a vaporizing part, a heating part, an automatic control part, a burning part, a liquid supply part and a drying part, wherein the vaporizing part comprises a vaporizer, the burning part comprises a burner, the liquid supply part comprises a liquid storage tank, the drying part comprises a drying room, and the heating part comprises a heat transfer oil furnace; a heating source is arranged in the heat transfer oil furnace which is connected with an overflow barrel through a pipeline; an output end of the heat transfer oil furnace is connected with the vaporizer and the drying room through the pipeline and a circulating pump respectively; and the vaporizer and the drying room are connected with the heat transfer oil furnace through respective output pipes respectively to form a heat transfer oil circulating loop.

Owner:方国良 +1

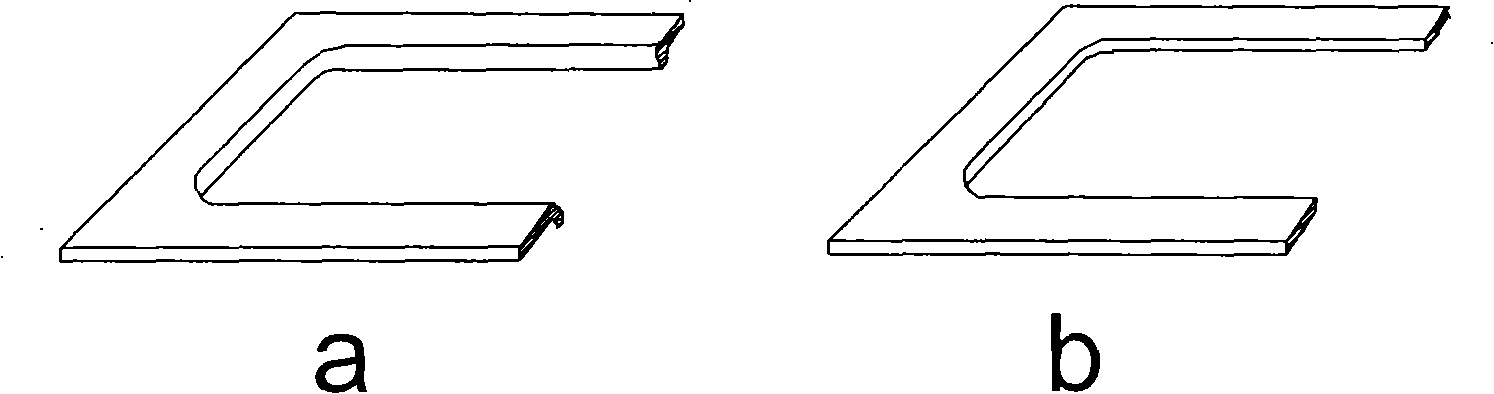

Fin plate type heat exchanger

InactiveCN106556274ASimple structureSmall pressure dropLaminated elementsStationary plate conduit assembliesEngineeringPlate fin heat exchanger

The invention relates to a fin plate type heat exchanger, in particular to a heat exchanger in a condensation method VOCs organic gas recovering device. At present, a plate type heat exchanger adopted in a condensation method device has the main problems that the pitch of fins is small, pressure drop is large and accumulated water exists. The fin plate type heat exchanger aims to overcome the defects in the prior art and is simple in structure, small in pressure drop, free of accumulated water and easy to manufacture. Rectangular stainless steel sheets are pressed into sheets covered with Y-shaped concave-convex corrugated plates, and V-shaped fins are connected to the surfaces of the sheets. The faces, without the fins, of two sheets are folded, flat steel is embedded in the periphery of the faces, thus the faces are closed, and fin plate type heat exchanger elements are obtained, wherein the middle of each element is provided with concave-convex corrugation gaps, the surface of the outer side of each element is covered with the V-shaped fins, and holes are formed in the opposite angles of each element and connected with pipes to form cold gas logistics inlet and outlet channels; and a plurality of elements are overlapped neatly, and the adjacent spaces of the elements form hot gas logistics channels. An end socket and a connecting pipe are installed on an inlet and an outlet of the two ends of each channel correspondingly, and manufacturing of the fin plate type heat exchanger is completed. Two kinds of gas different in temperature reversely pass through the respective logistics channels to complete sheet dividing wall type heat exchange, and organic gas is condensed and liquefied.

Owner:张丽 +1

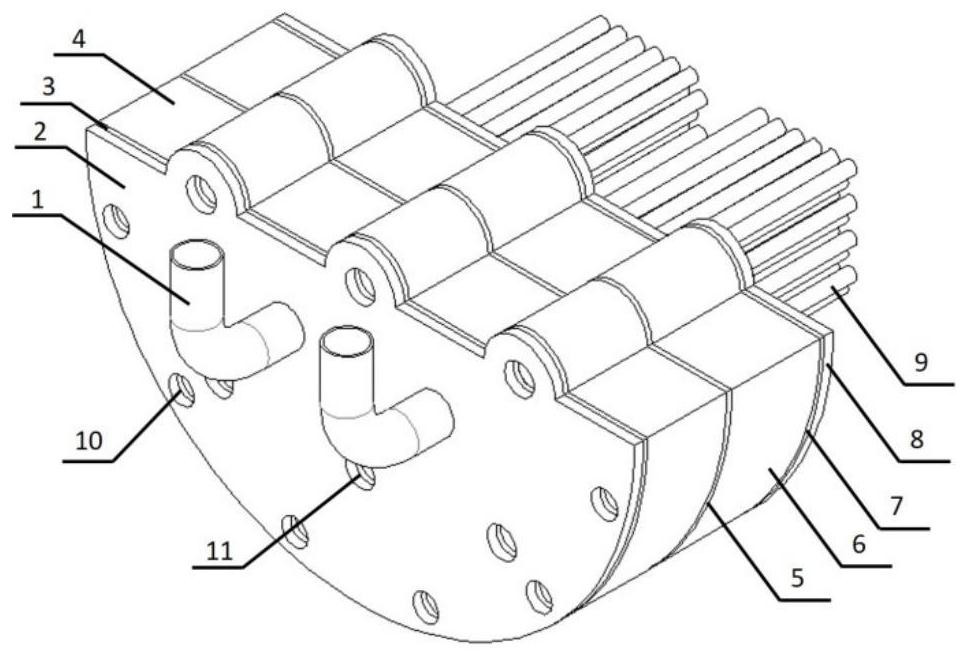

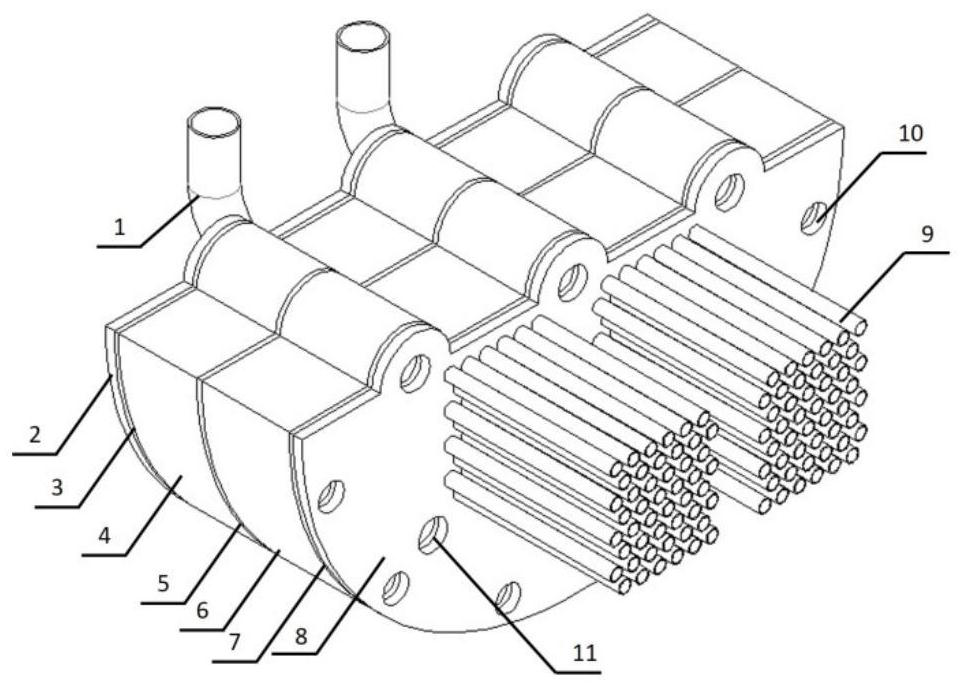

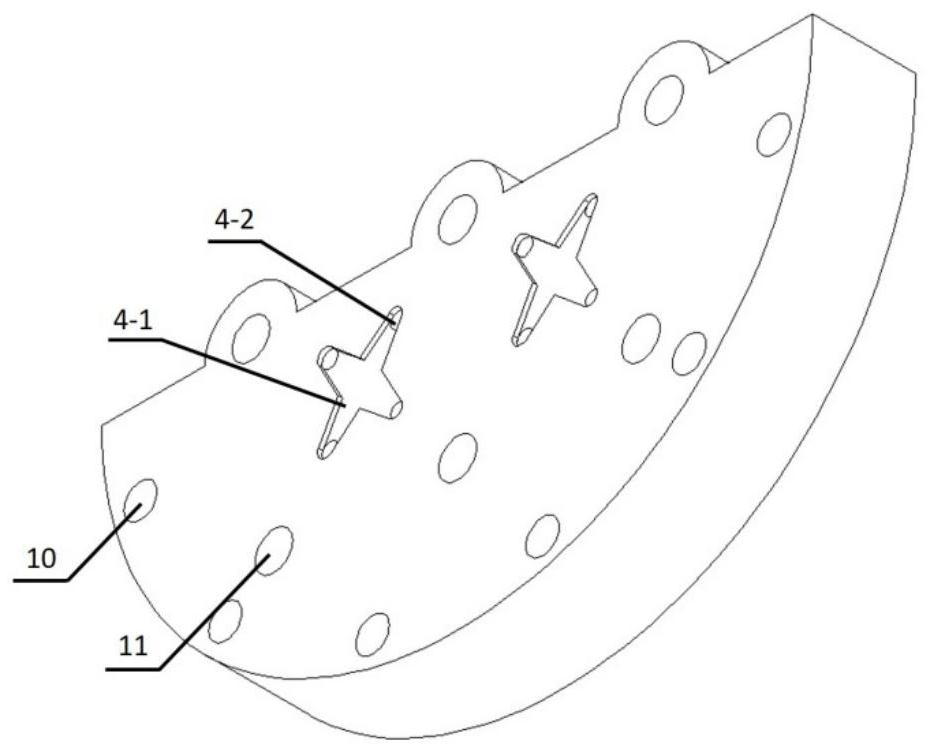

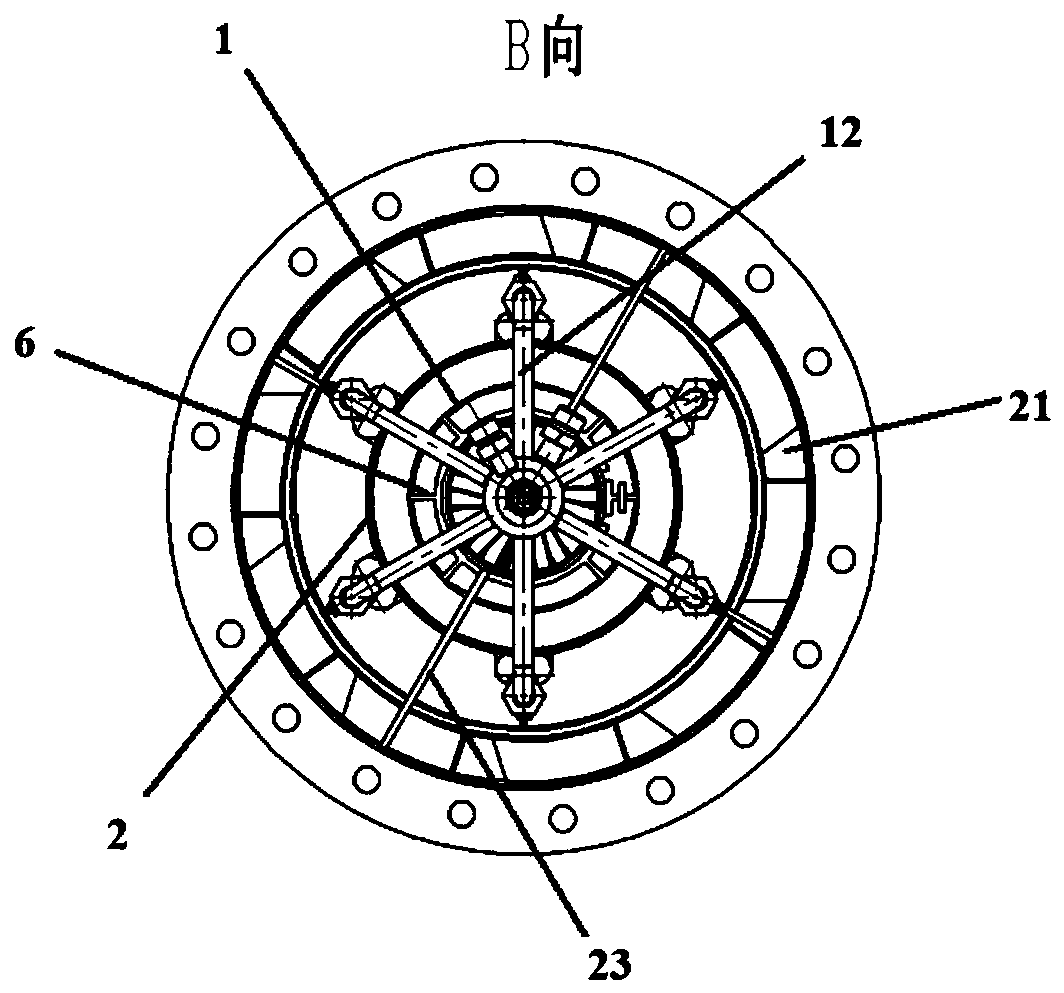

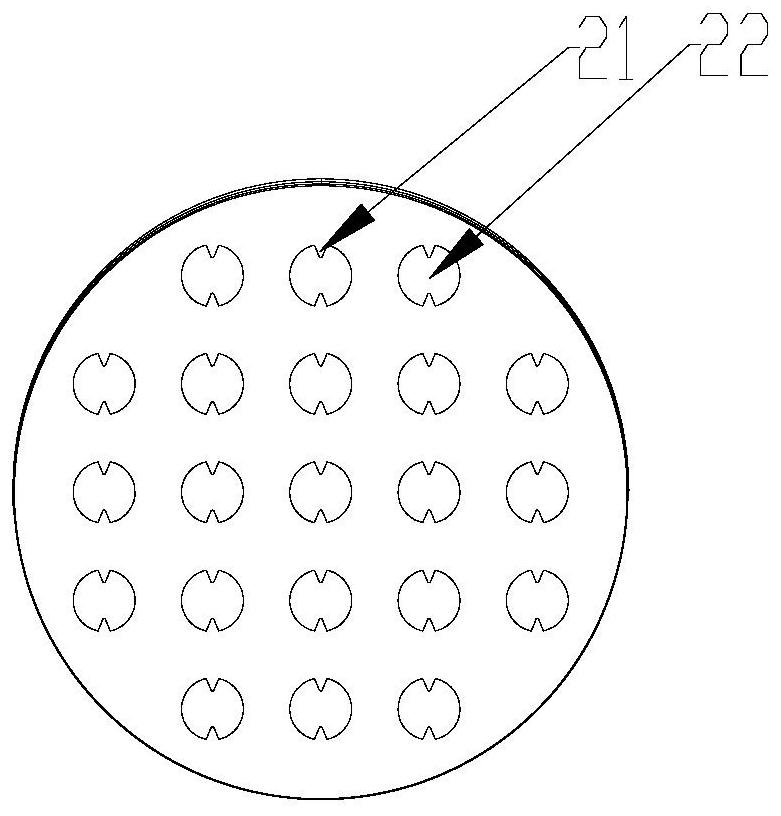

Refrigerant flow equalizing device for shell-and-tube heat exchanger

ActiveCN112923608AEvenly distributedAvoid resistanceEvaporators/condensersFluid circulation arrangementWire cuttingEngineering

The invention discloses a refrigerant flow equalizing device for a shell-and-tube heat exchanger. The refrigerant flow equalizing device comprises an inlet tube, an end cover plate, a first-stage distributor, a second-stage distributor, a tube plate and a heat exchange tube, wherein the end cover plate is arranged on one side of the first-stage distributor, the other side of the first-stage distributor is connected with the second-stage distributor, the tube plate is arranged on one side of the second-stage distributor, and the heat exchange tube is arranged on the tube plate; a first-stage cross-shaped distribution flow channel is machined in the side wall, close to the end cover plate, of the first-stage distributor, and the inlet tube penetrates through the end cover plate to communicate with the first-stage cross-shaped distribution flow channel; and a second-stage cross-shaped distribution flow channel is machined in the side wall surface, close to the first-stage distributor, of the second-stage distributor, and a third-stage distribution flow channel is machined in the other side of the second-stage distributor. According to the refrigerant flow equalizing device, a refrigerant working medium in the inlet tube is evenly distributed into the heat exchange tube, the overall working medium efficiency of the heat exchanger is improved, the flowing resistance and pressure drop in the distributor are reduced, waste of the heat exchange area caused by uneven working medium distribution is avoided, machining can be carried out through simple machining methods such as linear cutting and milling, and large-scale manufacturing and popularization are convenient.

Owner:江苏世林博尔制冷设备有限公司

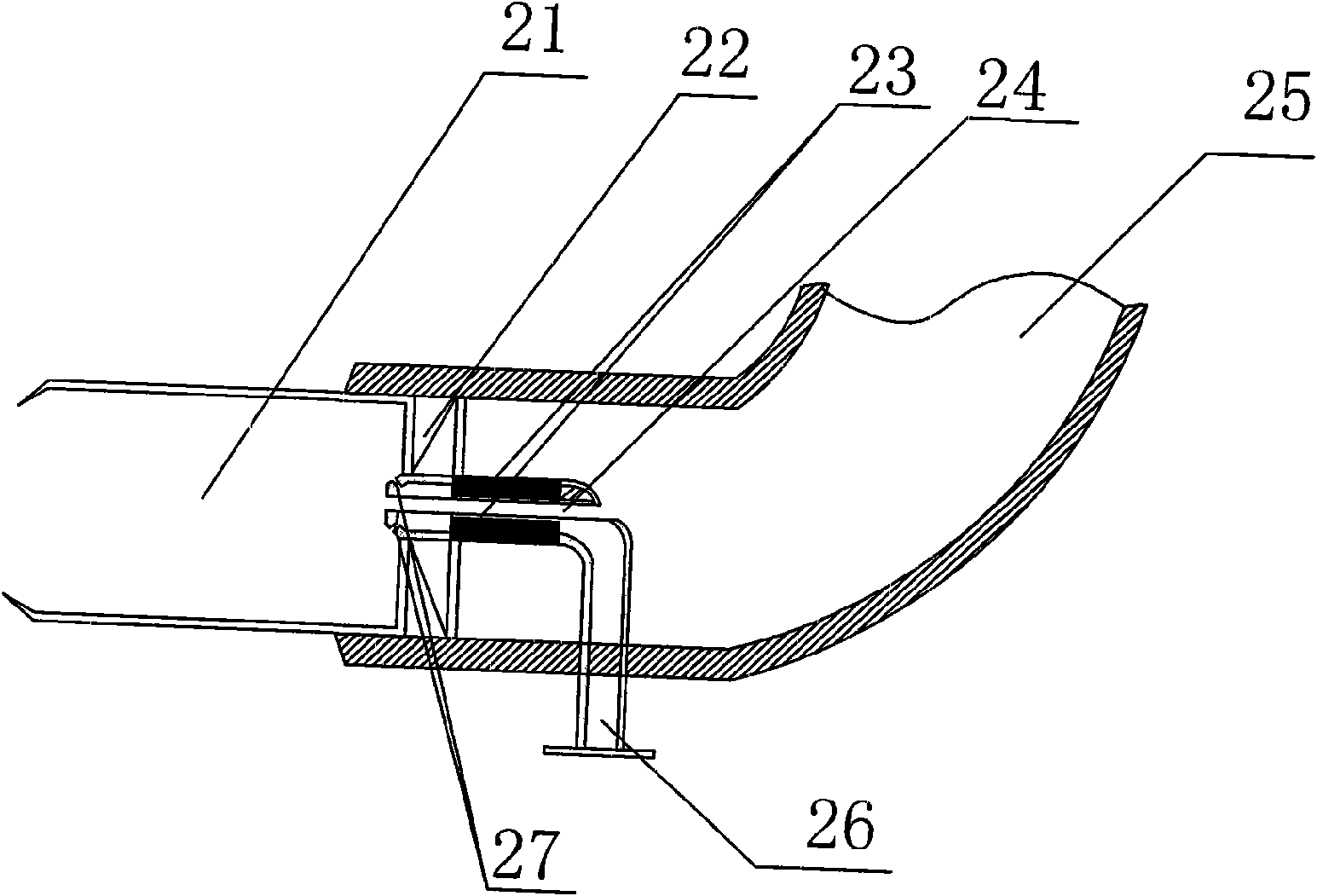

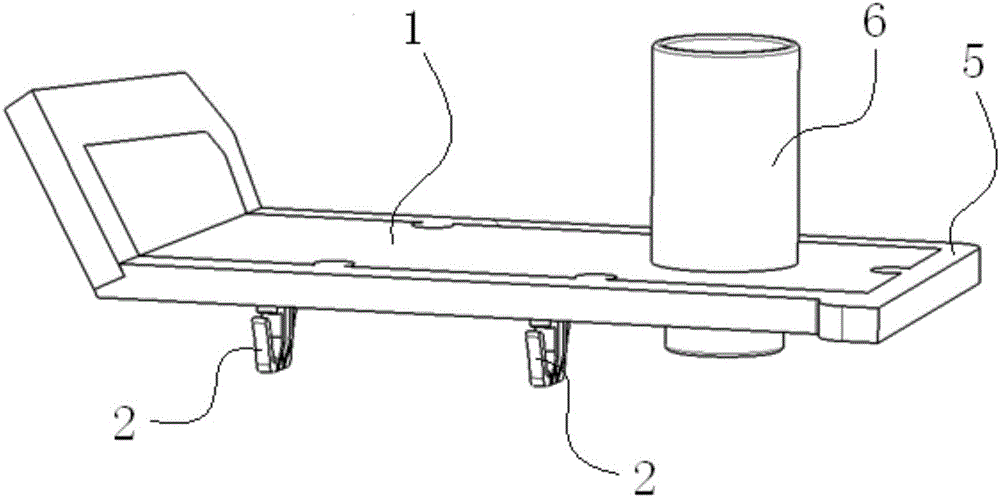

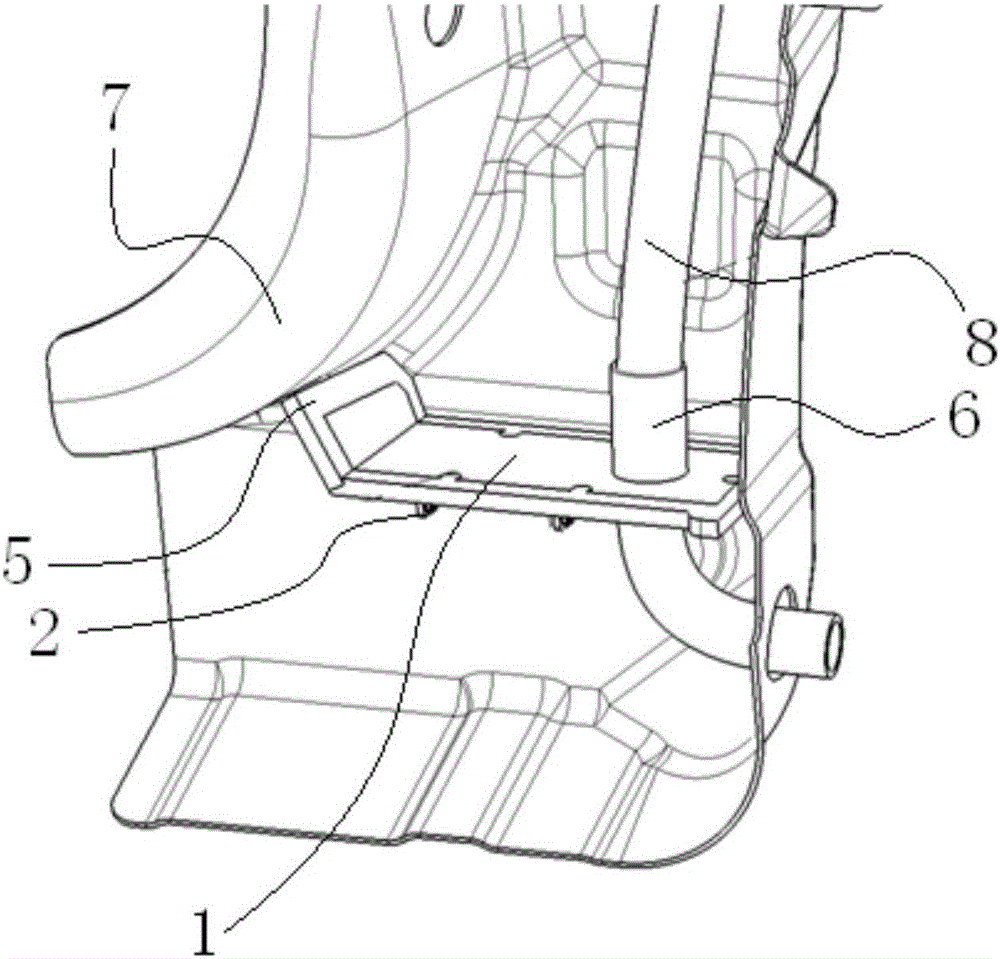

Automobile body cavity sound insulation rubber block

ActiveCN104986125AEasy to installNo manual alignment requiredVehicle componentsPulp and paper industryInjection moulding

The invention discloses an automobile body cavity sound insulation rubber block. The automobile body cavity sound insulation rubber block includes a sound insulation substrate, installation clamping buckles arranged at the lower surface of the sound insulation substrate, a guide tube of which the outer wall is connected with the sound insulation substrate, a plugging cover, and a foam material which is embedded at the circumference of the sound insulation substrate, wherein the guide tube passes through the sound insulation substrate, the plugging cover is matched with the outlet of the guide tube so that the guide tube can be as opened and closed, and the sound insulation substrate, the installation clamping buckles, the guide tube and the plugging cover are formed through integrated injection molding; and the guide tube is provided with an inlet tube located at the upper surface of the sound insulation substrate and an outlet tube located at the lower surface of the sound insulation substrate, wherein the inlet tube is an elliptic cone tube which is large at the upper part and is small at the lower part. With the sound insulation rubber block adopted, the installation of a skylight drainage pipe is more convenient, and the guide tube will not be plugged by the foamed foaming material.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

A kind of preparation method of degradable biological wound dressing and obtained product

ActiveCN105833331BUniform textureGood biocompatibilityAbsorbent padsBandagesWound dressingBiocompatibility Testing

The invention discloses a preparation method for degradable biological wound dressing and an obtained product. The preparation method comprises the following steps: first, cross-linking sodium hyaluronate and a cellulose derivative under an alkaline condition; then, cross-linking the sodium hyaluronate and the cellulose derivative under an acid condition; dialyzing, purifying and granulating the obtained cross-linked gel; uniformly mixing the cross-linked gel and chitosan aqueous solution; removing air bubbles, pouring a mixture into a mould, and drying to obtain the degradable biological wound dressing. The method disclosed by the invention is high in safety and easy and convenient to operate; a cross-linking system is prepared by one step; two-step cross-linking can be completed by only regulating the pH value; the cross-linking time is greatly shortened; industrial production is facilitated. The obtained product is high in biocompatibility and high in safety, and is suitable for liquid suction, wound protection and repair of a mild to severe seepage skin wound; secondary damage is prevented; the degradable biological wound dressing is convenient to replace and convenient to use.

Owner:BLOOMAGE BIOTECHNOLOGY CORP LTD

Multi-nozzle alcohol-based burner

PendingCN110425523ARun completelyGuaranteed uptimeAir supply regulationLiquid fuel burnerCycloneAlcohol

The invention discloses a multi-nozzle alcohol-based burner. The device comprises an air duct outer pipe and a multi-sage fuel supply unit, wherein multi-stage air duct pipes are coaxially arranged inside the air duct outer pipe in sequence; the air duct pipe located at the most center is a first-stage air duct pipe; the outside of the first-stage air duct pipe is sleeved with a second-stage air duct pipe; an ignition device, an air duct cyclone and an annular air distributor are arranged at the inlet of the first-stage air duct pipe; a central nozzle is arranged in the inner ring of the air duct cyclone; and the central nozzle is connected with a central branch pipe; the fuel supply units respectively communicate with a plurality of annular branch pipes; and the plurality of annular branch pipes are parallel to the center line of the multi-stage air duct pipes and are circumferentially arranged around the outer side of the second-stage air duct pipe. According to the multi-stage zonedcombustion technology, a rich combustion zone and a quenching zone are formed in the first-stage air duct pipe, and a lean combustion zone is formed at the outlet of the first-stage air duct pipe, sothat atomized liquid and combustion air are fully mixed; combustion is complete, and nitrogen oxide emission is reduced; and variable load regulation of the burner is achieved using the multi-stage fuel supply unit.

Owner:XIAN AEROSPACE SOURCE POWER ENG CO LTD

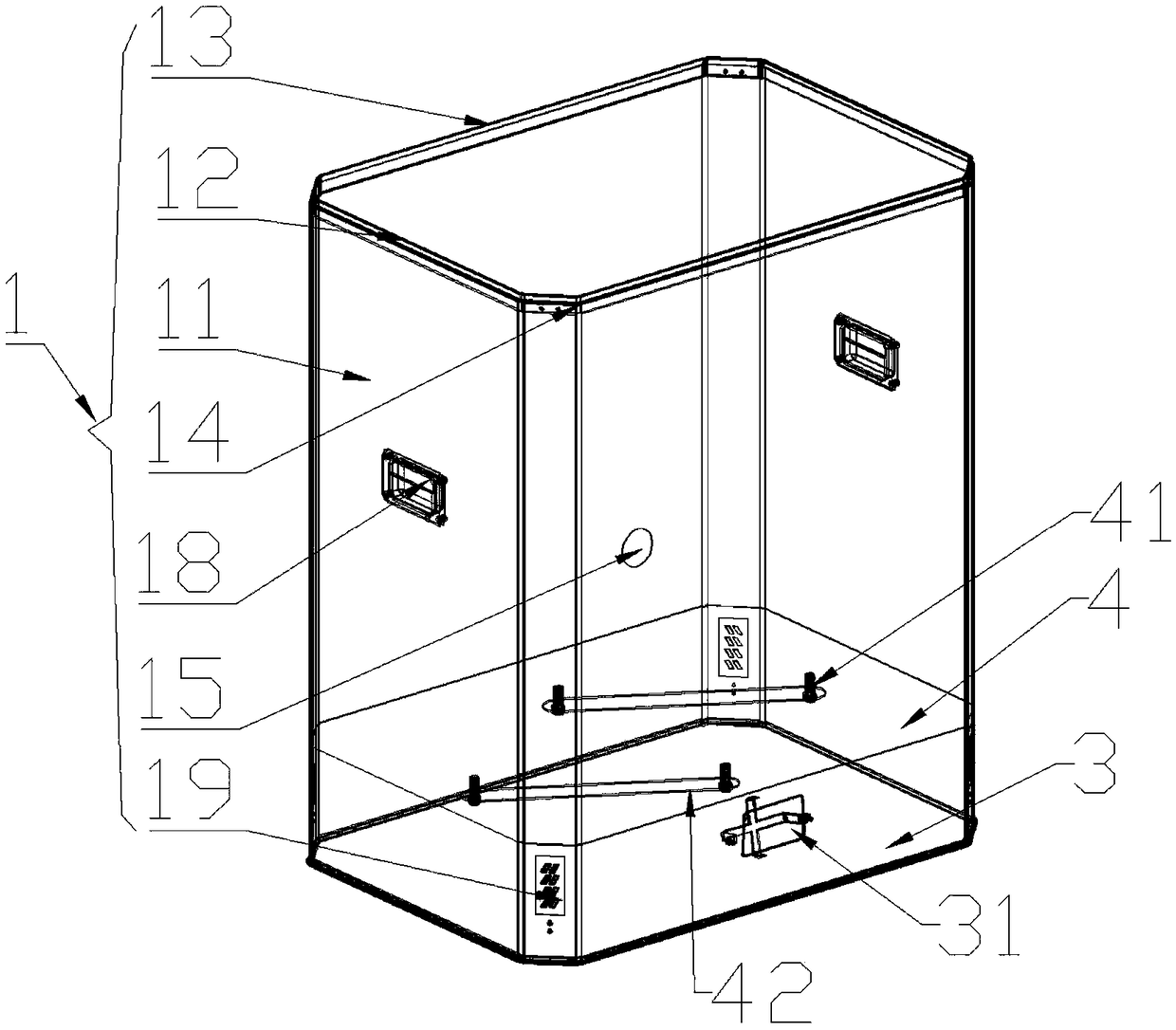

3D printing object surface polishing and strengthening device

ActiveCN108790175AReduce restrictionsHigh strengthAdditive manufacturing apparatus3D object support structuresEngineeringHolding tank

The invention discloses a 3D printing object surface polishing and strengthening device. The device comprises an outer shell, a top cover arranged at the top of the outer shell, a bottom cover arranged at the bottom of the outer shell, a separation plate arranged in the outer shell, a polishing liquid holding tank formed above the separation plate, a liner arranged above the polishing liquid holding tank, a tray arranged in the liner, an electric heating plate arranged under the separation plate, and an electronic relay arranged on the bottom cover. The 3D printing object surface polishing andstrengthening device can hold polished objects made of multiple materials and multiple types of polishing liquid, is uniform in polishing, high in polishing efficiency and excellent in polishing effect, improves the rupture strength and the toughness of the polished objects, recycles the polishing liquid, is safe in operation, protects the environment, and saves the cost; and the polishing devicecan be zoomed according to equal proportion, and the capacity can be increased or reduced according to special polishing demands, so that the size application range of the polished objects is more free.

Owner:神匠(深圳)新技术有限公司

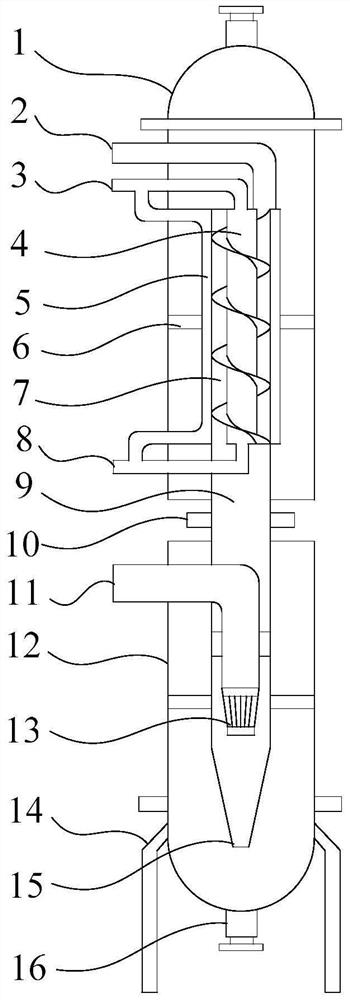

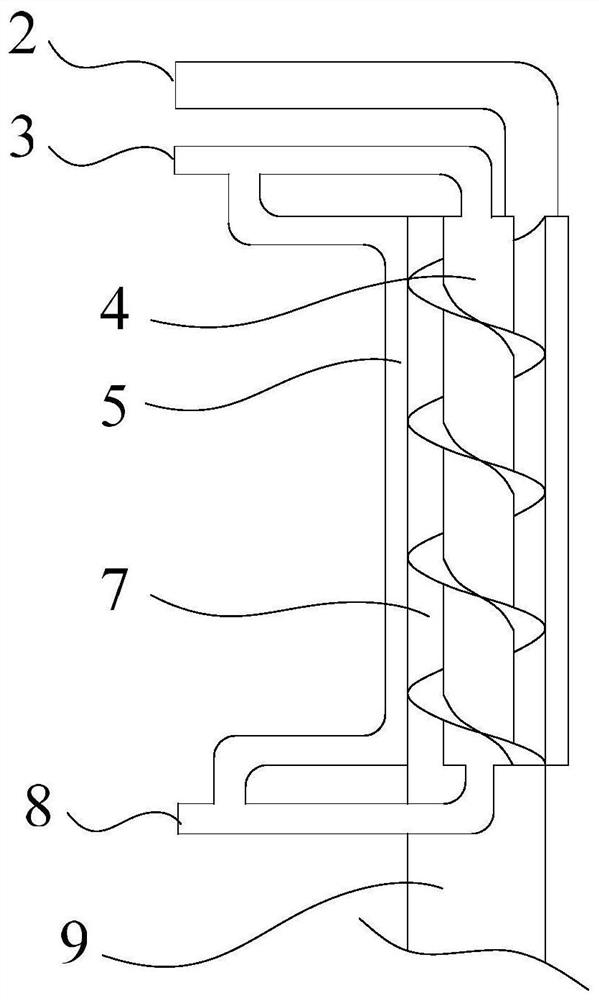

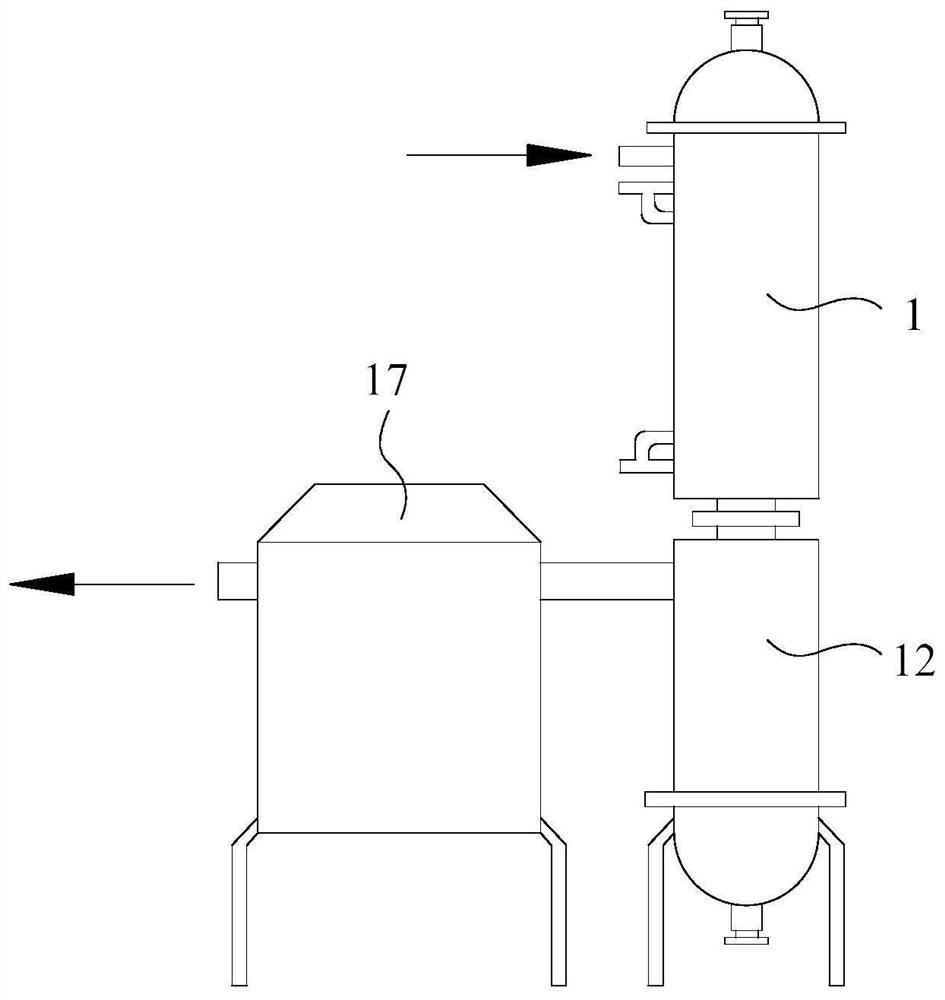

Heat exchange and separation integrated cyclone separation device

PendingCN113351385AImprove heat transfer effectImprove gas-liquid separation efficiencyReversed direction vortexCycloneThermodynamics

The invention provides a heat exchange and separation integrated cyclone separation device. The cyclone separation device comprises a shell, the shell is provided with an air inlet, an air outlet and an oil-gas mixture channel communicating with the air inlet and the air outlet; a heat exchange device for conducting heat exchange on an oil-gas mixture and an axial flow type cyclone separator are further arranged in the shell; the oil-gas mixture channel penetrates through the heat exchange device to lead to the cyclone separator, the oil-gas mixture channel is provided with a spiral flow channel in the heat exchange device, and the spiral flow channel is used for guiding the oil-gas mixture to spirally flow so as to be consistent with the airflow vortex direction of the cyclone separator. The heat exchange device and the separator are sequentially arranged in the cyclone separation device, high-temperature oil gas can be cooled and then separated, the spiral flow channel is formed in the inner cavity of the heat exchange device, the heat exchange area of the high-temperature oil-gas mixture is increased, and the heat exchange efficiency is improved; the spiral flow channel guides the airflow into a spiral shape to enter the axial flow type cyclone separator for multi-stage separation, and the high-temperature gas-liquid separation effect is effectively enhanced.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Fin plate type heat exchanger

InactiveCN106556282ASimple structureSmall pressure dropLaminated elementsEngineeringPlate fin heat exchanger

The invention relates to a fin plate type heat exchanger, in particular to a heat exchanger applied to a device for recovering organic gases of volatile organic compounds (VOCs) with a condensation method. At present, plate type heat exchangers adopted in condensation devices have main problems of small fin spacing, large pressure drop and existence of accumulated fluids, and the invention aims to overcome defects in the prior art and provides the fin plate type heat exchanger which is simple in structure, small in pressure drop, free from fluid accumulation and easy to manufacture. Thin rectangular stainless steel plates are pressed to form plate sheets full of herringbone concave-convex ripples, V-shaped fins are connected onto one surface of each plate sheet, surfaces, without the fins, of every two plate sheets are closed, flat steel is embedded in peripheries, the plate sheets are airtight, fin plate type heat exchanger components are obtained, the concave-convex ripple spacing is arranged in middles of the components, outer-side surfaces of the components are full of the V-shaped fins, holes are formed in opposite angles, and pipes are connected and used as cold gas flow inlet and outlet passages; and a plurality of the components stacked neatly, and adjacent spaces of the components form hot gas flow passages. Glands and adapter pipes are mounted at inlets and outlets at two ends of the passages, and the fin plate type heat exchanger is manufactured. Partition heat exchange of the plate sheets is completed in the process that two gases at different temperatures pass through the respective flow passages backwards, and the organic gases are condensed and liquefied.

Owner:张丽 +1

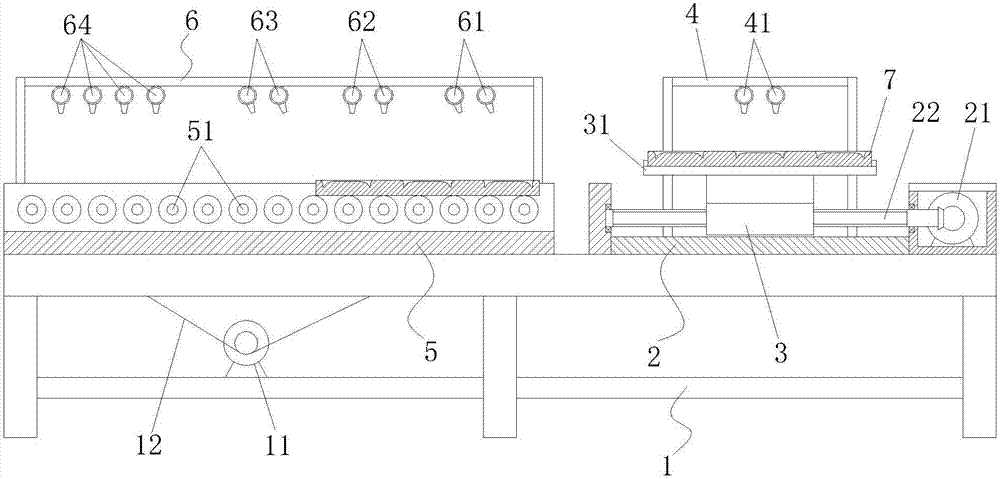

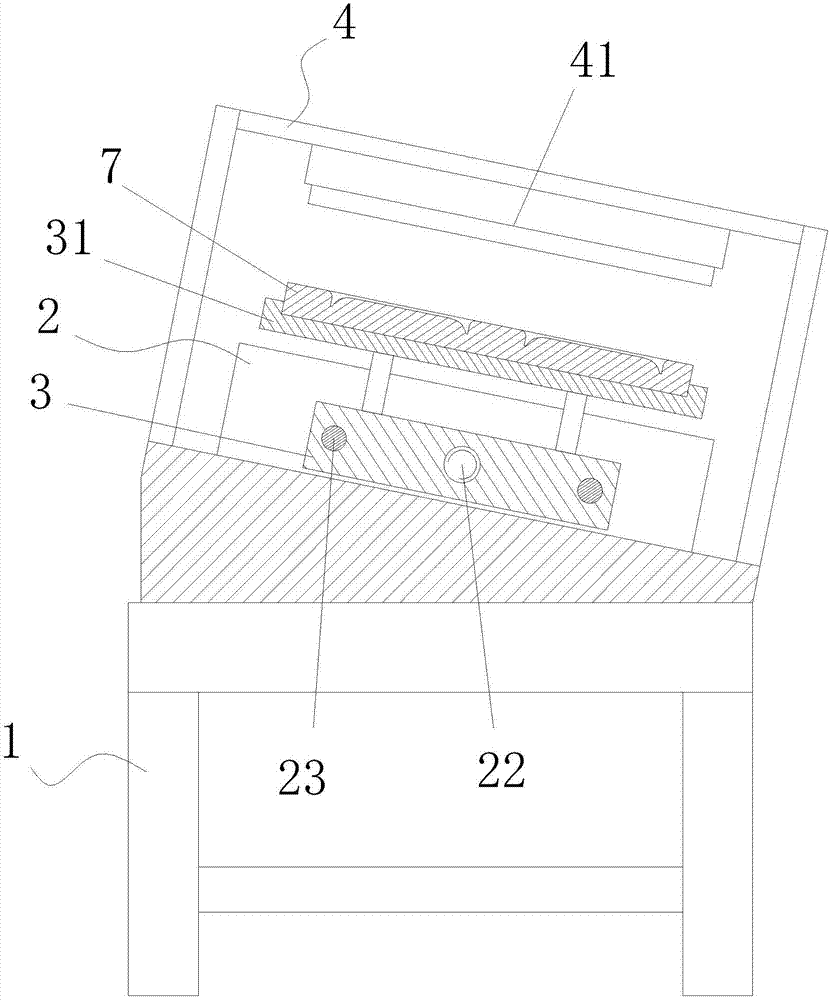

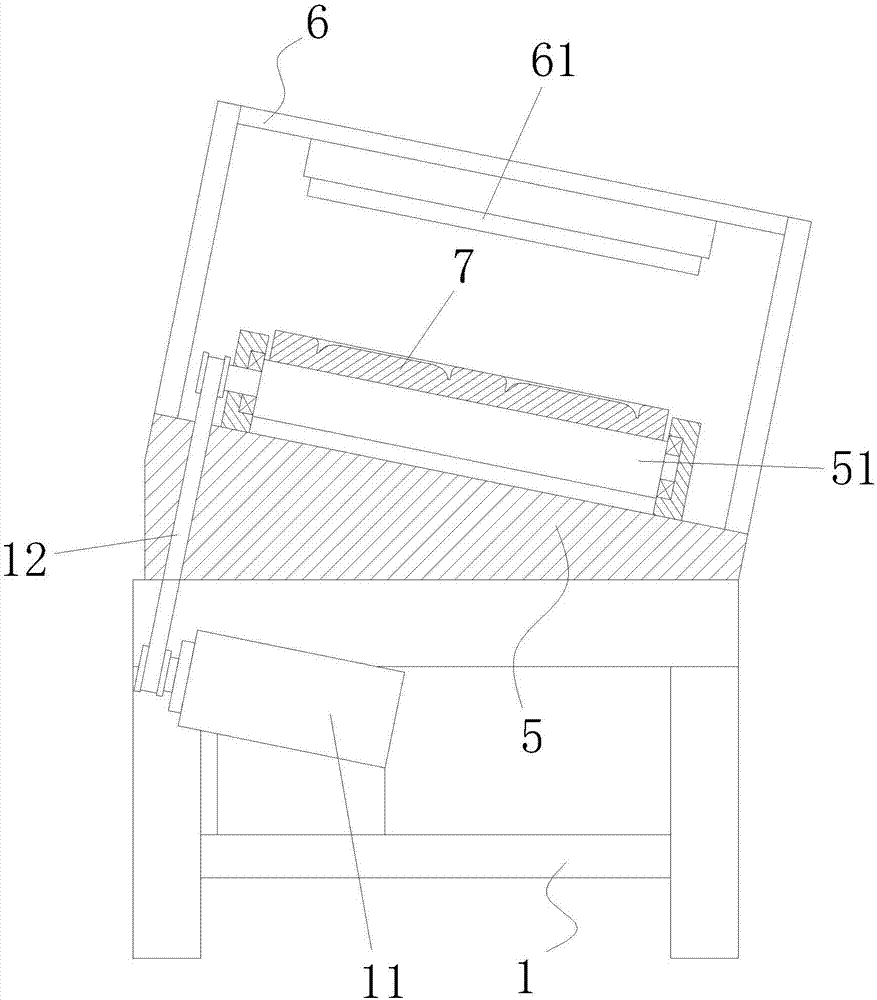

Dip angle provided special-shaped glass cover plate anti-dazzle surface treatment equipment

ActiveCN107962501AGood anti-glare surfaceEasy to useAbrasive machine appurtenancesGlass coverTherapeutic effect

The invention relates to dip angle provided special-shaped glass cover plate anti-dazzle surface treatment equipment which comprises a rack. A substrate, an etching device, a polishing device and a drying device are sequentially arranged on the rack in the material conveying direction. Multiple grooves used for containing glass cover plates are formed in the substrate. Convex portions completely attached to the inner surfaces of the glass cover plates are arranged in the grooves. Clearances are reserved between the circumferential side walls of the convex portions and the inner side walls of the grooves. The etching device comprises a panel which moves back and forth and is used for containing the substrate. Multiple droppers which are arranged above the panel to spray etching liquid to the glass cover plates on the substrate are further included. The equipment is simple in structure and good in surface treatment effect.

Owner:福建和达玻璃技术有限公司

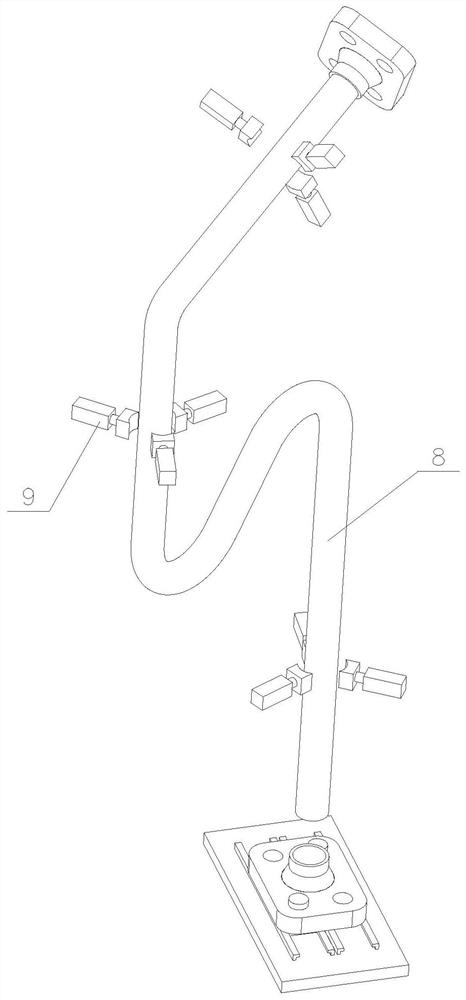

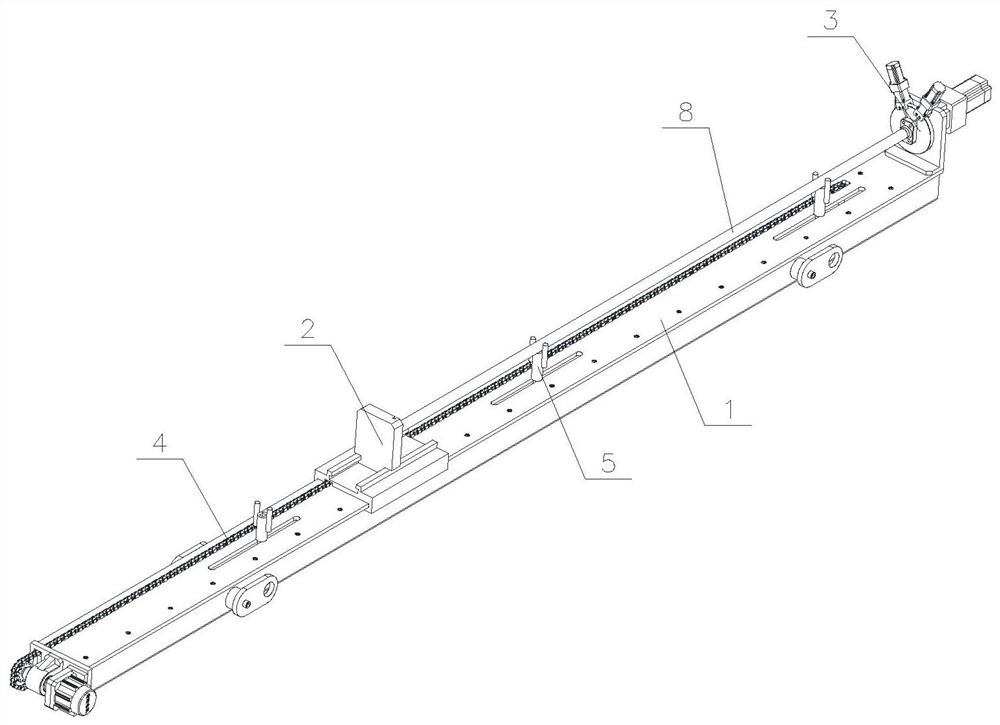

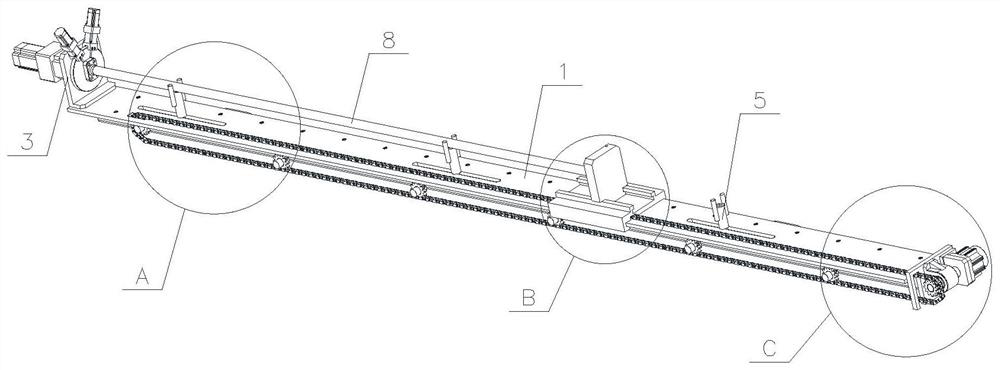

Bending and welding device for super-long pipe flange and machining technology

PendingCN111941076AEasy to operateImprove processing efficiencyOther manufacturing equipments/toolsWelding apparatusStraight tubeElectric machinery

The device comprises a base; a fixed flange seat and a rotating flange seat slide relatively on the base; a fixed flange and a rotating flange which directly facing each other are correspondingly mounted on the fixed flange seat and the rotating flange seat; and a rotating motor for driving the rotating flange to rotate is mounted on the rotating flange seat. The invention discloses a bending andwelding device for a super-long pipe flange. According to the super-long pipe flange bending and welding device, additional manual cooperation is not required, the workload of workers is reduced, thewelding efficiency is improved, the welding precision and the welding quality are guaranteed, in addition, an oil pipe in a straight pipe state can be phosphatized and cleaned conveniently, and rusting caused by the residual accumulated liquid in the oil pipe is prevented. The invention further discloses a machining technology for welding and then bending the ultra-long pipe flange.

Owner:江苏耀坤液压股份有限公司

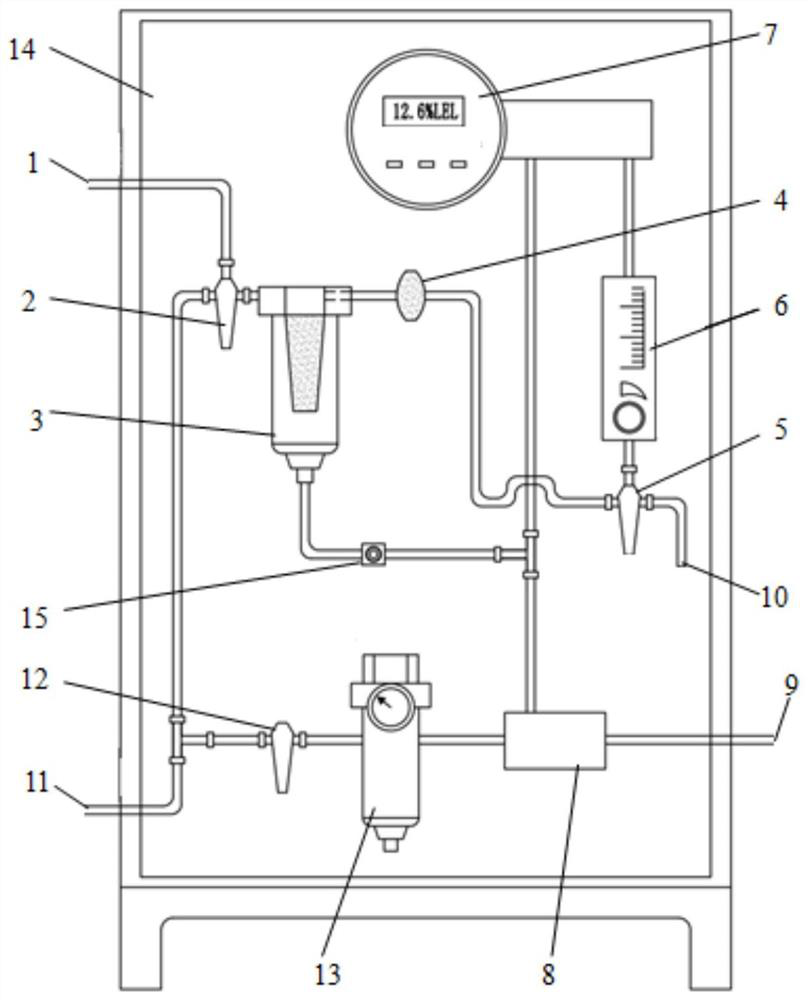

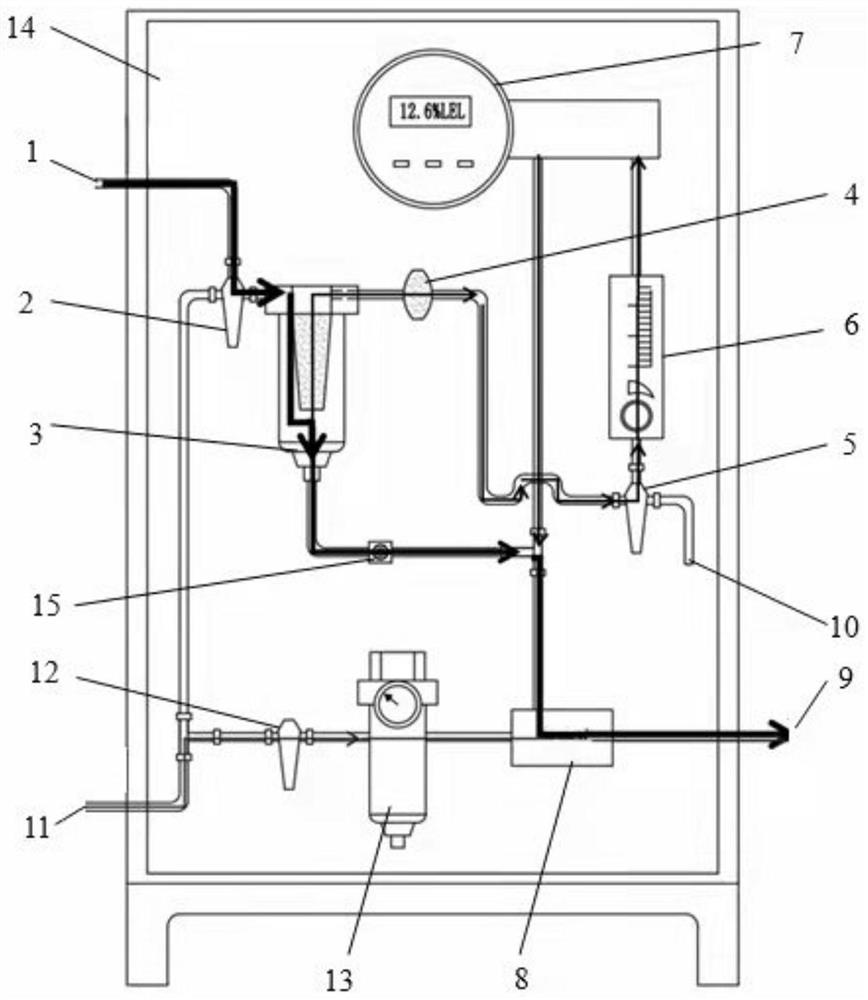

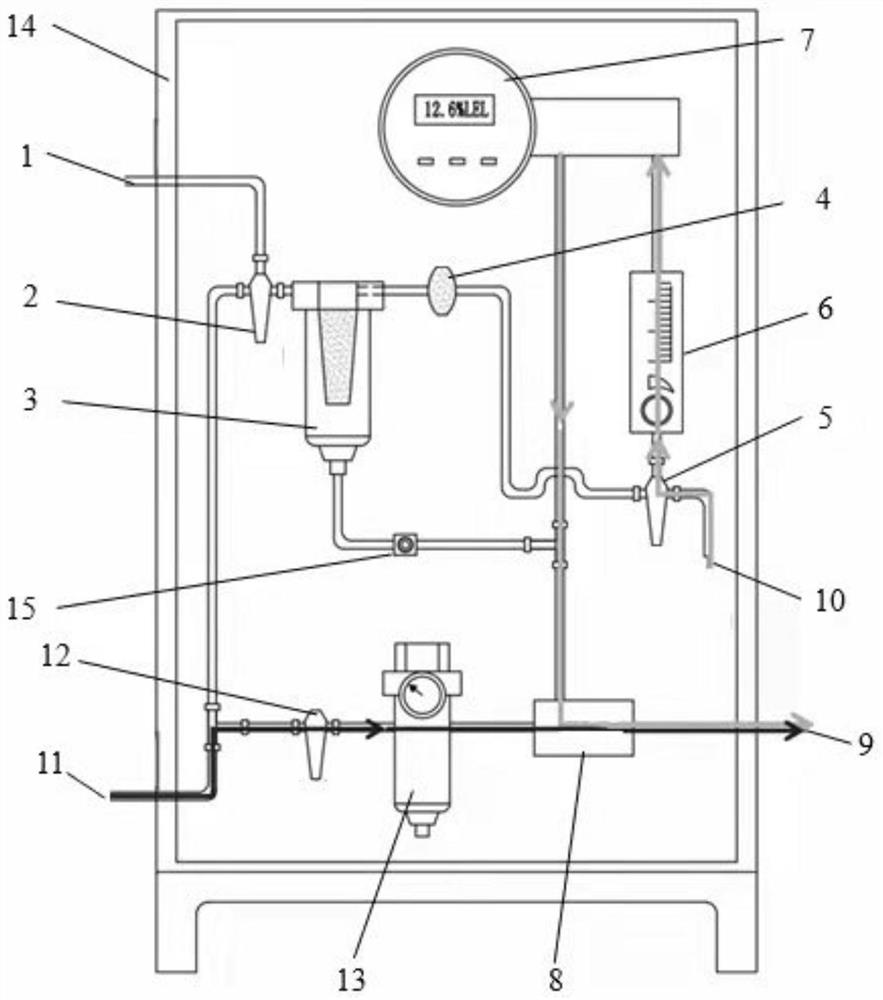

VOCs gas continuous rapid sampling system and sampling method

PendingCN114459837AGuaranteed speedGuaranteed long-term maintenance-freeWithdrawing sample devicesGas analyser calibrationGas concentrationGas passing

The invention discloses a VOCs gas continuous rapid sampling system which comprises a sampling gas inlet, a valve A, a primary filter, a valve B, a float flowmeter, a gas concentration sensor, a pneumatic pump and a sampling gas outlet which are sequentially connected through a pipeline, a side outlet of the primary filter is connected with the valve B, and a bottom outlet of the primary filter is connected with the pneumatic pump through a pipeline. The invention also discloses a sampling method of the VOCs gas continuous rapid sampling system, which comprises the following steps: VOCs gas is introduced into the sampling system through the sampling gas inlet, the VOCs gas is divided into two paths when passing through the primary filter, one path with small flow enters the gas concentration sensor through the float flowmeter, gas sampling is completed, and the other path with small flow enters the gas concentration sensor through the float flowmeter; one path with large flow is directly discharged from the sampling gas outlet under the suction force of the pneumatic pump, so that the speed of the sampling gas entering the gas concentration sensor is effectively increased, and the rapidity of gas sampling is ensured.

Owner:西安昱昌环境科技有限公司

Non-return quantitative and constant pressure injection device

The invention discloses a non-return quantitative constant-pressure injection device which comprises a nozzle body, a valve core mechanism, an injection oil cylinder, a hydraulic system and a controller, wherein a flow channel and a liquid inlet are formed in the nozzle body; the valve core mechanism for opening or closing the nozzle body is mounted in the nozzle body; the injection oil cylinder comprises an oil cylinder body and a hydraulic rod with a first piston at the front end part; the hydraulic rod with the first piston extends into the flow channel of the nozzle body; the hydraulic system is connected with the oil cylinder body and is used for driving the injection oil cylinder. The injection device is characterized by further comprising a hydraulic rod stroke control device; both the hydraulic system and the hydraulic rod stroke control device are electrically connected with the controller. The injection device is simple in structure and high in reliability, and can achieve intermittent, quantitative and constant-pressure injection.

Owner:佛山市韵雄塑料五金制品有限公司

A wide temperature range low temperature environment test device

ActiveCN110346665BUniform temperature fieldNo effusionHeating or cooling apparatusTemperature control using electric meansSolenoid valveEngineering

The invention discloses a low-temperature environment test device with a wide temperature range, which relates to the field of low-temperature environment tests, and includes a thermal insulation cabin, a liquid nitrogen supply system, a gas nitrogen generation and pressure stabilization system, a heating system, a cooling system, and a high and low temperature circulation pipeline system , liquid accumulation prevention device and measurement control system, wherein the gas nitrogen generation and pressure stabilization system is composed of a liquid nitrogen vaporizer, a nitrogen pressure reducer, a nitrogen pipeline safety valve, and a nitrogen pipeline solenoid valve. The insulation cabin is divided into a static pressure chamber, Working space and circulating air duct, the heating system is composed of electric heater and solid state relay in the circulating air duct, the cooling system is composed of liquid nitrogen wall evaporator, liquid nitrogen secondary evaporator and liquid nitrogen evaporator in the circulating air duct, high and low temperature The circulation pipeline system connects the insulation cabin, liquid nitrogen supply system, gas nitrogen generation and pressure stabilization system, heating system, and cooling system to form a loop. The invention can realize the test temperature environment in the ultra-low temperature zone, has uniform temperature field, no liquid accumulation phenomenon, and is safe and reliable.

Owner:SHANGHAI JIAOTONG UNIV

Chitosan biological film-forming glue and preparation method thereof

ActiveCN103550814BImprove solubilityUse of biological activityAbsorbent padsBandagesBiotechnologyMicrobiology

The invention relates to an external spray type antibacterial liquid dressing, and particularly relates to chitosan biological film-forming glue and a preparation method thereof. The chitosan biological film-forming glue comprises the following raw materials in percentage by weight: 0.5%-6% of modified chitosan, 0.01%-0.15% of mint, 0.01%-0.15% of acidifying agents, 0.2%-0.4% of radix scutellariae, 0.1%-0.3% of phellodendron and the balance of deionized water. The chitosan biological film-forming glue disclosed by the invention is prepared into a solution by adopting the modified chitosan, thereby keeping the self physicochemical characteristics and function roles of the chitosan and achieving good solubility property. The chitosan biological film-forming glue disclosed by the invention has good biocompatibility, multiple unique functions, namely higher solubility, easiness for organism absorption, and the like which do not exist in general chitosan, and well utilizes the biological activity of the chitosan.

Owner:GUANGXI XINYE BIOLOGICAL TECH

Tube type vaporization device for liquefied gas for industrial use

InactiveCN100443803CBurn fullyContinuous and stable combustionLiquid fuel feeder/distributionCombustion typesCombustorAutomatic control

Owner:肖杰

Steam valve assembly and device with steam valve assembly

The invention belongs to the technical field of cooking utensils and relates to a steam valve assembly and a device with the steam valve assembly. The steam valve assembly comprises a steam valve body and a foam breaking structure; the steam valve body is provided with a steam valve cavity, an air inlet and an air outlet, wherein the air inlet and the air outlet are communicated with the steam valve cavity; and the foam breaking structure is connected to the steam valve body, is communicated with the air inlet and is suitable for breaking foam. With the steam valve assembly and the device with the steam valve assembly of the invention adopted, the foam passing through the foam breaking structure is punctured, so that the overflowing of the foam can be prevented.

Owner:GREE ELECTRIC APPLIANCES INC

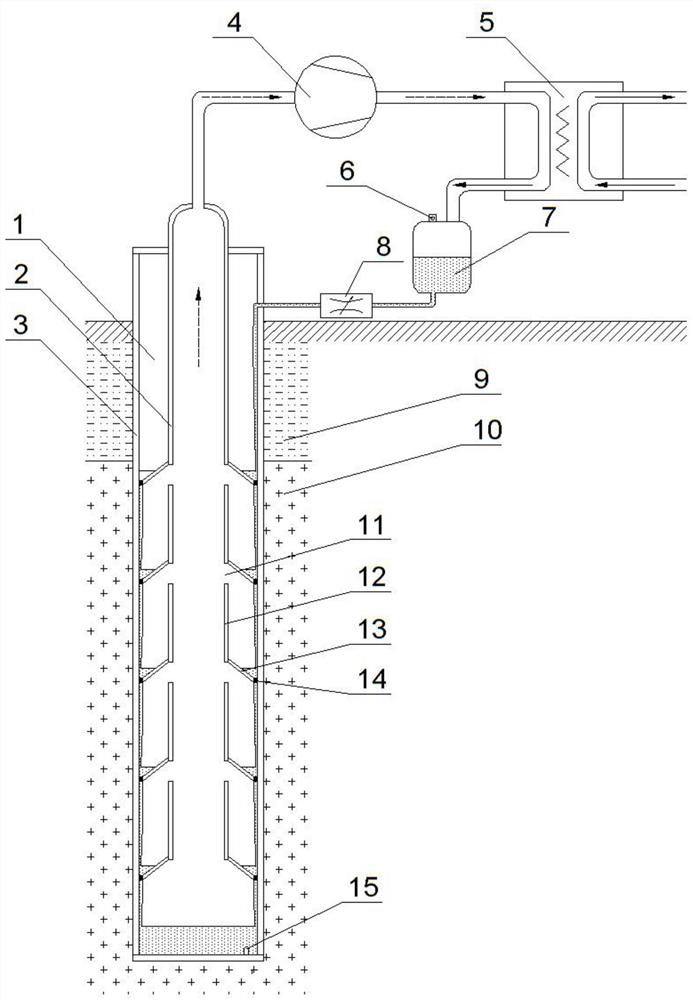

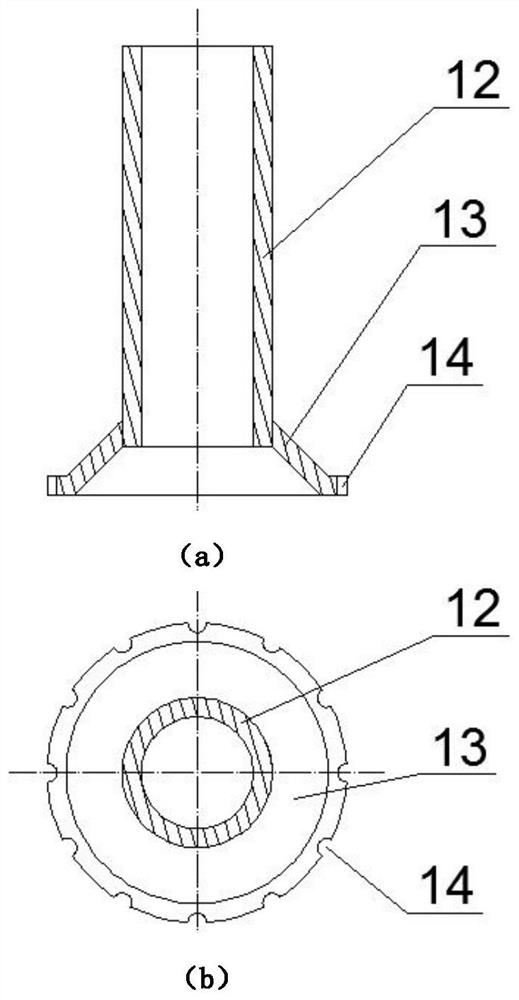

Heat pump system and method for achieving efficient evaporation through geothermal well

ActiveCN113847755ASmall footprintImprove heat pump efficiencyCollector components/accessoriesHeat pumpsLiquid storage tankGeothermal heat pump

The invention discloses a heat pump system and method for achieving efficient evaporation through a geothermal well, and relates to the field of geothermal energy development. The heat pump system comprises a stepped underground evaporator, a compressor, a condenser, a liquid storage tank and a throttling valve. The underground evaporator comprises an inner pipe and an outer pipe, the inner pipe is designed to be of a multi-section structure, and each section is composed of a gas flow guide pipeline, a baffle plate and a seepage hole. Under the action of the structure, liquid working media flowing into the underground evaporator flow downwards in the manner of being tightly attached to the inner wall of the outer pipe, absorb heat from underground rock mass to be gasified and become gaseous working media to flow upwards to the ground. Compared with the prior art, the designed underground evaporator cannot generate the gas-liquid entrainment and liquid accumulation effects, efficient evaporation of the liquid working media can be achieved through the geothermal well, heat supply through water pump circulation is not needed, ground equipment needed by the heat pump system is simplified, the running efficiency of the heat pump system can be obviously improved, and then the overall economical efficiency of the ground source heat pump system is improved.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com