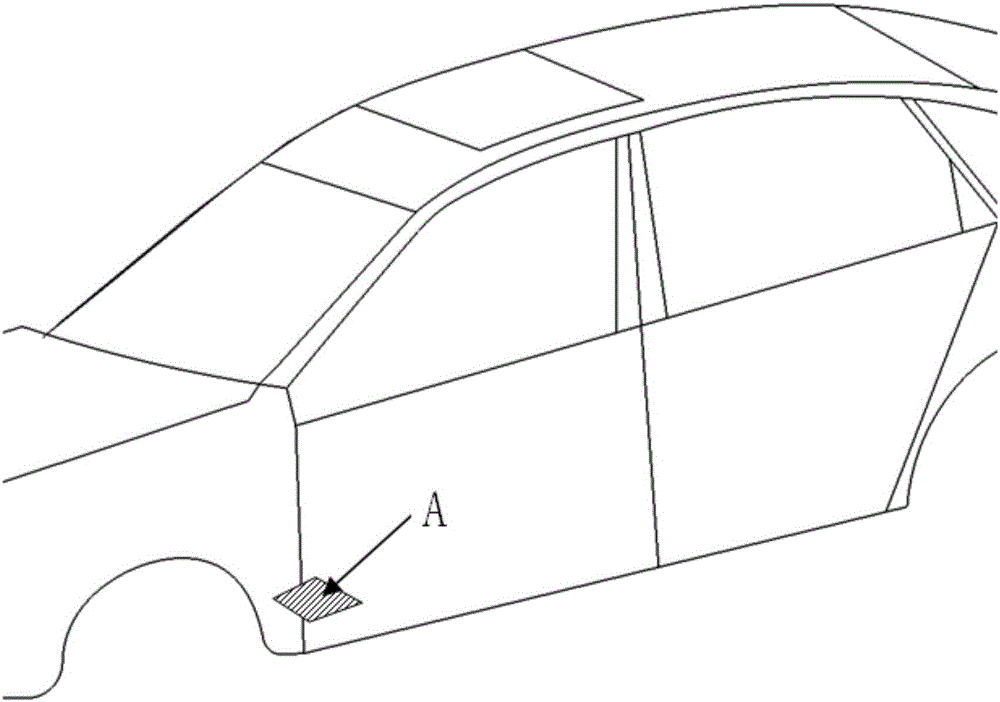

Automobile body cavity sound insulation rubber block

A technology of automobile body and sound insulation glue, applied in vehicle parts, transportation and packaging, etc., can solve the problems of sound leakage of drain pipes, influence of sound insulation and noise reduction, easy blockage, etc. Convenient and fast effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below in conjunction with the accompanying drawings.

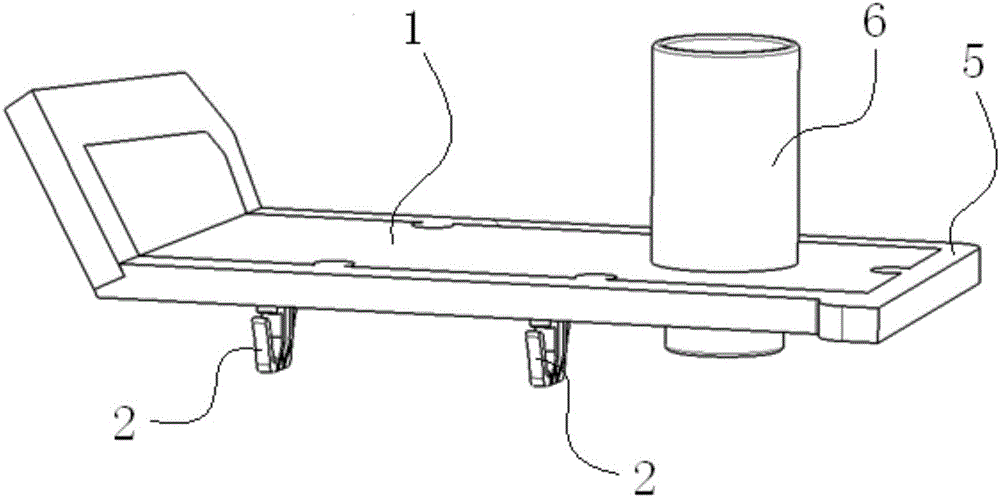

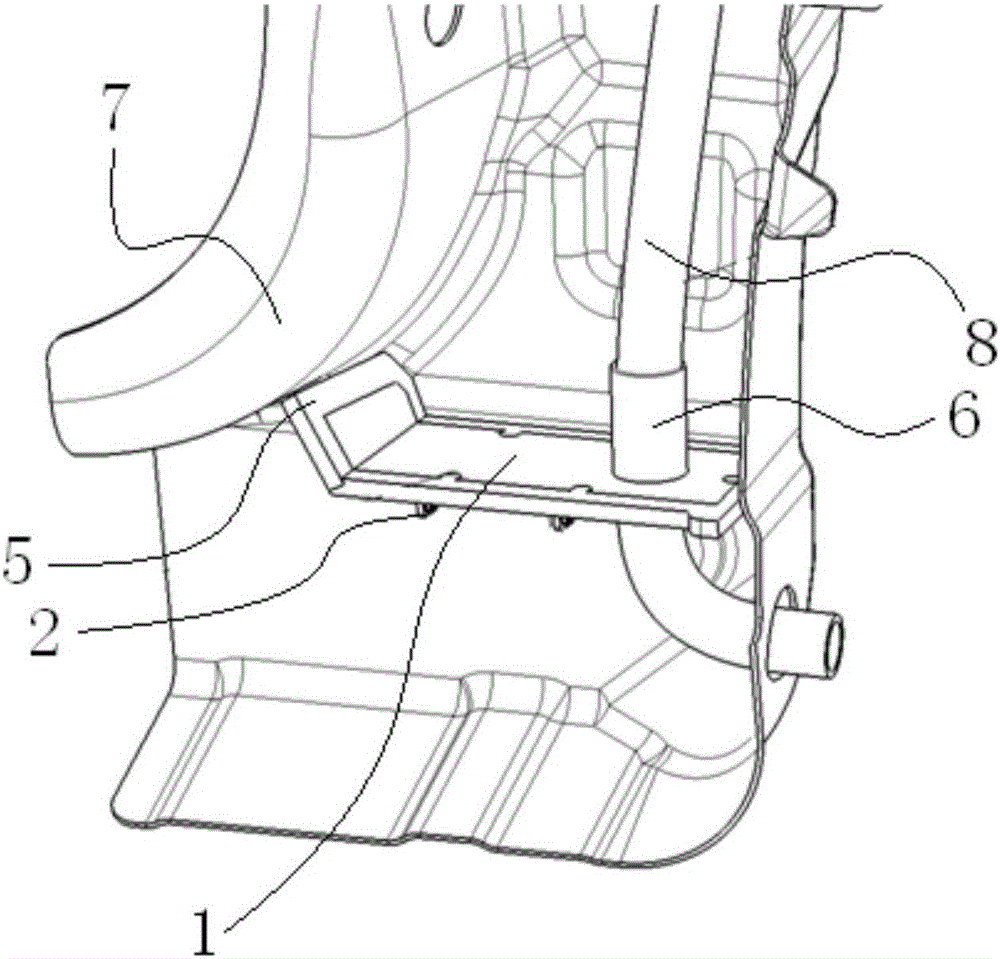

[0028] Such as Figure 4 , Figure 5 The car body cavity sound-insulating rubber block shown includes a sound-insulating base 1, two installation buckles 2 arranged on the lower surface of the sound-insulating base 1, a guide pipe 3 passing through the sound-insulating base 1 and connecting the outer wall with the sound-insulating base 1, and The outlet of the guide tube 3 cooperates with the blocking cover 4 for opening / closing the guide tube and the foam material 5 embedded in the soundproof base 1, the soundproof base 1, the installation buckle 2, the guide tube 3 and the cover 4 It is integrally injection-molded from nylon material, and the foam material 5 is EVA material, which is inlaid in one circle of the sound-insulating matrix through a secondary injection molding process. The guide pipe 3 has an inlet pipe 31 located on the upper surface of the soundproo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com