3D printing object surface polishing and strengthening device

A surface polishing and 3D printing technology, applied in the field of 3D printing, can solve the problems of single specification of material components, insufficient recycling of chemical solutions, and ordinary people cannot afford to consume them, so as to achieve good polishing effect, prevent uneven polishing, and strengthen resistance. The effect of crack strength and toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

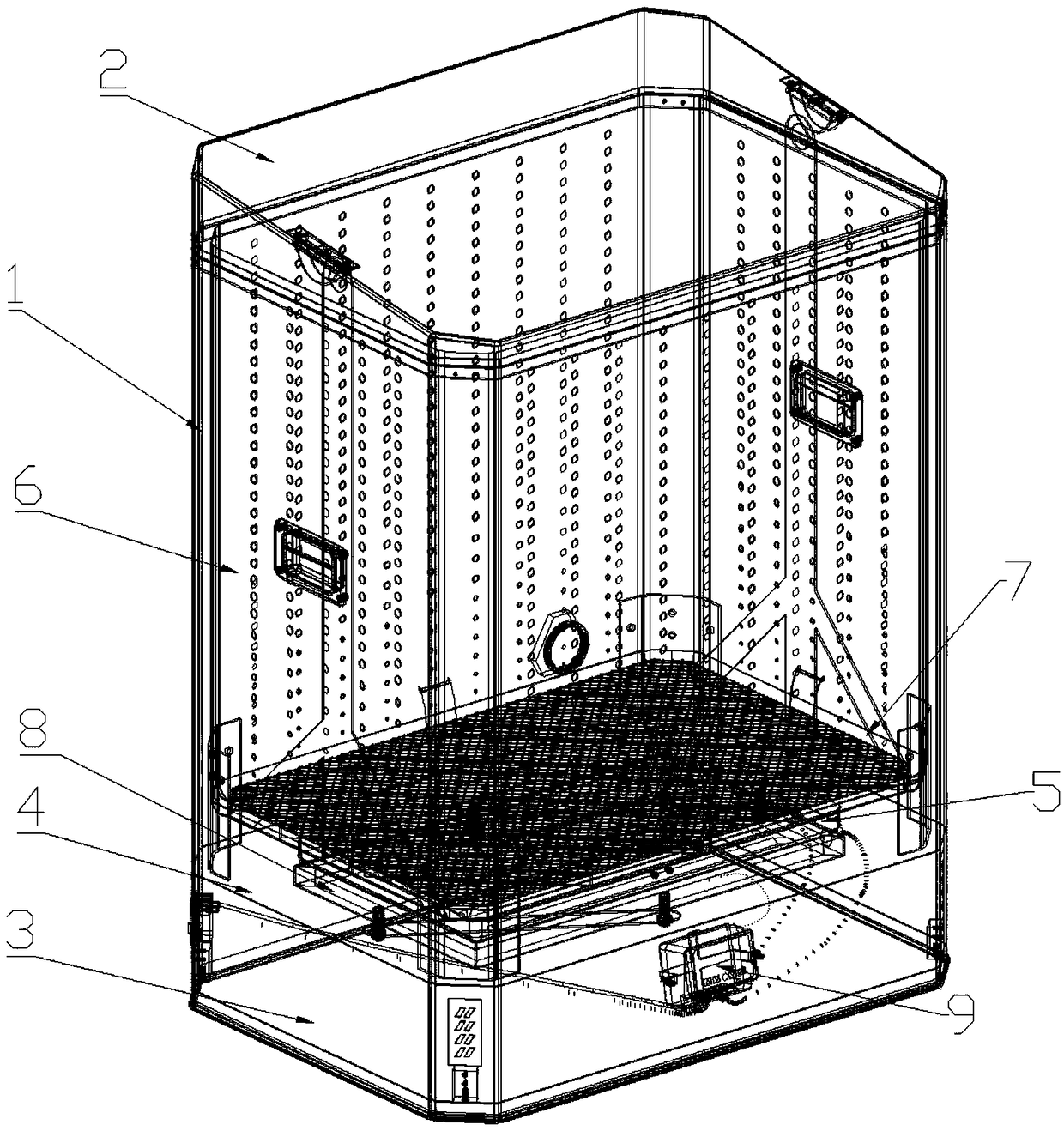

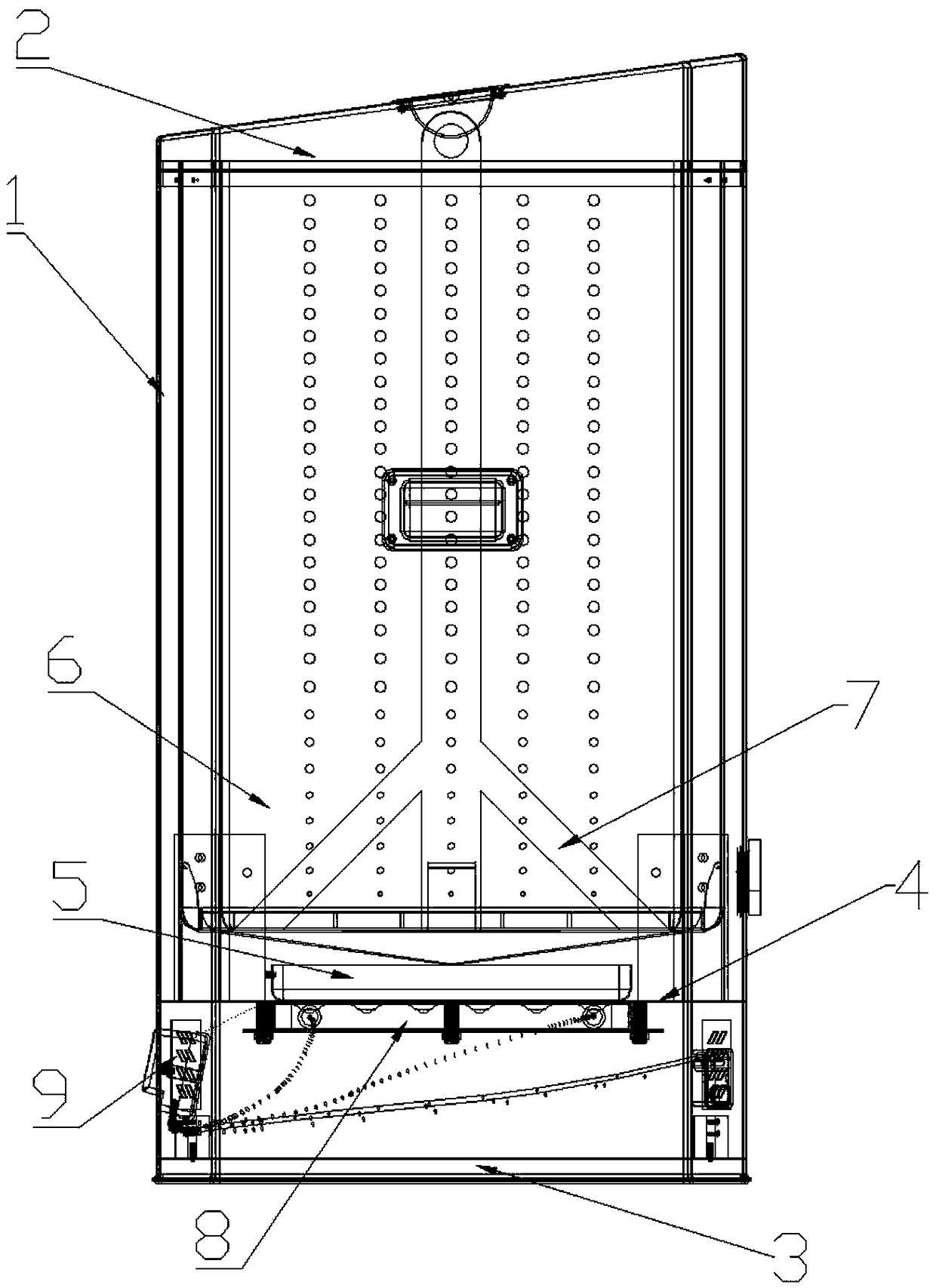

[0037] Please combine figure 1 and figure 2 , the present invention provides a device for polishing and strengthening the surface of a 3D printed article, comprising: a casing 1, a top cover 2 arranged on the top of the casing 1, a bottom cover 3 arranged at the bottom of the casing 1, and a bottom cover arranged on the casing 1 The internal partition 4, the polishing solution storage tank 5 above the partition 4, the inner tank 6 above the polishing solution storage tank 5, and the tray placed on the inner bottom surface of the inner tank 6 7. The electric heating plate 8 arranged under the partition 4 and the electronic relay 9 arranged on the bottom cover 3 .

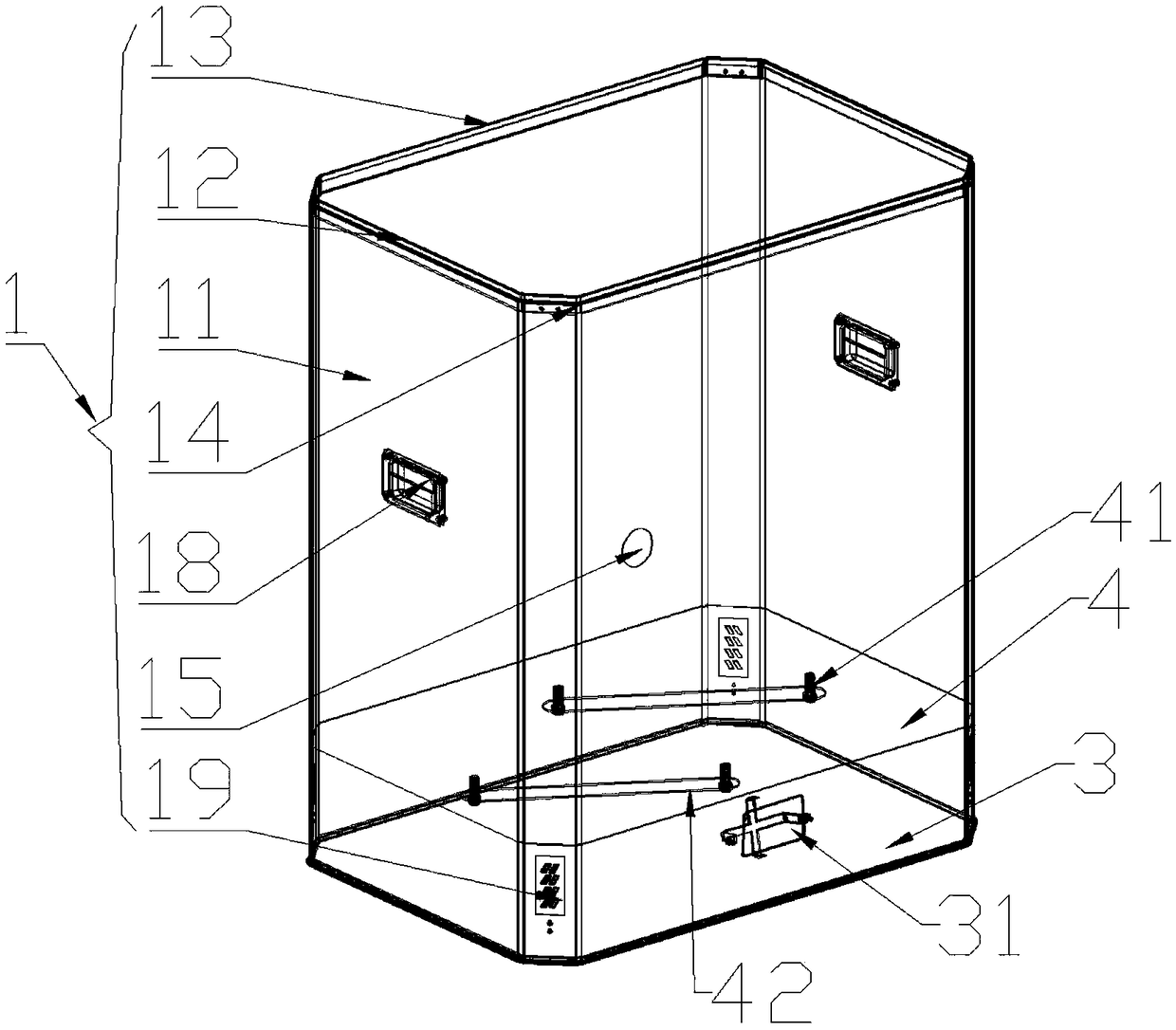

[0038] see image 3 with Figure 4, the housing 1 includes a casing 11, an inlay frame 12 arranged above the casing 11, an elastic sealing ring 13 arranged on the inlay frame 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com