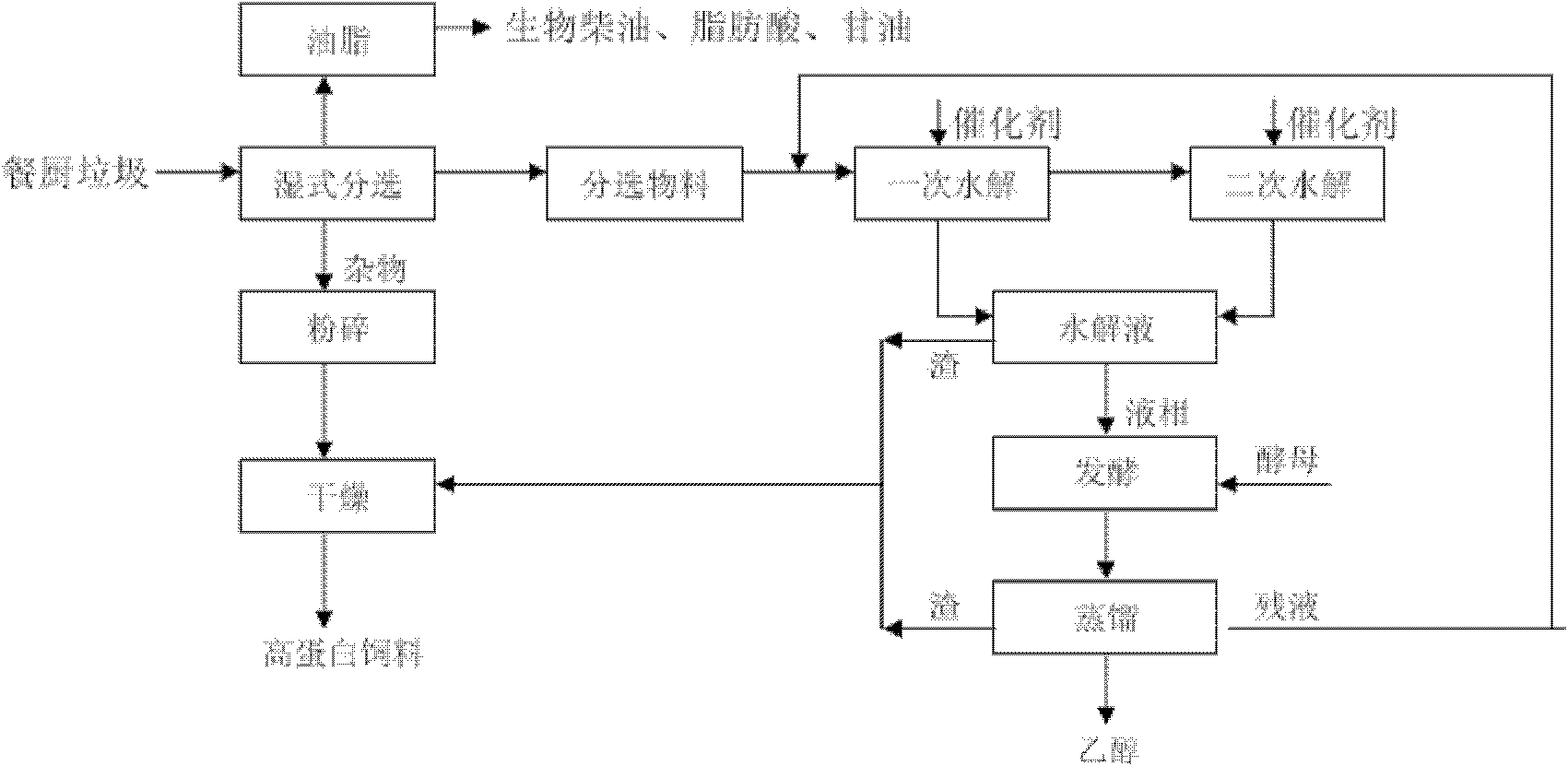

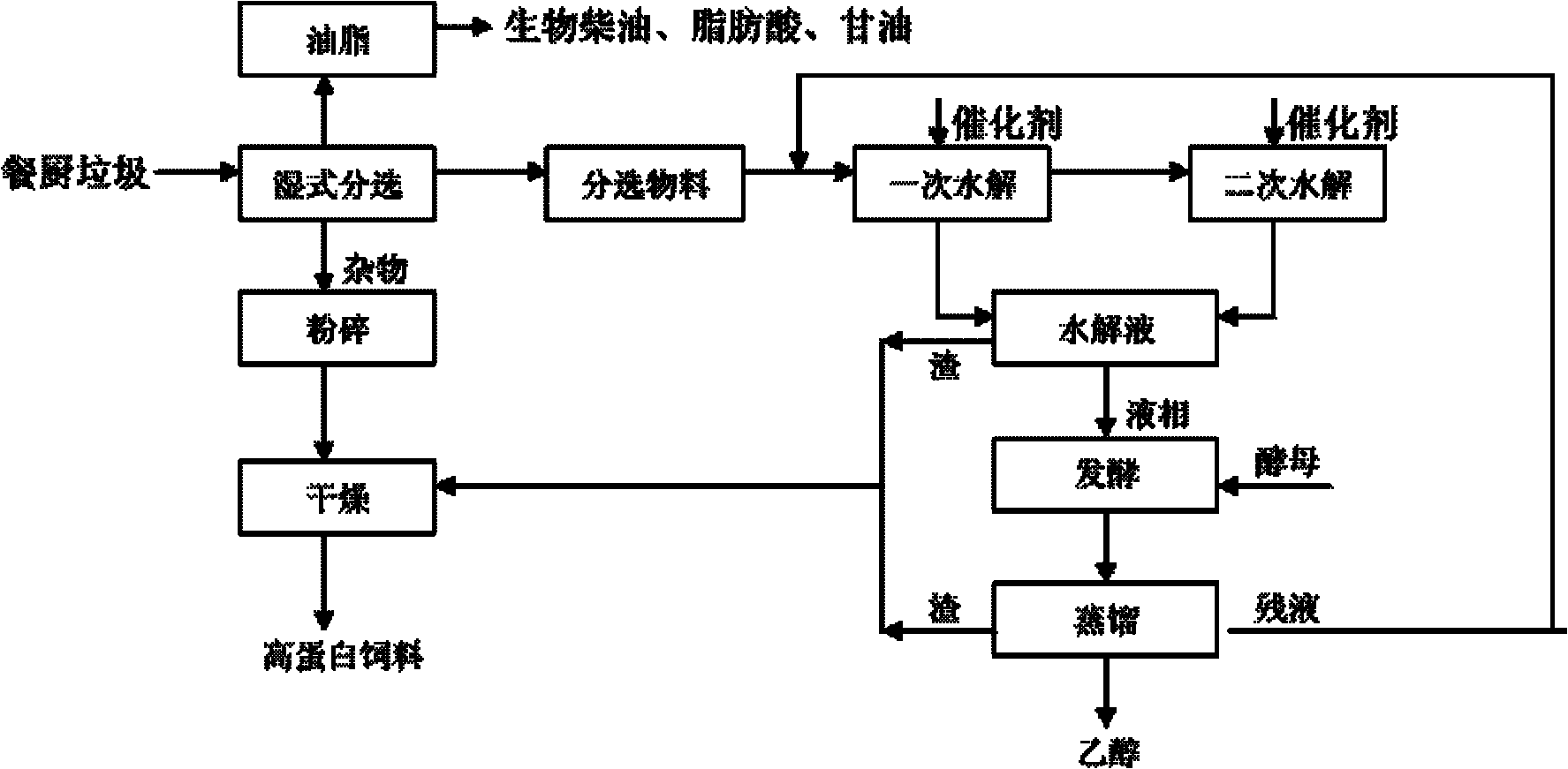

Recycling method for cleaning and processing kitchen waste

A kitchen waste and cleaning treatment technology, which is applied to the removal of solid waste, animal feed, and the recovery of fat oil/fatty acid from waste, etc., can solve the problems of high impurities, low fertilizer quality, waste of resources, etc., and achieve good economic benefits. High degree of hydrolysis, energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] 1. Take 1000Kg of kitchen waste, vacuum suction into the wet sorting system, put the food waste into the temporary storage tank to heat the material to 40~50℃, then transfer it to the oil-water separator to separate the liquid phase material after standing. Add 0.05% oil-water separator under stirring, release the water phase after standing to obtain the recovered oil phase, and prepare biodiesel from the oil phase; the oil-water separator is a polymer cationic amide surfactant.

[0055] 2. The rest of the garbage enters the liquid pool and is sent to the homogenization tank by the feed pump. The homogenizer is turned on for 10-15 minutes to homogenize. The residual liquid is added to the distilled residual liquid storage tank to adjust the weight ratio of solid to liquid. After homogenizing for 5 minutes, the feed liquid is pumped into the primary hydrolysis tank for the first hydrolysis. After the hydrolysis is completed, it is filtered while hot, the filtrate is sent to ...

Embodiment 2

[0062] 1. Take 1000Kg of kitchen waste, vacuum suction into the wet sorting system, put the food waste into the temporary storage tank to heat the material to 40~50℃, then transfer it to the oil-water separator to separate the liquid phase material after standing. Under stirring, 0.01% by weight oil-water separating agent is added, and after standing still, the water phase is released to obtain the recovered oil phase, and the oil phase is used to prepare biodiesel and fatty acid. The oil-water separating agent is a polymer cationic amide surfactant;

[0063] 2. The remaining garbage enters the material-liquid pool, and is sent to the homogenization tank by the feed pump. The homogenizer is turned on for 10-15 minutes, and the weight ratio of solid to liquid (solid-liquid ratio) is adjusted by the distillation residual liquid storage tank. After homogenizing for 5 minutes, the feed liquid is pumped into the primary hydrolysis tank for the first hydrolysis, filtered while hot, the...

Embodiment 3

[0070] 1. Take 1000Kg of kitchen waste, vacuum suction into the wet sorting system, put the food waste into the temporary storage tank to heat the material to 40~50℃, then transfer it to the oil-water separator to separate the liquid phase material after standing. Adding 0.03% by weight oil-water separating agent under stirring, and releasing the water phase after standing to obtain the recovered oil phase. The oil phase is used to prepare biodiesel, fatty acid and glycerin. The oil-water separating agent is a polymer cationic amide surfactant;

[0071] 2. The rest of the garbage enters the liquid pool and is sent to the homogenization tank by the feed pump. The homogenizer is turned on for 10-15 minutes to homogenize. The residual liquid is added to the distilled residual liquid storage tank to adjust the weight ratio of solid to liquid. After homogenizing for 5 minutes, the feed liquid is pumped into the primary hydrolysis tank for the first hydrolysis, filtered while hot, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com