Multi-split system capable of defrosting alternately without stopping as well as defrosting control method

A multi-connected system, rotating defrosting technology, applied in refrigerators, mechanical equipment, refrigeration components, etc., can solve problems such as high power consumption, shorten the service life of compressors, affect customer experience, etc., to achieve high defrosting efficiency, Simple action and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

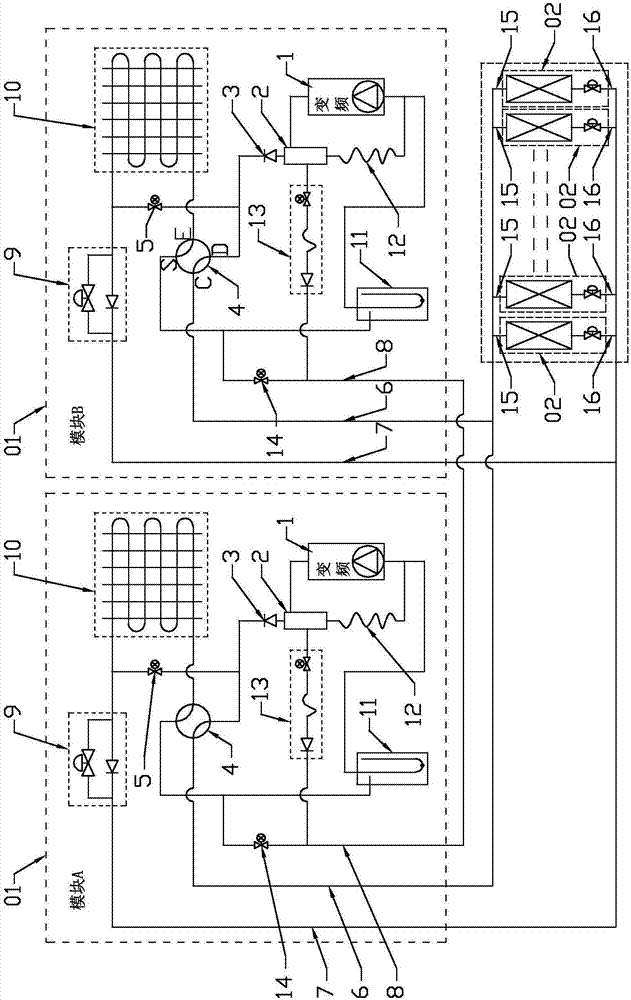

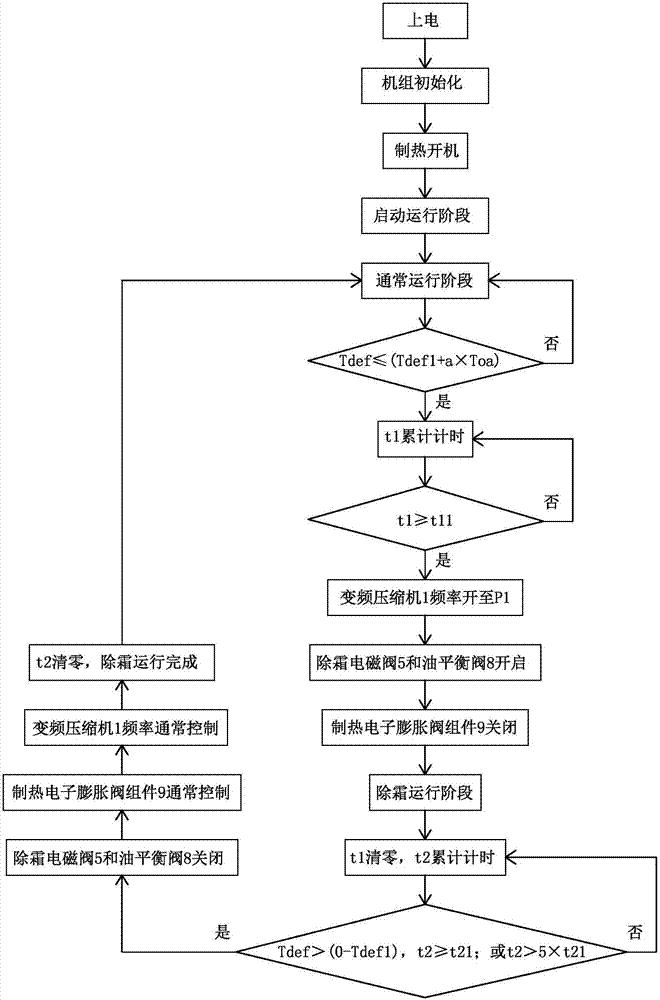

[0045] The multi-connected system of the combination of the two modules shown includes outdoor basic module 1, outdoor basic module 2, multi-connected indoor units of corresponding capacity, and air-conditioning pipelines connecting the indoor and outdoor units in parallel. The outdoor basic module A is set as the main module. Then the outdoor basic module B is a slave module, and the movement process of the unit is:

[0046] S1 unit is powered on;

[0047] S2 unit initialization;

[0048] S3 Heating start, the unit enters the start-up phase;

[0049] S4 The unit enters the normal operation stage;

[0050] The S5 unit continuously detects the outdoor ambient temperature Toa and the outdoor heat exchanger temperature Tdef, and any module satisfies: the outdoor heat exchanger temperature Tdef≤(defrosting temperature Tdef1+environmental correction factor a×outdoor ambient temperature Toa), and t1≥t11, and If there is no defrosting operation module in the system, then the modul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com