Hog house structure with external fermentation bed and manufacturing method of padding layer for fermentation bed

A production method and fermentation bed technology, applied in the field of pig breeding, can solve the problems of high proportion of sawdust, unfavorable use in summer, shortage of resources, etc., and achieve the effects of improving the degree of resource utilization, increasing the safety of use, and reducing bacterial infection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

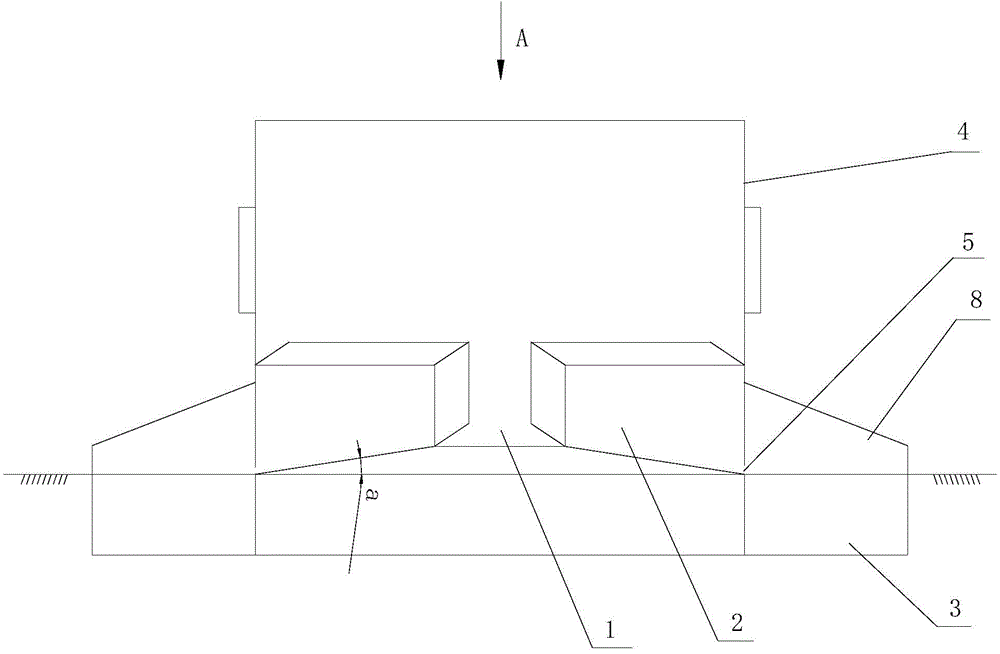

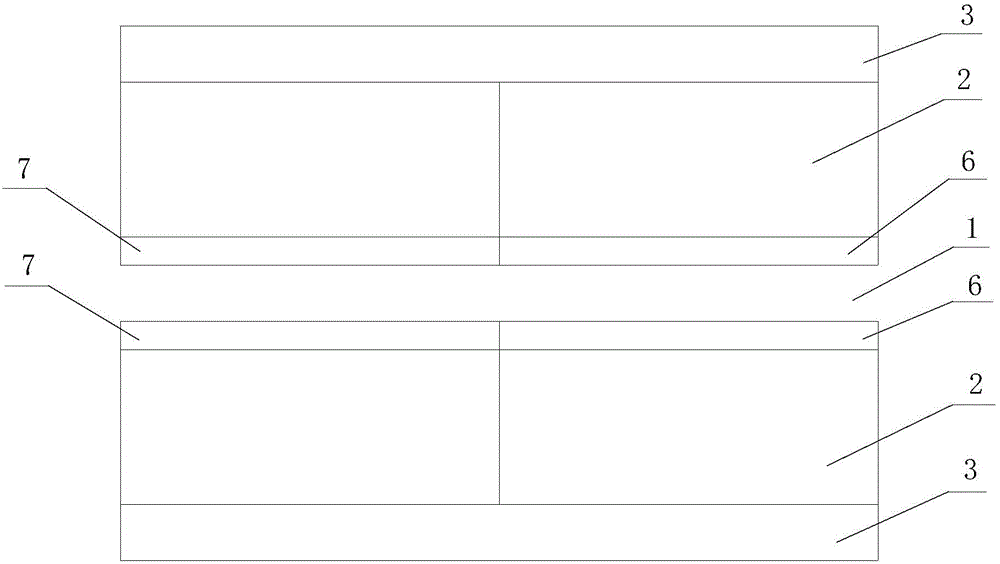

[0034] In this embodiment, a kind of pig house structure with external fermentation bed, such as figure 1 or figure 2 As shown, it includes aisle 1, pig bed 2 and fermentation bed 3. The aisle and pig bed are set indoors, and the fermentation bed is set outdoors. The outer wall of the shed is arranged parallel to the pig bed, and the bottom of the outer wall of the pig house is provided with a wall sewage outlet 5, and the fermentation bed and the pig bed are connected through the wall sewage outlet; a bedding layer is laid inside the fermentation bed.

[0035] Taking the ground of the aisle as the reference horizontal plane, from the direction of the aisle to the outer wall of the pig house, the ground of the pig bed is inclined downward by 5-10° (such as figure 1 angle a) in . The setting of the inclination angle can facilitate the flow of pig urine and part of the waste water from flushing the pig house (supplementing the moisture content in the litter) into the fermenta...

Embodiment 2

[0046] In this embodiment, a method for making a bedding layer for a fermentation bed in a piggery structure described in Example 1 comprises the following steps:

[0047] (1) Mix the raw materials of the litter layer, and the mass content of water in the formed mixture is 45%; the raw materials include sawdust, corn stalks, diatomaceous earth and auxiliary fermentation agent;

[0048] (2) Stack and ferment the mixture, and stir once when the temperature of the middle layer of the mixture reaches 50-65°C (usually about 3 days);

[0049] (3) The mixture is stacked and fermented, and when the temperature of the middle layer of the mixture drops to 45°C (generally about 3 days), the mixture is laid on the fermentation bed;

[0050] (4) After the fermentation bed is put into use, the litter layer should be mixed once a week by the mixer, and the raking depth should be 20-30cm.

[0051] The content of each constituent raw material in the litter layer is as follows: the mass ratio ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com