Tube type vaporization device for liquefied gas for industrial use

An industrial oil and vaporization device technology, applied in the direction of combustion method, liquid fuel supply/distribution, combustion type, etc., can solve the problems of inconsistency in combustion degree, inability to solve the problems of fluid backflow, uneven heating temperature, etc., and achieve low cost and raw materials wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

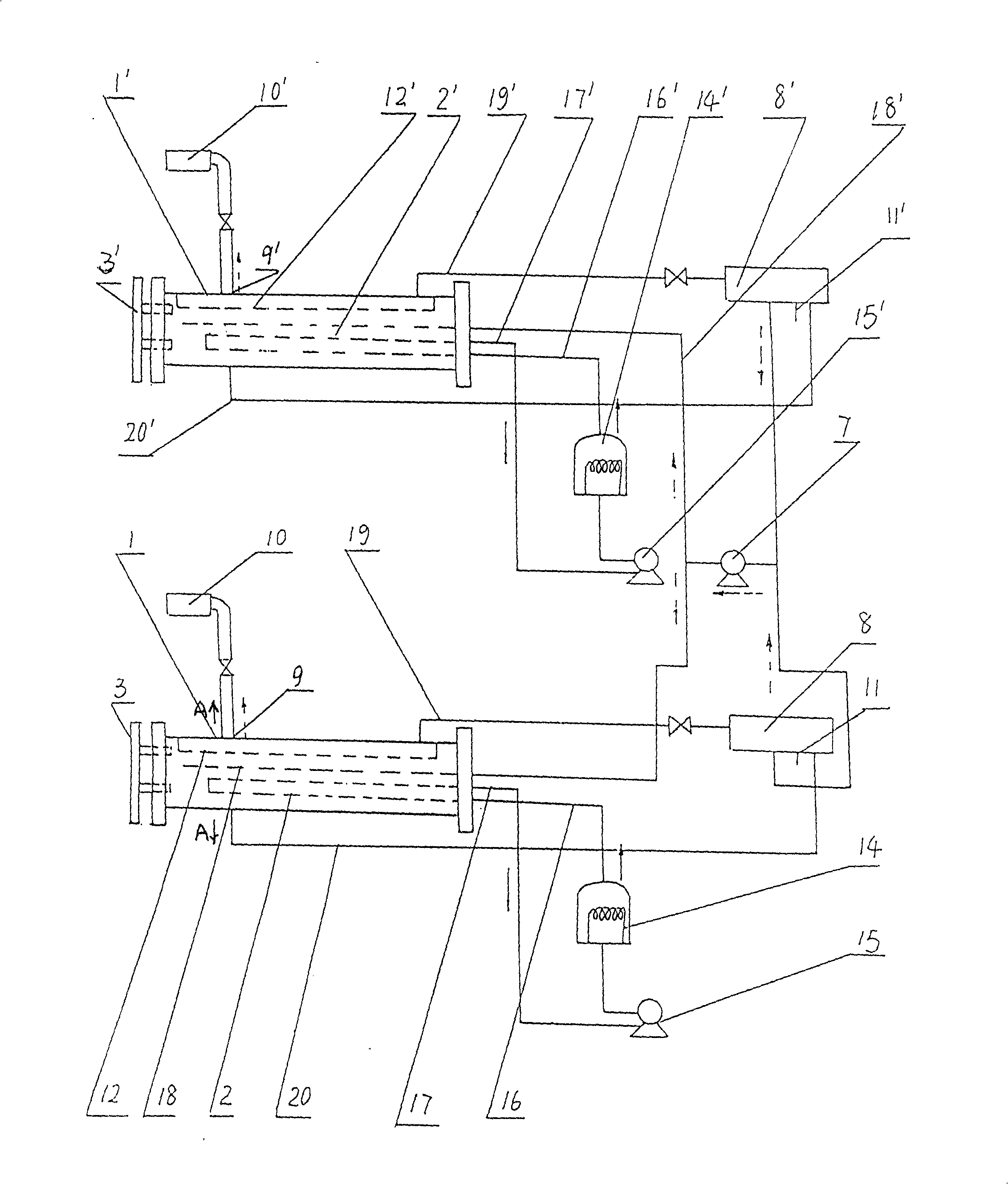

[0021] Such as figure 1 As shown, when the present invention is implemented, the vaporization part includes two sets of vaporization pipes 1, 1'; the liquid supply part includes two balance liquid storage tanks 8, 8', and an oil delivery pump 7; The combustion part includes burners 10, 10'; the heating part includes two sets of heating pots 14, 14' and hot oil pumps 15, 15' matched with the heating pots, and the heating pots in the heating part are vertical and horizontal or tubular. The hot oil output ports of the two sets of heating parts are respectively communicated with the heating medium circulation conduit inlets 4, 4' of the two sets of vaporization parts through respective heat oil pumps 15, 15' and pipelines 16, 16', and the heating medium circulation conduits 2, The outlets of 2' are respectively connected to the heating pots 14 and 14' through the respective output pipes 17 and 17' through the hot oil pumps 15 and 15' to form a heat transfer medium circulation loo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com