Refrigerant flow equalizing device for shell-and-tube heat exchanger

A shell-and-tube heat exchanger and refrigerant technology, which is applied in the direction of evaporator/condenser, refrigerator, refrigeration components, etc., can solve the problem of uneven distribution of refrigerant flow, avoid low heat exchange efficiency, simple assembly method, Effects with low requirements on required conditions and equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below with reference to the accompanying drawings.

[0027] The present embodiment will be described as an example of a refrigerant flowery device for a dual system housing heat exchanger. In accordance with the concept of the present invention, based on the prior art, through logic analysis, reasoning or limited experiments, such as single system heat exchanger, or other form of refrigeration, should be within the scope of protection determined by the claims .

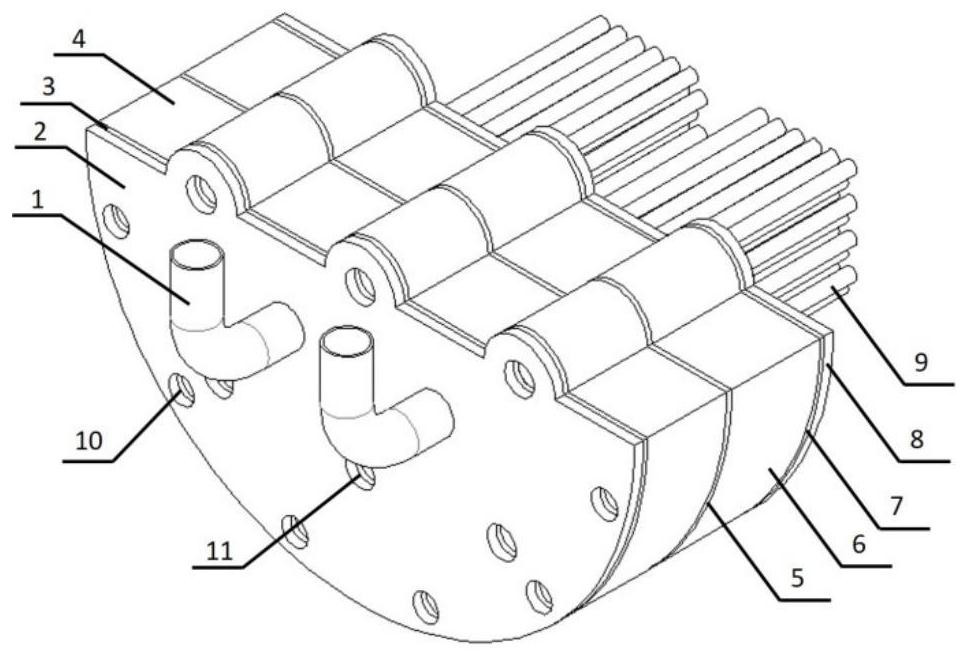

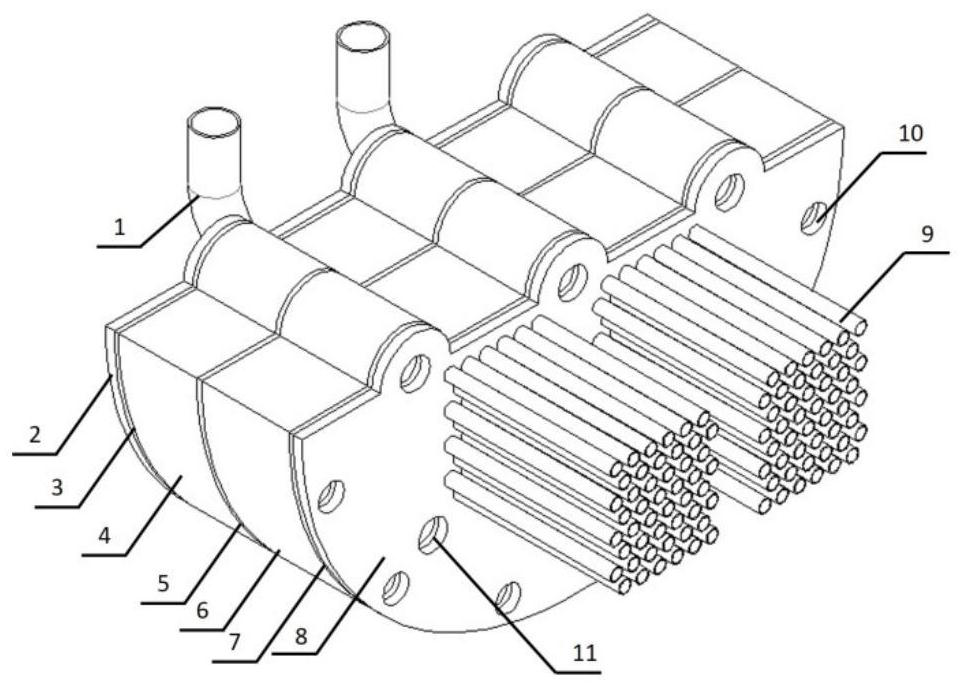

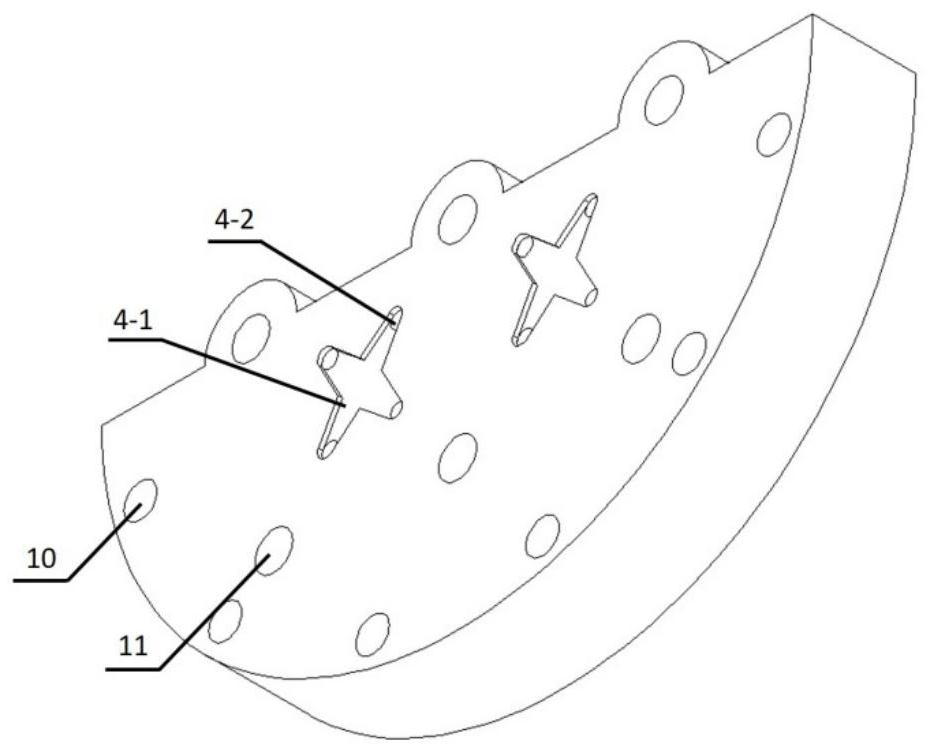

[0028] Refer Figure 1 - Figure 7 The refrigerant mesh current flow device of the housing heat exchanger includes inlet tubes 1, end cover plate 2, 1-stage dispenser 4, secondary dispenser 6, tube plate 8, first sealing pad 3, second Sealing pad 5, the third feeding pad 7, and the heat exchange tube 9, etc.

[0029] Among them, an end cover 2 is provided on one side of the first-order dispenser 4, and a first sealing pad 3 is provided between the first-level dispenser ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com