Patents

Literature

49results about How to "Enable co-processing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

System and process of ceramsite production and co-processing of dangerous waste

PendingCN107642786AGood economic and environmental benefitsEnable co-processingIncreasing energy efficiencyIncinerator apparatusContaminated soilsCo-processing

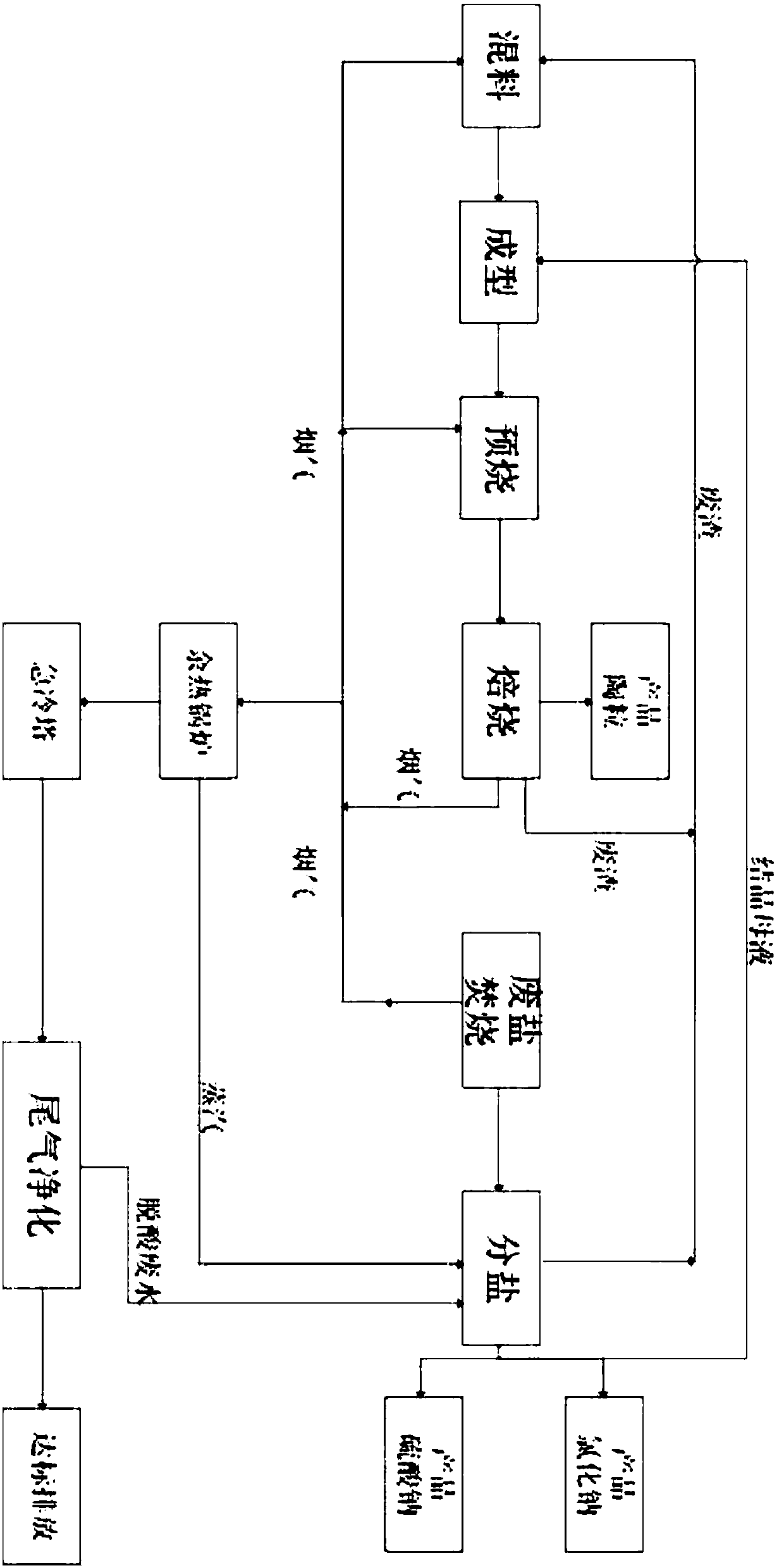

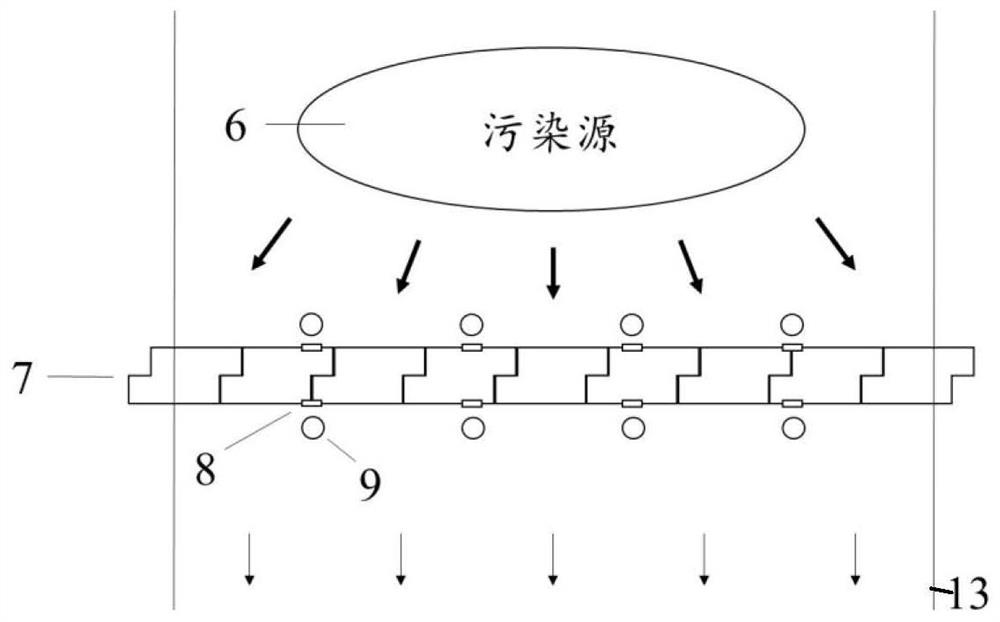

The invention belongs to the technical field of dangerous waste processing and comprehensive utilization, and provides a method for ceramsite production and co-processing of dangerous waste. The method mainly includes a ceramsite production process and a waste salt comprehensive utilization process; the ceramsite production process includes material blending, molding, pre-burning, roasting and other process steps; the waste salt comprehensive utilization process includes incineration, salt separation, waste heat utilization, tail gas purification and other process steps. By adopting the process, co-processing of the dangerous waste and various solid waste including high-salinity dangerous waste, high-heat dangerous waste, sludge, contaminated soil, slags and the like can be achieved; maximum utilization and harmless processing of the intermediate pollutants, including smoke, flying dust, slags, mother liquid and the like, which are generated in the production process, waste heat resources and all the dangerous waste raw materials can be achieved in the system, the ceramsite high in strength, sodium chloride products high in purity and sodium sulfate products high in purity are finally obtained, and the tail gas satisfies the emission standards. The process is compact and reasonable and easy to popularize and implement and has great economic benefits, environmental benefits andsocial benefits.

Owner:山东清博生态材料综合利用有限公司

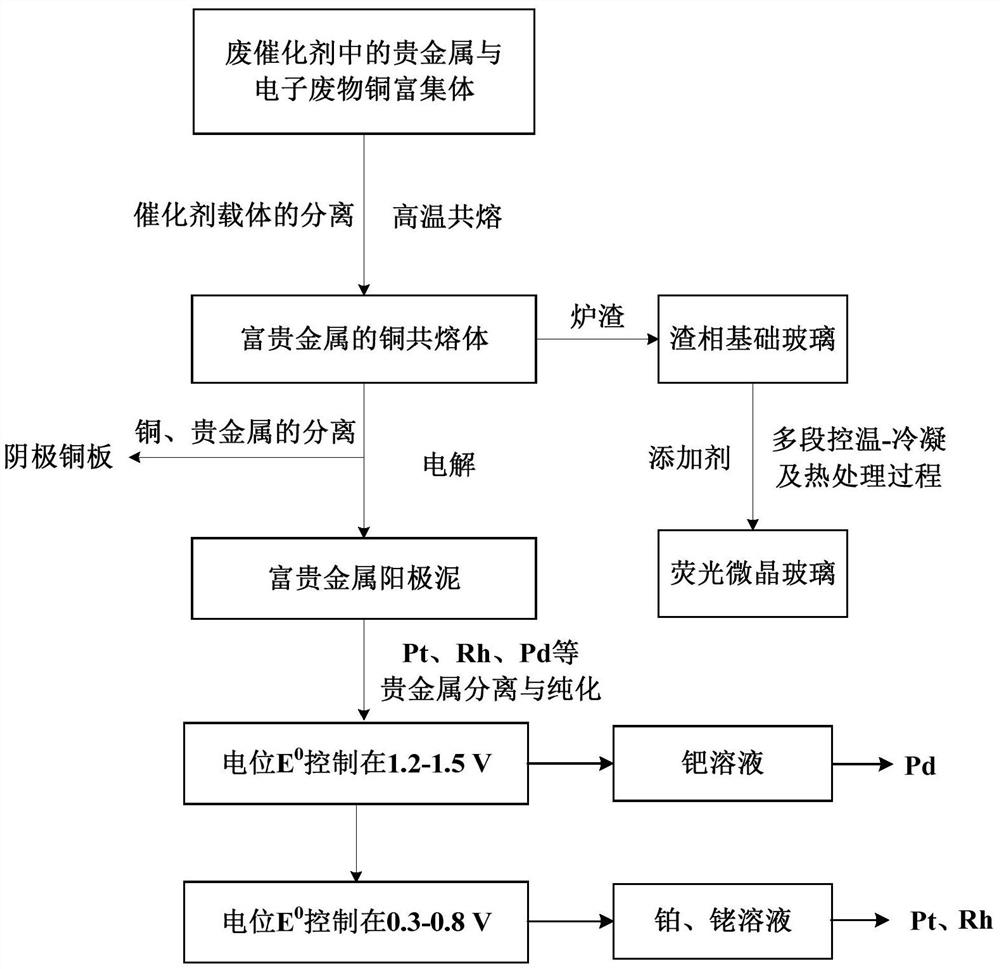

Method for collaborative resource between waste circuit board and automobile tail gas waste catalyst

ActiveCN109136532AEasy to separateEnable co-processingProcess efficiency improvementElectrostatic separationEngineering

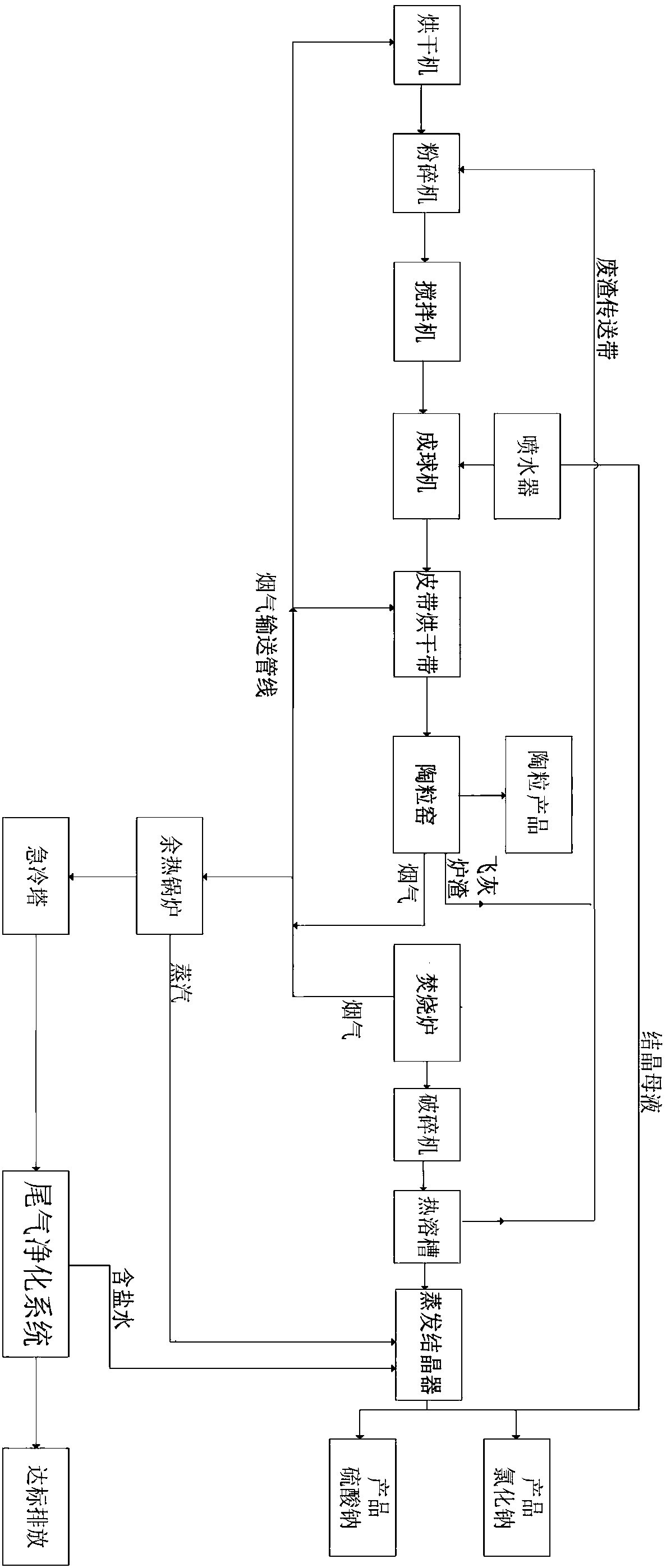

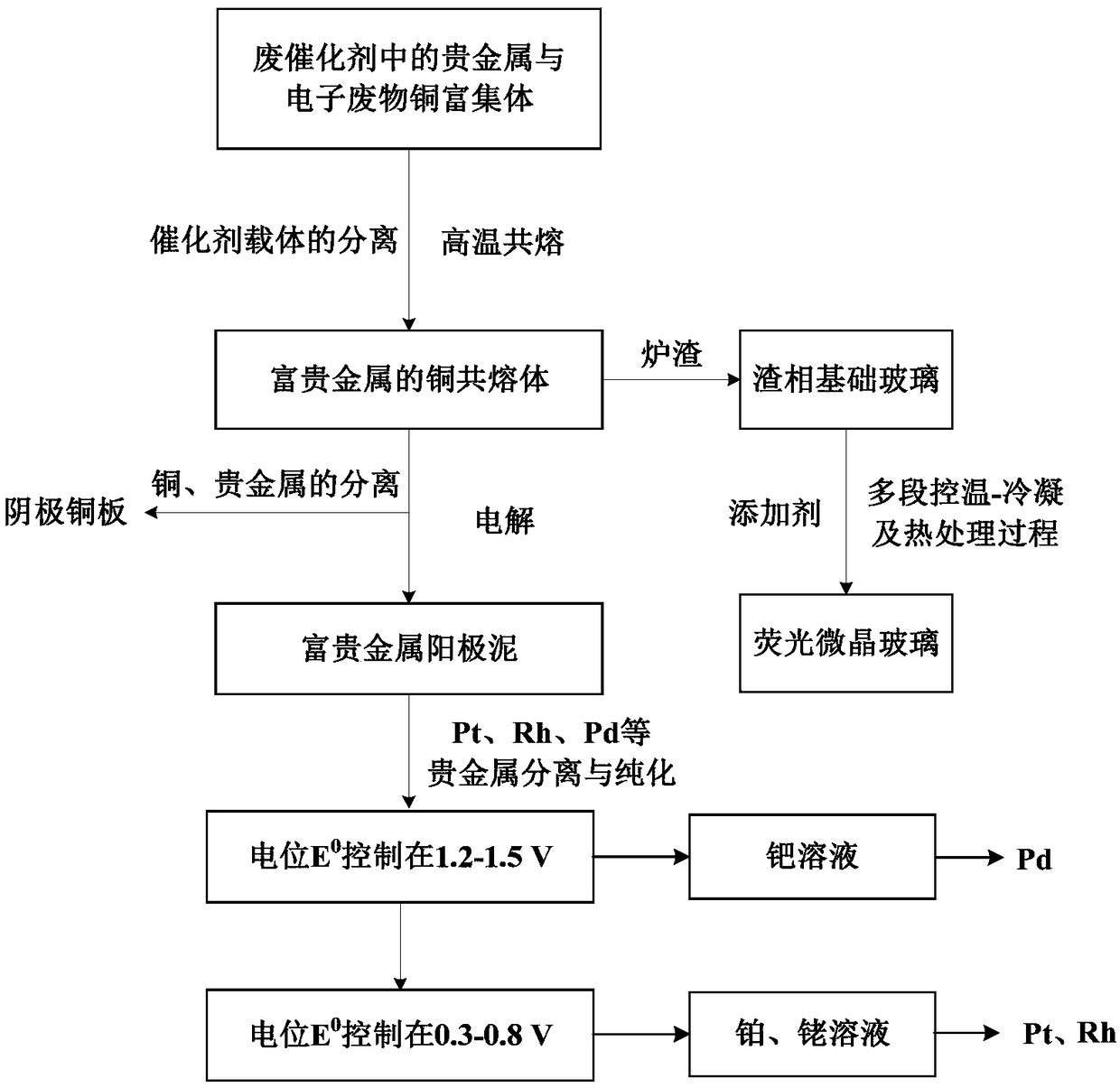

The invention discloses a method for collaborative resource between a waste circuit board and an automobile tail gas waste catalyst. The method comprises the following steps: firstly, obtaining a copper-rich collective through performing crushing, magnetic separation and high voltage electrostatic separation on the waste circuit board; crushing the automobile tail gas waste catalyst to obtain waste catalyst powder; mixing the copper-rich collective and the waste catalyst powder to obtain mixed powder; adding a reagent in a certain amount of mixed powder in proportion, placing in a high-temperature muffle furnace for reaction and cooling to a room temperature after the completion of the reaction to obtain a product of which an upper layer is a glass layer, and a lower layer is a copper layer; separating the copper layer from the glass layer, taking out, crushing, then placing the glass layer in the muffle furnace for heat treatment; after the completion of the treatment, pouring microcrystalline glass liquid into a mold while the microcrystalline glass liquid is still hot, reducing the temperature and forming; after a room temperature is lowered, preparing out fluorescent microcrystalline glass. In the process, the recovery rate of precious metals exceeds 98 percent, the precious metals are enriched for 20 times or more, and the obtained fluorescent microcrystalline glass can betaken as an LED fluorescent lamp and other materials. To sum up, the method has the characteristics of being efficient, environmentally friendly and high in resource degree and is suitable for large-scale industrial application.

Owner:SHANGHAI JIAO TONG UNIV

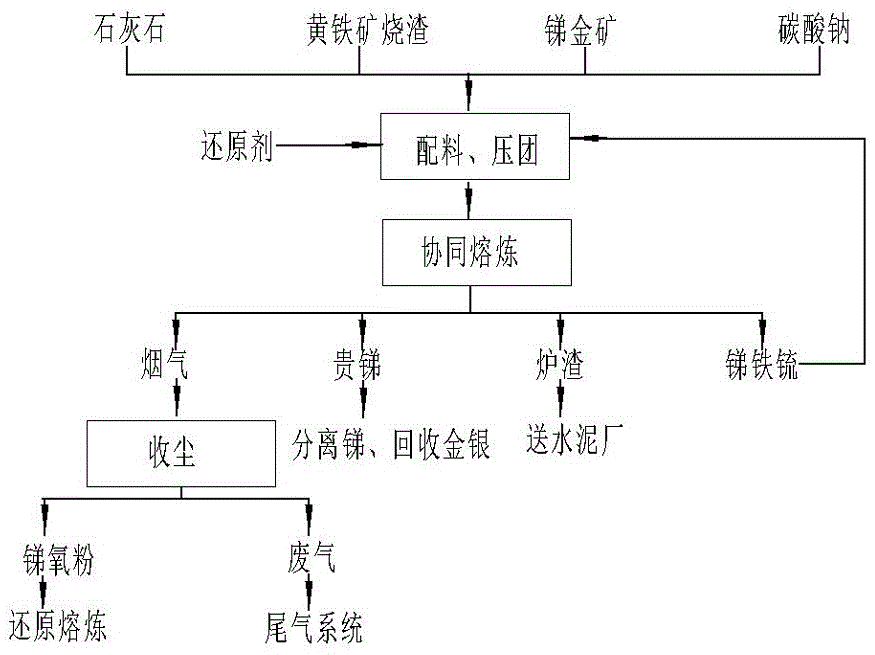

Method of enriching valuable metals through collaborative smelting of gold-antimony deposit and auriferous pyrite cinder

The invention discloses a method of enriching valuable metals through collaborative smelting of a gold-antimony deposit and auriferous pyrite cinder. According to the method, in a smelting burdening process of the gold-antimony deposit, auriferous pyrite cinder replaces the original flux iron ore concentrate, the gold-antimony deposit and the auriferous pyrite cinder are subjected to collaborative smelting together, and a given amount of sodium carbonate is added for reducing a melting point of slag and improving the flowability of a melt, so that the smelting temperature is reduced effectively, the valuable metals like gold and silver in the auriferous pyrite cinder and antimony concentrate can be enriched in crude metallic antimony more, and the probability of oxygenation volatilization of antimony is reduced. The method has the outstanding advantages as follows: firstly, one-step smelting allows antimony to generate metallic antimony more, and the scattering problem of antimony in crude metal, flue gas and iron-antimony matte in the traditional technology is solved; secondly, difficult-to-treat solid waste, namely the auriferous pyrite cinder is used comprehensively, the iron ore concentrate is replaced, the consumption of primary resources is reduced and the industrial solid waste is treated collaboratively; finally, the valuable metals, namely gold and silver in the concentrate and the auriferous pyrite cinder are enriched and recovered, the energy consumption is reduced, and the collaborative smelting effects of comprehensive recovery, low carbon cleaning and production process centralization are exerted.

Owner:合肥龙之韵医药技术有限公司

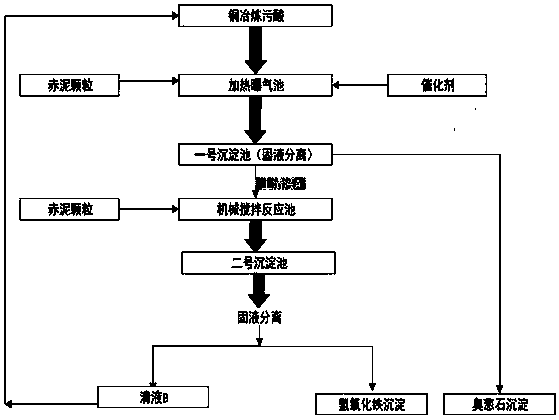

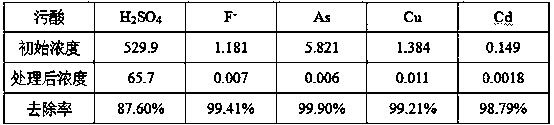

Method for removing multiple pollutants in copper smelting waste acid by using Bayer process red mud

ActiveCN108128917AEnable co-processingReduce secondary pollutionWaste water treatment from metallurgical processMultistage water/sewage treatmentIron saltsRed mud

The invention relates to a method for removing multiple pollutants in copper smelting waste acid by using Bayer process red mud. The method comprises the steps of oxidizing trivalent arsenic into pentavalent arsenic in the waste acid by using a way of continuously aerating while heating; then, adding Bayer process red mud particles, controlling an arsenic-iron molar ratio and a pH value, forming amorphous iron arsenate by using iron in the Bayer process red mud and arsenic in the copper smelting waste acid, and then oxidizing to form stable iron arsenate so as to remove the arsenic in the waste acid and absorb the multiple pollutants in the waste acid. After the scheme is adopted, iron salt used for treating the arsenic does not need to be additionally added, so that the economic cost is reduced; the method realizes the co-disposal of the solid waste produced by the copper smelting industry and the Bayer process red mud produced by the alumina industry, and reduces the secondary pollution to the environment. The method also can obtain iron hydroxide with an economic value by controlling the pH value while changing the Bayer process red mud waste into valuable and treating the wasteacid; due to the increment and decrement of input cost, an enterprise can obtain considerable economic benefit.

Owner:KUNMING UNIV OF SCI & TECH

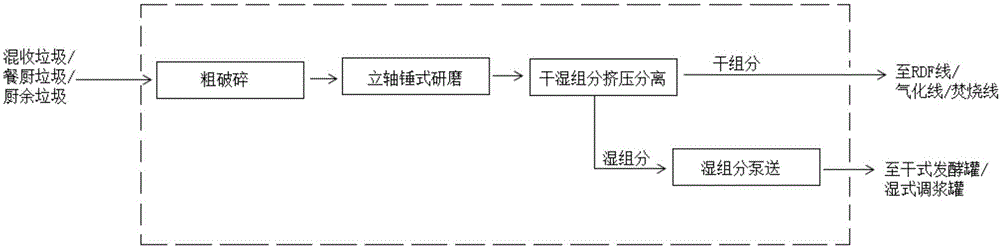

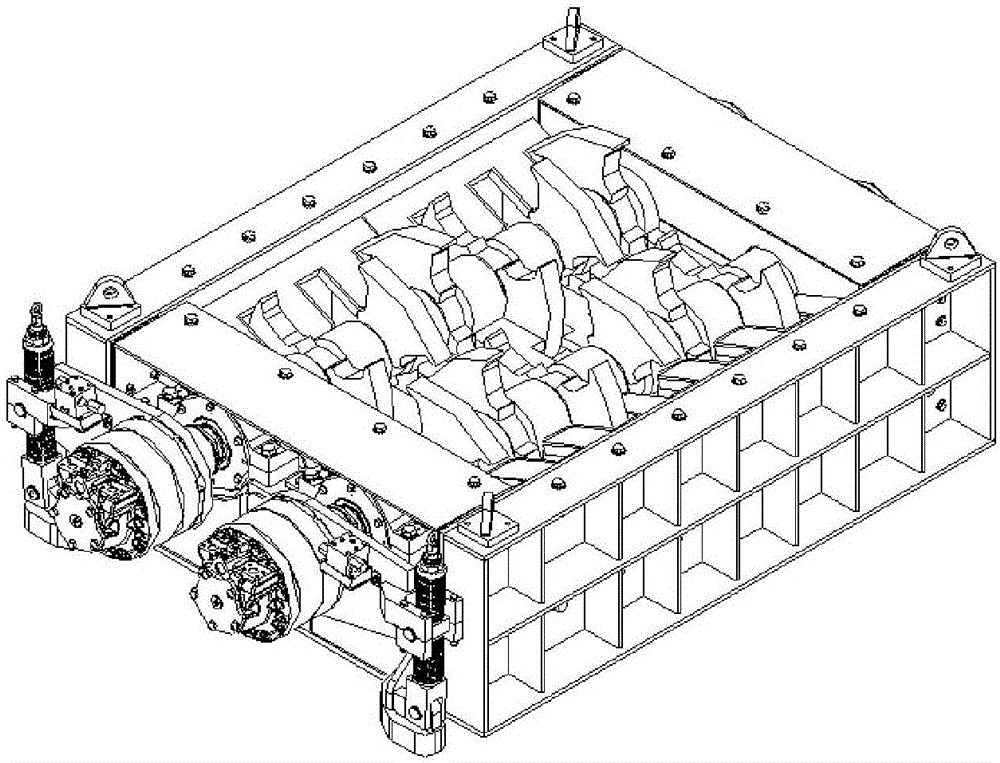

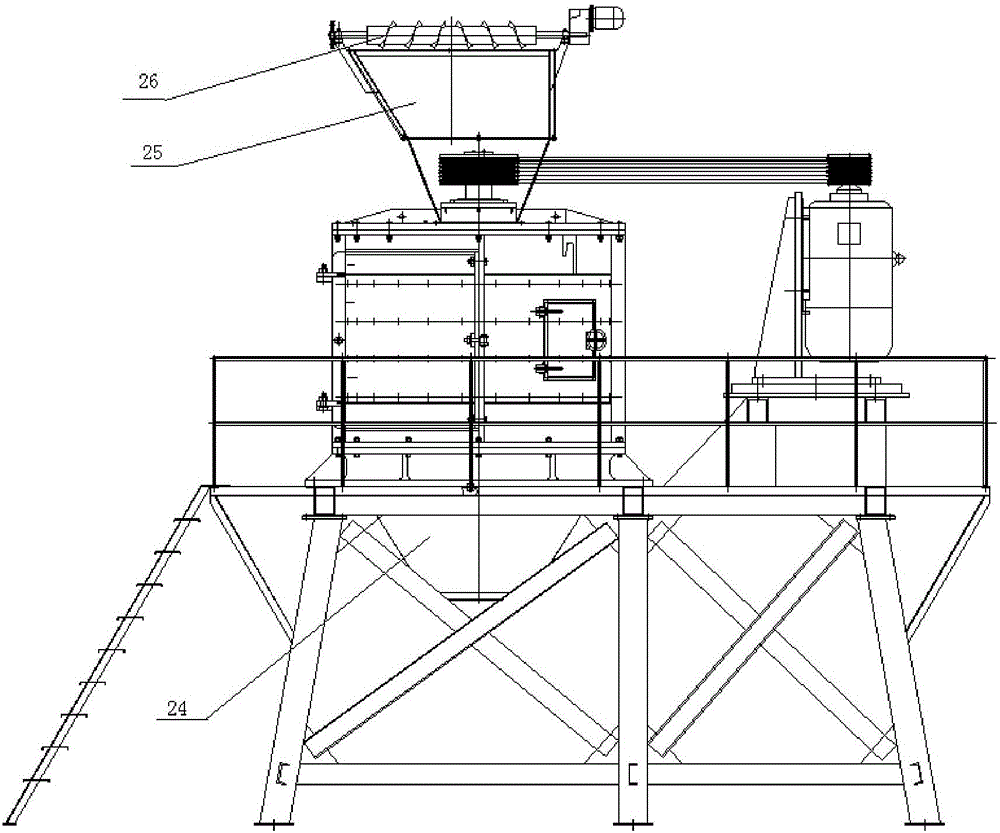

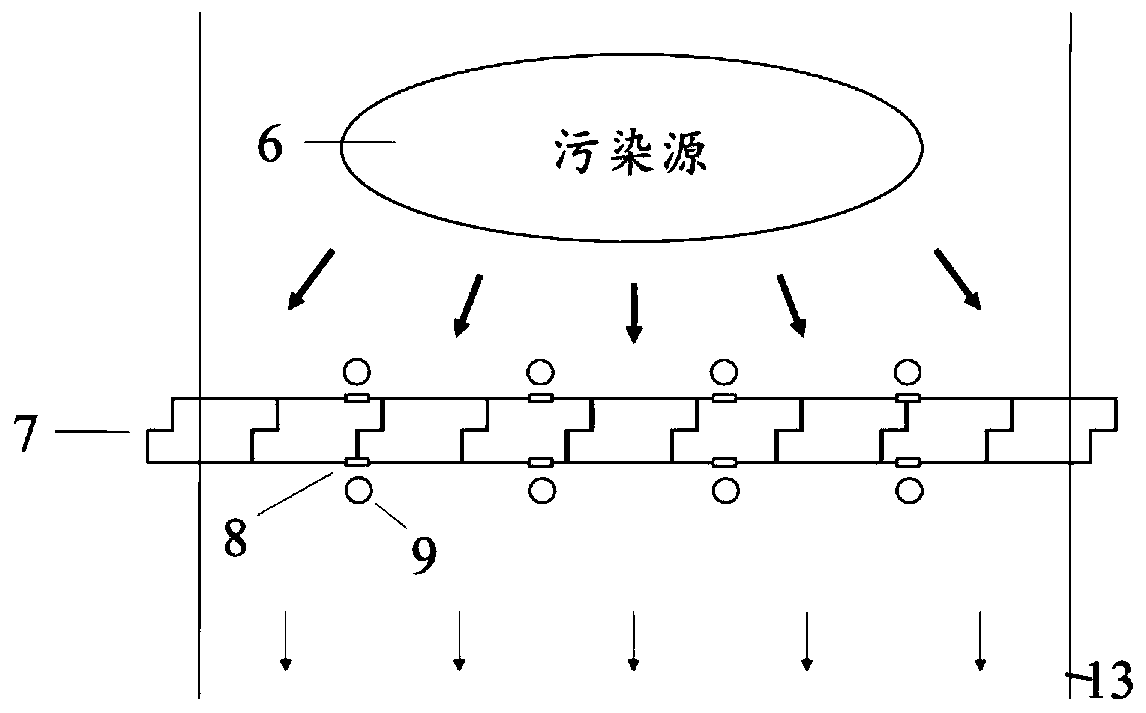

Mechanical pretreatment system and process for municipal domestic waste comprehensive treatment

ActiveCN106734083AEnable co-processingAdvanced principleSolid waste disposalGrain treatmentsAdditive ingredientOrganic matter

The invention discloses a mechanical pretreatment system for municipal domestic waste comprehensive treatment (marsh production). The system comprises a coarse crushing unit, a vertical shaft hammer type grinding unit and a dry-wet component extrusion and separation unit which are arranged in sequence. The units are sequentially connected through a conveying machine. The invention further discloses a mechanical pretreatment process for municipal domestic waste comprehensive treatment adopting the mechanical pretreatment system. The process comprises the process steps of coarse crushing, vertical shaft hammer type grinding and dry-wet component extrusion and separation. The technical defects that organic matter separation efficiency is low and the impurity content is high according to existing domestic waste comprehensive treatment mechanical pretreatment are overcome, the waste receiving adaptability is high, the equipment integration degree is high, continuous stable operation is achieved, various kinds of domestic waste with complex ingredients are used as raw materials, dry and wet components are produced to meet different follow-up technological requirements, coordinated treatment of various kinds of municipal domestic waste is achieved, and the system and the process are suitable for being applied and popularized.

Owner:BEIJING ENVIRONMENT ENG TECH CO LTD +1

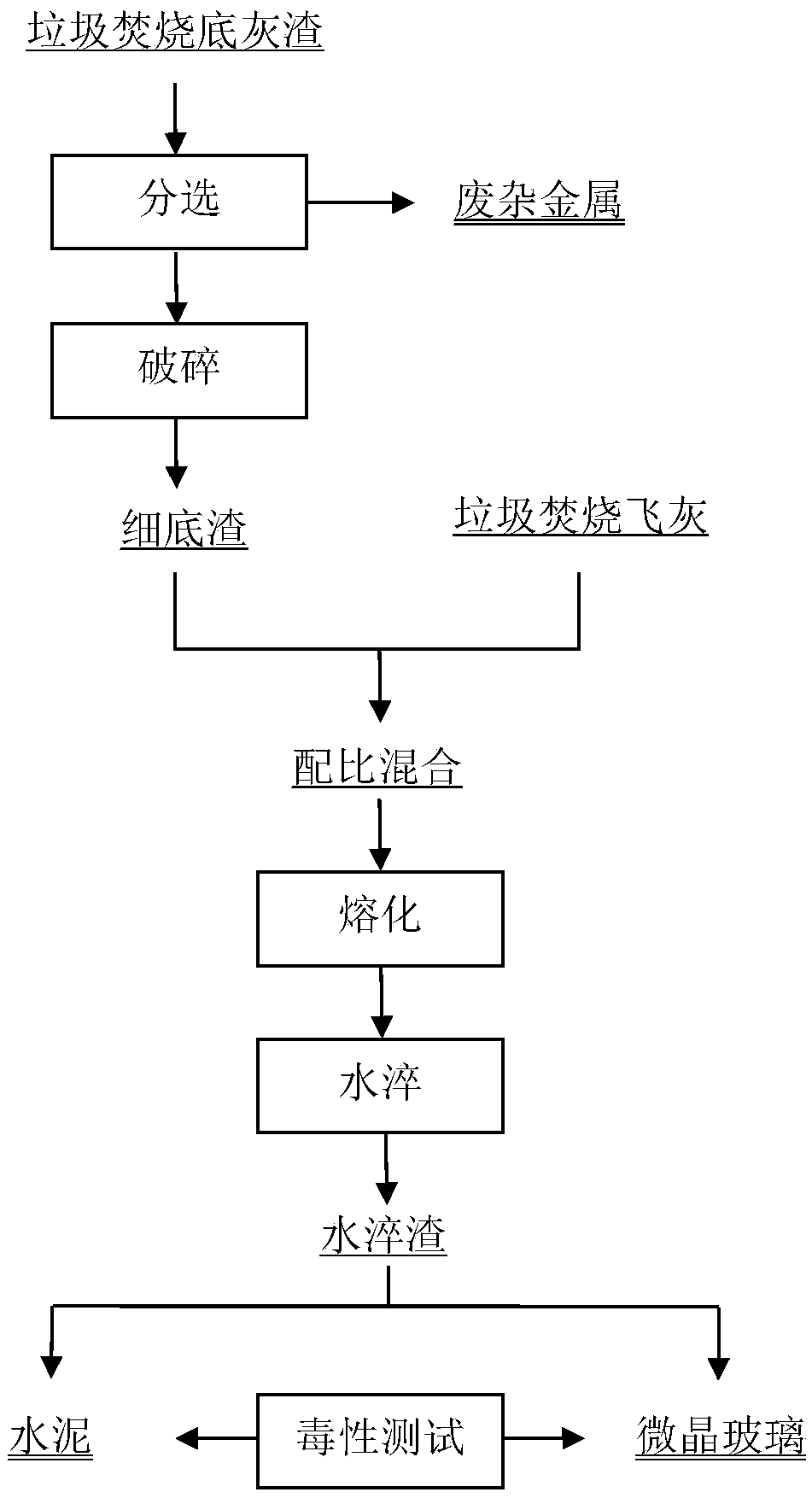

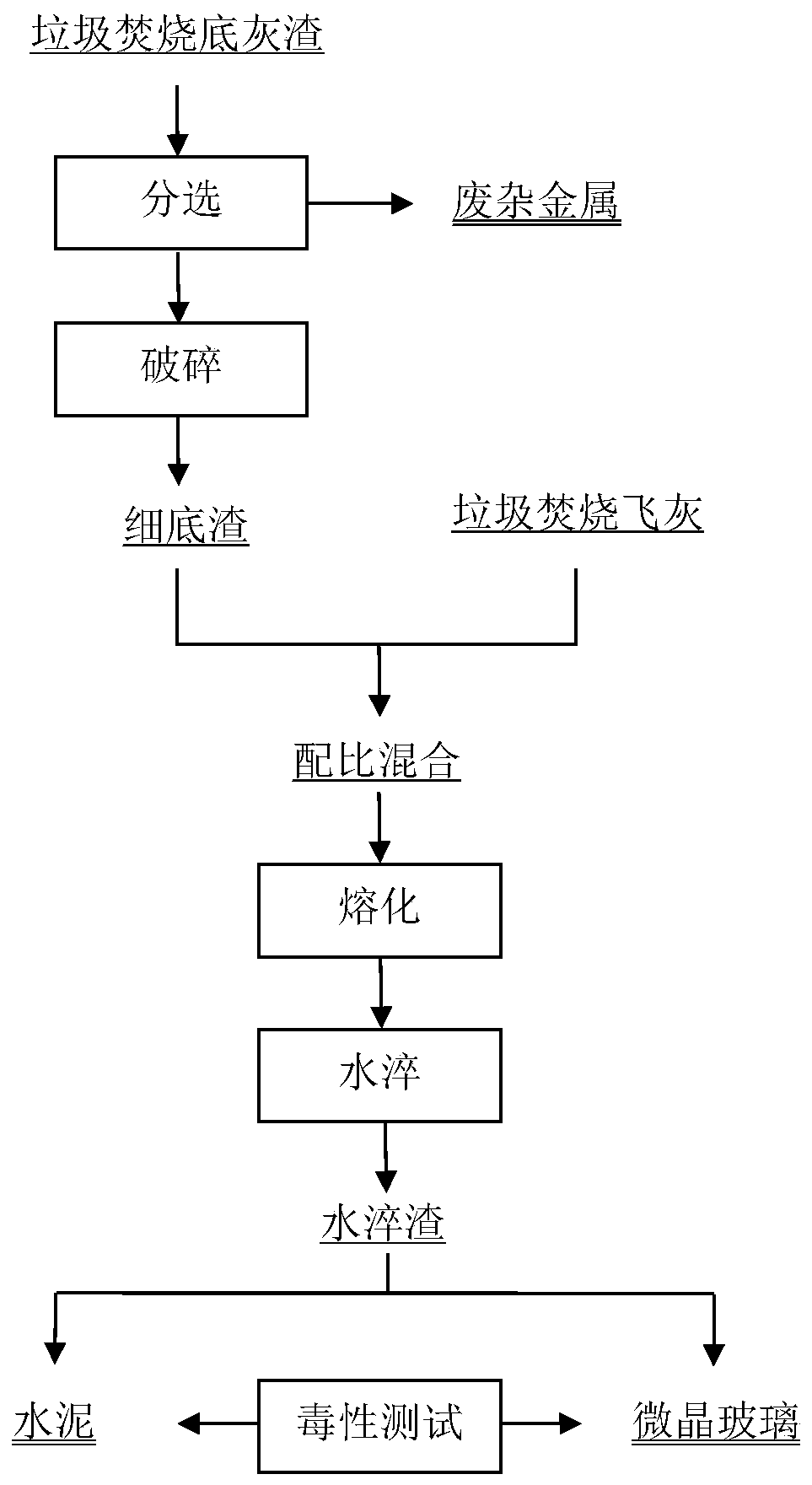

Garbage incineration ash slag heavy metal solidifying method

ActiveCN109516700AEnable co-processingReduce material consumptionCement productionProcess efficiency improvementResource utilizationSlag

The invention discloses a garbage incineration ash slag heavy metal solidifying method, and belongs to the field of solid waste disposal and resource utilization. The method comprises the following steps of obtaining waste sundry metal and fine bottom slag after sorting and crushing of the garbage incineration ash slag; using the waste sundry metal for metal regeneration; performing mixing, fusingand water quenching on the bottom fine slag with the garbage incineration ash slag; using the water quenching slag for cement and crystallized glass, wherein the heavy metal in the product is lower than the limit value of Identification Standards for Hazardous Wastes-Identification for Extraction Toxicity (GB 5085.3-2007). The method provided by the invention has the advantages that the process is simple; the industrialization is easy; the goals of safely solidifying garbage incineration ash slag heavy metal and recycling the garbage incineration ash slag heavy metal for cement and crystallized glass can be achieved.

Owner:UNIV OF SCI & TECH BEIJING

Biomass-based red mud ecological restoration method and system

ActiveCN111014254AEnable co-processingImplement resourcesSolid waste disposalTransportation and packagingSoil treatmentPorous carbon

The invention relates to a biomass-based red mud ecological restoration method and system, belongs to the technical field of red mud ecological restoration, and solves problems of high consumption ofchemical substances for alkaline regulation of red mud, complex other components during red mud soil treatment, high cost and low consumption of the red mud in the prior art. The method comprises steps of step 1, preparing raw materials; step 2, stirring the raw materials, the water and the red mud according to a certain ratio to obtain a mixed raw material; step 3, adding the mixed raw material into a high-pressure reaction kettle for hydrothermal carbonization, and performing solid-liquid separation of a hydrothermal carbonization product obtained by the water to obtain a hydrothermal carbonization solid component and a liquid component; step 4, preparing porous carbon; step 5, fully mixing the porous carbon and the hydrothermal carbonized solid component to prepare a red mud soil matrix; and step 6, carrying out electro-adsorption treatment of the hydrothermal carbonized liquid component, separating out heavy metal ions in the hydrothermal carbonized liquid component, and returningthe water obtained by treatment to the step 3. The method realizes ecological restoration of the red mud.

Owner:ZHENGZHOU UNIV

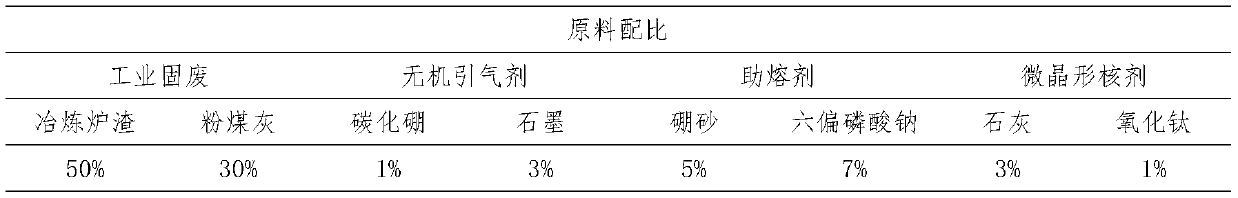

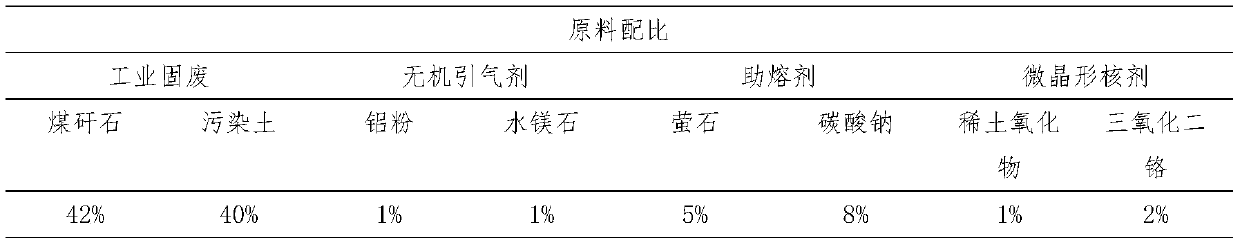

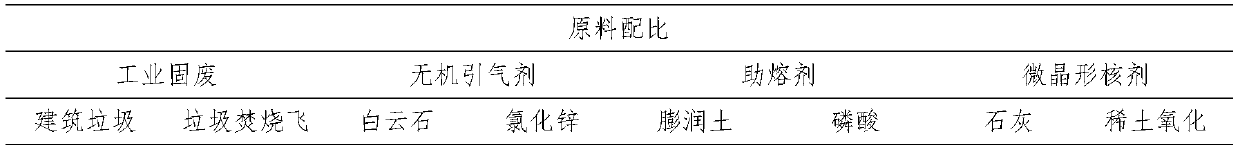

Artificial microcrystalline pumice material and method for preparing artificial microcrystalline pumice material from industrial solid waste by volcanic diagenesis method at low temperature

The invention discloses an artificial microcrystalline pumice material and a method for preparing the artificial microcrystalline pumice material from industrial solid waste by a volcanic diagenesis method at a low temperature. The material comprises the following chemical components: Al2O3, SiO2, CaO, MgO, Fe2O3, K2O and Na2O, and the weight ratio of the Al2O3 to the SiO2 to the CaO to the MgO tothe Fe2O3 to the K2O to the Na2O is (2-20):(65-90):(0.1-5):(0.1-5):(0.1-10):(0.1-10):(0.1-10). The preparation method comprises the following steps: 1) selecting raw materials; 2) mixing and grindingthe raw materials to obtain raw material powder; 3) carrying out forming, namely forming the raw material powder prepared in the step (2); 4) carrying out sintering, namely placing the formed raw material obtained in the step (3) into a high-temperature furnace for sintering, wherein the sintering temperature is 500-1000 DEG C; 5) carrying out cooling; and (6) carrying out modeling. The artificial microcrystalline pumice material has the advantages of low preparation temperature, controllable pore formation, light weight, high strength, excellent performance, wide application, abundant raw material sources and environmental friendliness. The preparation method of the artificial microcrystalline pumice material is simple and easy to implement and is low in cost.

Owner:XINHUASHENG ENERGY SAVING TECH CO LTD

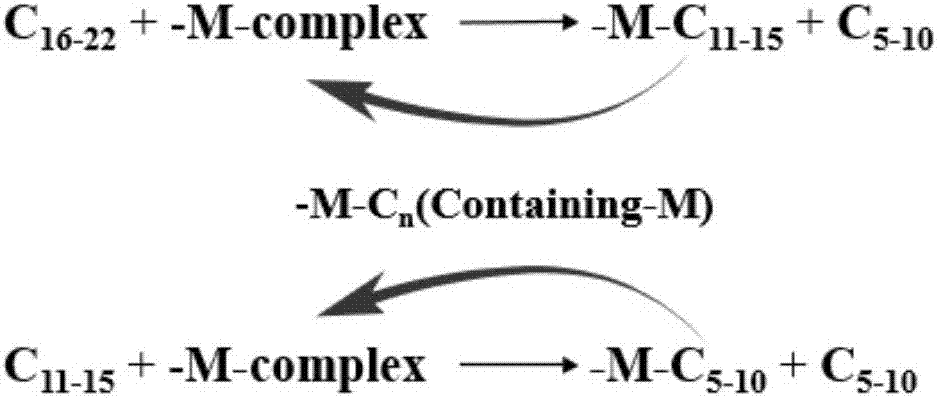

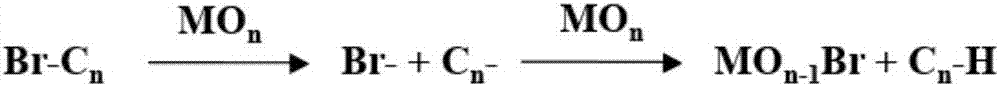

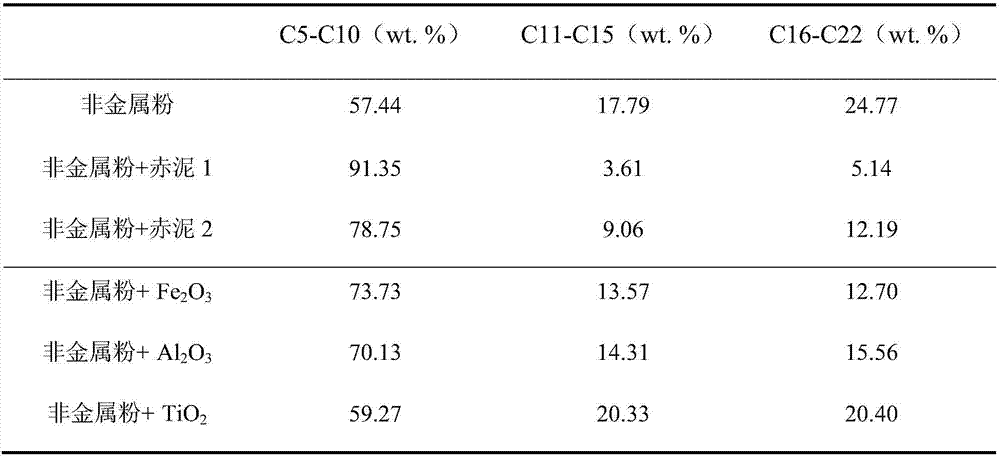

Method for catalytic pyrolysis of residual nonmetallic powder generated by crushing, separation and recycling of copper from waste circuit board

ActiveCN107457246ALightweightAvoid it happening againSolid waste disposalTransportation and packagingCatalytic pyrolysisCarbon number

The invention discloses a treatment method for catalytic pyrolysis of residual nonmetallic powder generated by crushing, separation and recycling of copper from a waste circuit board. The method comprises the steps that alkaline waste residues are added into the nonmetallic powder to be mixed evenly to obtain a mixture, then the mixture is subjected to pyrolysis, and accordingly co-pyrolysis of the nonmetallic powder and the alkaline water residues is achieved; and the alkaline water residues contain metallic oxide so as to promote catalysis of pyrolysis products, so that the bromine content in pyrolysis gas in the obtained pyrolysis products is decreased, the content of bromine fixed in pyrolysis residues is increased, and the proportion of light oil with the carbon number being 5-10 in pyrolysis tar is increased. By improving the reaction parameters and conditions of a key co-pyrolysis reaction, a microcosmic displacement mechanism corresponding to the reaction and the like, compared with the prior art, the method can effectively solve the problems that the pyrolysis tar in the pyrolysis products is mainly the heavy tar, and quality is low; and co-processing of the alkaline waste residues and the nonmetallic powder is achieved, and the problem of solid bromine is solved at the same time.

Owner:HUAZHONG UNIV OF SCI & TECH

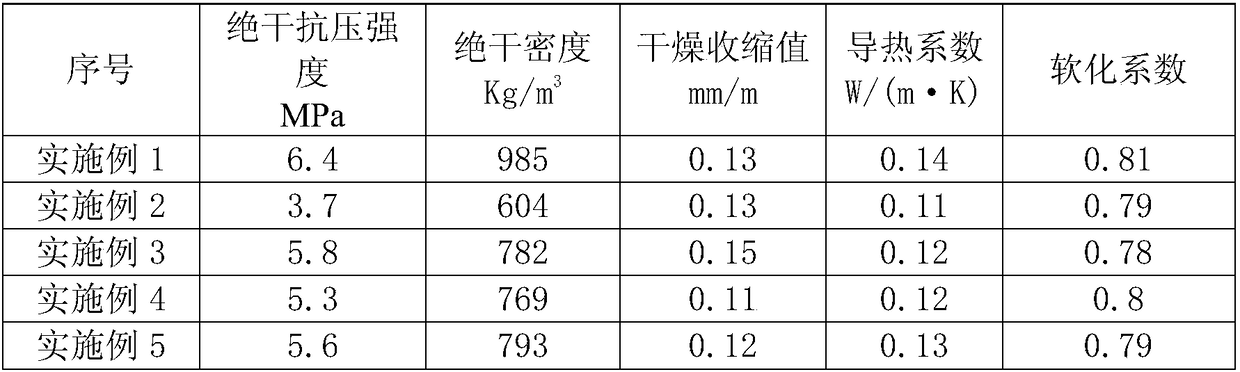

Phosphogypsum light-weight sheet material prepared from barium dreg and preparation method thereof

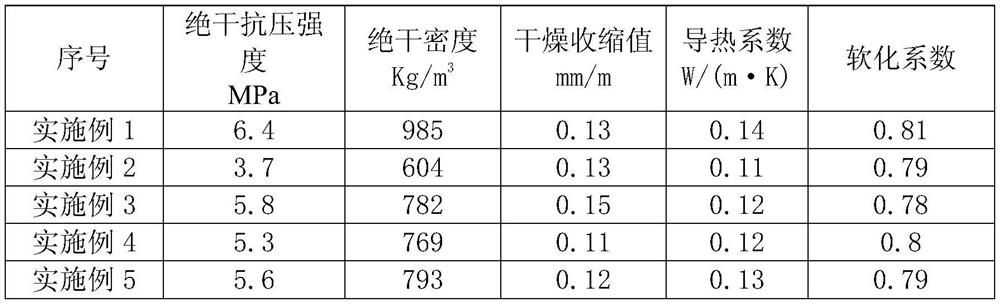

The invention relates to a phosphogypsum light-weight sheet material prepared from barium dreg and a preparation method thereof. The phosphogypsum light-weight sheet material is prepared from the following raw material components in parts by mass: 10 to 20 parts of the barium dreg, 4 to 10 parts of phosphogypsum dihydrate, 60 to 80 parts of phosphorous hemihydrate gypsum, 5 to 15 parts of metakaolin, 1 to 3 parts of carbide slag, 0.5 to 1.2 parts of light aggregate, 0 to 0.1 part of set retarder, 0.1 to 0.3 part of water reducing agent and 0 to 0.1 part of water-retaining agent. The phosphogypsum light-weight sheet material prepared from the barium dreg, provided by the invention, has the advantages of light weight and heat insulation; the volume weight is adjustable in a range of 600 to 1,000Kg / m<3> and the thermal conductivity coefficient is lower than 0.15W / (m*K); the phosphogypsum light-weight sheet material has no obvious layering and cracking and the problem that a traditional cement sheet material is cracked by shrinkage can be effectively overcome by utilizing a micro-expansion property of gypsum hydration; each performance of the prepared light-weight sheet material can meet standards of General Technical Requirements of Light Weight Panel used for Building Partition Wall JGT169-2016.

Owner:WUHAN UNIV OF TECH

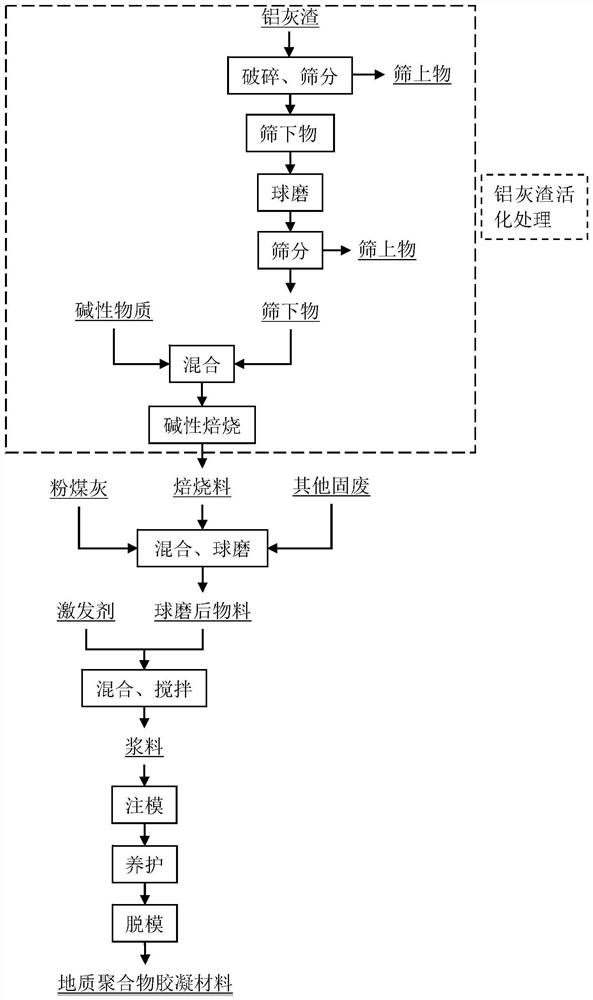

Method for preparing high-strength geopolymer cementing material from aluminum ash

ActiveCN112341017AAchieving Green DisposalImplement resourcesCement productionMetallic aluminumGeopolymer

The invention belongs to the field of green treatment and resource utilization of solid waste, and relates to a method for preparing a high-strength geopolymer cementing material from aluminum ash. The method comprises the following steps: firstly, crushing aluminum ash and conducting screening to separate out substances such as metal aluminum; then, subjecting the aluminum ash to ball milling andscreening to separate out substances difficult to crush; mixing an undersize product of the aluminum ash with a certain proportion of alkaline substances, and carrying out roasting at 200-1100 DEG Cfor 1-5 h; and after roasting is finished, mixing a roasted product with fly ash and other solid waste according to a certain ratio, adding water glass as an exciting agent, and carrying out stirring,injection molding, maintenance and demolding to obtain the geopolymer cementing material. The geopolymer cementing material prepared in the invention has the characteristic of high mechanical properties; and meanwhile, no harmful gas is generated in the preparation process. According to the method, green treatment and resource utilization of the aluminum ash can be realized, process is simple, and environmental burden is small.

Owner:UNIV OF SCI & TECH BEIJING

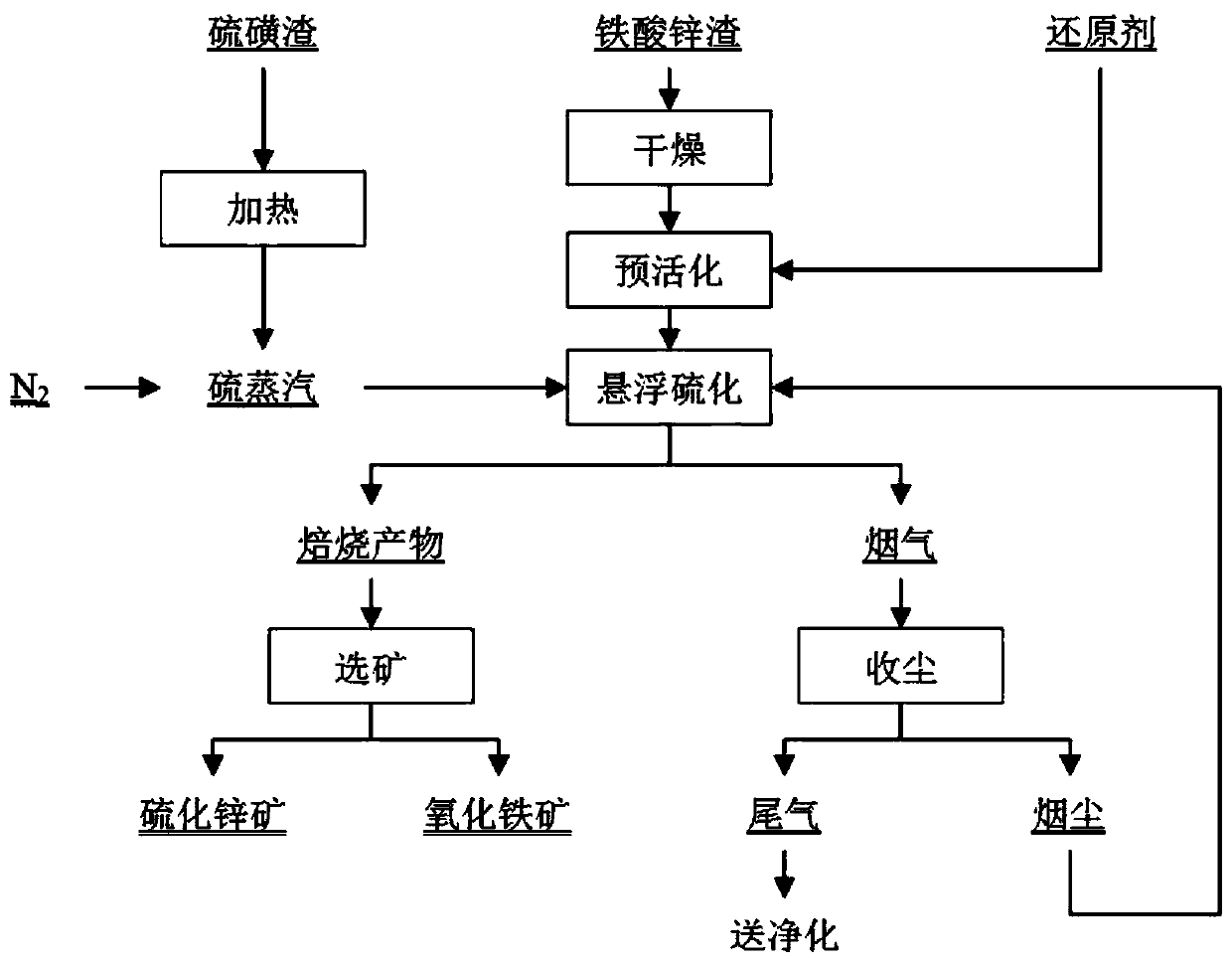

Method for recycling waste slag of zinc smelting plant

InactiveCN109576497AHigh suspension reduction efficiencyAvoid wastingProcess efficiency improvementBrown iron oxideZinc ferrite

The invention belongs to the field of mineral processing and nonferrous metal smelting, and particularly discloses a method for recycling waste slag of a zinc smelting plant. According to the method,zinc ferrite slag produced in a zinc hydrometallurgy process is used as a raw material, a carbonaceous reducing agent is added, sulfur slag produced by adopting a zinc direct leaching process is usedas a vulcanizing agent, reducing and vulcanizing are carried out at the temperature of 400-1000 DEG C in a fluidized bed, zinc sulfide and ferric oxide are obtained through reaction, tail gas is subjected to dust collecting and separation to obtain soot and tail gas, and a roasted product is subjected to beneficiation to obtain zinc sulfide ore concentrate and iron oxide ore. According to the method for recycling the waste slag of the zinc smelting plant, cooperative treatment and on-site resource recycling of the industrial solid waste are realized, pollution of the environment and waste of resources are avoided, and full utilization of the waste is completed. Meanwhile, the zinc ferrite slag is reduced and vulcanized to the zinc sulfide and the iron oxide by utilizing the high-efficiencyproperty of the suspension reaction, so that the advantages that the production efficiency is high, the low-temperature operation is achieved, products are easy to separate, the cooperative treatmentof the industrial solid waste and internal circulation of a plant area are achieved, and the logistics cost and the transportation risk are reduced are realized.

Owner:河套学院 +1

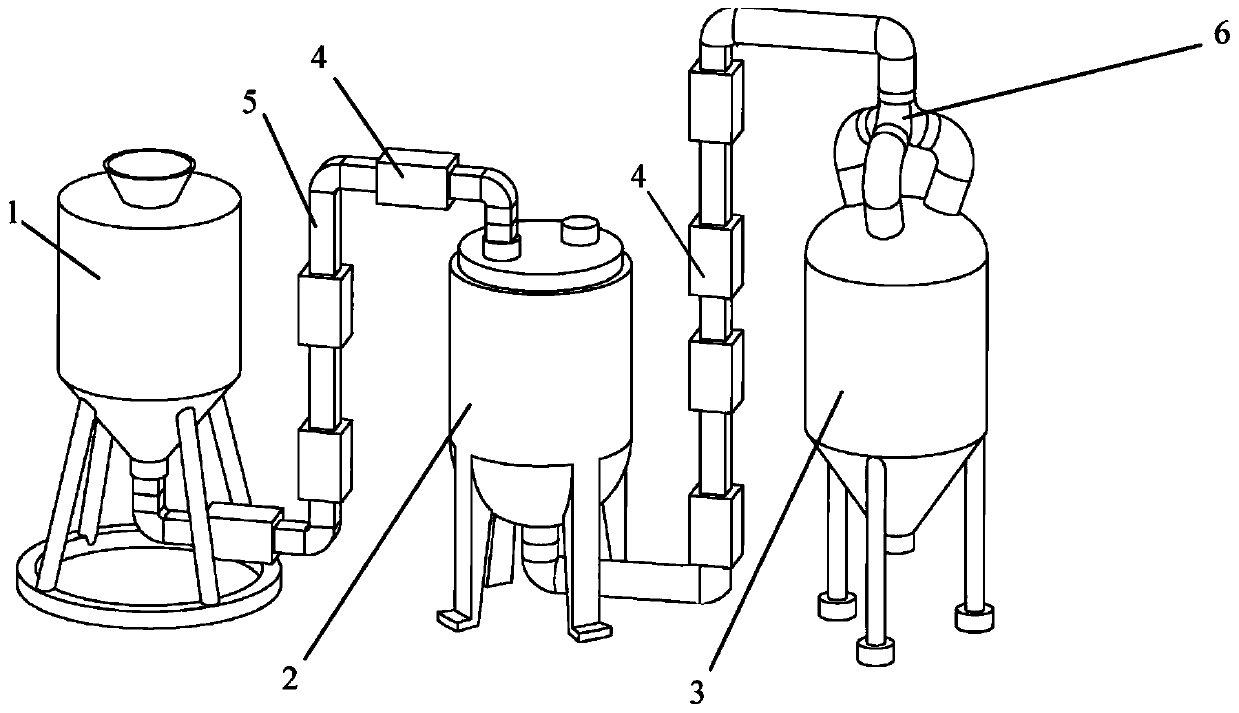

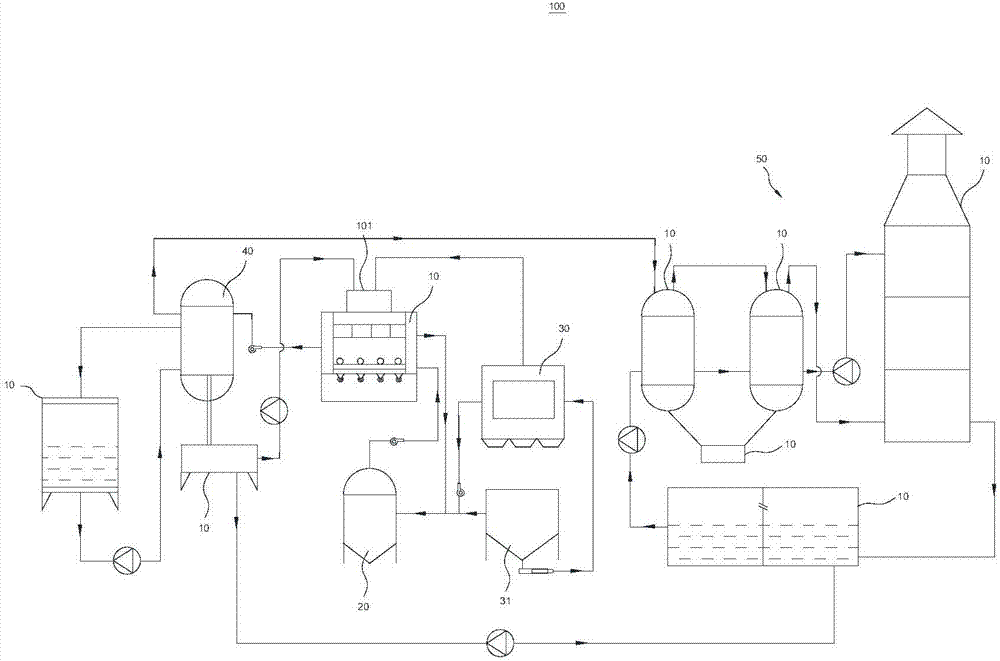

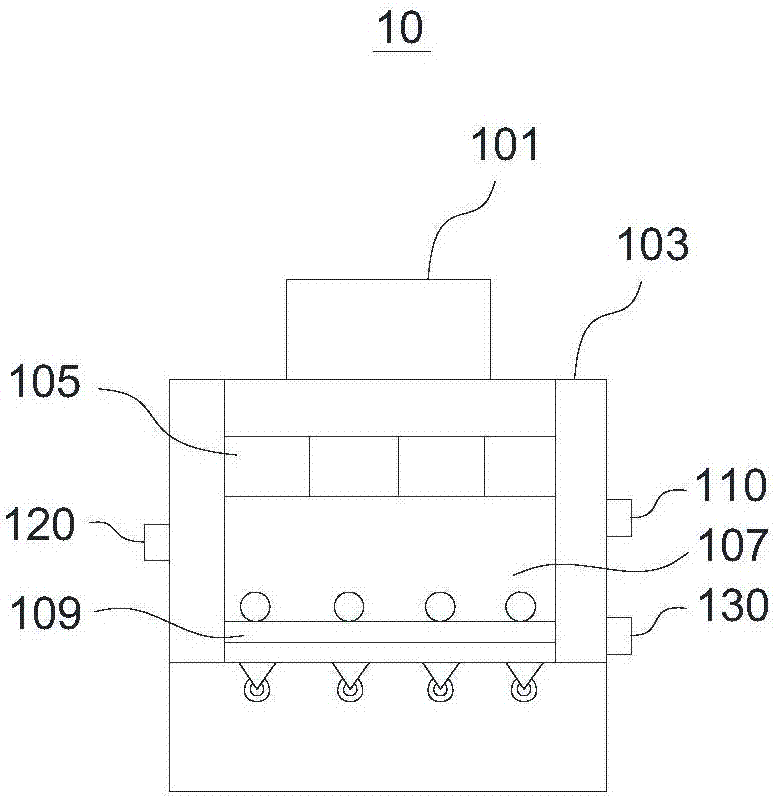

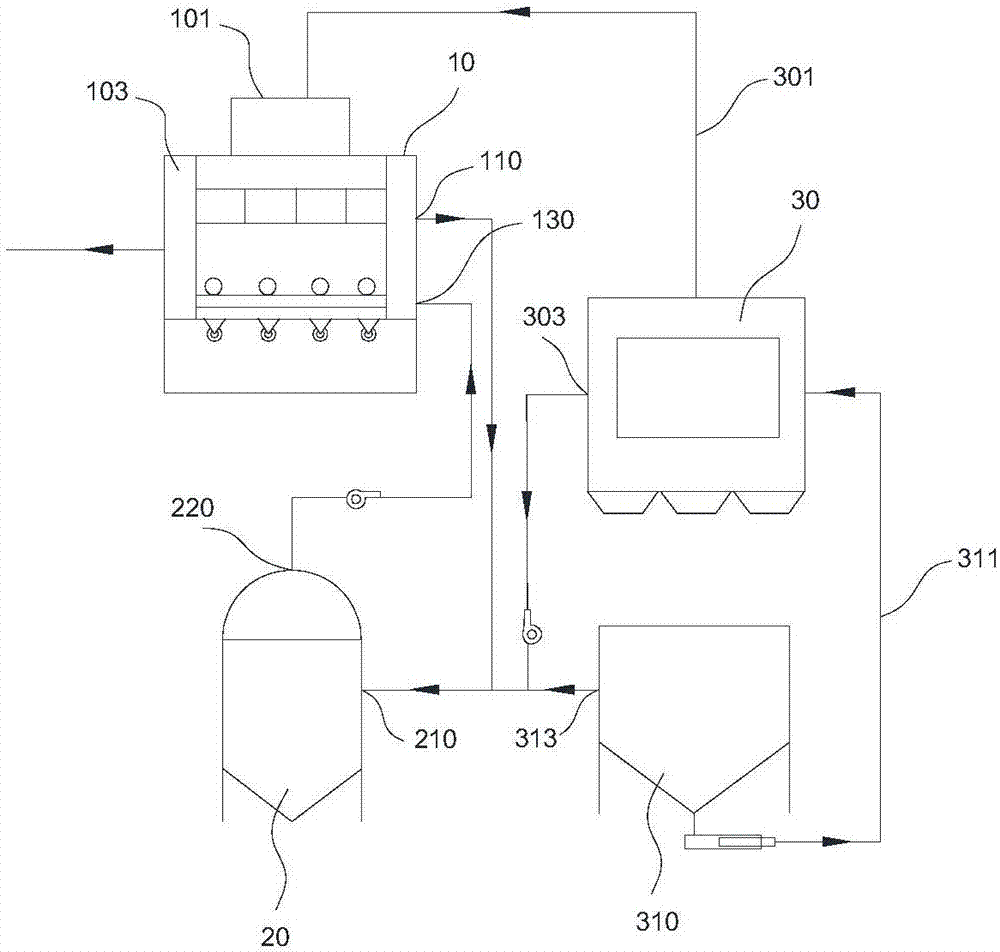

Garbage and sludge pyrolysis system and garbage treatment system

PendingCN107325830AEnable co-processingImprove heat utilizationSludge treatment by pyrolysisByproduct vaporizationAir preheaterDecomposition

The invention relates to the technical field of environmental protection, and provides a garbage and sludge pyrolysis system. The system comprises a pyrolysis gasifier, an air preheater, a sludge processor, a condenser and a tail gas treatment device, wherein the pyrolysis gasifier comprises a gasifier body and a feeding tank connected with the gasifier body; wet sludge is dried in the sludge processor and then transported to the feeding tank of the pyrolysis gasifier, and co-pyrolysis gasification treatment is conducted on household garbage and the transported sludge in the pyrolysis gasifier; meanwhile, waste gas generated by sludge drying and pyrolysis gasification gas generated by co-pyrolysis are transported to the pyrolysis gasifier through the air preheater to assist combustion and re-decomposition, flue gas generated by the pyrolysis gasifier is purified by the tail gas treatment device and then is in standard discharge. The system achieves sludge drying and the synergistic treatment of sludge and household garbage, and improves the utilization rate of pyrolysis gas, sludge and tar heat energy, and the pyrolysis gasification rate of garbage and sludge. Besides, the invention further provides a garbage treatment system including the garbage and sludge pyrolysis system.

Owner:湖南省环境保护科学研究院

A method for solidifying heavy metals in waste incineration ash

ActiveCN109516700BEnable co-processingReduce material consumptionCement productionProcess efficiency improvementSlagProcess engineering

The invention discloses a garbage incineration ash slag heavy metal solidifying method, and belongs to the field of solid waste disposal and resource utilization. The method comprises the following steps of obtaining waste sundry metal and fine bottom slag after sorting and crushing of the garbage incineration ash slag; using the waste sundry metal for metal regeneration; performing mixing, fusingand water quenching on the bottom fine slag with the garbage incineration ash slag; using the water quenching slag for cement and crystallized glass, wherein the heavy metal in the product is lower than the limit value of Identification Standards for Hazardous Wastes-Identification for Extraction Toxicity (GB 5085.3-2007). The method provided by the invention has the advantages that the process is simple; the industrialization is easy; the goals of safely solidifying garbage incineration ash slag heavy metal and recycling the garbage incineration ash slag heavy metal for cement and crystallized glass can be achieved.

Owner:UNIV OF SCI & TECH BEIJING

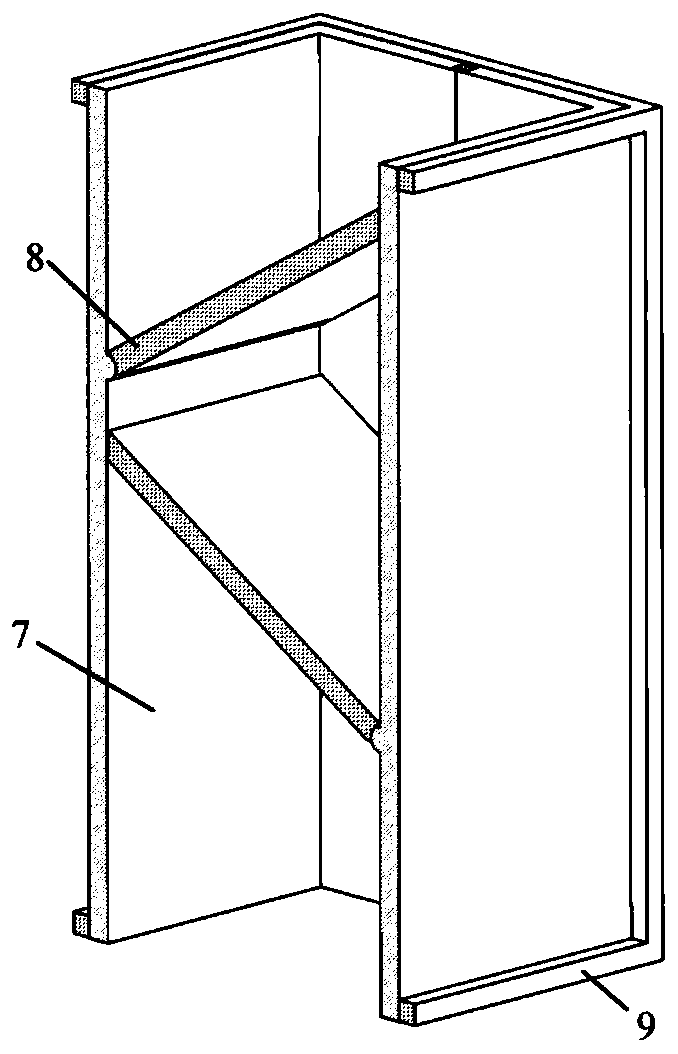

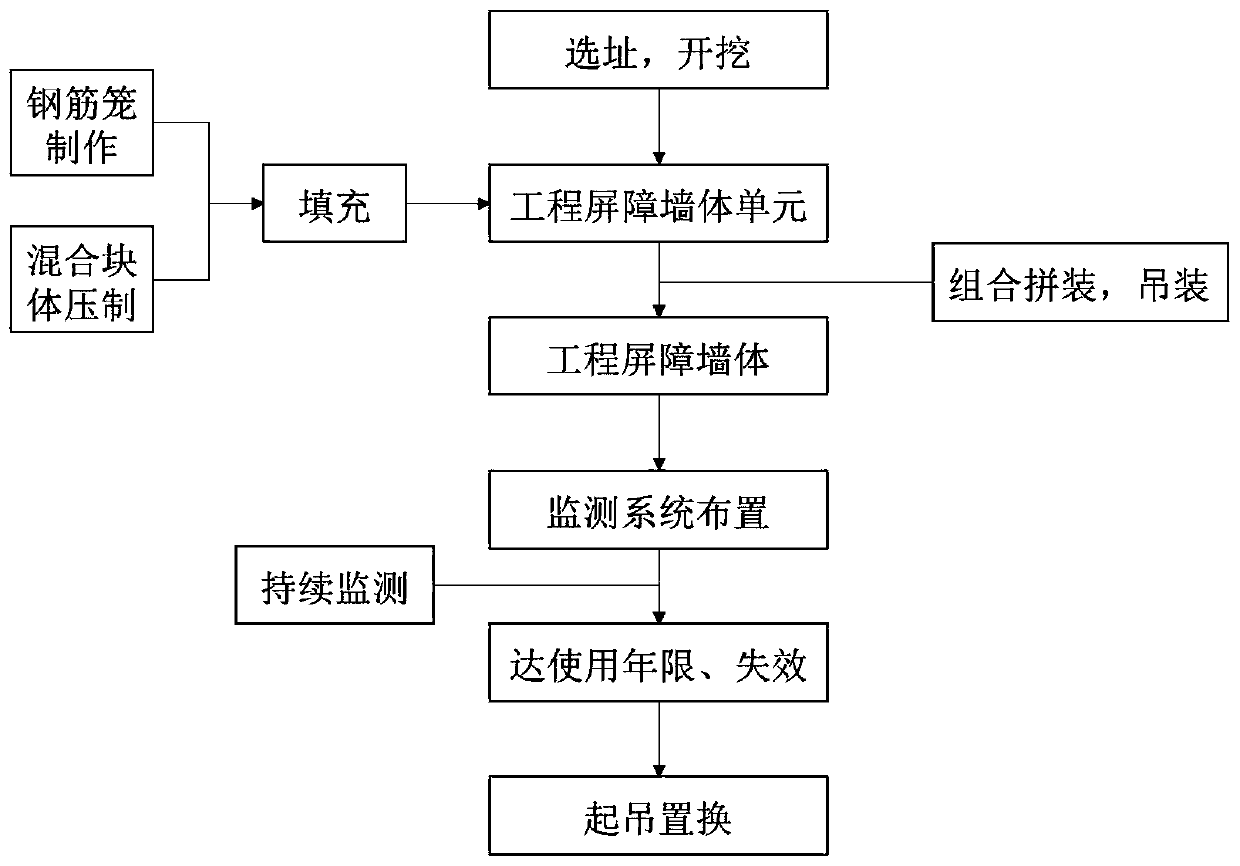

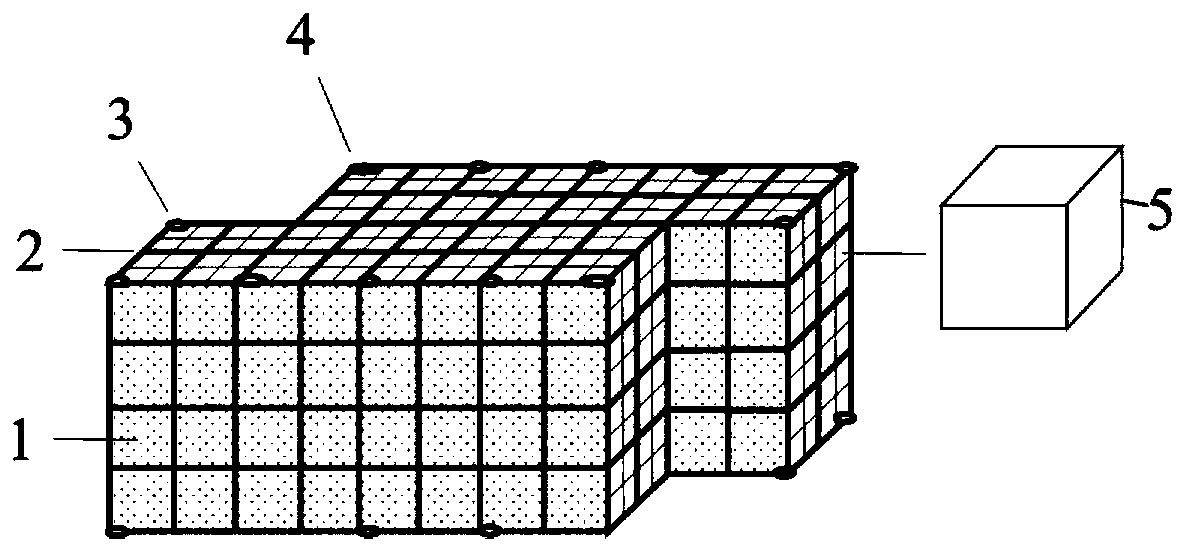

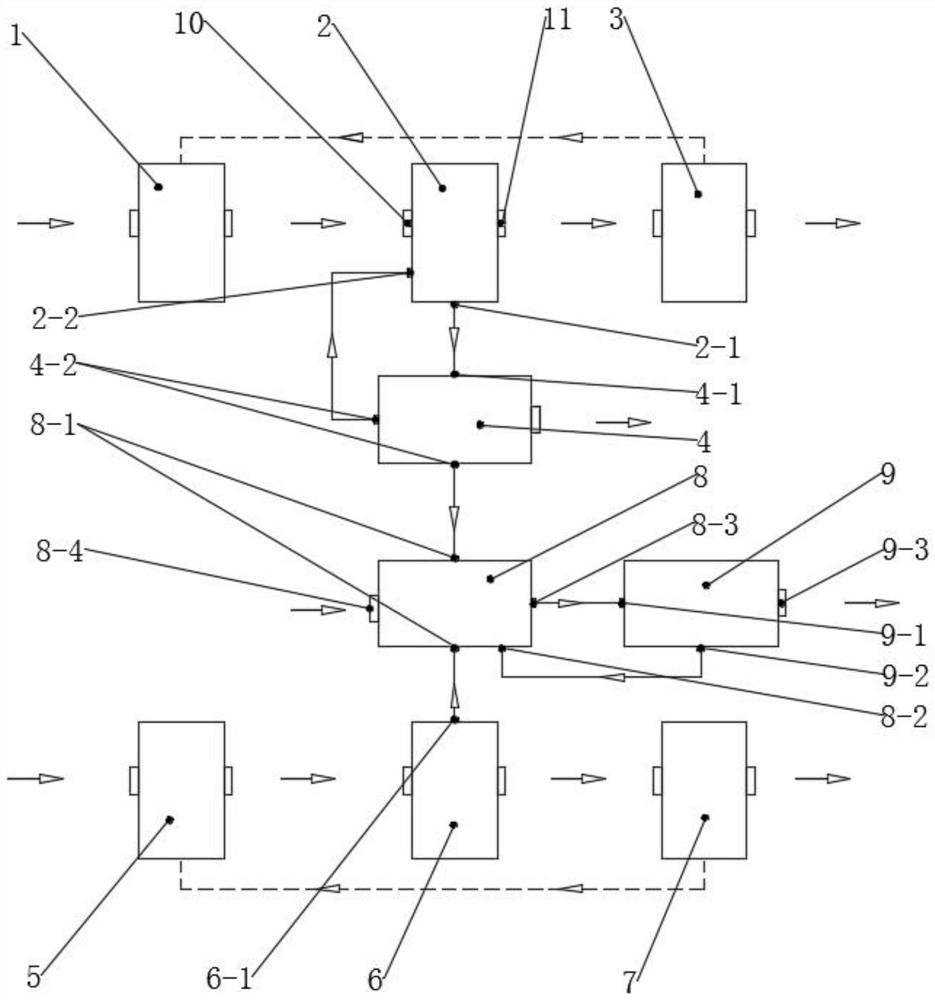

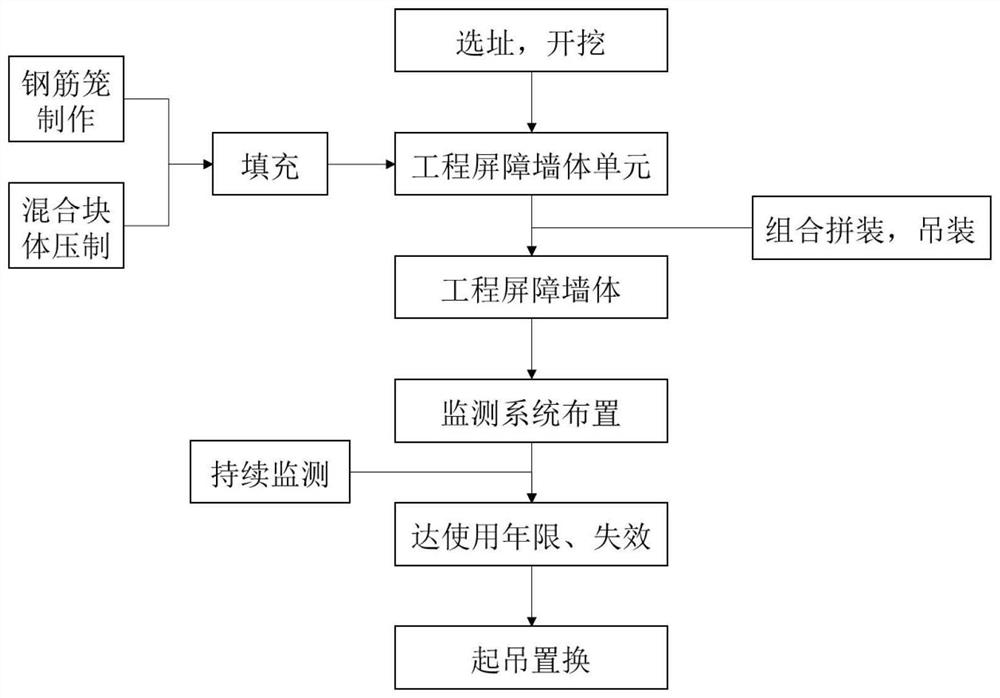

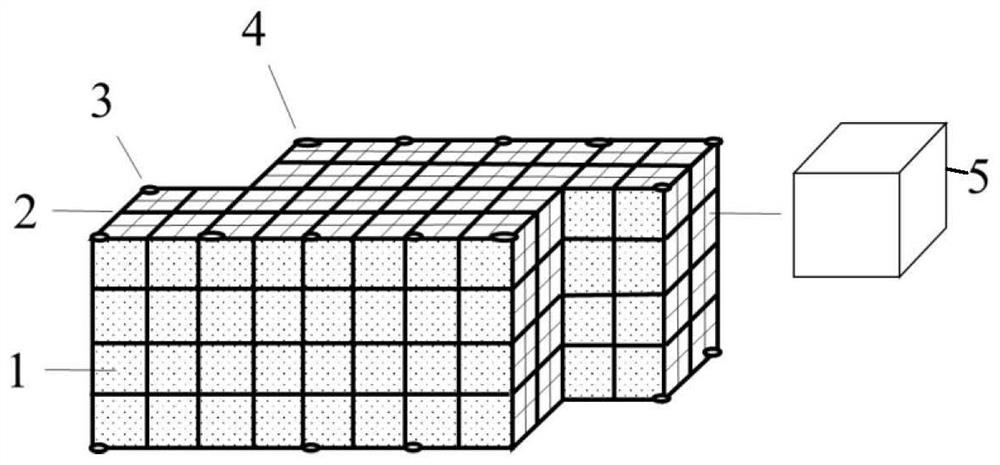

Construction method of vertical engineering barrier system for neutralizing acid mine wastewater

ActiveCN111101538ADiffusion migration retardationLow costWaste water treatment from quariesArtificial islandsArchitectural engineeringWastewater

The invention provides a construction method of a vertical engineering barrier system for neutralizing acid mine wastewater. The method comprises the following steps of conducting site selection for construction of an engineering barrier, and digging an engineering barrier drench; making a reinforcement cage, and distributing geotechnical cloth at the inner side of the reinforcement cage in the seepage direction; making fixed block bodies, and filling the reinforcement cage with the mixed block bodies to form engineering barrier wall units; conducting combined splicing on the engineering barrier wall units, and hoisting the engineering barrier wall units into the engineering barrier trench; and collecting data at the periphery of the engineering barrier to monitor the blocking effect on heavy metal. Compared with the prior art, the mixed block bodies are prepared from clay, flying ash and a chemical additive, the cost is low, and the treatment effect is good; the engineering barrier wall units are adopted for combined splicing, and the construction method is highly adaptable to the site condition and engineering demands; the construction steps are simple and feasible, and hoistingand lifting replacement are convenient; and the engineering barrier wall units can be produced and sold on a large scale, the economic benefit is high, and the construction period on the engineering barrier is greatly shortened.

Owner:CENT SOUTH UNIV

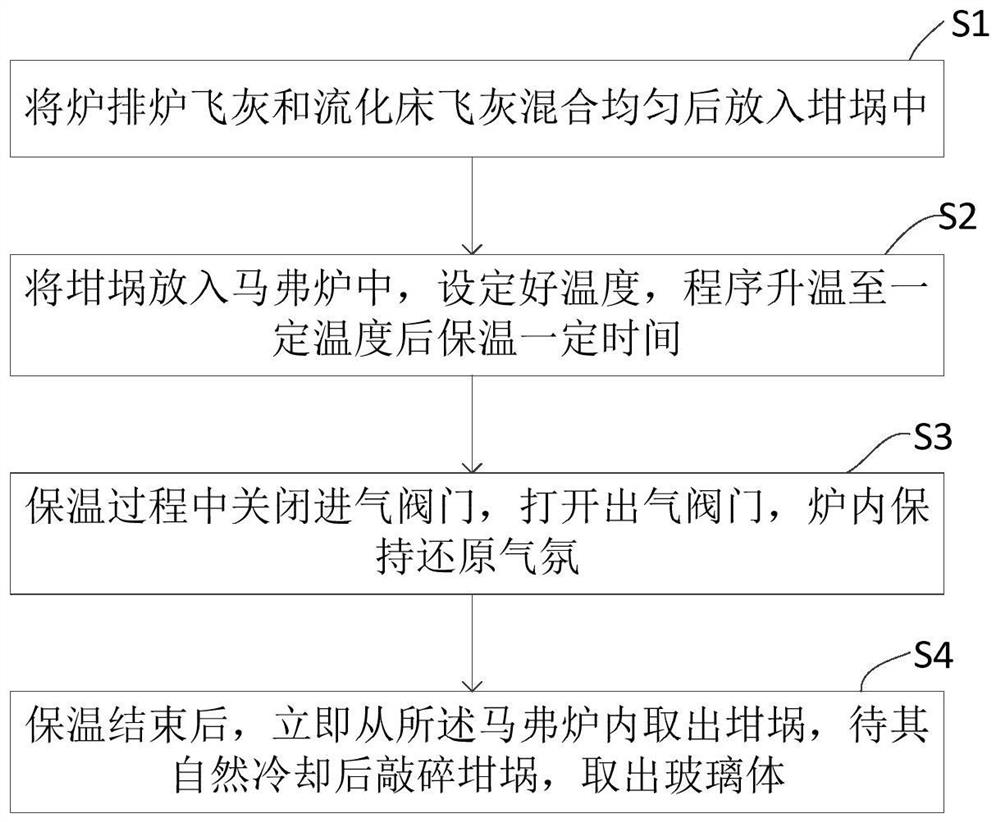

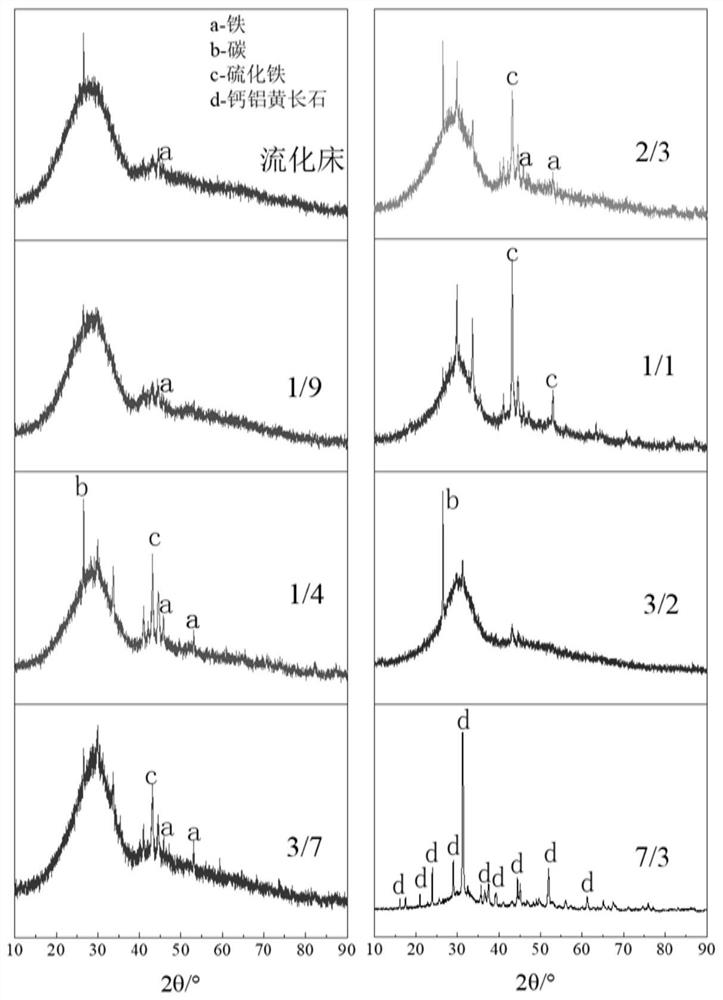

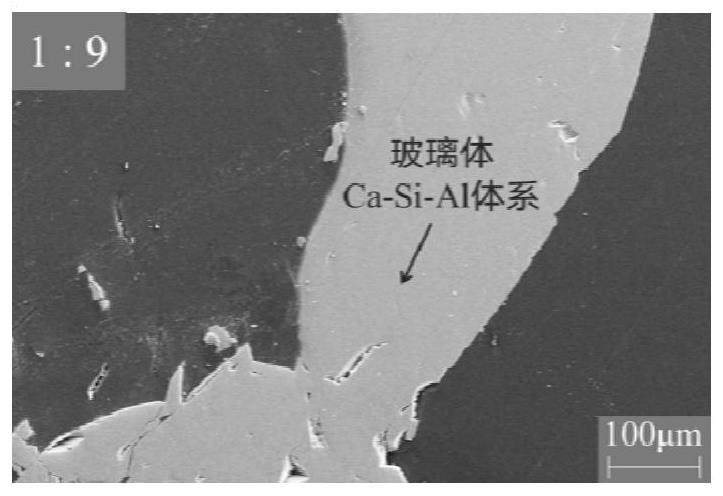

Method for preparing molten glass body by utilizing complementarity of two fly ash components

PendingCN114472475AEnable co-processingImprove stabilitySolid waste disposalTransportation and packagingCrucibleFluidized bed

The invention discloses a method for preparing a molten glass body by utilizing complementarity of two fly ash components. The method comprises the following steps: uniformly mixing grate furnace fly ash and fluidized bed fly ash, and putting the mixture into a crucible; putting the crucible into a muffle furnace, setting the temperature, carrying out programmed heating to a certain temperature, and then carrying out heat preservation for a certain time; closing a gas inlet valve and opening a gas outlet valve in a heat preservation process, and keeping a reducing atmosphere in the furnace; and after the heat preservation is finished, immediately taking out the crucible from the muffle furnace, breaking the crucible after the crucible is naturally cooled, and taking out the glass body. The two kinds of hazardous waste are used for preparing the glass body, the operation steps are simpler, the economic cost is low, the melting temperature is reduced (energy consumption is reduced), the prepared glass body is high in stability and safety (for example, the heavy metal fixing effect is good, and the leaching toxicity is low) and good in application prospect, co-treatment of the two kinds of fly ash (hazardous waste) is achieved, and the application prospect is wide. And in addition, metal recovery can be achieved.

Owner:TSINGHUA UNIV

Method for producing biogas through coupling biodiesel oil byproduct crude glycerine purification and pretreated agriculture and forestry residue fermentation

ActiveCN108640815AGood economic and environmental benefitsLow costOrganic compound preparationWaste based fuelBiogasIon exchange

The invention provides a method for producing biogas through coupling biodiesel oil byproduct crude glycerine purification and pretreated agriculture and forestry residue fermentation. The method comprises the following steps: adding a methanol solution of phosphoric acid into biodiesel oil byproduct crude glycerine, meanwhile, adding agriculture and forestry residues, carrying out uniform stirring so as to obtain a crude glycerine solution, subjecting the crude glycerine solution to standing, carrying out filter pressing so as to separate out a solid phase, i.e., treated agriculture and forestry residues and a liquid phase, subjecting the treated agriculture and forestry residues to anaerobic fermentation to produce the biogas, subjecting the liquid phase to standing layering so as to obtain an upper layer, i.e., a methanol phase and a lower layer, i.e., a glycerine phase, recycling methanol, neutralizing glycerine until the glycerine is neutral, adsorbing the neutral glycerine solution with activated charcoal, then, filtering the glycerine solution, and subjecting the filtered filter liquor to ion exchange and concentration, thereby obtaining purified glycerine. According to themethod, biodiesel oil crude glycerine purification and agriculture and forestry residue pretreatment are treated in a cooperated manner, available ingredients are effectively recovered from the biodiesel oil byproduct crude glycerine, and thus, the recoverable utilization of resources is achieved, so that the method has good economic and environmental benefits.

Owner:汕头市利利新能源科技有限公司

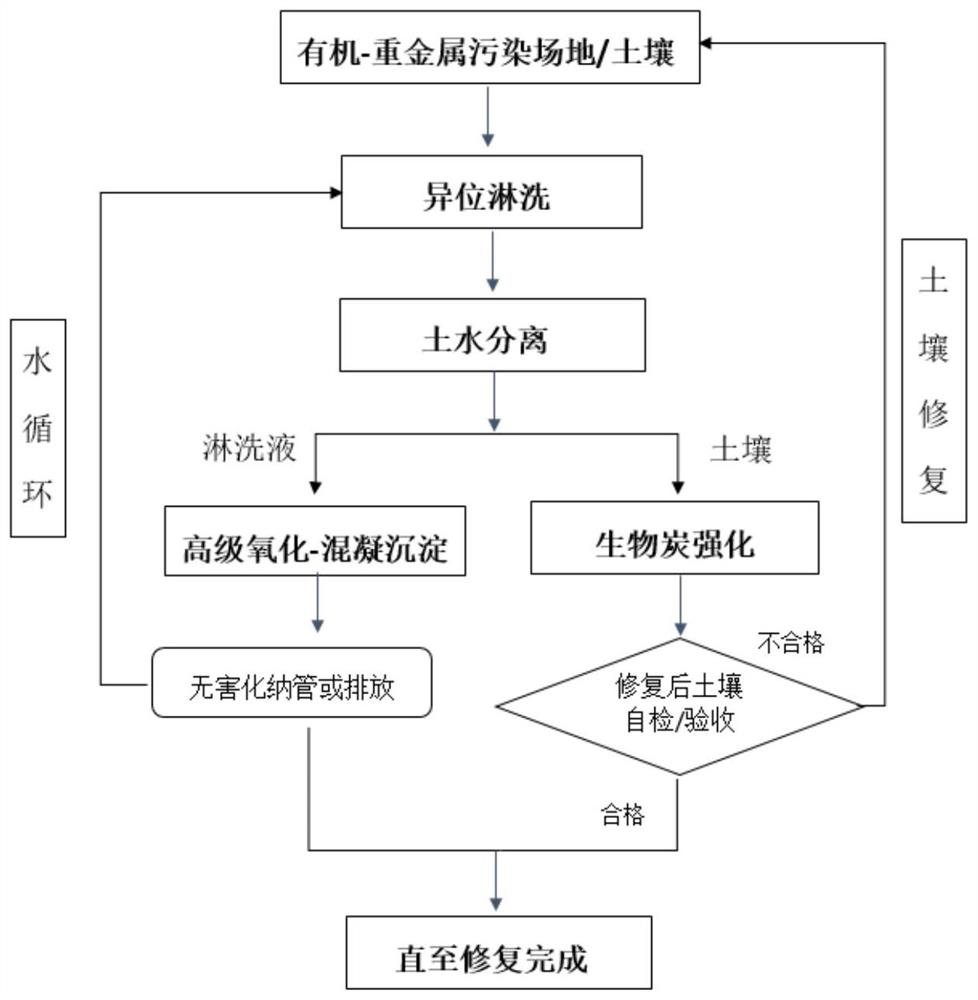

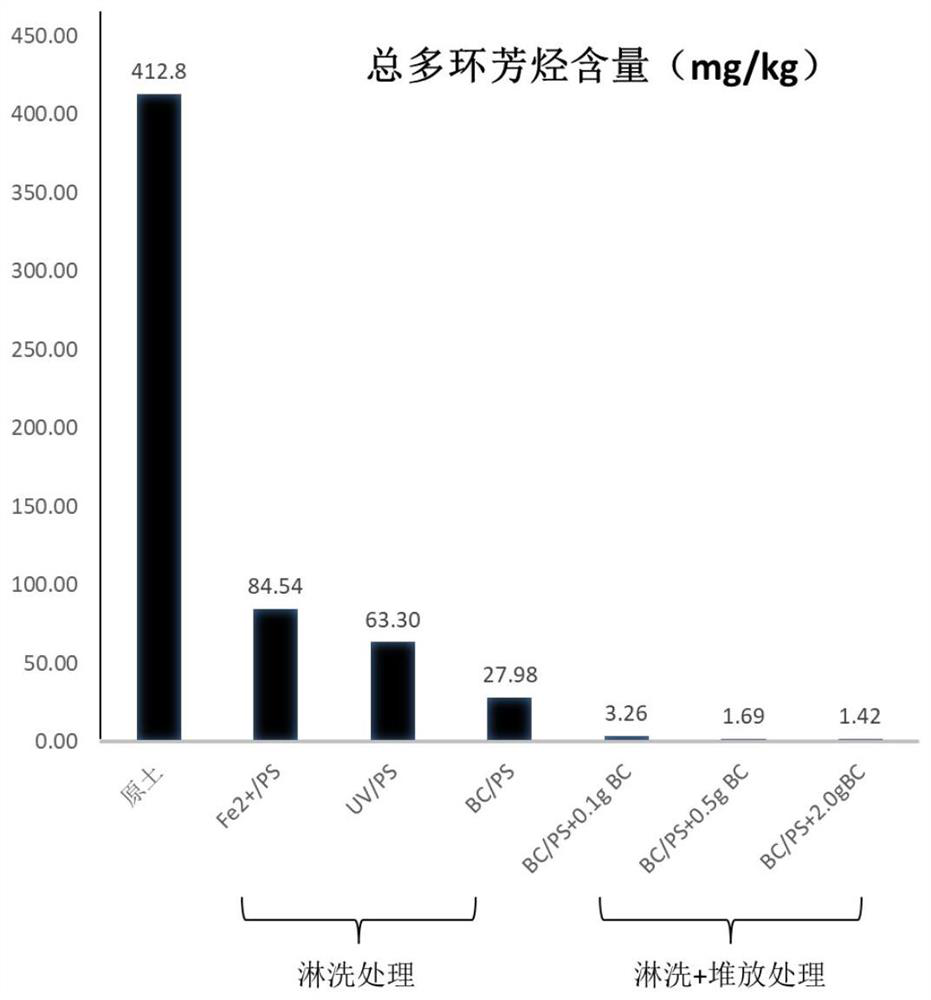

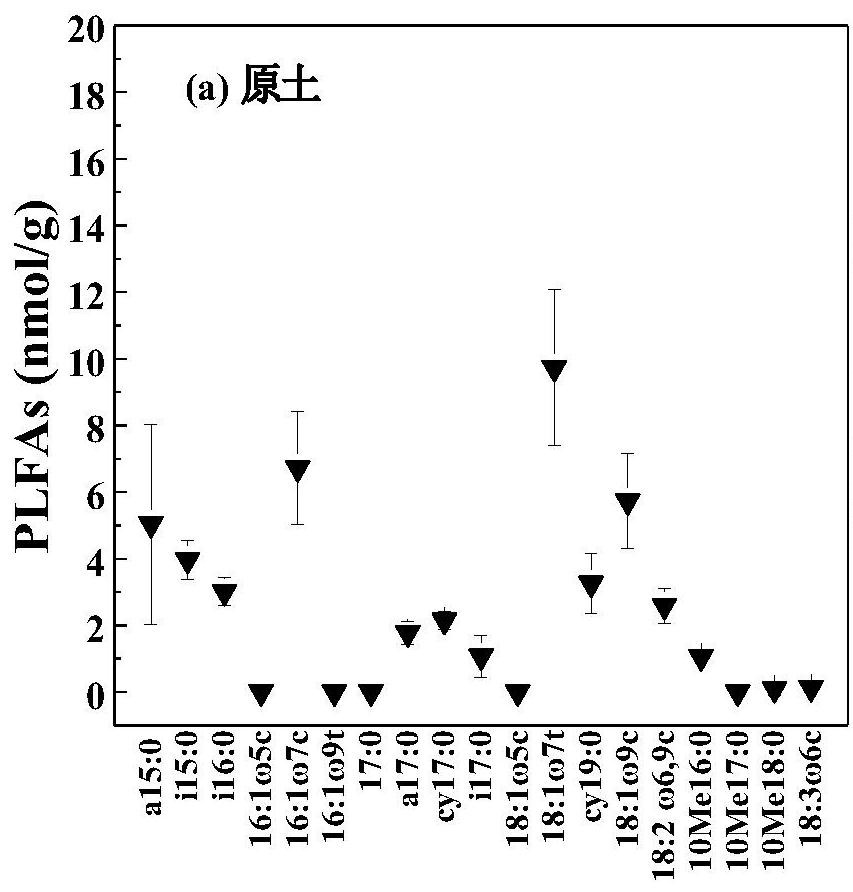

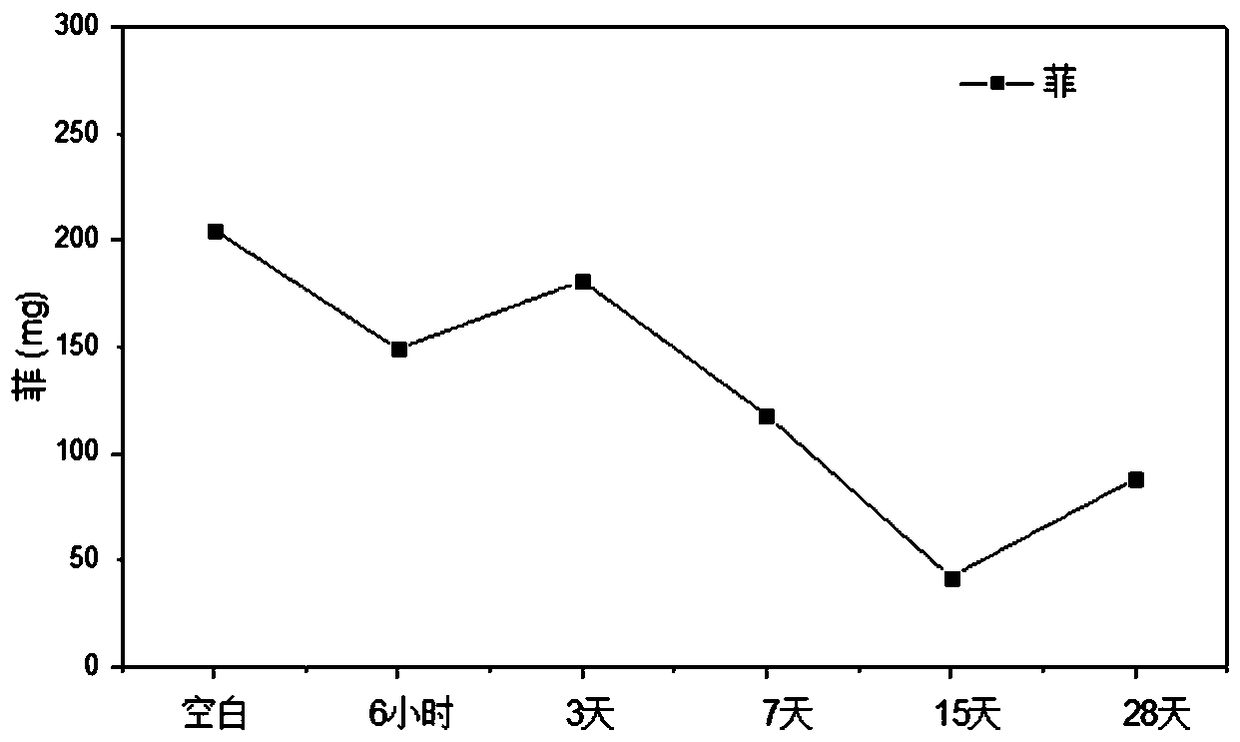

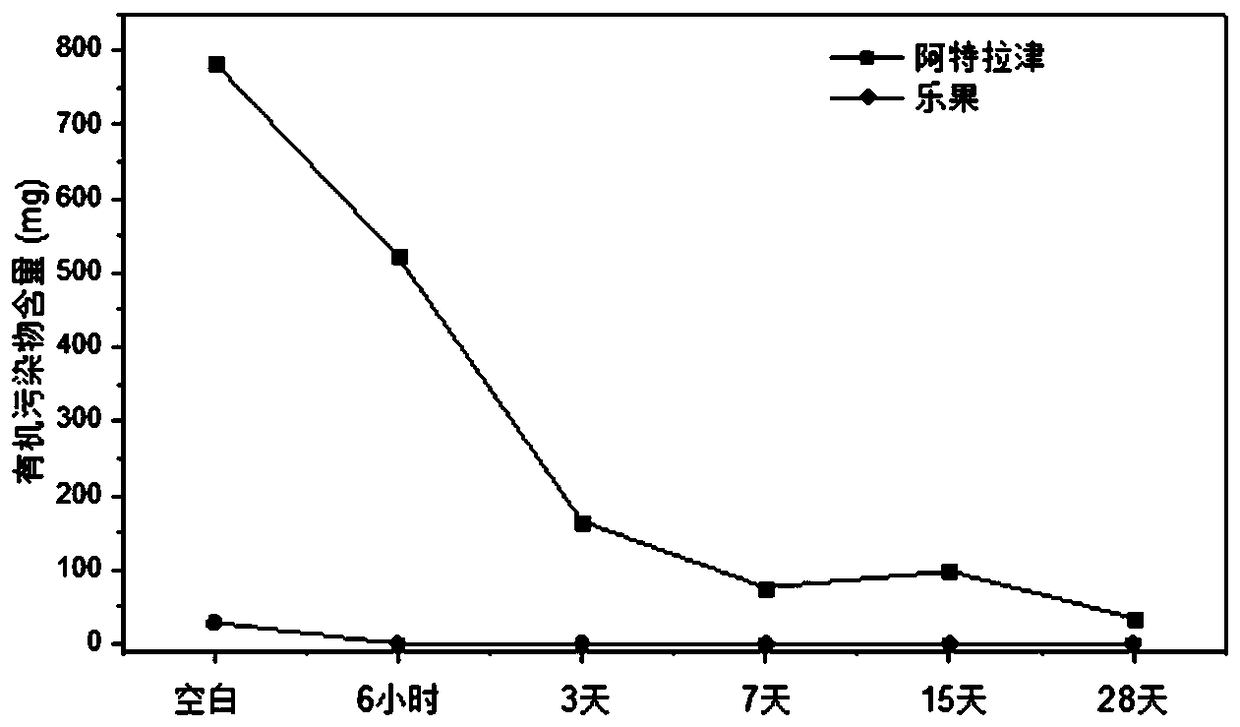

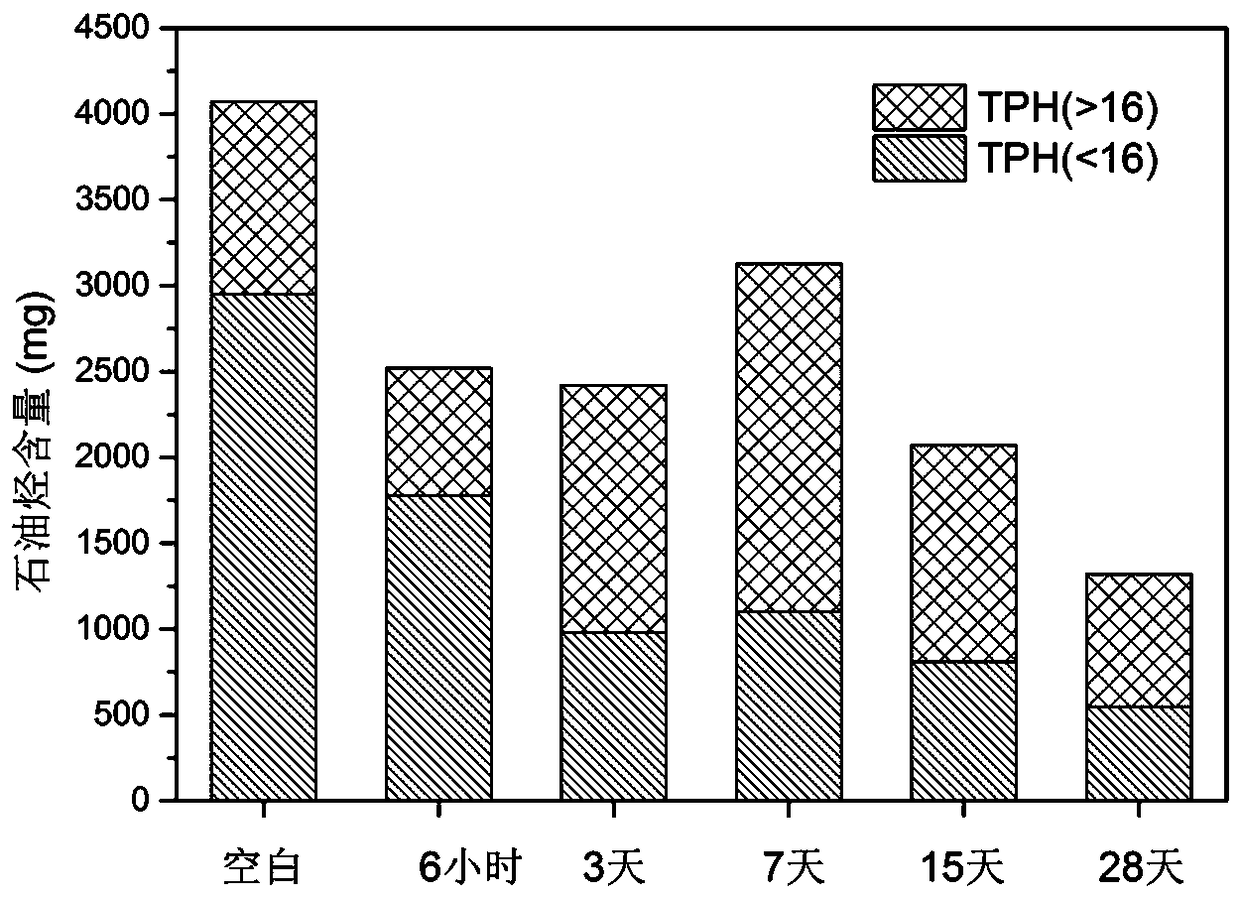

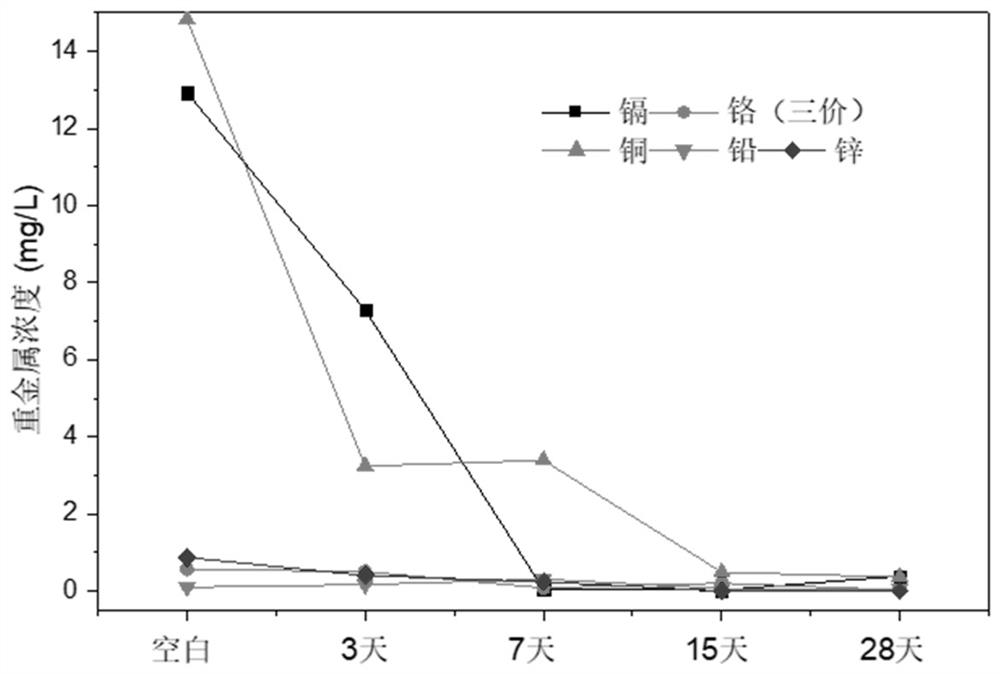

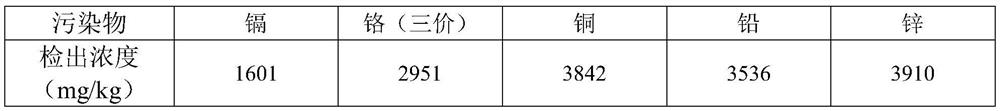

Method for repairing organic-heavy metal composite contaminated soil by coupling chemical oxidation with biochar enhanced microorganisms

InactiveCN112122334AEnable co-processingGood synergyContaminated soil reclamationSodium sulfateBiochar

The invention discloses a method for repairing organic-heavy metal composite contaminated soil by coupling chemical oxidation with biochar enhanced microorganisms. The method comprises the following steps of: crushing to-be-remediated soil, carrying out wet screening until the particle size is less than 4mm, adjusting the soil-water ratio of a soil aqueous solution to 1: 3-1: 5, adjusting the pH value to 5, adding a sodium persulfate solution activated by charcoal, carrying out leaching treatment, oxidizing organic pollutants by sodium persulfate while leaching, and transferring heavy metal pollutants from the soil to the aqueous solution; after the soil and water are separated by dehydration equipment, treating liquid by advanced oxidation equipment, further oxidizing organic pollutants,adjusting the pH value of heavy metals to 9-10, and enabling the heavy metals to reach the standard after coagulation and precipitation; recycling the treated aqueous solution for soil leaching in theprevious step; and adding the charcoal into the separated soil, uniformly mixing, stacking, keeping ventilation, further oxidizing residual organic matters in the soil, slowly releasing the heavy metals, and increasing the microbial activity of the soil until the contaminated soil reaches the standard.

Owner:ZHEJIANG METALLURGICAL RES INST +1

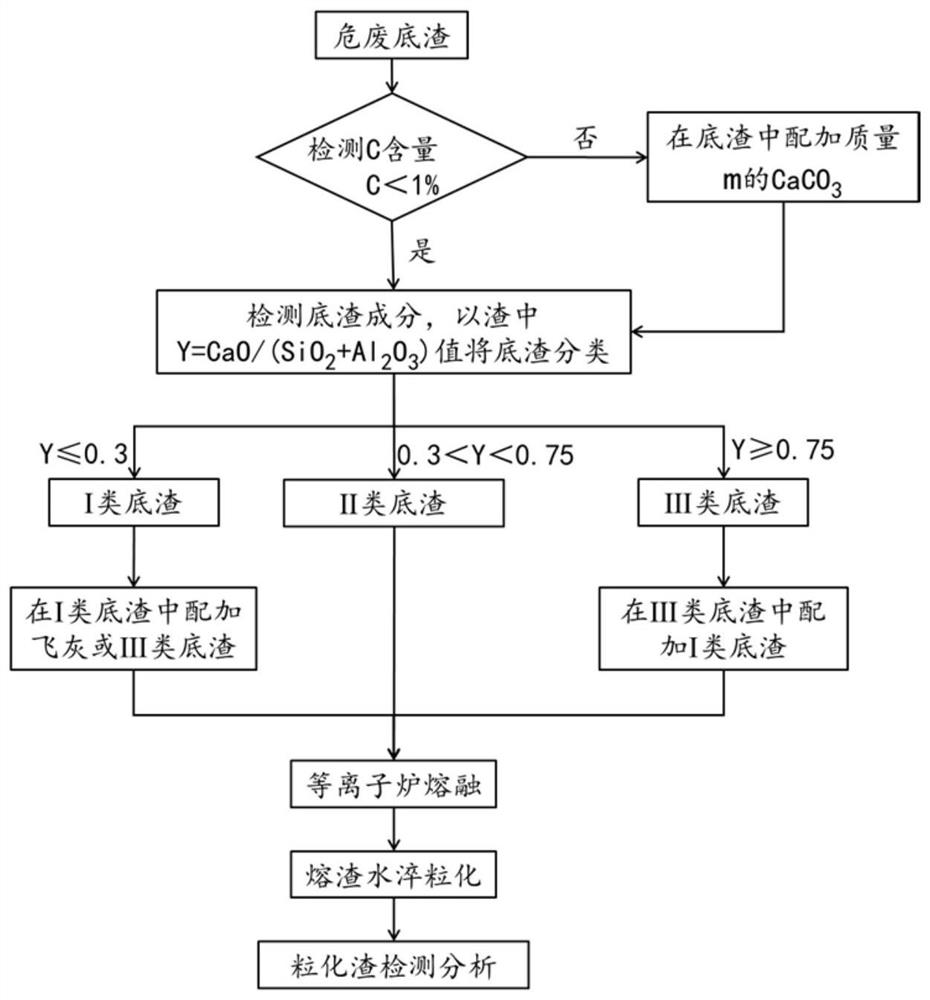

Method for synergistically preparing glass body from hazardous waste incineration ash residues and for decarburizing

ActiveCN113118181AEnable co-processingGood removal effectTransportation and packagingSolid waste disposalDecarburizationOxide

The invention discloses a method for synergistically preparing a glass body from hazardous waste incineration ash residues and for decarburizing. The method comprises the following specific steps that the content of residual carbon in hazardous waste bottom slag is measured, and if the content of the residual carbon is greater than or equal to 1%, and CaCO3 is added into the bottom slag; chemical components of the hazardous waste bottom slag are detected, and the bottom slag is divided into three types according to the ratio of calcium oxide to the sum of silicon oxide and aluminum oxide in the hazardous waste bottom slag; different types of bottom slag as well as the bottom slag and fly ash are synergistically blended, and it is guaranteed that the ratio of the calcium oxide to the sum of the silicon oxide and the aluminum oxide is within 0.3-0.75; and the mixture is added into a plasma furnace for melting and heat preservation, the molten slag flows out of a slag discharging outlet, and the glass body is obtained after water quenching and cooling. Through compounding of the bottom slag, different waste materials are synergistically used for preparing the glass body, the effects of treating waste with waste and co-treating are achieved, and the treatment cost is reduced. Meanwhile, calcium carbonate is used as the decarburizing agent to remove the carbon in the bottom slag, and the residual carbon content in the glass body is reduced.

Owner:EVERBRIGHT ENVIRONMENTAL PROTECTION TECH RES INST SHENZHEN CO LTD +3

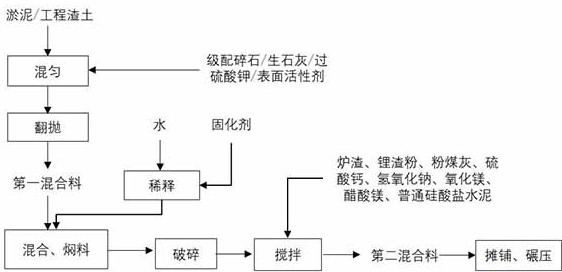

Method for preparing road material from high-water-content sludge/engineering residue soil

ActiveCN114349437AIncrease added valueEasy to dehydrateSolid waste managementPotassium persulfateSlag

The invention relates to a method for preparing a road material from high-water-content sludge / engineering muck. The method comprises the following steps: fully mixing the sludge / engineering muck with quick lime, graded broken stone, potassium persulfate and a surfactant, and turning until the water content is reduced to be below the optimal water content to obtain a first mixture; diluting a soil stabilizer with a proper amount of water, adding the diluted soil stabilizer into the first mixture, uniformly stirring, and braising for later use; crushing the raw materials, conveying the crushed raw materials to stirring equipment, uniformly adding the furnace slag, the lithium slag powder, the fly ash, the calcium sulfate, the sodium hydroxide, the magnesium oxide, the magnesium acetate and the ordinary Portland cement into the stirring equipment, supplementing water to the optimal water content according to conditions, and fully stirring to obtain a second mixture; according to the method, high-water-content sludge / engineering muck can be treated, the dehydration process is simple, and a road base or a subbase with a high additional value can be prepared; most raw materials are solid wastes which are cheap and easily available, so that the treatment cost is greatly reduced, and the environment-friendly benefit is high; the obtained road material is high in stability and good in water resistance.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

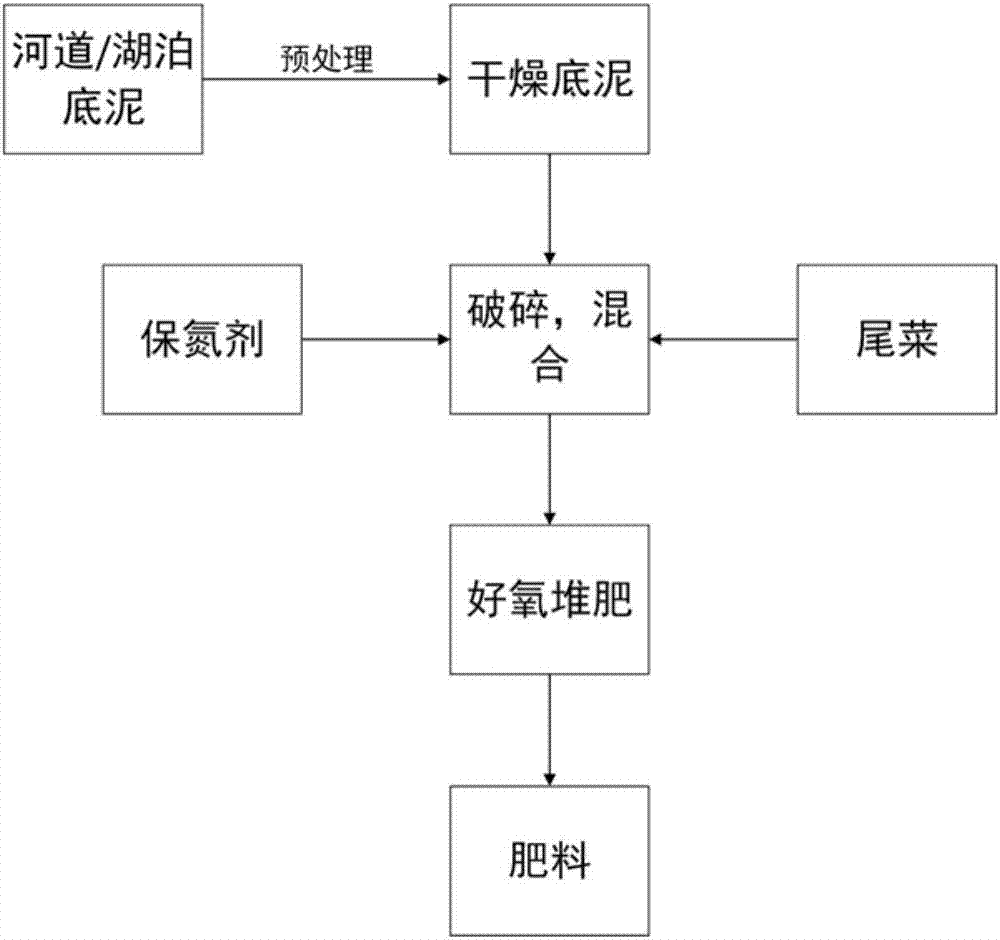

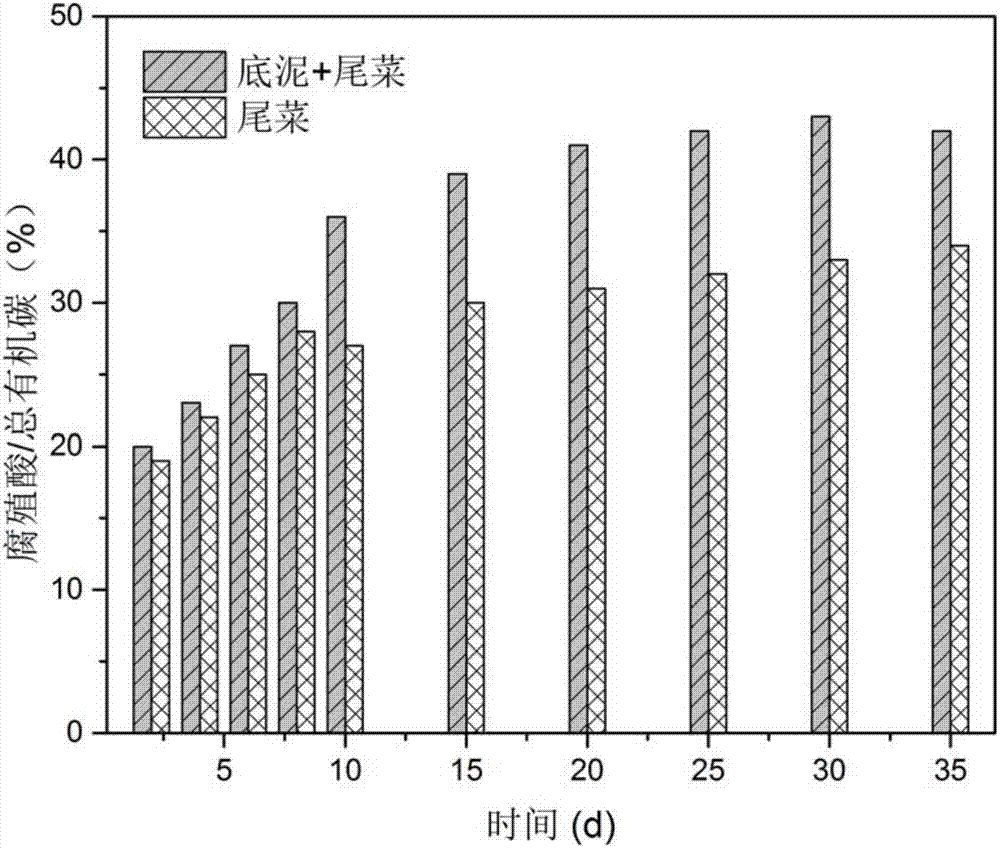

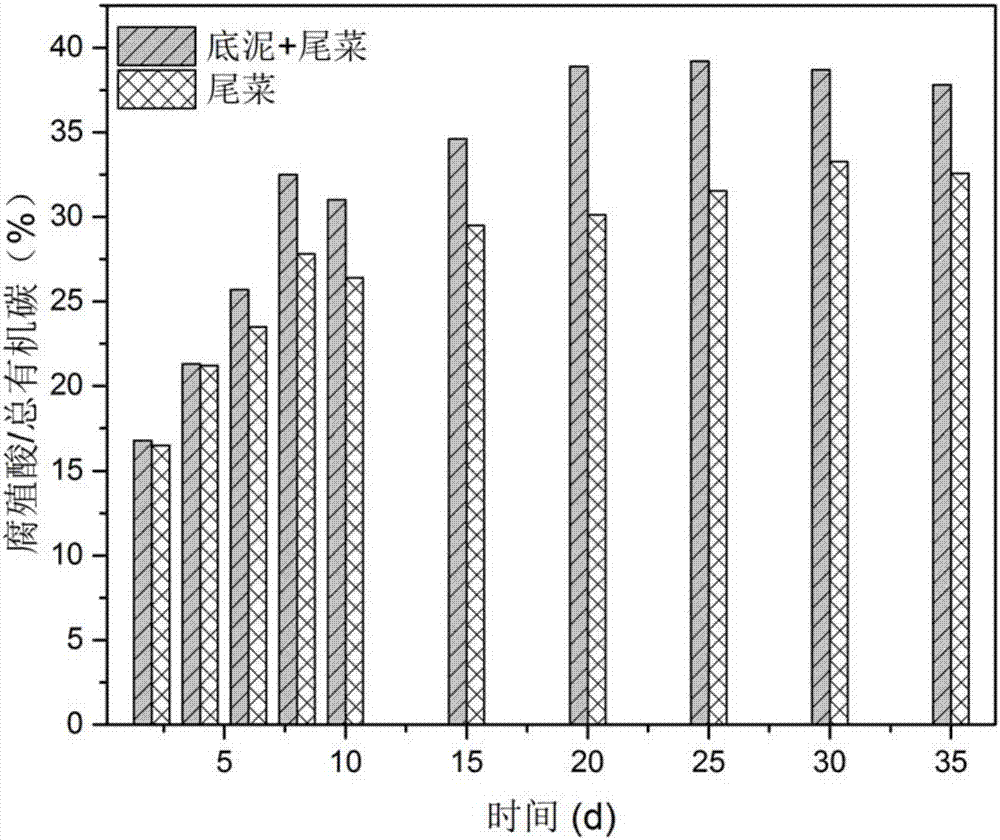

Method for performing aerobic humification on residual vegetable added with high-humus-containing river sediment

InactiveCN106905036AFacilitated DiffusionReduce moisture contentSuperphosphatesBio-organic fraction processingNitrogenOxygen

The invention relates to a method for performing aerobic humification on residual vegetable added with high-humus-containing river sediment. The method particularly comprises the following steps: taking river sediment or lake sediment, adding an eluting agent to remove heavy metal, and drying the eluted river sediment or the lake sediment in the sun until the moisture content is less than 50 percent to prepare dry sediment; measuring the total organic carbon, the total organic nitrogen and the C / N ratio of the dry sediment and the residual vegetable separately, mixing the dry sediment, the residual vegetable and a nitrogen-retaining agent uniformly and crushing to prepare mixed stacked materials; putting the mixed stacked materials into a humification warehouse, performing aerobic humification by a forced ventilation mode, turning the pile for once every other 5 to 8 days, measuring the total organic carbon content, the total organic nitrogen content and the total humic acid content in the fermentation process, and ending until the component content value is stable. Compared with the prior art, the method has the advantages that the steps are simple, the economic practicability is high, co-treatment of the river and lake sediment and the residual vegetable is realized, the humification progress is accelerated and the quality of the humic fertilizer is improved.

Owner:TONGJI UNIV

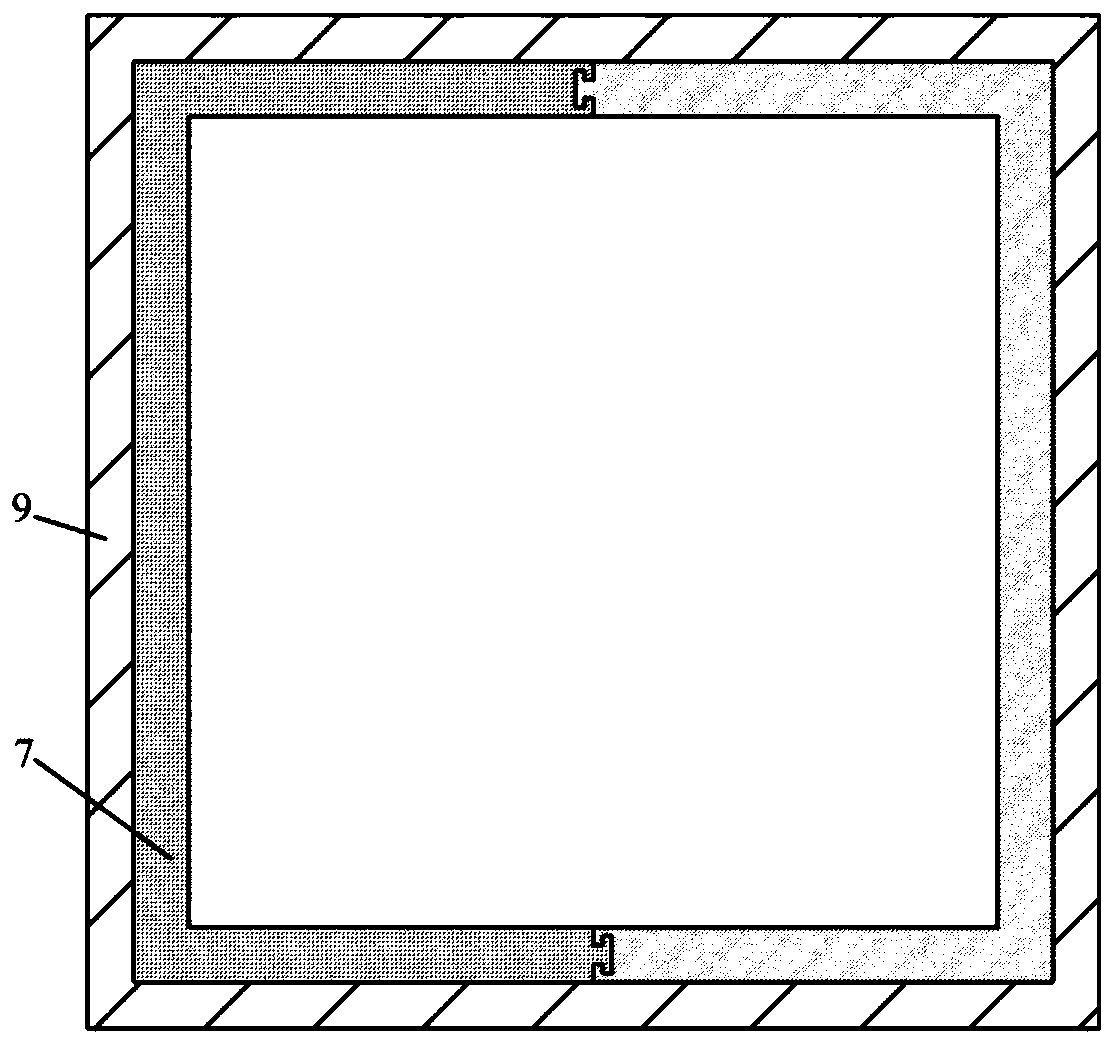

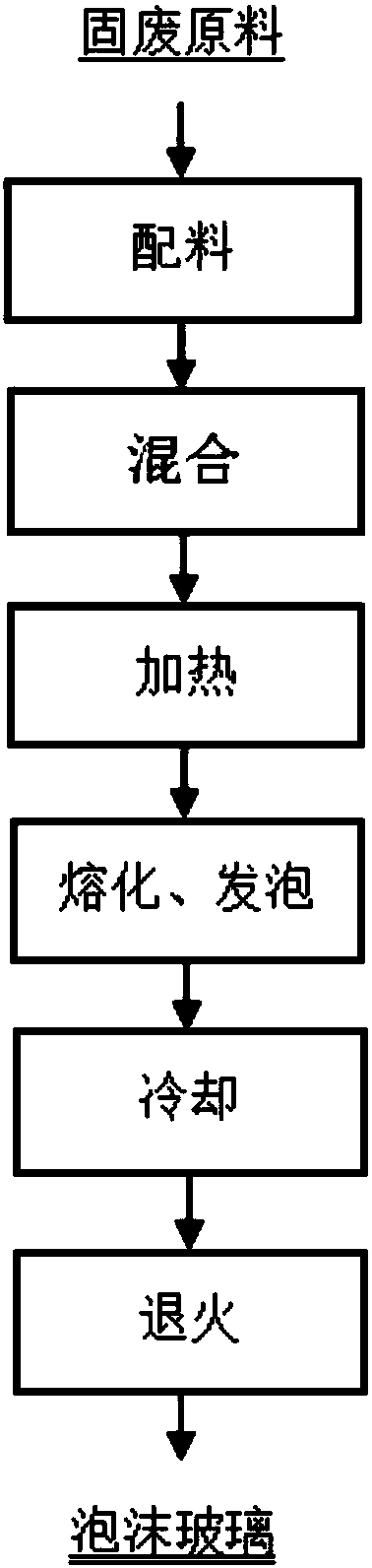

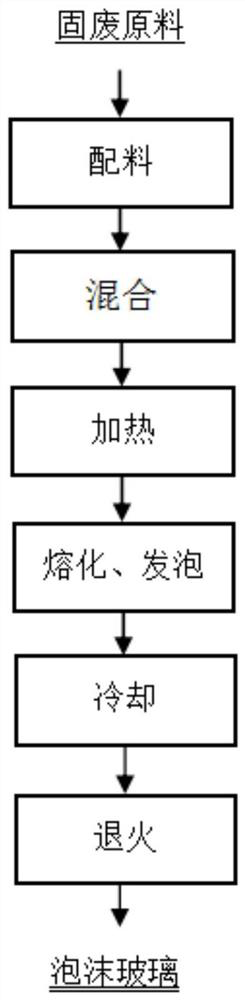

Method for preparing foam glass from solid waste

ActiveCN107673586AReduce manufacturing costReduce lossGlass shaping apparatusResource recoveryWaste treatment

The invention belongs to the technical field of solid waste treatment and resource recovery, and discloses a method for preparing foam glass from solid waste. According to the method, the solid wasteserves as a raw material and is matched, mixed and melted, foam bodies formed by gas generated when the raw materials are heated, and the foam bodies are cooled to obtain the foam glass. The foam glass has the advantages of low heat conduction coefficient and flame resistance and can be used for building heat retaining fireproof materials. According to the method, solid waste is harmlessly treatedand utilized in a high-valued manner, and the method had the advantages of wide raw material source and low production cost.

Owner:UNIV OF SCI & TECH BEIJING

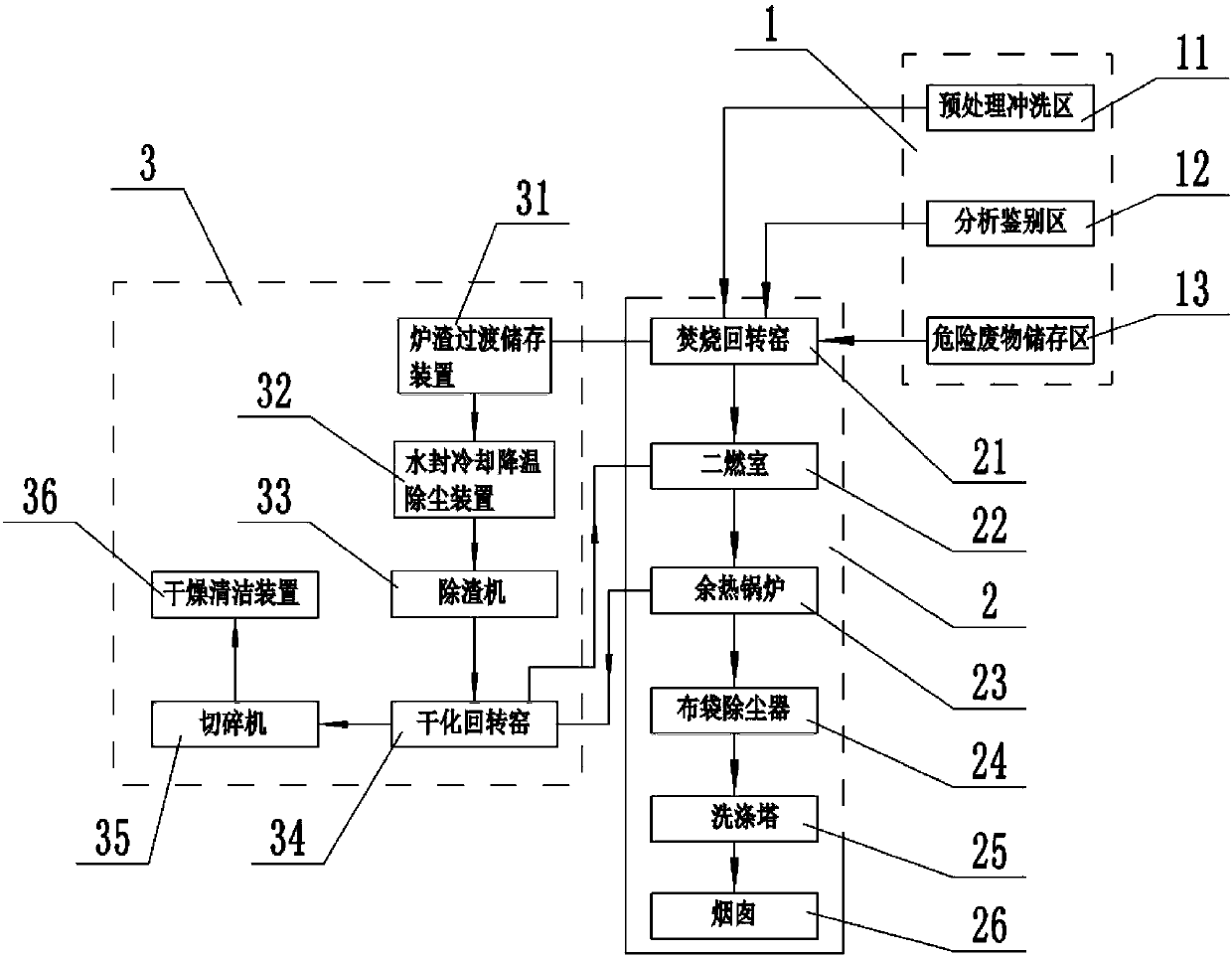

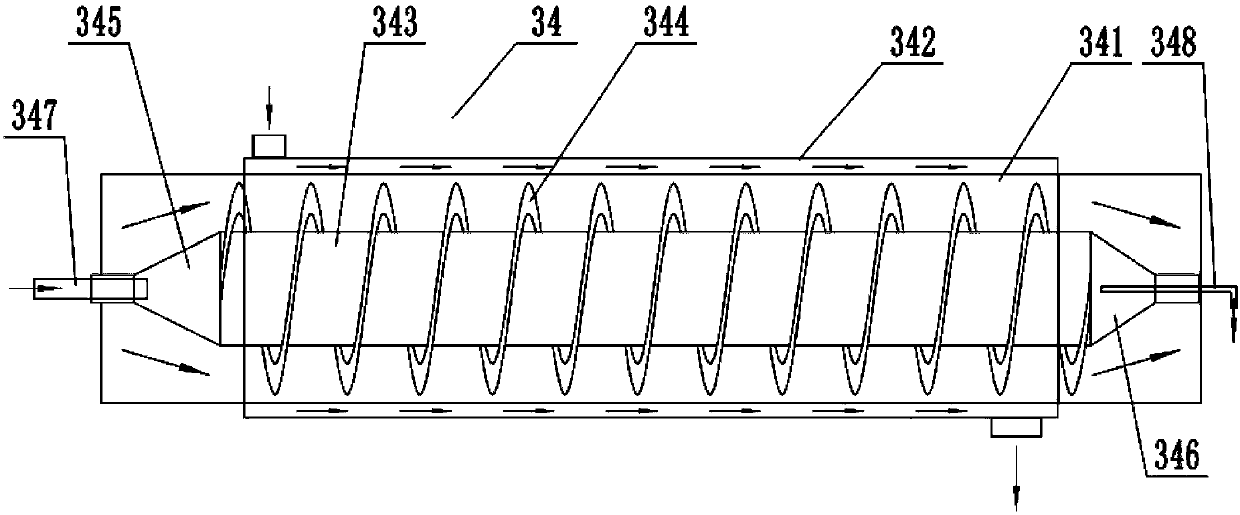

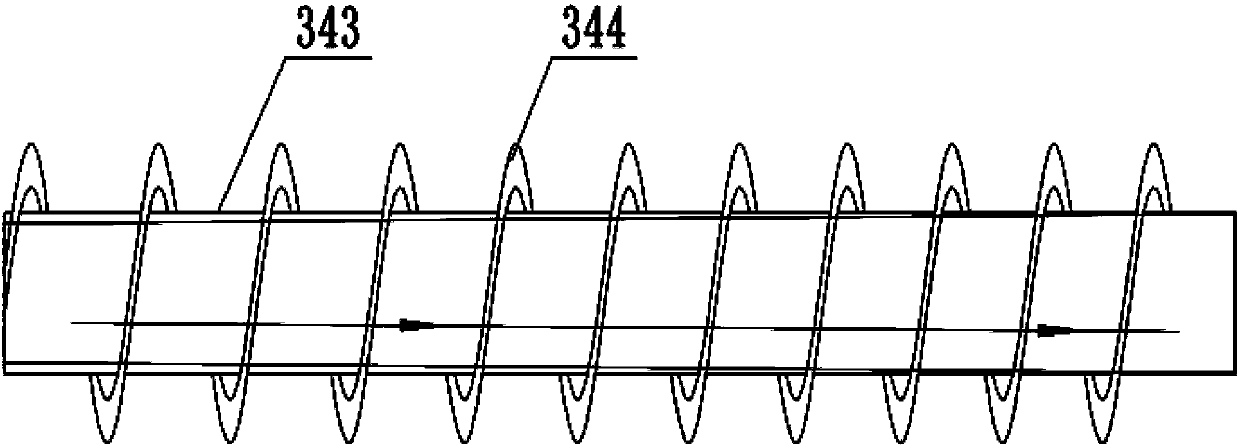

Incineration and drying integrated treatment process of hazardous wastes

InactiveCN107795998AReduce moisture contentRealize resource utilizationCombustion technology mitigationIncinerator apparatusCombustion chamberResource utilization

The invention relates to an incineration and drying integrated treatment process of hazardous wastes. According to the incineration and drying integrated treatment process of the hazardous wastes, a hazardous waste pretreatment system, an incineration system and a drying system are included; the hazardous waste pretreatment system comprises a pretreatment flushing area, an analyzing and identification area and a hazardous waste storage area which are connected sequentially; the incineration system comprises an incineration rotary kiln, a secondary combustion chamber, a waste heat boiler, a bag-type dust remover, a scrubbing tower and a chimney which are connected sequentially; and the drying system comprises a furnace slag transition storage device, a water-seal cooling and temperature-reducing dedusting device, a slag remover, a drying rotary kiln, a shredding machine and a drying cleaning device which are connected sequentially. According to the incineration and drying integrated treatment process of the hazardous wastes, incinerated hazardous waste furnace slag is dried and then treated, the dried and treated furnace slag is low in moisture content, the reuse rate is greatly increased, the cost is greatly saved, meanwhile, resource utilization of boiler steam is realized, and co-processing is realized.

Owner:苏州浩长空环保科技有限公司

Method for synergistic recycling of waste circuit boards and waste catalysts from automobile exhaust

ActiveCN109136532BEasy to separateEnable co-processingProcess efficiency improvementElectrostatic separationPtru catalyst

The invention discloses a method for collaborative resource between a waste circuit board and an automobile tail gas waste catalyst. The method comprises the following steps: firstly, obtaining a copper-rich collective through performing crushing, magnetic separation and high voltage electrostatic separation on the waste circuit board; crushing the automobile tail gas waste catalyst to obtain waste catalyst powder; mixing the copper-rich collective and the waste catalyst powder to obtain mixed powder; adding a reagent in a certain amount of mixed powder in proportion, placing in a high-temperature muffle furnace for reaction and cooling to a room temperature after the completion of the reaction to obtain a product of which an upper layer is a glass layer, and a lower layer is a copper layer; separating the copper layer from the glass layer, taking out, crushing, then placing the glass layer in the muffle furnace for heat treatment; after the completion of the treatment, pouring microcrystalline glass liquid into a mold while the microcrystalline glass liquid is still hot, reducing the temperature and forming; after a room temperature is lowered, preparing out fluorescent microcrystalline glass. In the process, the recovery rate of precious metals exceeds 98 percent, the precious metals are enriched for 20 times or more, and the obtained fluorescent microcrystalline glass can betaken as an LED fluorescent lamp and other materials. To sum up, the method has the characteristics of being efficient, environmentally friendly and high in resource degree and is suitable for large-scale industrial application.

Owner:SHANGHAI JIAOTONG UNIV

A method for preparing foam glass from solid waste

ActiveCN107673586BReduce manufacturing costReduce lossGlass shaping apparatusResource recoveryProcess engineering

The invention belongs to the technical field of solid waste treatment and resource recovery, and discloses a method for preparing foam glass from solid waste. According to the method, the solid wasteserves as a raw material and is matched, mixed and melted, foam bodies formed by gas generated when the raw materials are heated, and the foam bodies are cooled to obtain the foam glass. The foam glass has the advantages of low heat conduction coefficient and flame resistance and can be used for building heat retaining fireproof materials. According to the method, solid waste is harmlessly treatedand utilized in a high-valued manner, and the method had the advantages of wide raw material source and low production cost.

Owner:UNIV OF SCI & TECH BEIJING

Method mixing decoration waste and soil to treat organic polluted soil

ActiveCN109127713ARaw materials are easy to getSimple processContaminated soil reclamationBrickPollution soil

The invention discloses a method mixing decoration waste and soil to treat organic polluted soil and belongs to technical field of solid waste recycling and soil remediation. The method includes: simply preprocessing mixed decoration waste to allow the components of the mixed decoration waste to be 5 parts of aggregate, 3 parts of brick, 5 parts of wood / sawdust, 5 parts of paper board / paper scrapsand 2 parts of mortar / soil, mixing the preprocessed decoration waste and soil according to certain mass ratio and loading into a zero headspace extractor, adding anaerobic water until the water submerges the surface of the solid 3-5cm, and standing and performing reaction under a shady and cool condition for 28 days to effectively lower total organic pollutant content in decoration waste-soil, wherein the preprocessing includes crushing, screening and the like. The method has the advantages the method is a green and cheap building waste recycling and polluted soil remediation method, and themethod is simple in process, good in remediation effect and free of a capacity increasing problem and is a solid waste treatment technology conforming to green sustainable repairing.

Owner:SHANGHAI MUNICIPAL ENG DESIGN INST GRP +1

Device and method for synergistically treating edible mushroom waste and modifying ardealite

PendingCN113184825AReach the quality standard of resource utilizationEnable co-processingSulfur preparation/purificationCarbon preparation/purificationFlue gasProcess engineering

The invention relates to a device and method for synergistically treating edible mushroom waste and modifying ardealite, belongs to the technical field of waste resource utilization equipment, and mainly aism to solve the technical problems that an existing edible mushroom waste and ardealite waste treatment process is complicated, cannot be recycled. According to the technical schemes, the device comprises a biomass drying device, a pyrolyzing furnace, a charcoal cooling device, a pyrolysis flue gas impurity removal device, an ardealite drying device, an ardealite calcining furnace, an ardealite cooling device, a reduction furnace, a gas purification and desulfurization device and a plurality of conveying and feeding devices. The device and method have the advantages of reasonable design, low cost, simplicity in operation, high working efficiency and the like.

Owner:YUNNAN AGRICULTURAL UNIVERSITY +1

A construction method of vertical engineering barrier system for neutralizing acid mine wastewater

ActiveCN111101538BEnable co-processingImplement resourcesWaste water treatment from quariesArtificial islandsArchitectural engineeringWastewater

The invention provides a construction method of a vertical engineering barrier system for neutralizing acidic mine wastewater. The method comprises the following steps: selecting a site for construction of an engineering barrier, excavating an engineering barrier ditch; making a reinforcement cage, and placing the reinforcement cage on the reinforcement in the direction of seepage Geotextiles are laid on the inside of the cage; mixed blocks are made, and the mixed blocks are filled into the steel cage to form engineering barrier wall units; the engineering barrier wall units are combined and assembled, and hoisted into the engineering barrier ditch; data is collected around the engineering barrier , to monitor the heavy metal blocking effect. Compared with the prior art, the raw material of the mixed block of the present invention is prepared from clay, fly ash, and chemical additives, which has lower cost and good treatment effect; it adopts the combination and assembly of engineering barrier wall units, and adapts to site conditions and engineering needs. Strong; the construction steps are simple and easy, and the lifting and replacement are convenient; the engineering barrier wall units can be produced and sold on a large scale, with high economic benefits, and greatly shorten the construction period of the engineering barrier.

Owner:湖南省和清环境科技有限公司

A kind of phosphogypsum light board prepared by using barium slag and its preparation method

The invention relates to a phosphogypsum light-weight sheet material prepared from barium dreg and a preparation method thereof. The phosphogypsum light-weight sheet material is prepared from the following raw material components in parts by mass: 10 to 20 parts of the barium dreg, 4 to 10 parts of phosphogypsum dihydrate, 60 to 80 parts of phosphorous hemihydrate gypsum, 5 to 15 parts of metakaolin, 1 to 3 parts of carbide slag, 0.5 to 1.2 parts of light aggregate, 0 to 0.1 part of set retarder, 0.1 to 0.3 part of water reducing agent and 0 to 0.1 part of water-retaining agent. The phosphogypsum light-weight sheet material prepared from the barium dreg, provided by the invention, has the advantages of light weight and heat insulation; the volume weight is adjustable in a range of 600 to 1,000Kg / m<3> and the thermal conductivity coefficient is lower than 0.15W / (m*K); the phosphogypsum light-weight sheet material has no obvious layering and cracking and the problem that a traditional cement sheet material is cracked by shrinkage can be effectively overcome by utilizing a micro-expansion property of gypsum hydration; each performance of the prepared light-weight sheet material can meet standards of General Technical Requirements of Light Weight Panel used for Building Partition Wall JGT169-2016.

Owner:WUHAN UNIV OF TECH

Method of Reducing Toxicity of Heavy Metals in Soil by Decorating Garbage-Soil Mixed Treatment

ActiveCN109226237BThe removal effect hasWith adsorptionContaminated soil reclamationCardboardSolid surface

The invention discloses a method for reducing the toxicity of heavy metals in soil by using decoration garbage-soil mixed treatment, which belongs to the technical field of solid waste resource utilization and soil remediation. The method includes: crushing and screening mixed decoration garbage The components are 2~4 parts of aggregate, 1~3 parts of wood / chips, 1~2 parts of cardboard / chips, 2~4 parts of mortar, 1~2 parts of bentonite, 1~2 parts of quartz sand, and The soil was mixed and filled into a polytetrafluoroethylene column according to a certain mass ratio, and anaerobic water was added to cover the solid surface by 3-5 cm, then allowed to stand and react for 28 days. The invention can remove most of the heavy metal pollutants in the soil that may cause damage to the human body and the environment by changing the form distribution of the heavy metal. The invention is a green and cheap waste construction waste resource utilization and polluted soil repair means, and the raw materials are easy to obtain, the process is simple, the repair effect is good, and there is no capacity increase problem.

Owner:SHANGHAI MUNICIPAL ENG DESIGN INST GRP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com