Fin plate type heat exchanger

A heat exchanger and finned plate technology, applied in the field of finned plate heat exchangers, can solve problems such as being unsuitable for low-temperature recovery and treatment of organic matter gases

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with accompanying drawing.

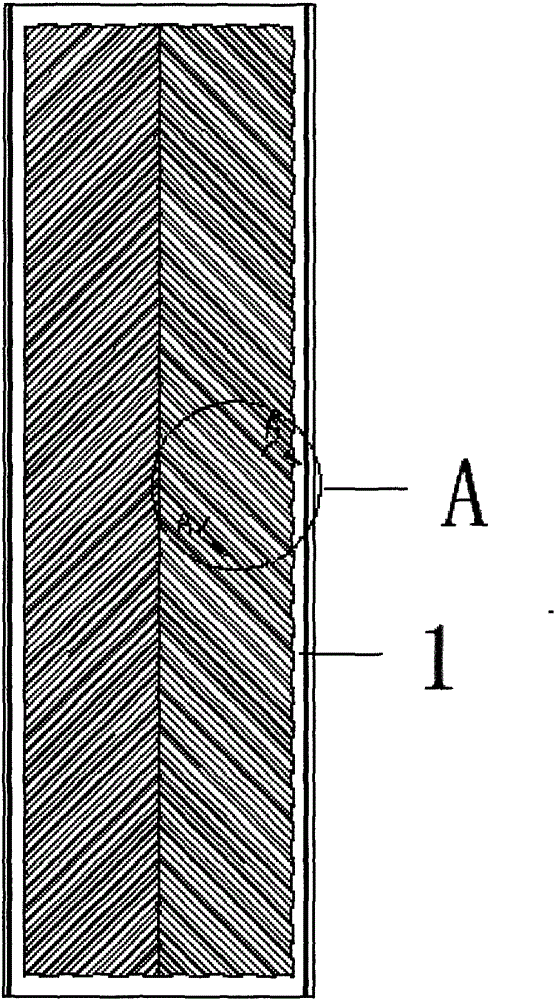

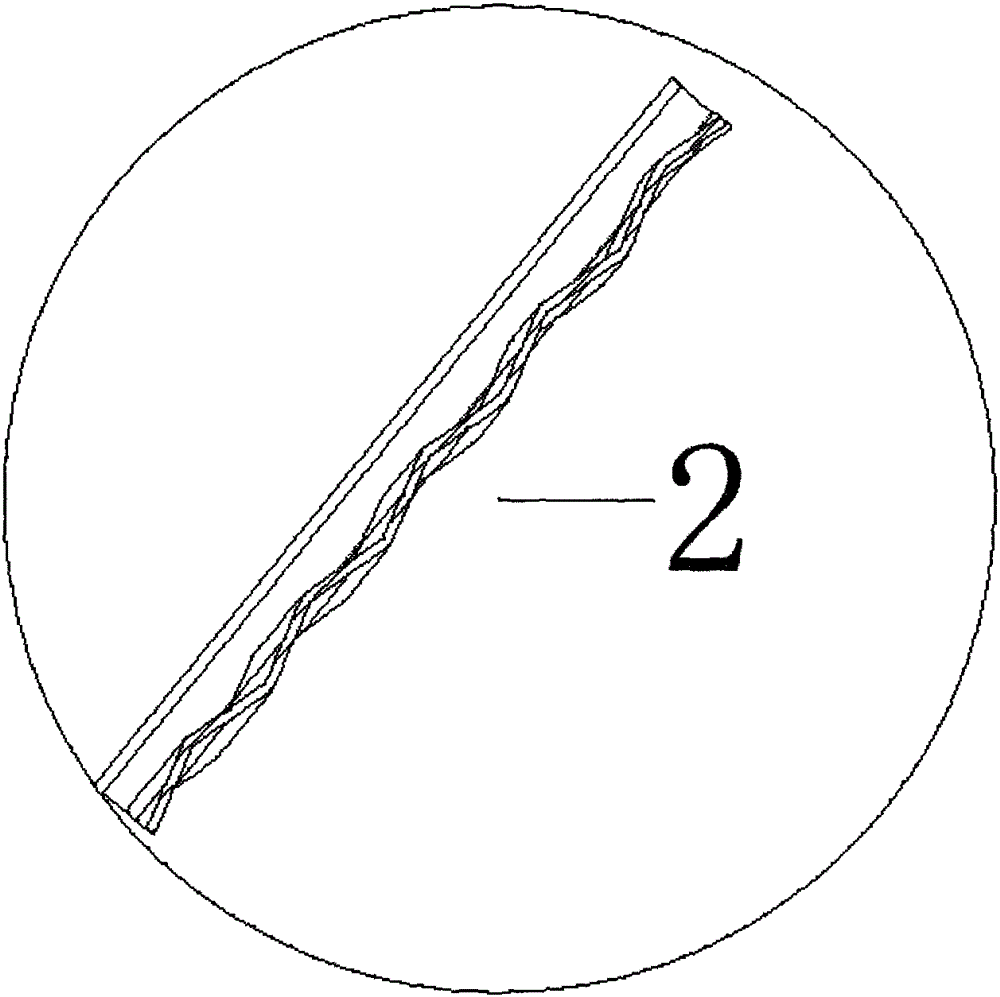

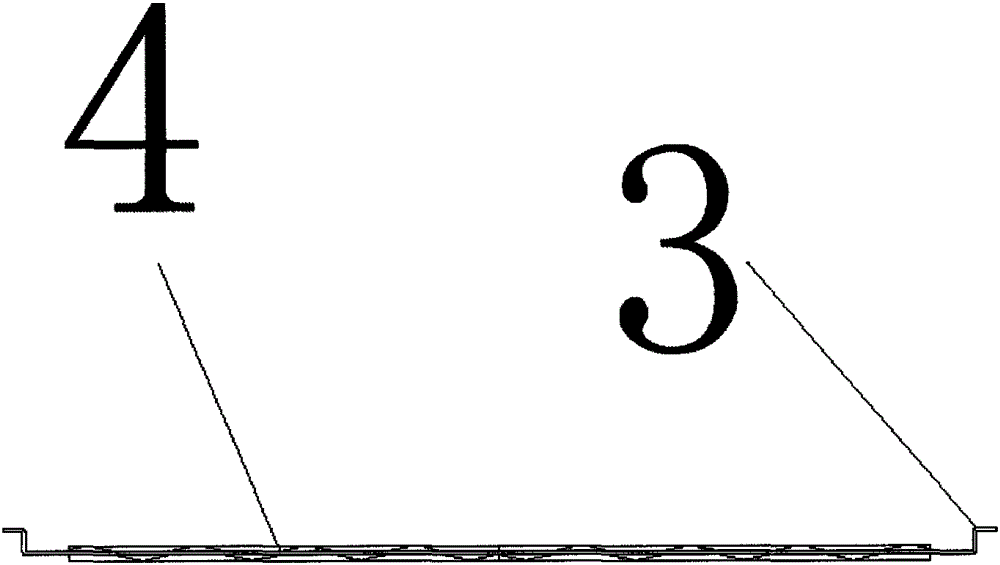

[0023] refer to figure 1 , figure 1 It is the front view of the corrugated plate of the present invention. The rectangular stainless steel sheet is pressed into a plate covered with "herringbone"-shaped concave-convex corrugations; the two length edges of the corrugated plate are folded into two 90-degree folds, and the Reserved as a rectangular groove for installing the sealing strip; figure 2 for figure 1 The cross-sectional view at A in the middle shows that the concave-convex corrugations protrude or sink on both sides of the plate with the same size; image 3 for figure 1 The top view of the plate, indicating that the folded edge 3 is folded twice at 90 degrees along the length edge, and the folded edges on both sides are symmetrical;

[0024] refer to Figure 4 , Figure 4 For the fin plate diagram of the present invention, the stainless steel strip thin plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com