Curved edge glass cover anti-glare surface treatment equipment and treatment method

A glass cover and surface treatment technology, applied in metal processing equipment, manufacturing tools, abrasive jet machine tools, etc., can solve the problems of unguaranteed etching, inconvenient glass disassembly and installation, etc., and achieve stable performance, simple device structure, and convenient use Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

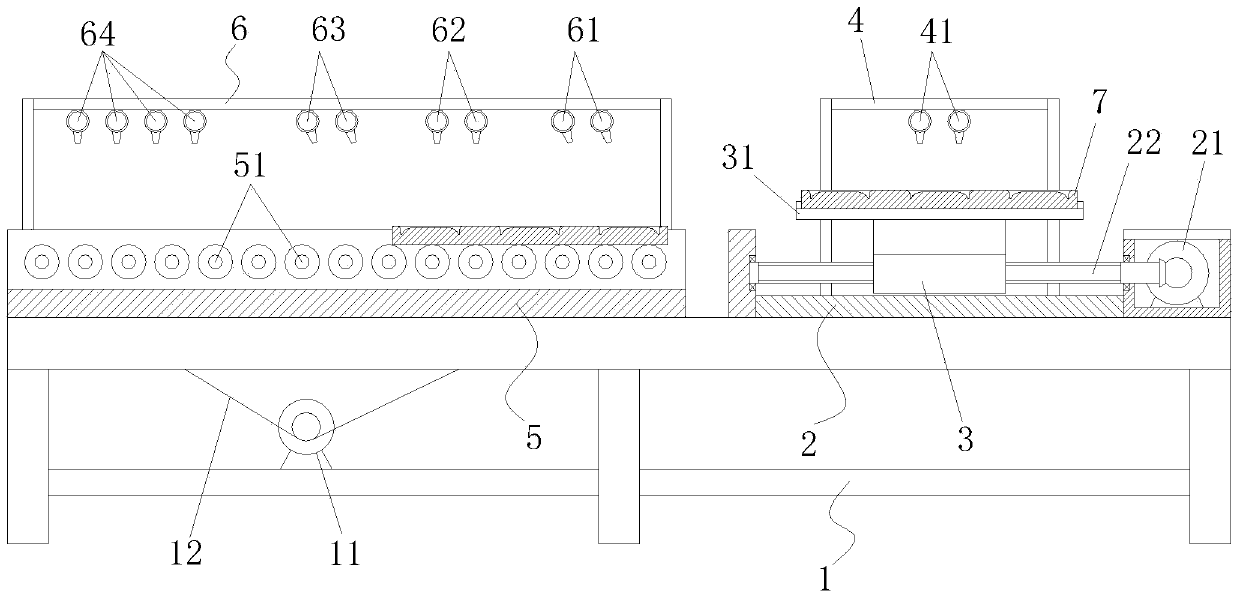

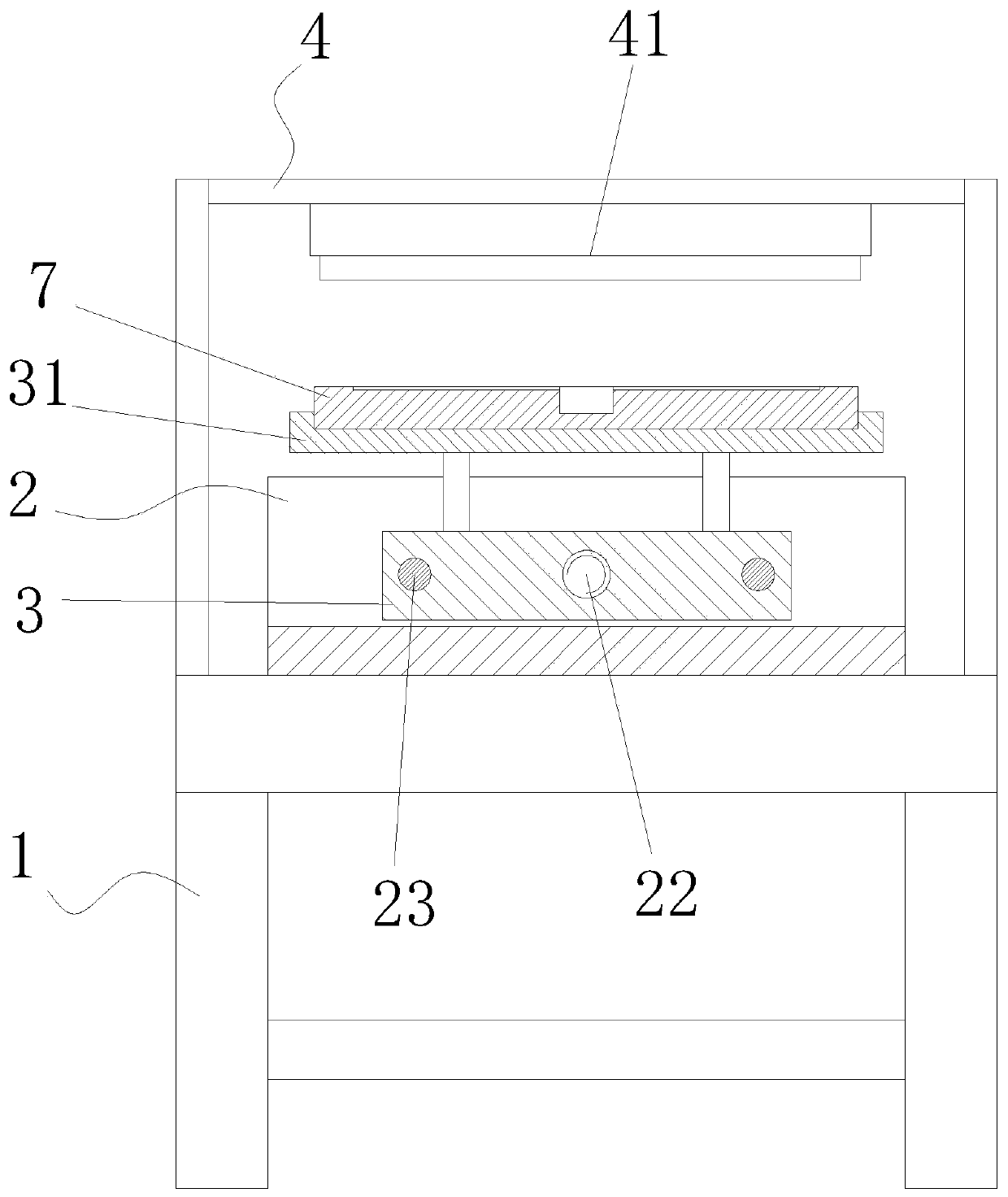

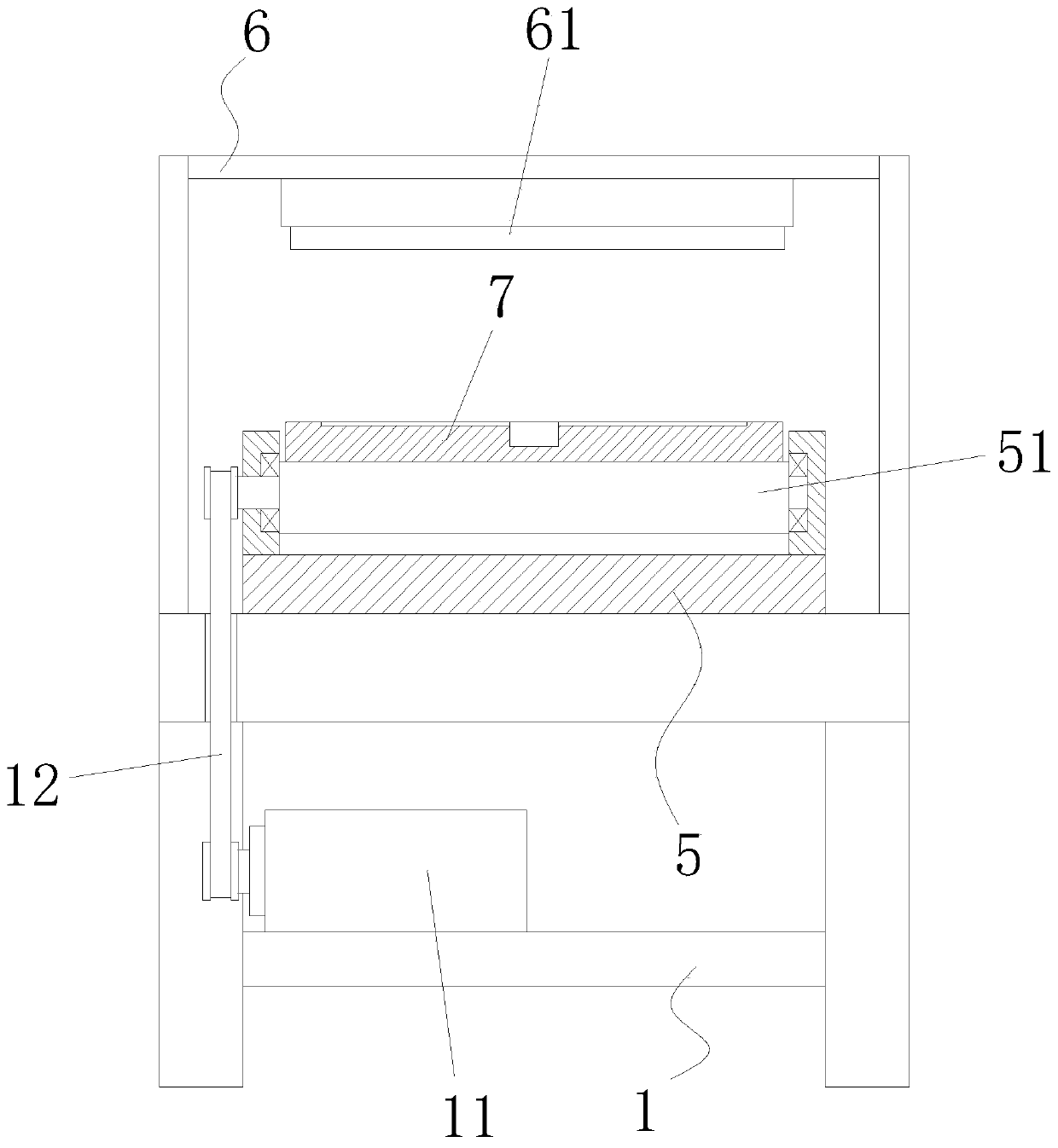

[0027] Embodiment one: if Figure 1~5 As shown, an anti-glare surface treatment equipment for a curved edge glass cover plate includes a frame 1, on which a substrate 7, an etching device, a polishing device and a drying device are sequentially arranged along the material conveying direction, and the substrate is provided with There are a number of grooves 71 for placing the glass cover. The grooves are provided with protrusions 72 that completely fit the inner surface of the glass cover. The two ends of the protrusions are in contact with the two ends of the grooves. There is a gap between the two side walls of the groove, a drain channel 73 is arranged in the middle of the base plate, and a drain port 74 communicating with the drain channel is provided at one end of the gap, (the drain channel helps the liquid in the groove flow out along the liquid discharge port to avoid liquid accumulation, so that the bottom glass cover in the groove is over-etched), the etching device i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com