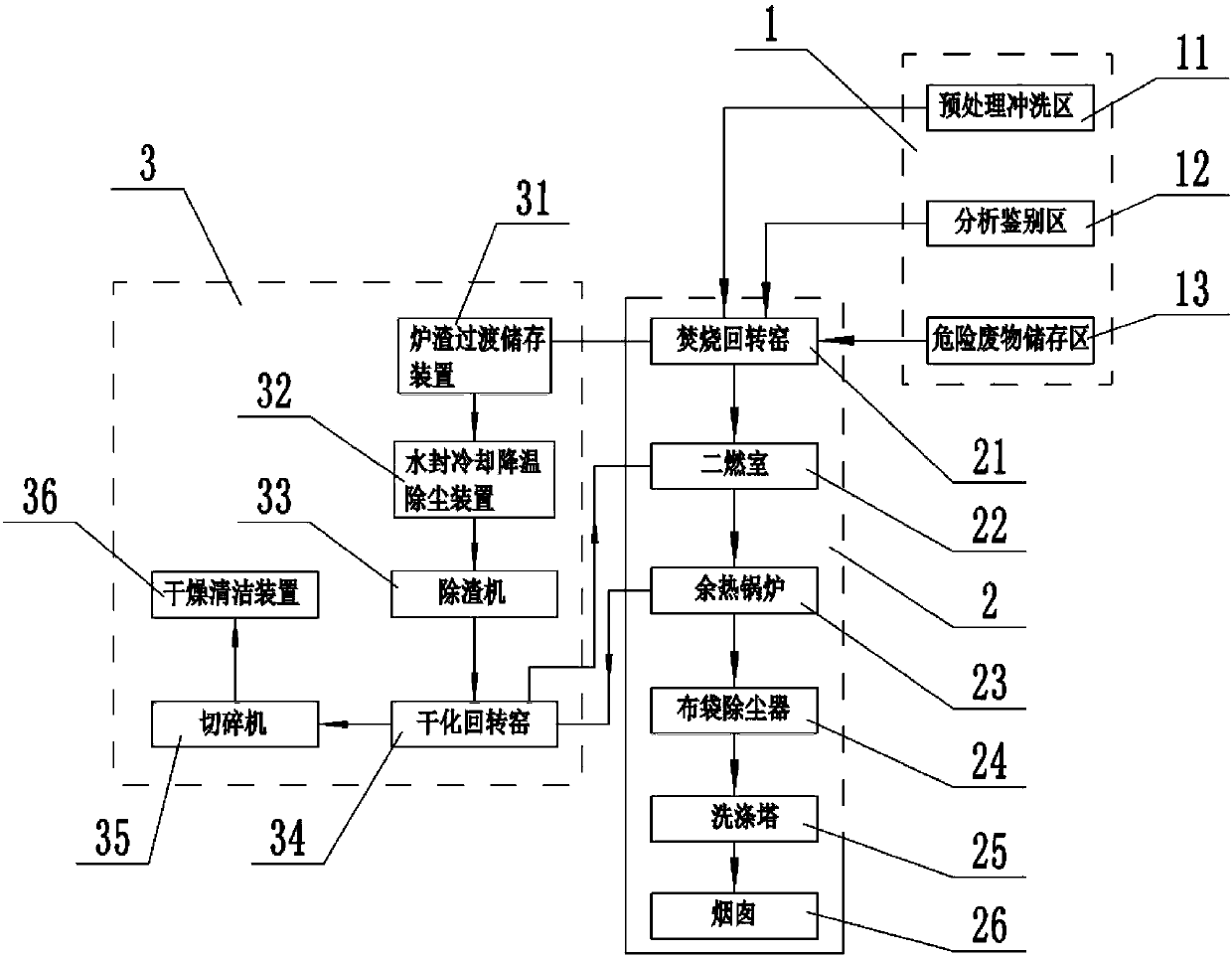

Incineration and drying integrated treatment process of hazardous wastes

A technology of hazardous waste and treatment process, which is applied in the field of incineration and drying treatment system of hazardous waste, which can solve the problems of energy waste and high cost, achieve good effect, low moisture content, and realize the effect of resource utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

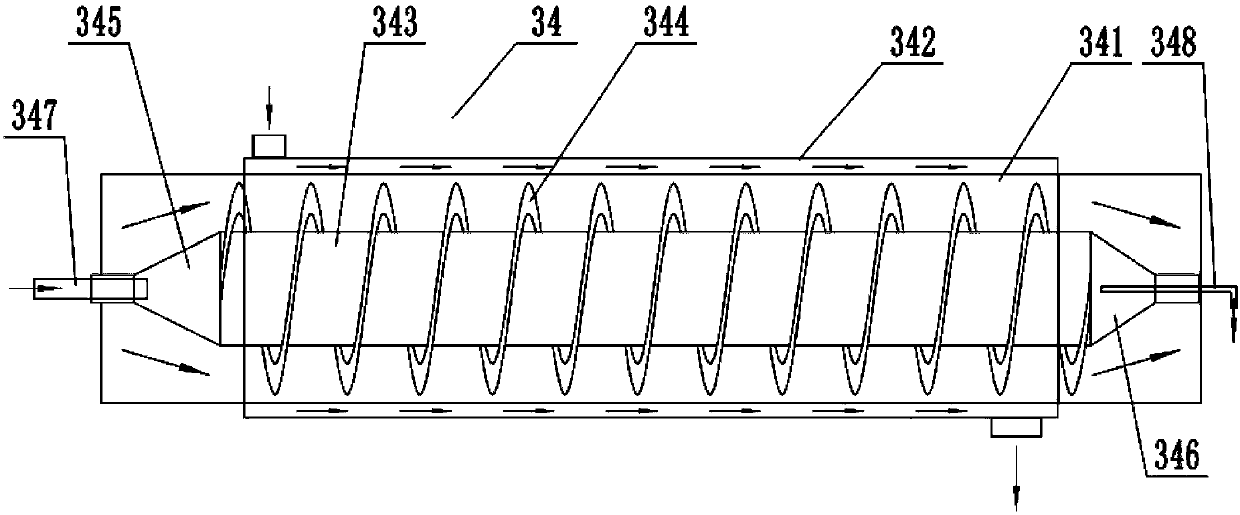

[0036] Embodiment 2: as the preferred scheme of embodiment 1, such as figure 2 As shown, the drying rotary kiln 34 includes a kiln body 341, a roller screw conveying device installed in the kiln body 341, and a steam jacket 342 wrapped around the outer periphery of the kiln body 341. The steam inlet of the steam jacket 342 and the steam of the waste heat boiler 23 The outlet is connected. The present invention adopts indirect drying, that is, a layer of steam jacket 342 is wrapped on the outside of the rotary kiln, steam is passed through the steam jacket 342, and slag with high moisture content is discharged in the kiln, and the slag is dried to a moisture content of less than 5%. Compared with the original slag, which has a moisture content of about 40-50%, the reduction is about 40%, which greatly saves costs. At the same time, the resource utilization of boiler steam is realized, and the waste gas generated enters the secondary combustion chamber for treatment, without in...

Embodiment 3

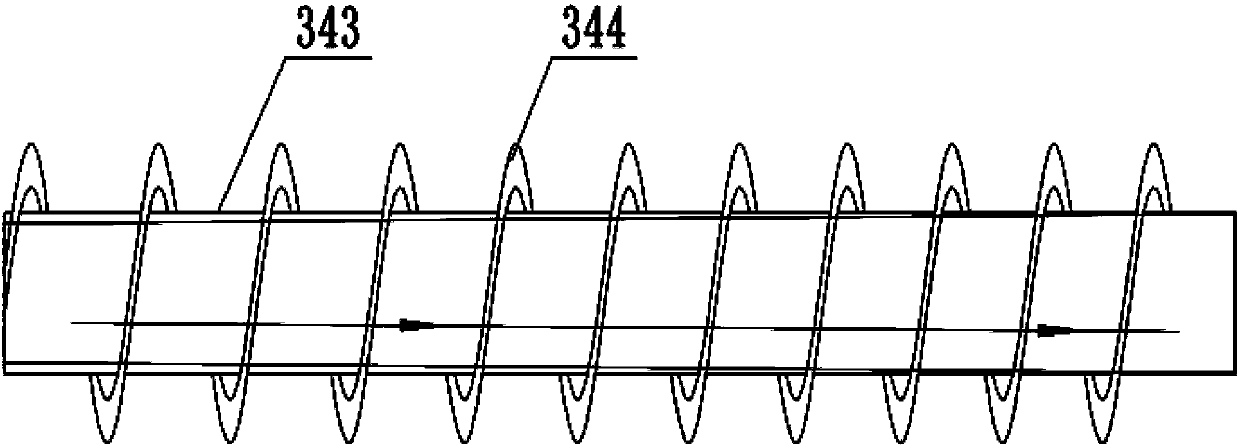

[0037]Embodiment 3: As a preferred solution of Embodiment 2, the roller screw conveying device includes a roller 343 movably installed in the kiln body 341, a spiral conveying blade 344 installed on the outer periphery of the roller 343, and the two ends of the roller 343 respectively have tapered inlet ends 345 and the tapered outlet end 346. Between the outer wall of the drum 343 and the inner wall of the kiln body 341, there is an annular compartment where the spiral conveying blade 344 can be installed. The slag is introduced into the compartment through the tapered inlet 345, and after drying, it is exported from the tapered outlet 346. . The present invention adopts the method of annular compartments to slowly push the slag from one end of the drum 343 to the other end through the spiral conveying blade 344, which has a large dispersion area and excellent drying effect.

Embodiment 4

[0038] Embodiment 4: As a preferred solution of Embodiment 3, the drum 343 is a hollow structure, the tapered inlet end 345 is equipped with a steam inlet pipe 347 leading into the inner chamber of the drum, and the tapered outlet end 346 is equipped with a condensing pipe leading into the inner chamber of the drum. Water outlet pipe 348. Hot steam is passed into the inner cavity of the drum 343, and the hot steam in the steam jacket 342 heats the drum 343 internally and externally, thereby improving the drying effect of the slag.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com