Bending and welding device for super-long pipe flange and machining technology

A welding device and super-long technology, applied in welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of lower welding efficiency, hidden dangers of welding quality, and obstacles to oil pipe production and manufacturing, so as to improve welding efficiency and welding accuracy, reduce Worker workload, effect of reducing worker workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0068] The specific implementation manners of the present invention will be further described below in conjunction with the drawings and examples. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

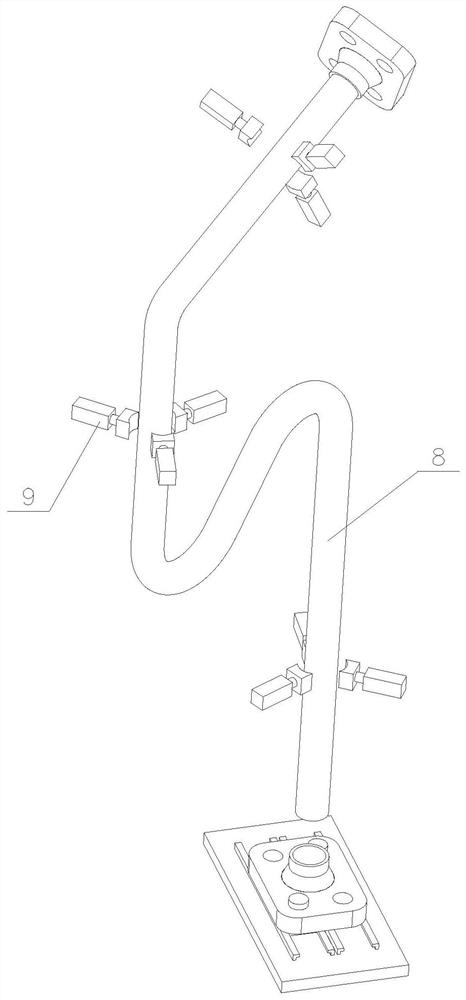

[0069] Such as figure 1 As shown, in the prior art, when the ultra-long oil pipe 8 is welded, the oil pipe 8 is first bent, and the oil pipe 8 is bent into an irregular shape with multiple bends, and one end of the oil pipe 8 is welded. After that, the oil pipe 8 is hoisted and transported by driving (not shown in the figure), with the end of the oil pipe 8 not welded to the flange facing down, the angle position of the oil pipe 8 is adjusted, and the angle position of the oil pipe 8 is clamped and fixed by various clamps 9 , prevent the oil pipe 8 from shaking and shifting during the welding process, which affects the welding accuracy, and then adjust the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com