Process and device thereof for vaporizing petroleum gas by heat transfer oil for ceramic industry

A technology of ceramic industry and heat transfer oil, which is applied in lighting and heating equipment, combustion equipment, and the combustion of block fuel and gaseous fuel, etc. It can solve problems such as backflow of effusion, inconsistent combustion degree, uneven heating temperature, etc. , to achieve the effects of reducing production costs, prolonging service life, reducing high temperature oxidation speed and gel thickening speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

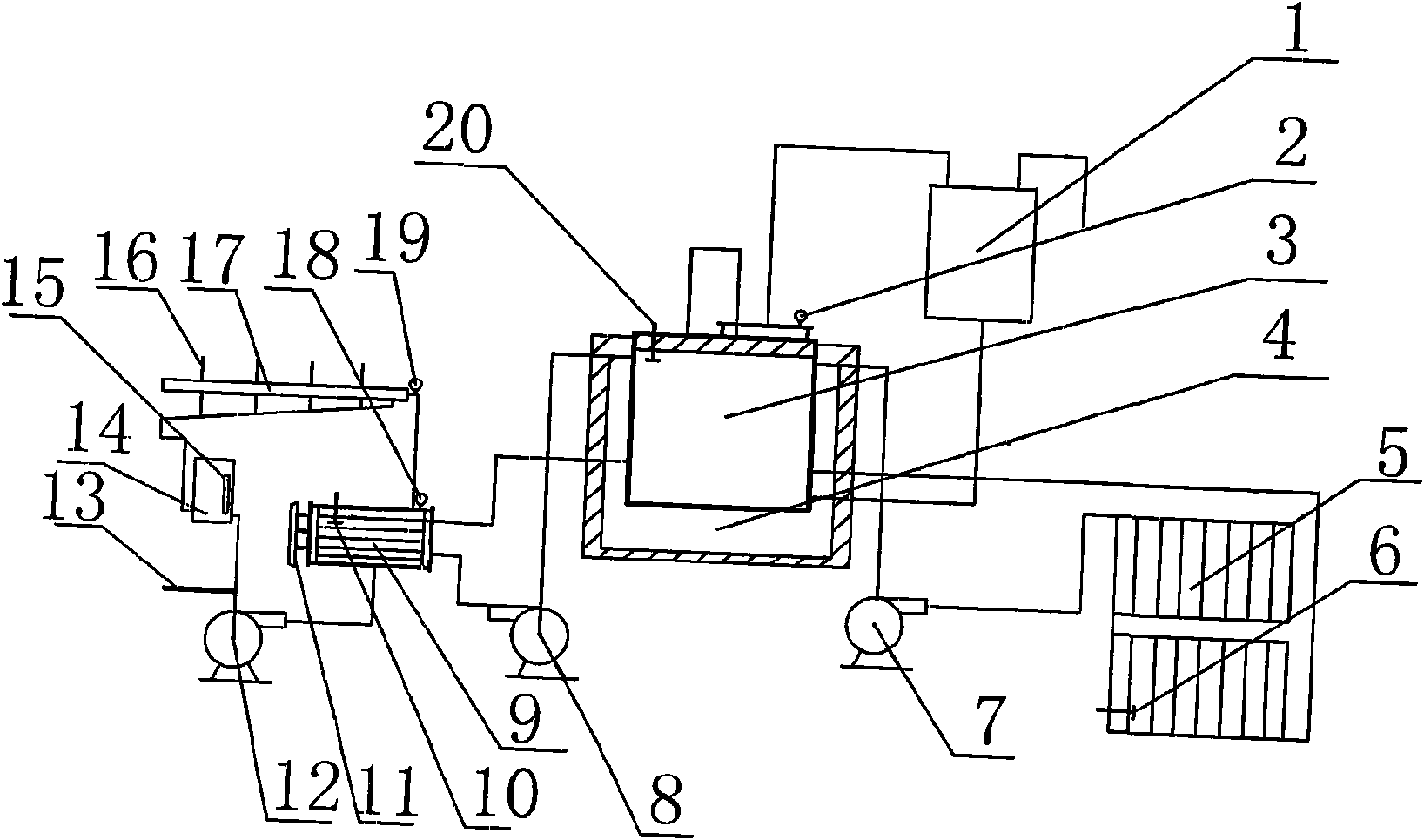

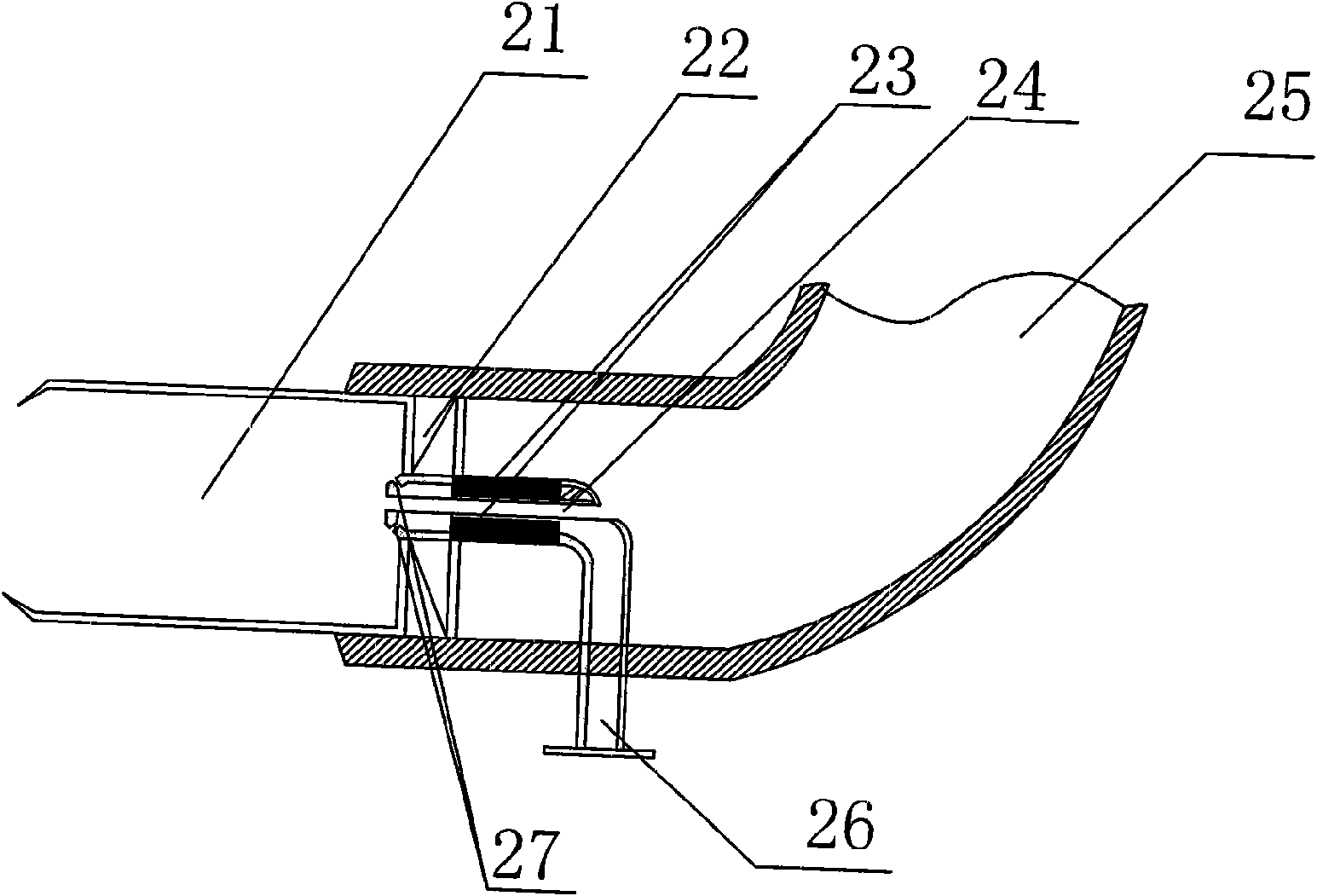

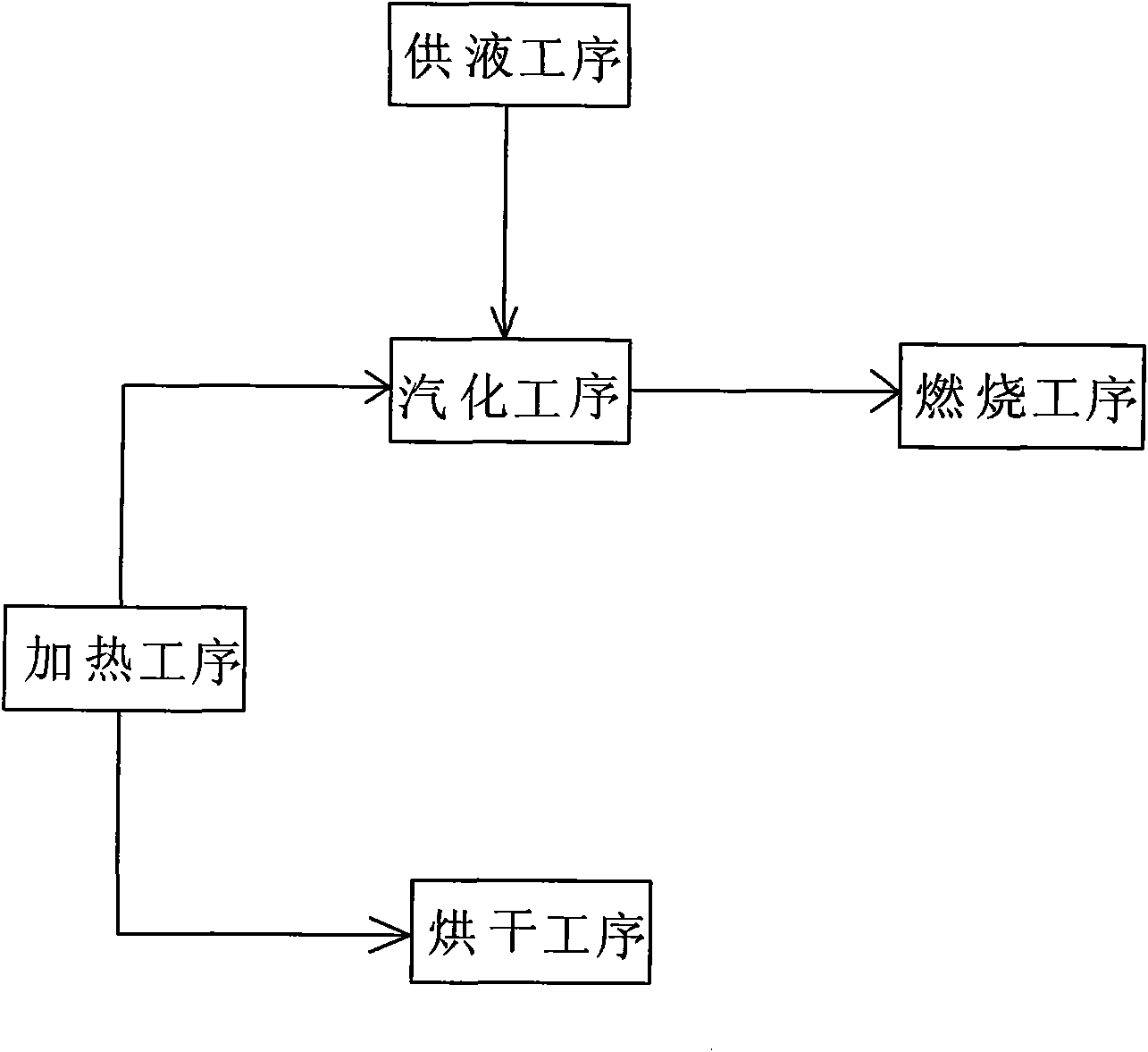

[0022] This embodiment is a process for vaporizing petroleum gas with heat transfer oil for the ceramic industry, such as image 3 As shown, it includes five steps: liquid supply process, heating process, vaporization process, drying process and combustion process. Enter the vaporizer, drying room and heat-conducting oil furnace until the oil level of the overflow barrel reaches 1 / 10 of the height of the barrel, control the temperature in the heat-conducting oil furnace at 250°C to 300°C, and heat the heat-conducting oil; After the temperature reaches the set value, start the heat-conducting oil circulation pump of the drying equipment, pump the high-temperature heat-conducting oil into the exhaust pipe of the drying room, and heat the drying room. When drying the ceramic mold, the temperature of the drying room is controlled at 65 ℃ ~ 75 ℃, when drying the ceramic body, the temperature of the drying room is controlled at 80 ℃ ~ 90 ℃; at the same time, the high temperature hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com