Dip angle provided special-shaped glass cover plate anti-dazzle surface treatment equipment

A technology for surface treatment and special-shaped glass, which is applied to used abrasive treatment devices, metal processing equipment, abrasives, etc., can solve the problems of high cost, complex structure, troublesome use, etc., and achieves guaranteed etching consistency, simple structure, Easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

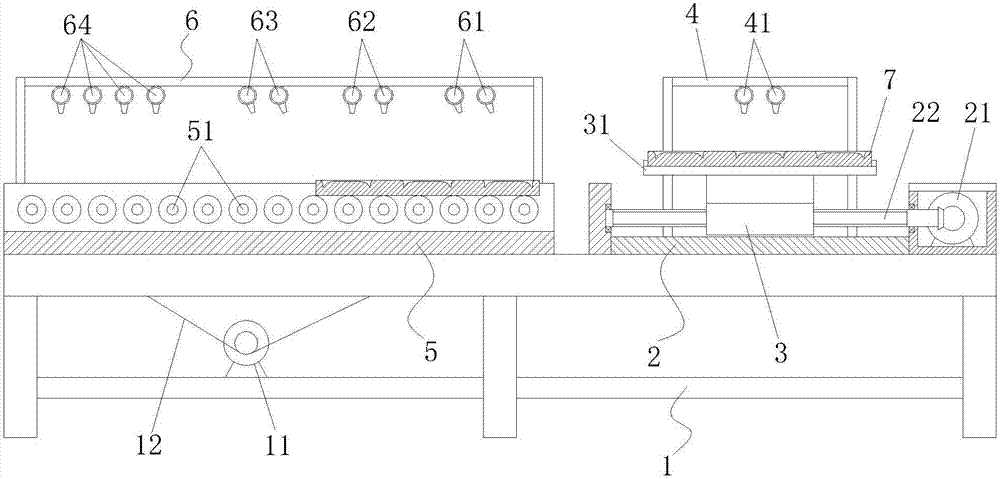

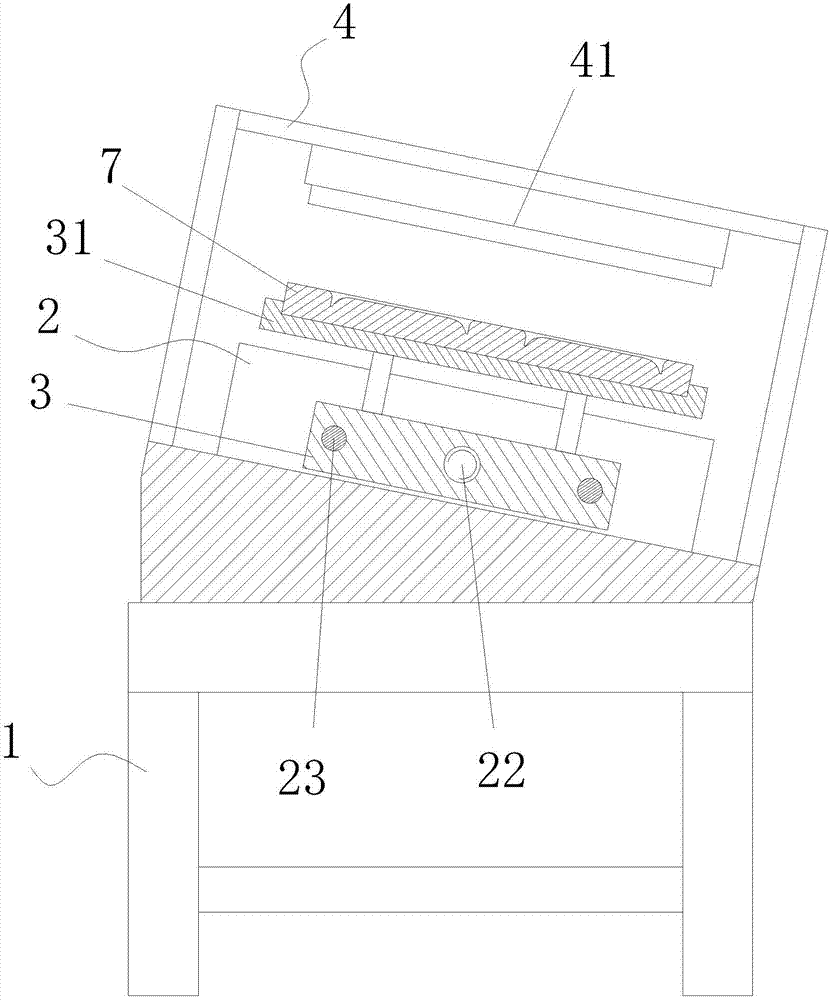

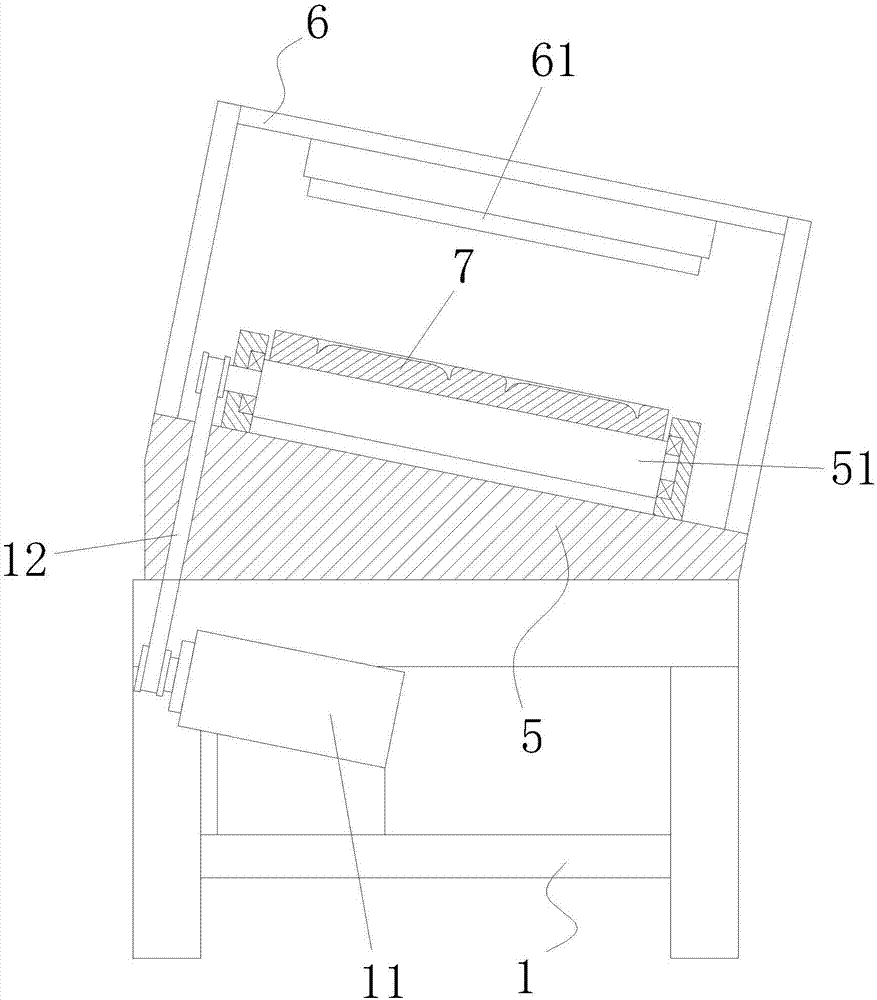

[0024] Embodiment one: if Figure 1~5 As shown, a special-shaped glass cover anti-glare surface treatment equipment with an inclination includes a frame 1, and a substrate 7, an etching device, a polishing device and a drying device are sequentially arranged on the frame along the material conveying direction, and the substrate There are several grooves 71 for placing the glass cover on the top, and a convex part 72 that completely fits the inner surface of the glass cover is arranged in the groove, and there is a gap between the side wall of the convex part and the inner wall of the groove. There is a gap (for accommodating the peripheral sidewall of the glass cover), and the etching device includes a panel 31 that moves back and forth for placing the substrate, and also includes a plurality of droplets arranged on the panel to spray the etching solution on the glass cover on the substrate. Pipe 41 (the frame is provided with the first support 4 for installing the dropper, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com