Method for collaborative resource between waste circuit board and automobile tail gas waste catalyst

A technology for waste circuit boards and waste catalysts, applied in the fields of resource utilization and industrial waste treatment, can solve the problems of consumption of reagents and low recovery rate, and achieve the effects of high degree of resource utilization, clean treatment process and simple process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

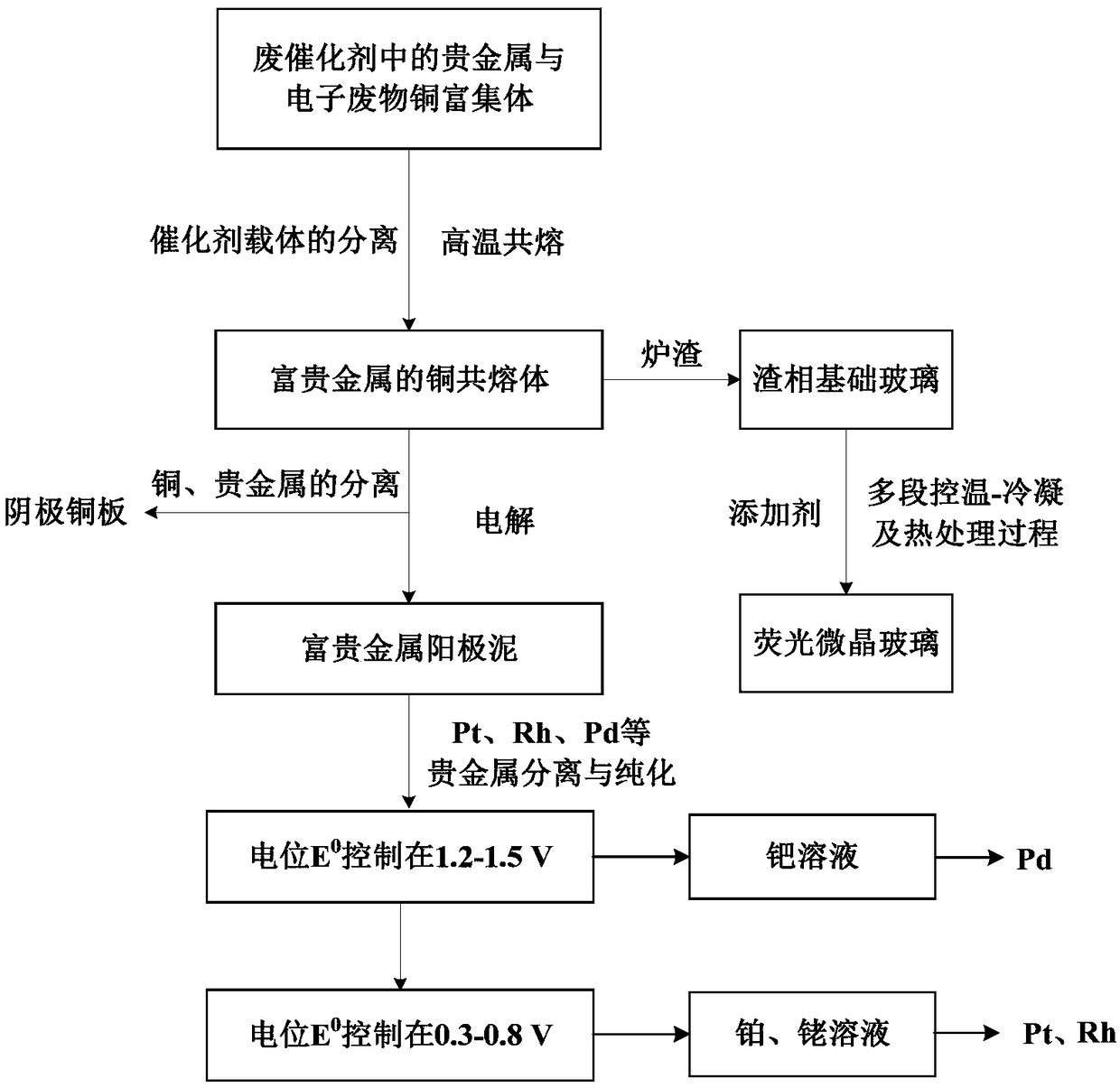

Method used

Image

Examples

Embodiment 1

[0032]Firstly, copper-enriched bodies are obtained by crushing, magnetic separation and high-voltage electrostatic separation of waste circuit boards. Then crush the waste catalyst of automobile exhaust gas to obtain waste catalyst powder. The two powders of the copper-enriched body and the spent catalyst are mixed to obtain a mixed powder. Based on the mixed powder, the reagents according to a certain formula include: 20% calcium oxide, 30% silicon dioxide, 10% borax, 8% sodium carbonate, 10% copper oxide and 5% coke powder. Then, the mixed powder was placed in a muffle furnace, the heating rate of the heating section was 10°C / min, the temperature was raised to 1300°C, and the temperature was kept for 0.5h. After the heat preservation was completed, the sample was taken out. Then the mixed powder sample shows obvious delamination phenomenon, the upper layer is a glass layer, and the lower layer is a copper layer, and the copper layer and the glass layer are separated. Take ...

Embodiment 2

[0034] Firstly, copper-enriched bodies are obtained by crushing, magnetic separation and high-voltage electrostatic separation of waste circuit boards. Then crush the waste catalyst of automobile exhaust gas to obtain waste catalyst powder. The two powders of the copper-enriched body and the spent catalyst are mixed to obtain a mixed powder. Based on the mixed powder, the reagents according to a certain formula include: 20% calcium oxide, 30% silicon dioxide, 10% borax, 8% sodium carbonate, 30% copper oxide and 5% coke powder. Then, the mixed powder was placed in a muffle furnace, the heating rate of the heating section was 10°C / min, the temperature was raised to 1300°C, and the temperature was kept for 2 hours. After the heat preservation was completed, the sample was taken out. Then the mixed powder sample shows obvious delamination phenomenon, the upper layer is a glass layer, and the lower layer is a copper layer, and the copper layer and the glass layer are separated. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com