VOCs gas continuous rapid sampling system and sampling method

A sampling system and gas technology, which is applied in the field of VOCs gas continuous and rapid sampling system, can solve the problems of long sampling time and low safety of VOCs gas treatment, and achieve fast cleaning without disassembly, long-term maintenance-free, and rapidity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

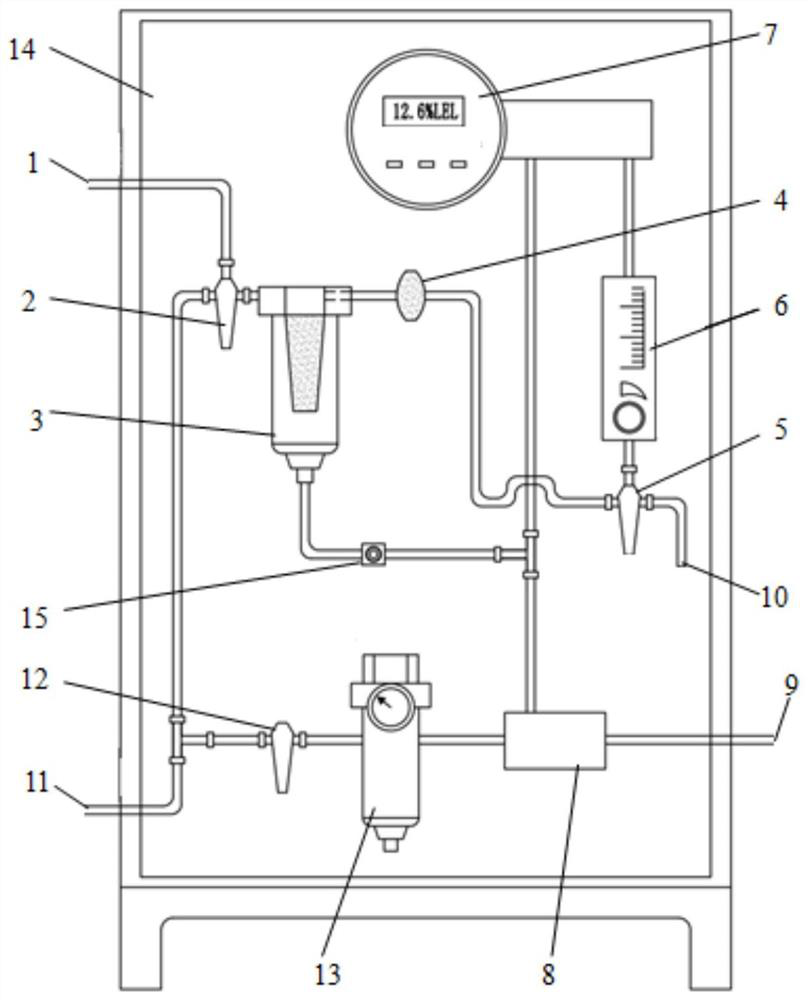

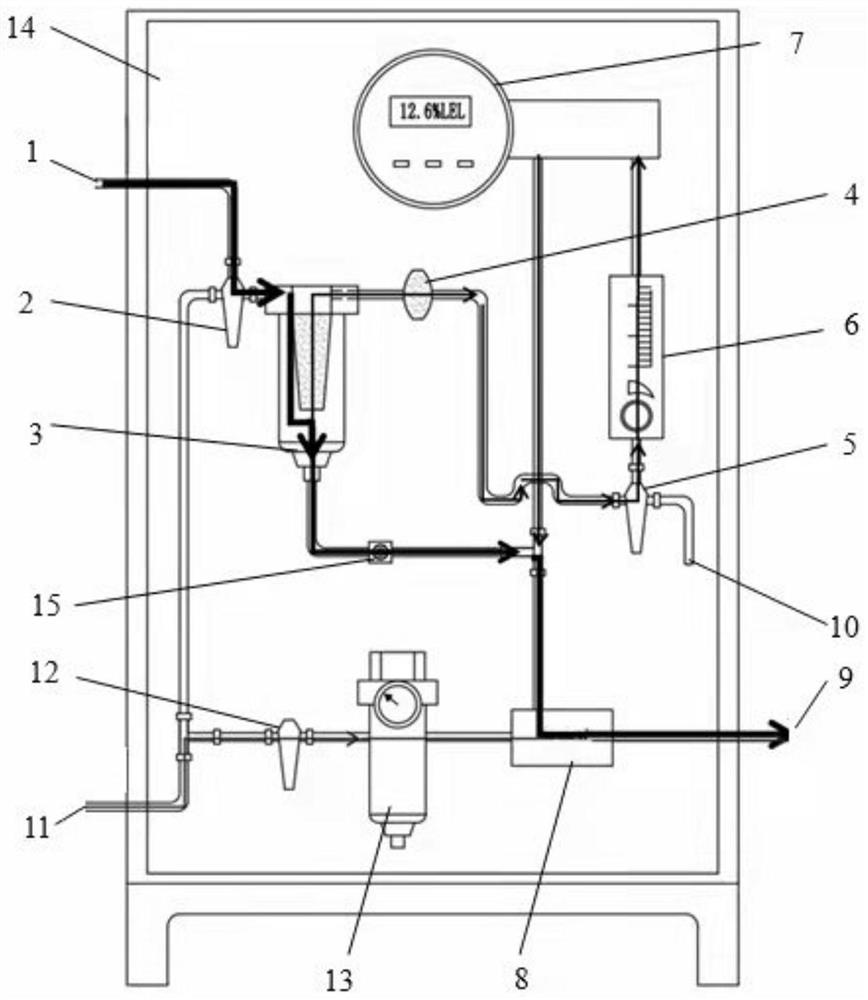

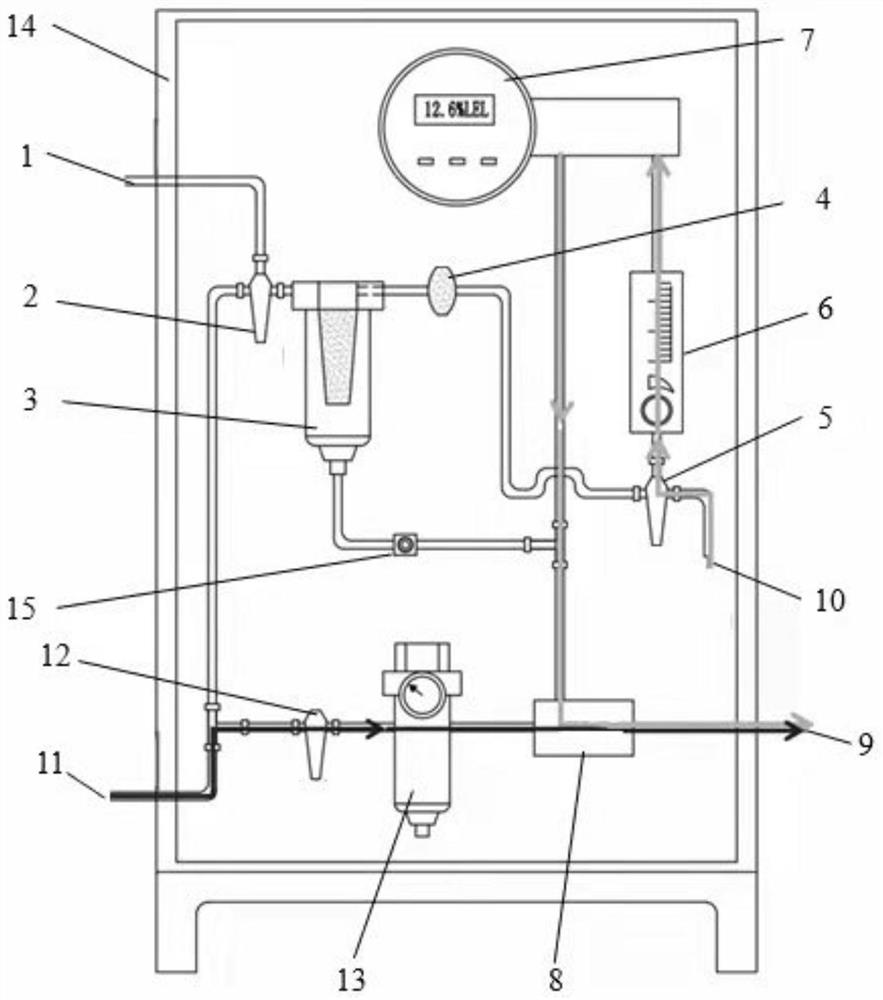

[0040] A kind of VOCs gas continuous rapid sampling system of the present invention, refer to figure 1 , including a sampling gas inlet 1, a valve A2, a primary filter 3, a hydrophobic filter 4, a valve B5, a rotameter 6, a gas concentration sensor 7, a pneumatic pump 8 and a sampling gas outlet 9 connected in sequence through pipelines, and also includes The sampling box 14, the primary filter is a three-way filter with automatic draining function, the side outlet of the primary filter 3 is connected to the valve B5, and the bottom outlet of the primary filter 3 is connected to the pneumatic pump 8 through a pipeline.

[0041] A flow regulating valve 15 is arranged between the primary filter 3 and the pneumatic pump 8 . The pneumatic pump 8 is connected with a compressed air inlet 11 , and a manual valve 12 and a pressure regulating valve 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com