Separation and recovery method for leaching solutions of waste battery material containing nickel, cobalt and manganese

A technology for separation and recycling of waste batteries, applied in battery recycling, waste collector recycling, recycling technology, etc., can solve the problems of difficult removal of impurity ions Ca and Mg, precipitation and entrainment loss, high content of valuable metals, etc., to achieve auxiliary The effect of less raw material consumption, low operating cost and high separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

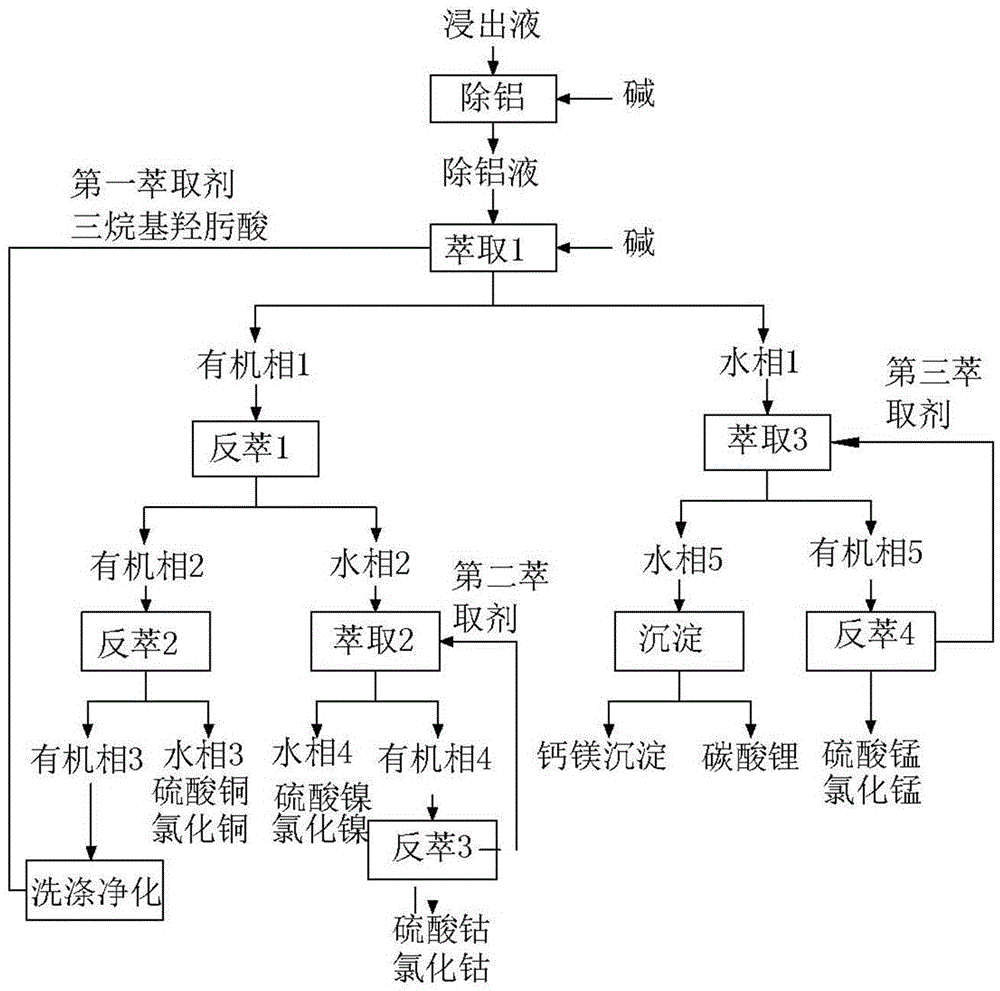

Image

Examples

Embodiment 1

[0038] The positive electrode material composition is nickel cobalt lithium manganese oxide waste battery leach solution 100L composition as follows:

[0039] the element

Ni

co

mn

Li

Cu

Ca

Mg

Content (g / L)

5.32

7.01

6.55

1.9

0.40

0.05

0.5

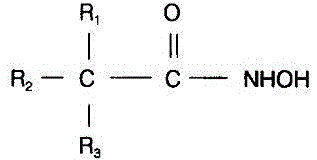

[0040] Extraction 1 uses trialkyl hydroxamic acid as the extractant reactant, the concentration is 10%-15%, compared to O:A=1.5:1 at room temperature, the extraction stage is 5-8, and 12% ammonia water is added to adjust the feed liquid The equilibrium pH is 4.4-5.8, and the organic phase 1 and the aqueous phase 1 are respectively obtained after phase separation. The organic phase 1 contains Ni, Co and impurity Cu, Fe ions, and 0.4mol / L sulfuric acid is used for stripping 1, and the organic phase 2 and the aqueous phase 2 are obtained after phase separation compared with O:A=1:1. Under this acidity, Ni and Co can be back-extracted in the aqueous phase 2, and Cu rem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com